文章编号:1004-0609(2012)05-1509-11

旋流数对铝熔炼炉熔炼过程的影响

王计敏1, 2,闫红杰1, 2,周孑民1, 2,李世轩3,贵广臣3

(1. 中南大学 能源科学与工程学院,长沙 410083;2. 中南大学 流程工业节能湖南省重点实验室,长沙 410083;

3. 苏州新长光热能科技有限公司,苏州 215008)

摘 要:针对现有的圆形铝熔炼炉,结合铝熔炼炉熔炼过程的特点,在铝熔炼炉热平衡测试的基础上,建立了合理的铝熔炼炉数学模型,并运用计算流体力学软件FLUENT实现燃烧空间和熔池的耦合物理场的数值模拟。同时分析了不同旋流数对铝熔炼炉熔炼过程的影响,依据提出的优化准则,确实旋流数大于0.6时能够获得最佳的熔炼性能。

关键词:铝熔炼炉;旋流数;熔炼过程;数值模拟

中图分类号:TF062 文献标志码:A

Influence of swirl number on melting process of aluminum melting furnace

WANG Ji-min1, 2, YAN Hong-jie1, 2, ZHOU Jie-min1, 2, LI Shi-xuan3, GUI Guang-chen3

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Hunan Key Laboratory of Energy Conservation in Process Industry, Central South University, Changsha 410083, China;

3. Suzhou Longray Thermal Technology Co. Ltd., Suzhou 215008, China)

Abstract: Based on validating results by heat balance test for aluminum melting furnace, a reasonable mathematical model which considering the feature of the aluminum melting process was established. The numerical simulation of coupling field between combustion space and aluminum bath in a round aluminum melting furnace was carried out using CFD software FLUENT. The influence of the swirl number on melting process of the aluminum melting furnace was analyzed. According to optimizing criterion which is put forward in this work, the optimal melting performance is obtained when the swirl number is larger than 0.6.

Key words: aluminum melting furnace; swirl number; melting process; numerical simulation

铝及铝加工材料在20多年前主要用于航天、航空等军事工业,目前已大量应用于国民经济的各个领域。在铝加工企业中,铝熔炼炉是必不可少的加热设备,其主要作用是向铸造机提供铝液。当前,铝加工行业面临的主要问题是能源成本的迅速增长、环境保护的严格要求和优质铝合金的需求。为此,许多科技工作者对铝熔炼炉熔炼过程进行了广泛而深入的研究。

LI等[1-3]建立了修正的Essenhigh/Tsai模型,并进行了热力学分析和炉壁热传导分析,为铝熔炼炉熔炼过程的优化提供了理论指导。试验是理论研究的基础,WILLIAMS等[4]、LAZIC等[5]及STEVENS和FORTIN[6]通过试验来研究提高铝熔炼炉熔炼性能的方法。这些研究均受到试验费用昂贵及操作困难的限制。随着计算机技术的发展,利用计算流体力学软件对铝熔炼炉进行数值研究,可节约物力资源和大量的时间、人力,并且能够真实反应铝熔炼炉内流体的流动、燃烧和换热现象,可获得较满意的研究结果。因此,许多学者[7-10]对铝熔炼炉炉内热工过程进行了数值模拟优化研究。此外,在铝及铝合金熔炼过程中,铝液表面和炉气发生氧化反应而形成氧化层, SOLOVJOV和WEBB[11]及KANTI等[12]研究了氧化层对铝熔炼炉熔炼过程的影响。使用电磁搅拌能使铝熔炼炉内合金成分和铝液温度更加均匀,并且减少了熔炼时间和炉渣的形成,RYDHOLM和SJODEN[13]、黄军等[14]、TAKAHASHI等[15]以及ALCHALABI等[16]对铝熔炼炉熔炼过程中电磁搅拌的作用进行了研究。对于其他类似的熔化炉,如镁合金熔化炉、玻璃窑炉和铝合金保温炉等,文献[17-19]对相关熔化炉的数值模拟进行了报道。

虽然铝熔炼炉曾被模拟,但研究者未考虑铝液的影响,忽略了燃烧空间与铝液间的相互作用。此外,燃烧器结构对改善铝熔炼炉的熔炼性能有较大影响。因此,本文作者结合铝熔炼炉熔炼过程的特点,建立合理的铝熔炼炉数学模型,并运用计算流体力学软件FLUENT实现燃烧空间和熔池的耦合物理场的数值模拟,同时分析旋流数对铝熔炼炉熔炼过程的影响。依据提出的优化准则,经过对不同旋流数下耦合场的优化分析,获得了最佳的旋流数。

1 模型的建立与实现

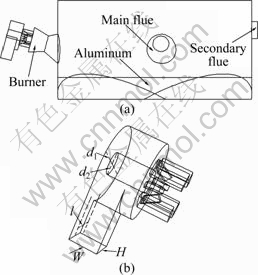

本研究中的铝熔炼炉呈圆筒形状,铝液位于熔炼炉下部,侧部安装有蓄热式燃烧器,其几何模型如图1所示。工作时,其中一个燃烧器用作主烟道,其烟气流量占总流量的80%,另一部分烟气则从辅助烟道流出。考虑燃烧器几何结构,本研究采用结构简单的涡壳旋流器使熔炼炉获得旋转射流。考虑中心管的影响,其旋流数(S)的计算公式如下[20]:

(1)

(1)

式中:d1、d2 分别为环形通道的内、外径;W、H分别为涡壳入口截面尺寸,即长、宽;l为偏心距。

图1 铝熔炼炉几何模型

Fig. 1 Geometry model of aluminum melting furnace: (a) Aluminum melting furnace; (b) Volute swirler

模型假设:

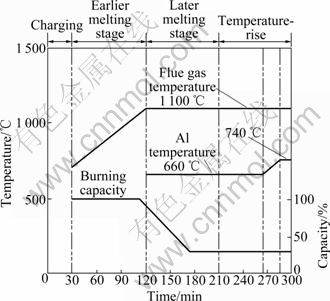

1) 结合铝熔炼过程及其特点(如图2所示[21]),根据工程实际,假设铝液不运动,界面无波动,忽略铝液表面的化学反应,只考虑铝液与周边空气的辐射和对流换热,不考虑铝液过热度。

2) 铝液上表面均匀覆盖一层Al2O3,且氧化充分完全[8,16],氧化层厚度和发射率分别假设为5 mm和0.33。

3) 由于经炉底、炉顶、炉侧外壁散热很小,可不考虑其热损失[22]。炉内壁发射率对铝的熔化过程影响较小,可假设炉膛壁面和铝液下表面为绝热边界,其炉内壁发射率设为0.8。

图2 铝熔炼炉温度及能量分配模型

Fig. 2 Temperature and energy distributing model of aluminum melting furnace

数学模型包括连续性方程、动量方程、能量方程以及化学组分守恒方程,另外还有湍流模型、燃烧反应模型以及辐射模型等。湍流模型采用广泛使用的标准k—ε模型;使用非预混燃烧模型来模拟天然气和空气的燃烧反应;P-1模型用来模拟炉壁、炉气及铝液之间的辐射换热。吸收系数假设符合介于简化模型和完全模型之间的WSGGM模型。流固耦合界面处采用式(2)描述。可使用计算流体力学软件FLUENT实现上述模型的数值计算。

(2)

(2)

式中:λAl为铝液的导热系数,T为热力学温度;n为单位方向矢量;h为局部对流换热系数,Tg为炉气温度,Tb为炉壁温度,Tw为耦合面温度,ε1为炉气对铝液的系统发射率,ε2为炉壁对铝液的系统发射率,σ为Stefan-Boltzmann常数。

不考虑液相区域中对流现象,则对于固相区域和液相区域来说,热流均以热传导方式传递,由于存在潜热,其支配导热过程的能量方程如下:

(3)

(3)

式中:fL为质量液相率,L为熔化潜热,cp,Al为铝液比热容,ρAl为铝液密度,λAl为铝液导热系数。

由式(3)可见,处理潜热项的关键在于求得液相率fL随温度的变化规律。假设熔化潜热在固液两相区内线性释放,采用式(4)的等价比热法对潜热进行处 理[23]。

(4)

(4)

式中:c1为固态铝比热容,c2为液态铝比热容,TS为固相温度,TL为液相温度,L为熔化潜热。

由于熔化温度区间内的导热过程不但要受相变潜热的影响,而且还要受本身组成改变所引起的物理特性变化的影响,所以两相区物性参数为

(5)

(5)

式中:xL为液相物性参数,xS为固相物性参数,TL为液相温度,TS为固相温度,xm为两相区物性参数。

结合图2,可假设燃烧量与液相率呈线性关系,则燃烧量的变化可由式(6)确定。

(6)

(6)

式中:fL为质量液相率。

铝液的初始条件: 300 K;空气质量进口边界条件:Mair-inlet=1.871 kg/s,Tair-inlet=823 K,fair-inlet= 0;天然气成分可按标准天然气成分计,其速度进口边界条件:Unatural-gas-inlet=43.195 m/s,Tnatural-gas-inlet=300 K,fnatural-gas-inlet=1;主烟道和辅助烟道分别为自由出流边界条件:Outflowmain-flue=0.8,Outflowsecondary-flue=0.2。铝液和Al2O3等的物性参数参考文献[8]。运用FLUENTUDF和FLUENT Scheme混合编程实现燃烧量的改变、液相率的计算、铝液物性参数改变和保存指定时刻结果文件等。当液相率达到100%时,保存最终结果文件并退出FLUENT。其FLUENT求解过程如图3所示,程序说明如下:

300 K;空气质量进口边界条件:Mair-inlet=1.871 kg/s,Tair-inlet=823 K,fair-inlet= 0;天然气成分可按标准天然气成分计,其速度进口边界条件:Unatural-gas-inlet=43.195 m/s,Tnatural-gas-inlet=300 K,fnatural-gas-inlet=1;主烟道和辅助烟道分别为自由出流边界条件:Outflowmain-flue=0.8,Outflowsecondary-flue=0.2。铝液和Al2O3等的物性参数参考文献[8]。运用FLUENTUDF和FLUENT Scheme混合编程实现燃烧量的改变、液相率的计算、铝液物性参数改变和保存指定时刻结果文件等。当液相率达到100%时,保存最终结果文件并退出FLUENT。其FLUENT求解过程如图3所示,程序说明如下:

采用liquid_fraction_func函数完成液相率计算。采用al_therm_conduction和al_density函数修正铝液的物性参数。采用capacity_proc过程实现燃烧量的改变和保存指定时刻结果文件。

图3 铝熔炼炉熔炼过程的FLUENT求解框图

Fig. 3 Solution procedure of FLUENT for aluminum melting furnace

2 模型验证

由于燃烧器和炉体的尺寸悬殊较大,采用多块网格结构。考虑计算资源紧张性和计算结果准确性,对网格数和时间步长进行无关性检验,比较两次炉膛温度相对标准差,若相对误差在5%以内,则证明网格的疏密和时间步长的长短对计算结果无影响。由图4可知,最终选取的网格数为377 442,时间步长为1 s。

图4 网格和时间步长无关性检验

Fig. 4 Grid and time step independenc test

为了验证模型的可靠性和准确性,运用烟气分析仪、铠装热电偶和压力计等测试工具,对某厂的35t蓄热式铝熔炼炉进行了热平衡测试和数值模拟。模拟结果和测试结果的对比列于表1。从表1可以看出,数值模拟结果和测试结果基本一致,模型较好地反映铝熔炼炉熔炼状况。图5所示为炉膛及铝液温度计算结果和测试结果的对比。从图5可知,计算和测试的结果变化趋势一致,其相对误差小于5%,从而验证了模型的正确性。但计算结果比测试结果稍大,主要由于在测试过程中,炉门敞开,由于负压作用冷空气进入炉内。此外,由于模拟过程中忽略炉壁的散热,故使得模拟结果有所升高。

表1 模拟和测试结果对比

Table 1 Comparison of simulation results and test values for aluminum melting furnace

图5 燃烧空间和熔池温度计算值与测试值对比

Fig. 5 Comparison of temperature between computational data and test data in combustion space and aluminum bath

3 优化准则及模拟方案

旋流数0.6是强弱旋流的分界值,由式(1)可知,通过改变涡壳旋流器中的一个或几个参数可改变旋流数S的大小。根据原始方案,提出的模拟方案如表2所列。

优化准则如下:

1) 熔炼时间尽可能短,铝液、炉膛温度相对标准差尽可能小[24-26]。

2) 炉膛主烟道出口温度要较高,但进入主烟道的温度不能超过1 473 K[27]。

3) 炉膛压力为微正压,控制在10~20 Pa之间,防止冷空气进入炉内和火焰外喷[5-6]。

4) 炉内气体为微氧化性气氛,既可保证天然气的完全燃烧,又可减小烟气带走的热量,炉膛出口氧气浓度应控制在3%以下[27-28]。

表2 不同旋流数下涡壳旋流器的尺寸

Table 2 Size of volute swirler for different swirl numbers

5) 对熔体纯洁度的要求,一般根据合金的品种和用途的不同而有一定差异,平衡含氢含量通常应在0.15~0.2 cm3/100 gAl以下[29]。一般的生产条件下,纯铝中的平衡含氢量由下面的经验公式表示:

lg c=-5 800/T+4.576+1/2lg p (7)

式中:c为铝熔体中氢的平衡含量,cm3/100 g Al;T为熔体热力学温度,K; p为炉气中的水蒸气分压,mmHg。

4 铝熔炼炉数值模拟结果分析

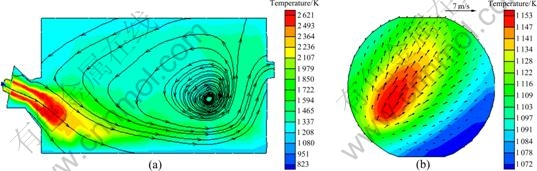

不同阶段蓄热式铝熔炼炉内温度分布如图6所示。由图6可看出,炉内火焰较长,约到达炉膛的中心位置,燃烧温度较高,有利于铝的熔化。烧嘴倾斜一定的角度,使高温气流冲向熔池液面中心,从而大大加强了炉内气体与铝料的对流传热,加快熔池内铝料的熔化速度。由于忽略了铝液流动,铝液间的传热以导热为主,故铝液纵截面温度大体上呈抛物线分布。由于火焰的温度较高,且速度较大,故铝液的较高温度区域位于和火焰接触面下方。高温烟气一部分从主烟道流出,一部分从辅助烟道流出,虽然燃烧器与辅助烟道的夹角为180°,但由于辅助烟道的高度高于燃烧器,延长了高温烟气在炉内的停留时间,加强了炉内气流的扰动,强化传热过程,提高了炉温,缩短熔炼时间。另外,仿真结果表明辅助烟道的存在,不仅可以调节炉温,而且可调节炉压。因此,如果炉压过高或过低,可关闭或打开辅助烟道来改变炉压。

图7所示为熔炼参数随熔炼时间的变化关系。从图7中可以看出,在固液区,铝液温度上升缓慢,表明大部分铝在发生相变,而离开固液相线时铝液温度呈线性增长,上升速度加快。液相率呈线性增长,这与假设熔化潜热在固液两相区内线性释放一致。炉膛温度先随熔炼时间增加而增加,而后由于燃烧量的减小,炉膛温度开始降低,直到燃烧量降低到0.3,炉膛温度又开始增加。熔化开始前,由于炉膛温度上升较快,耦合面热流密度随熔炼时间上升较快,当铝开始熔化时,由于液态铝的导热系数是固态铝的1/3~1/4,热流密度达到平衡状态,但当液相率超过约5%时,由于假设燃烧量随液相率增加而线性降低,故热流密度也线性降低,当液相率大于50%,燃烧量已稳定,故热流密度又开始缓慢降低。炉膛温度相对标准差随着熔炼时间的增加而减小,特别是在燃烧量变化范围内,呈线性减小。铝液温度相对标准差在熔炼开始时,随着熔炼时间不断增加,当铝开始发生相变时,铝液温度相对标准差又开始减小,当液相率达到某值,熔池上层熔体温度已超过熔化温度,开始熔化后升温,温度升高较快,而底部熔体仍处于未熔化,从而熔体上层与底部温差较大,故铝液温度相对标准差又开始增加。

图6 不同阶段铝熔炼炉内温度分布

Fig. 6 Temperature distribution in aluminum melting furnace at different melting periods: (a) fL=25%, τ=10 234 s; (b) fL=50%, τ=12 619 s; (c) fL=75%, τ=16 105 s

图8所示为炉膛和铝液上表面流场和温度场分布。由图8(a)可知,空气与天然气在烧嘴中混合后,从烧嘴倾斜方向喷射入炉内,气流喷入炉内后稍被下压,然后从铝熔体表面掠过,在炉膛末端先后遇到炉壁和炉顶后改变方向,从而在炉内形成一个较大的漩涡,使高温炉气在炉内形成循环气流,加强了炉内气流的扰动,延长高温炉气在炉内的停留时间。而从烧嘴喷出的气流稍有下压也是受到这个漩涡的影响。从图8(b)可以看出,最高温度位于熔体中心,炉内气流速度较高的区域中温度也较高。这是燃烧所产生的高温烟气对铝液上表面中心有较强烈的辐射换热和对流换热所造成的,与实际情况相符。

图7 熔炼参数随熔炼时间的变化关系

Fig. 7 Relationship between melting parameters and melting time: (a) Change curves of aluminum temperature, furnace temperature and liquid fraction with melting time; (b) Change curves of relative standard error of aluminum temperature and furnace temperature and heat flux through coupling face with melting time

图8 炉膛和铝液上表面流场和温度场分布

Fig. 8 Temperature field and flow field distributions of hearth and top surface of aluminum bath: (a) Hearth; (b) Top surface of aluminum bath

5 旋流数对铝熔炼炉熔炼过程的影响

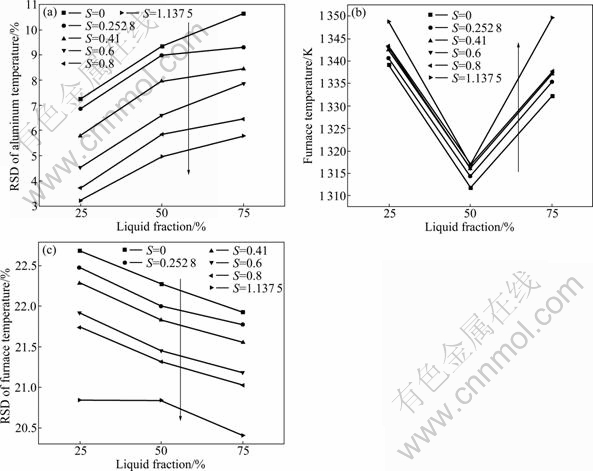

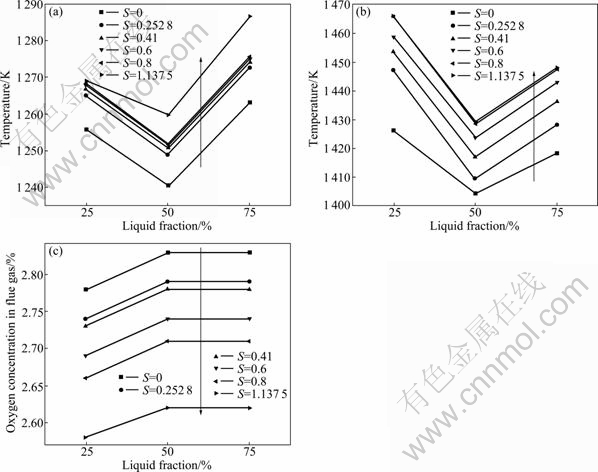

图9所示为不同旋流数下,铝液温度相对标准差、炉膛温度及其相对标准差随液相率的变化趋势。由于旋流数加强了炉内气流间的混合换热,所以炉膛温度随着旋流数的增加而增加,铝液温度相对标准差和炉膛温度相对标准差随着旋流数增加而减小。熔化期内,铝液温度相对标准差随着液相率的增加而增加,这是由于铝的熔化潜热大且黑度小,致使熔池上层熔体因熔化而温度升高较快,而底部熔体仍未熔化,造成熔体间较大的温差;由于气流间不断混合,炉膛温度相对标准差随着液相率的增加而减小。由于熔化前期燃烧量与液相率呈线性递减,故炉膛温度先随液相率增加而减小,而到了熔化后期,燃烧量已稳定,炉膛温度则随着液相率增加而增加。

图10所示为不同旋流数下烟道温度和炉膛出口氧气浓度随液相率的变化趋势。由于旋流数加强了空气和天然气混合燃烧,且增强了炉内气流的混合作用,所以烟道温度随着旋流数增加而增加,炉膛出口氧气浓度随旋流数的增加而减小,且烟气中的氧分低于3%。另外,通过比较图10(a)和(b),辅助烟道的温度要高于主烟道,这与该铝熔炼炉的结构有关,从图1可以看出,燃烧器与辅助烟道的水平夹角为180°,而与主烟道的水平夹角为90°,致使一部分高温烟气直接从辅助烟道排出。由式(6)可知,熔化前期,燃烧量随液相率增加而线性递减,而熔化后期燃烧量已稳定,故熔化前期烟道温度随液相率增加而减小,而熔化后期又开始增加;同理,炉膛出口氧气浓度在熔化前期则随液相率增加而增加,而在熔化后期恒定不变。

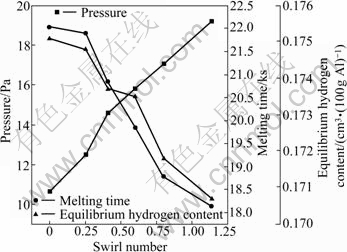

炉压、熔炼时间和平衡含氢量随旋流数的变化趋势如图11所示。由于旋流数促进了炉内气流的热交换,炉膛温度随着旋流数的增加而增加,随着炉膛温度的升高,炉气与铝液间的热交换增强,故熔炼时间随着旋流数的增加而缩短,而熔炼时间显著影响了熔体的烧损和吸氢。因此,旋流数的增加有利于减少熔体氧化烧损和熔体中含氢量,从而达到节能降耗和提高熔体质量的双重目的。从图11可以看出,不同旋流数下炉压符合控制要求,且炉压随着旋流数的增加而增加,平衡含氢量则随着旋流数的增加而减小。它们之间的变化关系都是由于旋流数的增加强化了炉内气流的换热所决定的。

图9 不同旋流数下铝液温度相对标准差、炉膛温度及其相对标准差与液相率的变化趋势

Fig. 9 Change trends of RSD of aluminum temperature, and furnace temperature and RSD of furnace temperature with liquid fraction for different swirl numbers: (a) RSD of aluminum temperature; (b) Furnace temperature; (c) RSD of furnace temperature

图10 烟道温度、炉膛出口氧气浓度与与液相率的变化趋势

Fig. 10 Change trends of flue temperature and oxygen concentration in flue gas with liquid fraction: (a) Main flue; (b) Secondary flue; (c) Oxygen concentration in flue gas

图11炉压、熔炼时间和平衡含氢量随旋流数的变化趋势

Fig. 11 Change trends of pressure, melting time and equilibrium hydrogen content with swirl number

图12所示为不同旋流数下炉膛温度分布及流线。从图12很容易看出,旋流数大于0,远离主烟道另一侧炉气出现较大的旋涡,这是炉膛温度及其相对标准差差别的主要原因。由于强旋流加强了气流的混合燃烧,使火焰的最高温度随旋流数的增加而减小,但其温度更加均匀,故炉膛温度更高。另外,旋流数不能太大,否则使主烟道的温度过高,且不符合炉膛压力控制。结合图9~11,依据优化准则可确定,旋流数大于0.6能获得最佳的熔炼性能。

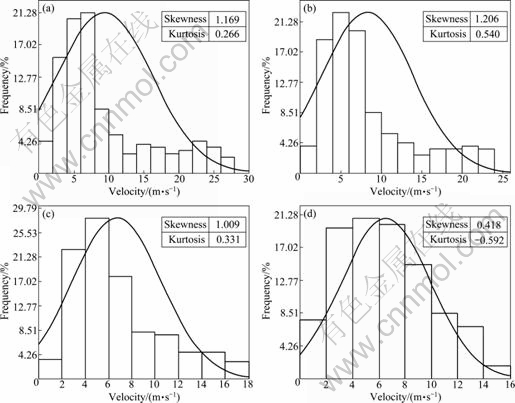

铝液上表面气流速度分布的频数趋于正态分布,也就是说,气流速度过小和过高现象都比较少,中等速度居多。可用偏度来描述气流速度分布与正态分布的对称性偏离程度,而偏度的绝对值数值越大表示分布形态的偏斜程度越大。峰度来描述气流速度分布与正态分布的陡缓性偏离程度,峰度越小越平坦。铝液上表面气流速度分布规律的变化显著影响了铝液温度相对标准差,因为它使炉气与铝液的对流换热发生变化,而对流换热是使铝熔化的主要途径。图13所示为不同旋流数下铝液上表面气流速度分布。由图13可知,旋流数大于0.6,铝液上表面气流速度分布更加均匀,因而铝液相对标准差的较小,这是因为铝液上表面气流速度分布决定了铝液温度变化规律。

图12 不同旋流数下炉膛温度分布及流线

Fig. 12 Temperature field distributions and streamline of hearth for different swirl numbers: (a) S=0; (b) S<0.6; (c) S=0.6; (d) S>0.6

图13 不同旋流数下铝液上表面气流速度分布

Fig. 13 Velocity distribution for top surface of aluminum bath on swirl number: (a) S=0; (b) S<0.6; (c) S=0.6; (d) S>0.6

6 结论

1) 通过比较分析铝熔炼炉熔炼过程的数值模拟的结果和测试值,说明建立的铝熔熔炼炉数学模型是合理的,模型能较好地反映铝及铝合金熔炼过程,表明可运用该模型进行铝熔炼炉熔炼过程的工艺参数优化研究。其结果分析表明旋流数大于0.6时,能获得最佳的熔炼性能。

2) 烟道温度、炉膛温度和炉压随着旋流数的增加而增加;铝液温度相对标准差、炉膛温度相对标准差、炉膛出口氧气浓度、熔炼时间和平衡含氢量随旋流数的增加而减小。

3) 熔化期内铝液温度相对标准差随着液相率的增加而增加,而炉膛温度相对标准随液相率增加而减小;熔化前期炉膛温度和烟道温度先随液相率增加而减小,熔化后期又增加;熔化前期炉膛出口氧气浓度则随液相率增加而增加,熔化后期趋于定值。

4) 铝液温度在固液区上升缓慢,而离开固液相线时铝液温度上升速度加快。炉膛温度、铝液温度相对标准差先随着熔炼时间增加而增加,达到极大值时又开始减小,达到极小值时又开始增加。炉膛温度相对标准差随熔炼时间的增加而减小。耦合面热流密度随着熔炼时间增加先增加到平衡状态,当液相率超过某值时又减小。

REFERENCES

[1] LI T X, KING P, HASSAN M, KUWANA K, SAITO K. An analytical furnace model for optimizing aluminum melting furnaces [C]// Light Metals 2005. Warrendale: TMS, 2005: 875- 879.

[2] LI T X, HASSAN M, KUWANA K, SAITO K, KING P. Performance of secondary aluminum melting: Thermodynamic analysis and plant-site experiments [J]. Energy, 2006, 31(12): 1433-1443.

[3] Penmetsa S S, Li T X, King, SAITO K. Scale modeling of aluminum melting furnaces [C]// Light Metals 2005. Warrendale: TMS, 2005: 181-185.

[4] Edward M W, Donald L S, Ken O. Evaluating aluminum melting furnace transient energy efficiency [C]// Proceedings of Symposia Held During TMS 2009 Annual Meeting and Exhibition. Warrendale: TMS, 2009: 43-51.

[5] Lazic L, Varga A, Kizek J. Analysis of combustion characteristic in a aluminum melting furnace [J]. Metalurgija, 2005, 44(3): 192-199.

[6] Stevens W, Fortin J Y. Development of a pilot “top-charge” melt furnace to examine the fundamental melting in aluminum [C]// Light Metals 2002. Warrendale: TMS, 2002: 747-750.

[7] GoLchert B M, Zhou C Q, Quenette A, HAN Q,KING P E. Combustion space modeling of an aluminum furnace [C]// Light Metals 2005. Warrendale: TMS, 2005: 887-892.

[8] Nieckele A O, Naccache M F, Gomes M S P. Numerical modeling of an industrial aluminum melting furnace [J]. Journal of Energy Resources Technology, 2004, 126 (1): 72-81.

[9] Golchert B, Kumar A, Venuturumilli R, Adhiya A, Belt C, Tessandori J. How flames/loads interaction affects furnace efficiency in round top furnace operation [C]// Proceedings of Symposium Held During the 2007 TMS Annual Meeting. Warrendale: TMS, 2007: 61-66.

[10] Golchert B, Ridenour P, Walker W, GU M,ZHOU C Q. Effects of nitrogen and oxygen concentration on NOx emissions in aluminum furnace [C]// IMECE2006—Power. New York, 2006: 325-326.

[11] Solovjov V P, Webb B M. Prediction of radiative transfer in aluminum-recycling furnace [J]. Journal of the Institute of Energy, 2005, 78(1): 18-26.

[12] Kanti D A, Mukhopadhyay A, Sen S, Puri I K. Numerical simulation of early stages of oxide formation in molten aluminum-magnesium alloys in a reverberatory furnace [J]. Modelling and Simulation in Materials Science and Engineering, 2004, 12(3): 389-405.

[13] Rydholm B, Sjoden O. Optimized furnace design with electromagnetic stirring [C]// Light Metals 2005. Warrendale: TMS, 2005: 201-208.

[14] 黄 军, 王宝峰, 赵莉萍, 李建超. 铝熔炉电磁搅拌磁场与流场的数值模拟[J]. 特种制造及有色合金, 2008, 28(2): 119-121.

Huang Jun, Wang Bao-feng, Zhao Li-ping, LI Jian-chao. Numerical simulation of magnetic field and flow field in aluminum melt with electromagnetic stirring [J]. Special Casting and Nonferrous Alloys, 2008, 28(2): 119-121.

[15] Takahashi K, Maruyama M, Ishikawa N. Simulation for loss of electromagnetic stirring force due to the penetrated aluminum into the furnace lining [C]// Light Metals 2007. Warrendale: TMS, 2007: 49-58.

[16] Alchalabi R, Meng F, Peel A. Furnace operation optimization via enhanced bath circulation: Technologies for production increase and dross reduction [C]// Light Metals 2002. Warrendale: TMS, 2002: 739-746.

[17] 郭 臣, 龙思远, 徐绍勇, 游国强. 燃气镁合金熔化炉内气相燃烧过程的三维数值模拟[J]. 工业加热, 2008, 37(1): 10-14.

Guo Chen, Long Si-yuan, Xu Shao-yong, YoU Guo-qiang. Three-dimensional numerical simulation of gaseous combustion process in melting furnace for magnesium alloy of gas [J]. Industrial Heat, 2008, 37(1): 10-14

[18] Abbassi A, Khoshmanesh K H. Numerical simulation and experimental analysis of an industrial glass melting furnace [J]. Applied Thermal Engineering, 2008, 28(5/6): 450-459.

[19] ZHOU Nai-jun, ZHOU Shan-hong, ZHANG Jia-qi, PAN Qing-lin. Numerical simulation of aluminum holding furnace with fluid-solid coupled heat transfer [J]. Journal of Central South University of Technology, 2010, 17(6): 1389-1394.

[20] 何佩鏊, 赵仲琥, 秦裕琨. 煤粉燃烧器设计及运行[M].北京: 机械工业出版社, 1987: 83-88.

HE Pei-ao, ZHAO Zhong-hu, QIN Yu-kun. Design and operation of pulverized coal burner [M]. Beijing: China Machine Press, 1987: 83-88.

[21] 余志华. 浅谈熔铝炉优化设计技术[C]//铝型材技术(国际)论坛文集. 广州, 2004: 163-167.

Yu Zhi-hua. Review of optimizing technology on aluminum melting furnace [C]// Proceedings of Aluminum Technology (International). Gangzhou, 2004: 163-167.

[22] 李世轩, 李 浩. 铝熔炼炉热平衡测试及节能分析[J].有色冶金节能, 2009, 25(6): 40-42.

Li Shi-xuan, Li Hao. Thermal equilibrium test and energy saving analysis for aluminum smelting furnace [J]. Energy Saving of Non Ferrous Metallery, 2009, 25(6): 40-42.

[23] 杨 全. 金属凝固与铸造过程数值模拟[M]. 杭州: 浙江大学出版社, 1998: 38-48.

YANG Quan. Numerical Simulation of metal solidification and casting process [M]. Hangzhou: Zhejiang University Press, 1998: 38-48.

[24] 田荣璋. 铸造铝合金[M]. 长沙: 中南大学出版社, 2006: 182-151.

TIAN Rong-zhang. Aluminum casting alloy [M]. Changsha: Central South University Press, 2006: 182-151.

[25] 张忠玉. 铝及铝合金工艺与设备[M]. 长沙: 中南大学出版社, 2006: 37-43.

ZHANG Zhong-yu. Technique and equipment of aluminum and aluminum alloy [M]. Changsha: Central South University Press, 2006: 37-43.

[26] 傅志华. 铝熔炼炉热工过程与节能[J]. 冶金能源, 1987, 5(6): 30-33.

Fu Zhi-hua. Thermal process and energy saving of aluminum melting furnace [J]. Energy for Metallurgical Industry, 1987, 5(6): 30-33.

[27] 周家荣. 铝合金熔铸生产技术问答[M]. 北京: 冶金工业出版社, 2008: 71-81.

ZHOU Jia-rong. Question-answer of melting and casting technology for aluminum alloy [M]. Beijing: Metallurgy Industry Press, 2008: 71-81.

[28] 陆 岩, 刘援朝. 美国提高铝熔炼炉、热处理炉加热效率降低能耗的方法[J]. 世界有色金属, 2006, 20(6): 16-19.

Lu Yan, LIU Yuan-chao. Measures for increase of heating efficiency and decrease of energy consumption of aluminum smelting furnaces and heat-treating furnaces in the USA [J]. World Nonferrous Metals, 2006, 20(6): 16-19.

[29] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2005: 395-401.

WANG Zhu-tang, TIAN Rong-zhang. Handbook on aluminum alloy [M]. Changsha: Central South University Press, 2005: 395-401.

(编辑 何学锋)

基金项目:国家高新技术研究发展计划资助项目(2010AA065201);中南大学博士生创新基金资助项目(2009bsxt022)

收稿日期:2011-03-25;修订日期:2011-08-15

通信作者:闫红杰,教授,博士;电话:0731-88830897;E-mail: s-rfy@mail.csu.edu.cn