文章编号:1004-0609(2010)08-1455-06

AZ91D变形镁合金的动态应变时效现象

林 娜1,曾绍峰1, 2,彭开萍1,陈文哲1, 2

(1. 福州大学 材料科学与工程学院,福州 350108;

2. 福建工程学院 材料科学与工程系,福州 350108)

摘 要:在应变速率为1.11×10-4~1.67×10-3 s-1、温度为248~523 K的条件下,对固溶态AZ91D变形镁合金进行拉伸试验。结果表明: 在一定的拉伸应变速率和温度区间拉伸时,AZ91D镁合金在形变过程中发生动态应变时效(DSA)现象,其典型特征表现为其拉伸曲线出现锯齿波,所对应的锯齿波类型分别呈A型及A+B混合型;应变速率敏感性系数为负值;且出现加工硬化速率峰值;出现锯齿屈服的临界应变量随变形温度升高而减小,而随应变速率增加而增大;当形变温度大于323 K时,加工硬化速率随着温度升高反而急剧增大,在368 K时达到峰值。

关键词:AZ91D变形镁合金;动态应变时效;锯齿屈服;负应变速率敏感系数;加工硬化速率

中图分类号:TG113 文献标志码:A

Dynamic strain aging phenomenon of

AZ91D wrought magnesium alloys

LIN Na1, ZENG Shao-feng1, 2, PENG Kai-ping1, CHEN Wen-zhe1, 2

(1. College of Materials Science and Engineering, Fuzhou University,Fuzhou 350108, China;

2. Department of Materials Science and Engineering, Fujian University of Technology, Fuzhou 350108 China)

Abstract: A series of tensile tests of as-solid-solution treated AZ91D wrought magnesium alloys were carried out at strain rates ranging in 1.11×10-4-1.67×10-3 s-1 and temperatures ranging in 248-523 K. The results show that there occurs a dynamic strain aging (DSA) phenomenon during deformation of AZ91D magnesium alloy in certain ranges of temperature and strain rate. The typical characteristics of DSA include serrated flow, the corresponding related serrated types are defined as type A and type A+B. Negative strain-rate sensitivity and peak of work-hardening rate appear. The critical plastic strain for the onset of serrations decreases with increasing deformation temperature, while it increases with increasing strain rate. Moreover, the work-hardening rate increases sharply with increasing temperature when the deformation temperature is higher than 323 K, and reaches the peak value at 368 K.

Key words: AZ91D wrought magnesium alloy; dynamic strain aging; serrated yielding; negative strain-rate sensitivity; work-hardening rate

许多工业上常用的合金在塑性变形过程中会出现不稳定流变,其拉伸曲线不再光滑而表现反复的锯齿屈服流变。研究表明[1-3],这种现象是由于动态应变时效(Dynamic strain aging,简称DSA)效应引起的,动态应变时效的本质是运动的位错和扩散的溶质原子交互作用的结果。迄今为止,大多数研究主要是针对低碳钢和面心立方合金产生此效应的宏观现象、影响因素、微观组织、产生的机理和各种模型进行研究[3-8],但对密排六方结构材料DSA的研究报道还比较少见[9-11]。

镁合金的比强度和比刚度均优于钢及铝合金,且具有良好的减震降噪性能、电磁屏蔽性能、机械加工性能和易于回收等优点,被广泛应用于汽车、航空领域[12]。近几年,国际上对变形镁合金进行了大量的研究,为变形镁合金的应用提供了一定的基础。但目前关于变形镁合金的DSA效应的系统研究较少,本文作者试图通过对固溶态AZ91D变形镁合金在拉伸时出现的DSA现象及锯齿波型的研究,以期了解该材料在塑性变形中的不稳定塑性变形规律,为其塑性变形研究和应用提供更好的理论指导,同时也为密排六方结构材料产生DSA机理研究和模型建立提供理论依据。

1 实验

1.1 试样制备

本研究采用的材料为热挤压AZ91D镁合金,其化学成分如表1所列。将AZ91D镁合金棒按GB/T 6397—1986标准加工成d6 mm×30 mm, 端部为M12螺纹的标准短拉伸试样。试验前先对试件进行固溶处理,固溶工艺如下:(683±3) K,保温24 h(加Al2O3粉末作保护剂以防止氧化),水冷。

表1 AZ91D镁合金的化学成分

Table 1 Chemical composition of AZ91D Mg alloy (mass fraction, %)

1.2 拉伸试验

拉伸试验在Instron 1185型电子拉伸机上进行。应变速率分别为1.11×10-4、3.33×10-4、1.67×10-3 s-1。在每个应变速率下,从248~523 K进行系列温度拉伸试验, 温度间隔为25 K。其中248和273 K下的拉伸试验在无水酒精溶液中进行,用液氮作冷却剂;323~373 K的试样采用水浴加热,试验温度误差控制在±1 K范围内;398~523 K时采用Instron可控式三段控温电阻炉加热,试验温度误差控制在±3 K范围内。

1.3 应变速率敏感性试验

应变速率敏感性试验是在某一温度下以应变速率1.11×10-4 s-1将合金拉伸至应变量为2%时,应变速率迅速切换到1.67×10-3 s-1,测出此时应力的变化值Δσ,然后根据应变速率敏感性系数m的计算公式:m=lnΔσ/ln( /

/ ),得出应变速率敏感性系数。在248~523 K的范围内,每间隔25 K进行应变速率敏感性实验,每个温度至少进行3次试验,取应力变化的平均值。

),得出应变速率敏感性系数。在248~523 K的范围内,每间隔25 K进行应变速率敏感性实验,每个温度至少进行3次试验,取应力变化的平均值。

2 结果与分析

2.1 固溶态AZ91D变形镁合金的DSA现象

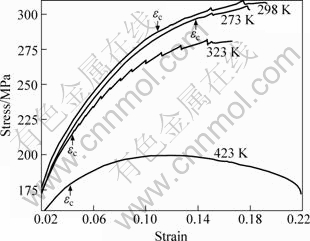

图1所示为在应变速率为1.67×10-3 s-1,温度分别为273、298、323、423 K下固溶态AZ91D镁合金的应力—应变曲线。由图1可见,当拉伸达到一定的变形量时(称为临界应变量εc,即产生锯齿屈服并开始出现第一锯齿的应变量),拉伸曲线不再光滑而出现锯齿屈服,即出现DSA现象;且在恒定的应变速率下,临界应变量εc(见图1中箭头所指)随着温度的升高逐渐减小。

图1 在应变速率为1.67×10-3 s-1、不同温度时固溶态AZ91D镁合金的应力—应变曲线

Fig.1 Stress—strain curves of as-solid-solution treated AZ91D Mg alloys at strain rate of 1.67×10-3 s-1 and different temperatures

试验结果表明,在不同应变速率条件下,固溶态AZ91D变形镁合金都发生DSA现象,临界应变量εc也出现相似的温度影响规律,即随着温度升高而减小。但是,出现DSA的温度范围有所变化,随着应变速率的升高,DSA的温区往高温方向漂移,如表2所列。此外,锯齿波的波形也与应变速率及温度有关。

表2 不同应变速率出现DSA对应的温区

Table 2 Temperature range corresponding to ccurrence of serrated flow phenomenon at different strain rates

根据“钱-萧-李判据模型”[3]所预示的出现锯齿屈服现象的应变速度—温度区间,发生DSA的温度位于0.2Tm~0.5Tm的范围内。而AZ91D镁合金的熔点Tm约为922 K,发生DSA的温度区间为248~423 K,也符合这个规律。

DSA的本质是扩散的溶质原子与运动中的位错交互作用的结果,与传统静态应变时效不同的是,材料在塑性变形的同时产生时效现象。因此,要发生DSA现象,溶质原子要能形成足够大的Cottrell气团,以便有效地钉扎位错。这就要求有一个临界塑性应变量εc,在变形初期,由于溶质扩散速度慢,不足以产生时效,应力—应变曲线呈现光滑状,而随着应变的增大,溶质原子在应变诱生空位的帮助下扩散速度加快,当变形增加到临界应变量εc,即达到位错密度的临界值[13]以后,钉扎住运动的位错,若位错继续运动,则需加大外力使位错脱钉,表现在拉伸曲线上不再是光滑的,而是出现了某种形式的锯齿波。临界应变量还与温度有关,温度越高,溶质原子扩散的能力越强,形成钉扎气团所需要的临界应变量εc就越小。

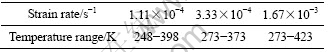

除了锯齿屈服外,DSA的另一个典型特征是负的应变速率敏感性。图2显示了固溶态AZ91D变形镁合金在应变量为2%时的应变速率敏感系数m随温度变化分布情况,在248~398 K的温度区间,m为负值或者接近于零的正值,而在温区以外的m值大于零,这进一步表明固溶态AZ91D镁合金在这个温区发生了DSA现象,此时,εc在此温度区间内具有负的温度系数。在DSA发生的温区内进行拉伸试验时,当应变速率突变时,相对于高的应变速率,低的应变速率下产生空位较少,溶质原子向运动位错扩散所需要的时间会比在高的应变速率下所需要的时间长。随着时效时间的延长,将有更多的溶质原子扩散到位错周围,从而提高了位错与扩散溶质原子间的相互作用力,因此流变应力增大,出现负的应变速率敏感性。运动位错与溶质原子相互作用的结果,其强弱还与溶质原子气团钉扎程度有关。只有当溶质原子气团对位错的钉扎作用足够大时,应力-应变曲线上才会出现锯齿屈服。如果溶质原子气团对位错有微弱的钉扎作用,虽然在应力-应变曲线上不会出现锯齿波,却能从应变速率敏感性上反映出来,使得应变速率敏感性系数变为负值。从某种意义上讲,负的应变速率敏感性系数作为DSA发生的判据比在应力—应变曲线上出现锯齿波作为DSA的判据更为准确[14]。

图2 应变速率敏感系数与温度的关系曲线

Fig.2 Relationship between strain rate sensitivity and temperature at strain of 2%

2.2 锯齿屈服曲线类型特征分析

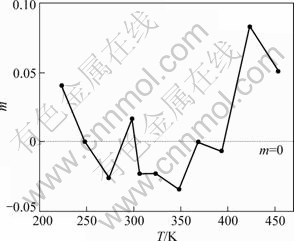

产生锯齿屈服的锯齿波型与应变速率、形变温度、应变量大小密切相关[3, 15]。图3所示为固溶态AZ91D镁合金在306 K时,3种不同应变速率下的拉伸曲线。从图3可知,该材料发生锯齿屈服时的锯齿波波形与应变速率以及应变量密切相关。当应变速率 为3.33×10-4、1.67×10-3 s-1的曲线所对应的类型为A型,而在相对较低的应变速率

为3.33×10-4、1.67×10-3 s-1的曲线所对应的类型为A型,而在相对较低的应变速率 =1.11×10-4 s-1,当应变量较小时表现为B型锯齿波,而当应变量较大时又表现为A型锯齿波。在一种应变速率下,随应变量的变化,波形发生变化,属于A、B混合波形齿波,故在此把其称为A+B混合波形齿波。

=1.11×10-4 s-1,当应变量较小时表现为B型锯齿波,而当应变量较大时又表现为A型锯齿波。在一种应变速率下,随应变量的变化,波形发生变化,属于A、B混合波形齿波,故在此把其称为A+B混合波形齿波。

图3 306 K时不同应变速率下固溶态AZ91D变形镁合金的应力—应变曲线

Fig.3 Curves of stress—strain for as-solid-solution treated AZ91D Mg alloy at different strain rates and 306 K

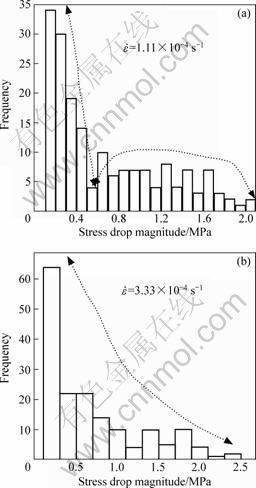

除了从锯齿屈服特征直接定义锯齿波型外,目前,还采用锯齿的应力跌落概率统计的函数曲线分布规律来定义锯齿波型。文献[14,16-17]对Al-Mg拉伸试验中应力跌落的概率统计分布规律的研究证明存在一定的特征尺度:当应力跌落的概率统计表现为单峰型二次函数曲线分布,则定义为B型;而A型的应力跌落概率统计遵循幂函数规律分布;当介于两者的分布情况,称之为双峰型分布,即为A+B型。本研究试验选取应力跌落幅度大于0.1 MPa的锯齿进行统计。为了考察其分布规律,将应力序列平均划分为10个区间,对提取出的各特征量取平均值。各组试验在相同的条件下至少进行3次,以保证实验结果的准确度。图4所示为应变速率分别为1.11×10-4 s-1、3.33×10-4 s-1时应力跌落—频数曲线。当 =3.33×10-4 s-1时应力跌落分布为幂函数,即A型;而当应变速率

=3.33×10-4 s-1时应力跌落分布为幂函数,即A型;而当应变速率 =1.11×10-4 s-1时应力跌落频率分布为双峰型,即A+B型。这与很多研究者通过应力跌落和随机的时空耦合相联系,对拉伸实验中的应力跌落的概率统计分布规律的研究是一致的[16-18]。

=1.11×10-4 s-1时应力跌落频率分布为双峰型,即A+B型。这与很多研究者通过应力跌落和随机的时空耦合相联系,对拉伸实验中的应力跌落的概率统计分布规律的研究是一致的[16-18]。

锯齿波的特征量包括[13, 19-22]:两锯齿加载时间tL,即前一个波谷到下一个波峰的时间;塑性松弛和回复时间tR;内应力激活未变形区域的特征长度尺度lp。tL主要取决于加载的应变速率和塑性应变行为,加载的过程是一个非弹性的过程,随着加载速率的降低,tL增大;当应变强化达到饱和时,tL为常数。tR内应力塑性松弛与回复时间受局部变形行为的影响。当应变速率一定时,tL减小并无限接近tR并且在再加载过程中内应力松弛程度较小,以致内应力激活未变形区域的特征长度尺寸lp增大。因而,与塑性变形带相关的时空耦合增强,应力跌落分布呈现规律性,表现为对称的抛物线分布,即B型锯齿发生。当应变速率进一步增大,tR/tL的比值随之增大,对应的塑性变形过程中几乎不存在应力松弛。因而,空间耦合变得相当活跃,从而诱导Luders带繁殖。在空域上表现为Luders带数量增加,且伴随应力跌落振幅广泛地发散,与此同时,渐渐地产生大量的小振幅应力跌落;在时域上表现为应力跌落频率分布为幂函数型,即A型锯齿波。而C型锯齿通常发生于较低的应变速率下,此时tL很大并无限大于tR,即tL>>tR,此时lp非常小。由于本试验所设定的应变速率区间属于固溶态AZ91D镁合金产生动态应变时效的高应变速率范围,所以在整个拉伸变形过程中,曲线不存在C型锯齿而表现为A型和A+B型锯齿。

图4 306 K下不同应变速率时固溶态AZ91D变形镁合金的应力跌落—频数曲线

Fig.4 Curves of stress drop vs frequency for as-solid-solution treated AZ91D Mg alloy at 306 K and different strain rates

2.3 DSA对AZ91D镁合金性能的影响

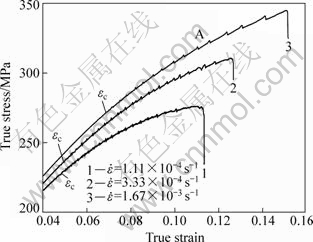

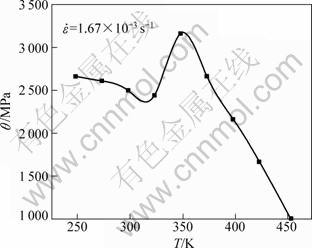

图5所示为固溶态AZ91D镁合金在1.67×10-3 s-1的应变速率下加工硬化速率与温度的关系曲线。加工硬化速率θ的计算式如下[15, 23]:θ=(σ2-σ0.2)/?ε。式中:σ2表示残余应变为2%时的应力;σ0.2表示残余应变为0.2%时的应力;?ε=0.018。

由图5可见,在248~323 K时,加工硬化速率随着温度升高而缓慢降低,然而,当温度大于323 K时,加工硬化速率随着温度升高而急剧升高,在368 K时达到峰值。这主要是由于DSA的出现引起的强化效应减缓了合金加工硬化系数随温度的上升而下降的趋势。特别是在含有间隙原子如C、N或O的体心立方或者密排六方金属中,DSA对加工硬化有很强的影响。

图5 加工硬化速率θ与温度的关系

Fig.5 Relationship between work-hardening rate and temperature at strain rate of 1.67×10-3 s-1

AZ91D镁合金在不同的应变速率内和温度区间塑性变形过程中,出现宽大的DSA温度区间(248~423 K)、锯齿屈服流变以及加工硬化速率峰值等特征,这对密排六方材料的塑性变形规律的研究以及塑性加工工艺制订和控制都有重要意义。

3 结论

1) 在所设定的应变速率下和试验温度范围内,固溶态AZ91D镁合金发生DSA现象,表现出为拉伸曲线中出现锯齿屈服,在一定的温区内,出现负的应变速率敏感性,以及加工硬化速率出现峰值。

2) 在所设定的应变速率下,只有在一定的温区内拉伸曲线才会出现锯齿屈服。在一定的应变速率下,出现锯齿屈服的临界应变量εc随变形温度升高而减小;而在一定的温度范围内,临界应变量εc随应变速率增加而增大。

3) AZ91D镁合金发生锯齿屈服时的锯齿波波形与应变速率以及应变量密切相关。当应变速率 为3.33×10-4 s-1、1.67×10-3 s-1时,曲线所对应的锯齿波类型为典型的A型,所反映的应力跌落条形图分布呈幂函数分布;而在相对较低的应变速率

为3.33×10-4 s-1、1.67×10-3 s-1时,曲线所对应的锯齿波类型为典型的A型,所反映的应力跌落条形图分布呈幂函数分布;而在相对较低的应变速率 = 1.11×10-4 s-1时,锯齿波类型为A+B混合型,所反映的应力跌落条形图分布为双峰分布。

= 1.11×10-4 s-1时,锯齿波类型为A+B混合型,所反映的应力跌落条形图分布为双峰分布。

4) DSA的强化效应使AZ91D镁合金的加工硬化速率出现峰值,延缓合金加工硬化系数随着温度上升而下降的趋势,当温度大于323 K时,加工硬化速率随着温度升高而急剧升高,并在368 K时达到峰值。

致谢

感谢福州大学测试试验中心在材料拉伸试验中给予的帮助!感谢杨开怀博士研究生在试验过程中的帮助!

REFERENCES

[1] KUNG J F, BAO H Y, GALLIGN J M. Collective behavior of dislocation[J]. Scripta Metallurgica et Materialia, 1995, 33: 301-305.

[2] TONG Wei, TAO Hong, ZHANG Nian, LOUIS G, HECTOR J. Time-resolved strain mapping measurements of individual Portevin-Le Chatelier deformation bands[J]. Scripta Materialia, 2005, 53: 87-92.

[3] 钱匡武, 李效琦, 萧林钢, 陈文哲, 张好国, 彭开萍. 金属和合金中的动态应变时效现象[J]. 福州大学学报, 2001, 29(6): 8-23.

QIAN Kuang-wu, LI Xiao-qi, XIAO Lin-gang, CHEN Wen-zhe, ZHANG Hao-guo, PENG Kai-ping. Dynamic strain aging phenomenon in metals and alloys[J]. Journal of Fuzhou University, 2001, 29(6): 8-23.

[4] SCHUH C A, NIEH T G. A nanoindentation study of serrated flow in bulk metallic glasses[J]. Acta Materialia, 2003, 51: 87-99.

[5] BARLAT F, GLAZOV M V, BREN J C, LEGE D J. A simple model for dislocation behavior, strain and strain rate hardening evolution in deforming aluminum alloys[J]. International Journal of Plasticity, 2002, 18: 919-939.

[6] VOYIADJIS G Z, ABED F H. Microstructural based models for bcc and fcc metals with temperature and strain rate dependency[J]. Mechanics of Materials, 2005, 37: 355-378.

[7] SOAR M A, CURTIN W A. Solute strengthening of both mobile and forest dislocations: The origin of dynamic strain aging in fcc metals[J]. Acta Materialia, 2008, 56: 4046-4061.

[8] 彭开萍, 陈文哲, 钱匡武. 3004铝合金动态应变时效的微观机理[J].材料热处理学报,2005, 26(6): 57-61.

PENG Kai-ping, CHEN Wen-zhe, QIAN Kuang-wu. The microsmics of dynamic strain aging in 3004 Al alloy[J]. Transation of Materials and Heat Treatment, 2005, 26(6): 57-61.

[9] WANG Cong, XU Yong-bo, HAN En-hou. Serrated flow and abnormal strain rate sensitivity of a magnesium-litihium alloy[J]. Materials Letters, 2006, 60: 2941-2944.

[10] TROJANOV Z,LUKAC P, MILICKA K, SZARAZ Z. Characterision of dynamic strain ageing in two magnesium alloys[J]. Material Science and Engineering A, 2004, 387/389: 80-83.

[11] CORBY C, CACERES C H, LUKAC P. Serrated flow in magnesium alloy AZ91[J]. Material Science and Engineering A, 2004, 387/389: 22-24.

[12] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 1-15.

CHEN Zhen-hua. Deformed magnesium alloys[M]. Beijing: Chemical Industry Press, 2005: 1-15.

[13] BHARATHI M S, LEBYODKIN M, ANANTHAKRISHNA G, FRESSENGEAS C, KUBIN L P. The hidden order behind Jerky flow[J]. Acta Materialia, 2002, 50: 2813-2824.

[14] 田宝辉, 李焕喜, 张永刚, 陈昌麒. Al-Li单晶体流变应力的应变速率敏感性[J]. 兵器材料科学与工程, 1997, 20(4): 14-19.

TIAN Bao-hui, LI Huan-xi, ZHANG Yong-gang, CHEN Chang-qi. Strain rate sensitivity of flow stress in Al-Li single crystals[J]. Ordnance Material Science and Engineering, 1997, 20(4): 14-19.

[15] 彭开萍. 面心立方合金动态应变时效的研究[D]. 福州: 福州大学材料科学与工程学院, 2007.

PENG Kai-ping. Study of dynamic strain aging in fcc alloys[D]. Fuzhou: College of Materials Science and Engineering, Fuzhou University, 2007.

[16] LEBYODKIN M, BRECHEK Y, ESRAIN Y, KUBIN L. Statistical behavior and localization patterns in the Portevin-Le Chatetlier effect[J]. Acta Materialia, 1996, 44: 4531-4541.

[17] CHATTERJEE A, SARKAR A, BARAT P, GAYATHRI N. Character of the deformation bands in the (A+B) regime of the Portevin-Le Chatelier effect in Al-2.5%Mg alloy[J]. Materials Science and Engineering A, 2009, 508: 156-160.

[18] LEBYODKIN M, BRECHET Y, DUNIN-BATKOVSKII L , ESTRIN Y, KUBIN L P. Spatio-Temporal dynamics of the Portevin-Le Chatelier effect: experiment and modelling[J]. Acta Materialia, 2000, 48: 2529-2541.

[19] LEBYODKIN M A, DUNIN-BATKOVSKII L R, BOBROV V S. Statistic aspects of low temperature discontinuous deformation[J]. Scripta Metallurgica et Materialia, 1995, 33: 773-780.

[20] BOHLE T, BONDAR G, ESTRIN Y, LEBYODKIN M A. Geometrically non-linear modeling of the Portevin–Le Chatelier effect[J]. Computational Materials Science, 2009, 44: 1076-1088.

[21] CHIHAB K, FRESSENEAS C. Time distribution of stress drops, critical strain and crossover in the dynamics of Jerky flow[J]. Materials Science and Engineering A, 2003, 356: 102-107.

[22] 卢俊勇, 蒋震宇, 张青川. A1-4%Cu多晶合金中锯齿形屈服现象的初步时序分析[J]. 金属学报, 2006, 42(6): 611-618.

LU Jun-yong, JIANG Zhen-yu, ZHANG Qing-chuan. Preliminary time series analysis of serrated yielding in Al-4%Cu alloy[J]. Acta Metallurgica Sinica, 2006, 42(6): 611-618.

[23] KANG D H, KIM D W, KIN S, BAE G T, KIM K H, KIM N J. Relationship between stretch formability and work-hardening capacity of twin-roll cast Mg alloys at room temperature[J]. Scripta Materialia, 2009, 61: 768-771.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50441013)

收稿日期:2009-09-29;修订日期:2010-02-01

通信作者:陈文哲,教授,博士;电话:0591-22863009;E-mail:chenwz@fzu.edu.cn