高压扭转工艺制备的W-25Re合金的微观组织和硬度

来源期刊:中国有色金属学报(英文版)2017年第12期

论文作者:钱陈豪 贺子阳 梁辰 吉卫喜

文章页码:2622 - 2629

关键词:高压扭转;W-25Re合金;显微组织;Hall-Patch公式;显微硬度演变

Key words:high-pressure torsion (HPT); W-25Re alloy; microstructure; Hall-Patch relationship; microhardness evolution

摘 要:研究W-25Re(质量分数,%)合金在7.7 GPa下经历不同温度10圈高压扭转变形(HPT)的微观组织和显微硬度。结果表明,在室温下经历10圈HPT变形的试样平均晶粒尺寸达到了极小值(约0.209 μm);且在室温和 573 K温度下经历10圈HPT变形的试样均获得极高的平均硬度(约HV 1200)。通过观察试样的微观结构,并结合Hall-Patch公式进行分析,发现晶粒细化和晶界强化是HPT形变W-25Re合金硬化的主要因素,并推断出烧结态W-25Re试样在HPT过程中存在脆性相析出。

Abstract: The evolution of microstructure and microhardness was studied in a commercial tungsten-25% rhenium (mass fraction) (W-25Re) alloy processed by the high pressure torsion (HPT) procedure under a pressure of 7.7 GPa up to 10 revolutions at different temperatures. The results show that the samples processed by 10 revolutions at room temperature could have the smallest grain size at around 0.209 μm. High saturation hardness (HV ~1200) could be achieved after the rapid strengthening stage for samples processed by 10 revolutions both at room temperature and at 573 K. Microstructural observation and analysis from Hall-Patch relationship could reveal that grain refinement and grain boundaries strengthening are the main factors of hardening mechanism in W-25Re alloy. It is also demonstrated that sintered W-25Re sample may have brittle phase separation phenomenon after HPT processing.

Trans. Nonferrous Met. Soc. China 27(2017) 2622-2629

Chen-hao QIAN1,2, Zi-yang HE3, Cheng LIANG4, Wei-xi JI1,2

1. Department of Mechanical Engineering, Jiangnan University, Wuxi 214122, China;

2. Jiangsu Key Laboratory of Advanced Food Manufacturing Equipment and Technology, Jiangnan University, Wuxi 214122, China;

3. Industrial and Manufacturing System Engineering Department, Iowa State University, Ames, Iowa 50011, United States;

4. School of Engineering, University of Liverpool, Brownlow Hill, Liverpool L69 3GH, United Kingdom

Received 20 September 2016; accepted 5 April 2017

Abstract: The evolution of microstructure and microhardness was studied in a commercial tungsten-25% rhenium (mass fraction) (W-25Re) alloy processed by the high pressure torsion (HPT) procedure under a pressure of 7.7 GPa up to 10 revolutions at different temperatures. The results show that the samples processed by 10 revolutions at room temperature could have the smallest grain size at around 0.209 μm. High saturation hardness (HV ~1200) could be achieved after the rapid strengthening stage for samples processed by 10 revolutions both at room temperature and at 573 K. Microstructural observation and analysis from Hall-Patch relationship could reveal that grain refinement and grain boundaries strengthening are the main factors of hardening mechanism in W-25Re alloy. It is also demonstrated that sintered W-25Re sample may have brittle phase separation phenomenon after HPT processing.

Key words: high-pressure torsion (HPT); W-25Re alloy; microstructure; Hall-Patch relationship; microhardness evolution

1 Introduction

Tungsten-25% rhenium (mass fraction) (W-25Re) alloy has been usually manufactured into wire for the thermocouple market. Recently, novel processing techniques for tungsten-rhenium are proposed for high-temperature structural components in many fields, especially in nuclear industry [1]. The use of tungsten and tungsten alloys for the helium-cooled diverter has been discussed and investigated for the first wall in reactor such as International Thermonuclear Experimental Reactor (ITER) [2-4]. However, tungsten alloy is known to exhibit serious embrittlement in several conditions, including room-temperature brittleness, irradiation-induced brittleness and recrystallization brittleness [5]. It has become a major driving force in developing ultrafine-grained (UFG) and nanocrystalline (NC) materials to solve aforementioned problems. In practice, high pressure torsion (HPT) is a method of severe plastic deformation (SPD) to produce bulk nanostructured materials with grain sizes sometimes below 100 nm [6] and the highest fraction of high-angle grain boundaries [7].

During HPT processing, a thin disk is placed horizontally between two massive anvils. It is subjected to a high pressure and then strain is applied through rotating one of the anvils. In order to compare the shear strain in HPT with linear strain in other SPD methods, the equivalent von Mises strain, εeq, is expressed for HPT as [8]

(1)

(1)

where N is the number of revolutions, r is the distance from the center of the disk and t is the sample thickness. The applied requirement for this equation is assuming strict confinement of the disk, no slippage between the W-25Re disk and the anvil, so there is no thickness reduction during the HPT processing. It is followed from Eq. (1) that the strain varies across the disk and reaches zero at the disk center where r=0.

Only limited reports are currently available with respect to the severe plastic deformation effects on the microstructure and mechanical properties of tungsten alloys. FALESCHINI et al [9] have studied three different tungsten alloys (pure W, a lanthanum-oxide dispersion strengthened W-alloy and a potassium doped tungsten alloy) processed by HPT. The ultrafine-grained microstructure with an average diameter of about 300 nm was shown, which is able to decrease the brittleness at room temperature significantly. WEI et al [10,11] have reported that HPT processed nanocrystalline W has high mechanical strength as well as that of some strong ceramics and its quasi-static and dynamic failure is not completely brittle. It has also revealed that the grain boundaries in the nanocrystalline W are mostly of large-angle type due to its high-energy nature. SABIROV and PIPPAN [12] have also reported that HPT can be successfully used to fabricate a W–25%Cu nanocomposite, and it is the first time to elevate HPT pressure up to 8 GPa. Usually, these experiments are based on pure tungsten or tungsten matrix composites under <6 GPa pressure and 5 HPT revolutions, but the high pressure (≥8 GPa) effect on hardness saturation is still uninvestigated [13-15]. Additionally, the raw materials in most studies are usually processed by mechanical alloying. Few works consider HPT as a tool to post-treat sintered heavy alloy components [16,17]. Accordingly, this work aims to reveal HPT effect on mechanical properties of sintered W-25Re alloy plate, which was processed at the pressure of 7.7 GPa, different temperatures and up to 10 HPT revolutions.

2 Experimental

2.1 Materials and processing

The raw tungsten-25%rhenium (mass fraction) alloy of 99.5% in purity was supplied by Zhonglai Ltd. (Chengdu, China). The as-received W-25Re alloy was shaped as plates in a sintered state with a sectional dimension of 25 mm × 25 mm and a thickness of around 1.5 mm. For HPT processing, the sintered samples were cut into disks with a diameter of 9.8 mm, and then these discs were mechanically polished using 800-2000 grit SiC papers to acquire a final thickness of 1.0 mm. The disks were HPT processed through 2.5 and 10 revolutions (thereafter referred to as 2.5R and 10R) under a quasi-constrained condition [18] with an imposed pressure of 7.7 GPa and a rotational speed for the lower anvil of 1 r/min at 573 K. To investigate temperature effect on microhardness evolution, another sample of 10R was HPT-processed at room temperature. The samples were quenched into water immediately after HPT processing, and there is no post heat treatment for all processed samples.

2.2 Materials characterization

After HPT, disks with a diameter of 3 mm for microstructural characterization were cut out near the edge of the HPT samples. For grain size and structure analysis, the HPT-processed disks were ground with abrasive papers for producing a mirror-like surface and then electrochemically polished by using methyl alcohol as solvent and concentrated sulphuric acid as solute with a volume ratio of 7:1 under the voltage of 16 V at room temperature. Electron back-scattering diffraction (EBSD) analysis was carried out by using a Carl Zeiss Auriga crossbeam 45-66 focused ion beam (FIB) scanning electron microscope (SEM) with the operating voltage of 12 kV and the step size of 20 nm at Nanjing University of Science and Technology (NJUST) (China). High- angle grain boundaries (HAGBs) were defined as boundaries having misorientation of more than 15° between adjacent grains and low-angle grain boundaries (LAGBs) having misorientation of 2°-15°. For transmission electron microscopy (TEM) examination, a sample processed by 10-revolution HPT at room temperature was firstly mechanically thinned down to 80 μm, cut into a disc with the diameter of 3 mm, and then twin-jet electropolished. An FEI TECNAI T20 microscope at NJUST (China) was employed to characterize microstructures at 200 kV. Differential scanning calorimetry (DSC) analysis was performed by using NETZSCH STA 449F3 with a heating rate of 10 °C/min during the temperature range of 298-1673 K in order to compare the strain energy storage among different samples. Vickers microhardness (HV) along three radial directions at every 0.6125 mm away from the disk center was measured by using a FM-700 Vickers microhardness tester under an applied load of 2.5 N for 15 s.

3 Experimental results

3.1 EBSD investigations of HPT-induced micro- structural evolution

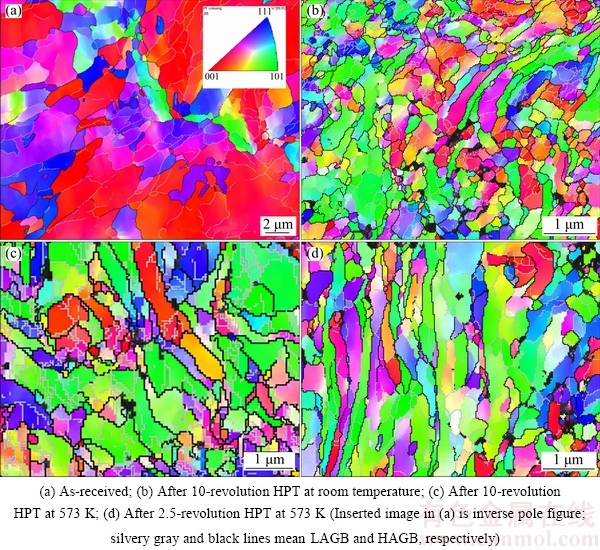

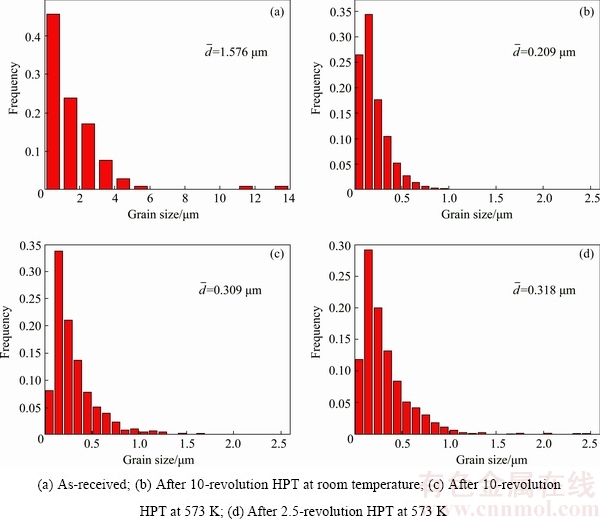

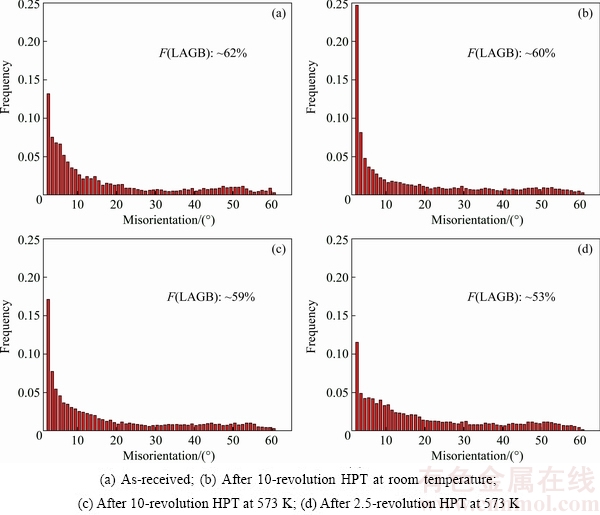

The as-received W-25Re alloy has a sintering microstructure (Fig. 1(a)) with an average grain size of about 1.576 μm (Fig. 2(a)) and 62% LAGBs (Fig. 3(a)). The grain sizes distribute in a very large range from about 100 nm to about 13 μm. Some textured microstructures are observed in Fig. 1(a), which were produced during sintering process. After HPT for 10 revolutions, ultrafine grain microstructures are obtained. As exhibited in the orientation map in Fig. 1(b), some grains were nearly equiaxed ultrafine, interweaved with a few elongated grains. A statistical analysis was carried out for more than 2000 grains. The results shown in Fig. 2(b) indicated that more than 90% grains are smaller than 0.5 μm and the average grain size is about 0.209 μm. Although the orientation distribution in Fig. 3(b) shows that 60% grain boundaries are LAGBs, and the texture intensity is very weak (Fig. 1(b)), even lower than that of the as-received sample (Fig. 1(a)).

Fig. 1 Orientation maps of W-25Re alloy

Fig. 2 Grain size distributions of samples

Fig. 3 Misorientation angle distributions of grains in samples

For investigating the influence of the processing temperature on the microstructure, a sample was HPT processed for 10 revolutions at 573 K. The grain orientation map of this sample is displayed in Fig. 1(c), in which grains were elongated along the direction of rotation, interweaved with some nearly equiaxed ultrafine grains. Many LAGBs and small sub-grains can be observed in the elongated grains. As shown in Fig. 2(c), the statistics suggest that there are 81% grains smaller than 0.5 μm and the average size of grains is about 0.309 μm, which is about 0.1 μm larger than the average grain size of the HPT-processed sample for 10 revolutions at room temperature. It is indicated that improving the HPT processing temperature will result in grains coarsening slightly. Figure 3(c) shows the misorientation distribution of grains in this sample and the relative frequency is nearly the same as that in samples of 10 HPT-processed at room temperature.

For studying the effect of the revolution on the microstructure of samples, 10 revolutions and 2.5 revolutions at 573 K were selected. Their grain orientation maps are respectively shown in Figs. 1(c) and (d), in which the grains have the similar morphology, size and size distribution (Figs. 2(c) and (d)). Compared with the 10R sample shown in Fig. 3(c), the fraction of LAGB in the 2.5R sample was slightly reduced but was still as high as ~53%, as illustrated in Fig. 3(d).

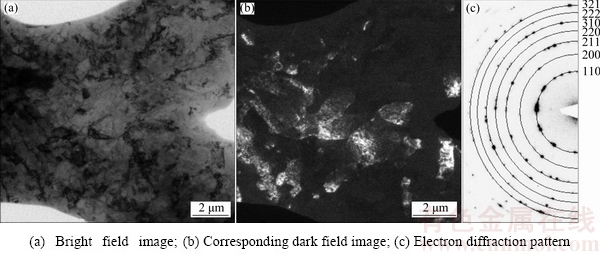

3.2 TEM investigation on microstructure of 10R sample at room temperature

Figure 4 shows the bright field (BF) TEM image and the corresponding dark field (DF) image of the sample processed by HPT for 10 revolutions at room temperature. As marked by arrows in Fig. 4(a), various dislocation configurations including dislocation cells and elongated subgrain boundaries accord with the characteristics of the inhomogeneous microstructures. In BF image, the profile of grains is not clear because there are serious distortions in grains. Many grains are in the stage of recovery period or at the beginning of recrystallization. The deformation energy influx by HPT for 10R at room temperature is not high enough for recovering or recrystallizing during the process, thus the unclear grain BF image is shown in transition period. The centered DF image was obtained for characterizing grains more clearly, as illustrated in Fig. 4(b). Much smaller grains can be observed. In addition, the elongated grains are actually subdivided into several nanograins with small misorientation. Corresponding selected area diffraction (SAED) patterns, as shown in Fig. 4(c), confirm that only W-structure exists in these areas, which implies that Re atoms completely dissolve into W-matrix.

Fig. 4 Typical TEM images of W-25Re alloy after 10-revolution HPT at room temperature

3.3 Mechanical properties

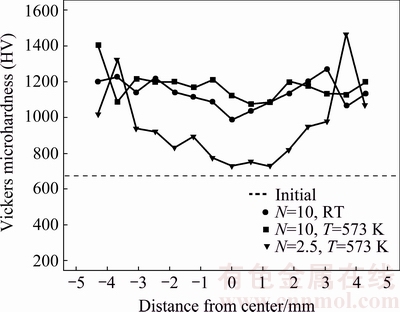

Comprehensive microhardness measurements were conducted on all samples. The microhardness distribution across the disk diameters is shown in Fig. 5 of the samples processed by HPT for 2.5 and 10 revolutions. The lower dashed line at HV 676 represents the as-received microhardness before processing. The investigation shows that the microhardness increases significantly as a function of the distance between the indentation and the center. As shown in Fig. 5 that, there is a clear linearity between hardness value and the distance. It should be attributed to the linear dependence of applied strain, as shown in Eq. (1). The blue curve represent for the sample processed by HPT for 2.5 revolutions. It should be noted that the area close to the center of the disk shows low hardness value (HV 750), which is very close to the untreated sample. On the other hand, for sample processed by HPT for 2.5 revolutions, the area near the edge of disk shows relatively high hardness value at around HV 1300. Nevertheless, for samples processed for 10 revolutions, the central region is significantly strengthened and almost reaches a homogeneous level with the hardness of HV 1200 throughout the whole disk.

Fig. 5 Vickers microhardness across diameter for samples processed by HPT and initial samples

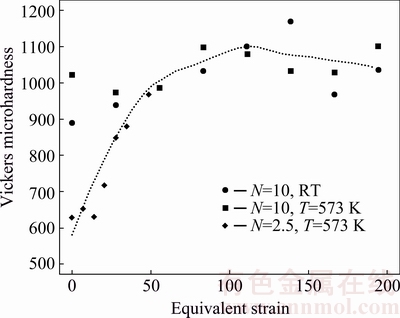

In order to obtain a more concise representation of hardness distribution, the plot of individual measurement point hardness versus equivalent strain is shown in Fig. 6. This type of plot is used widely in SPD processed samples, because sometimes it is hard to perform tensile and compression tests in small scale samples without customized holder [19]. The plot was first introduced by investigating SPD processed austenitic steel [20]. It could directly show the hardness evolution and transition to the final saturation stage. The fitted curve in dash line could indicate that strain hardening process occurs without recovery at a ultimate saturation state. The first rapid hardening stage is up to the strain level of ~50, and then there is a moderate strain hardening process followed until saturation stage above strain level of ~100, which is also consistent with microstructural observation in Fig. 1. The saturation condition for samples processed by HPT for 10 revolutions at 573 K is around HV 1200. However, when the strain is more than 150, the decline of microhardness could be seen. Therefore, it is reasonable to anticipate that when strain level is more than 150 (especially at high temperature), the brittle second-phase small particles (integrated in initial powder metallurgy process) are redistributed into grain boundaries of nanostructured W-Re matrix, like similar reports for other different alloy systems [21,22].

Fig. 6 Vickers microhardness against equivalent strain for samples processed by HPT and initial samples

4 Discussion

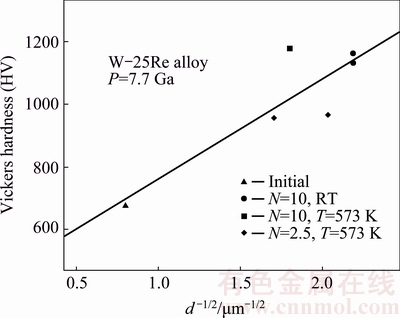

The results of this work support HPT as an effective tool for refining microstructure and strengthening of the tungsten-alloy, based on the reduction of the grain size from 1.6 μm to 0.209 μm. Although the early saturation stage could block further treatment to get higher fractions of HAGBs, HPT is still more preferable to treat heavy alloy than other SPD methods, since higher pressure could be easily achieved [23]. Since there is a pronounced microstructural refinement in as-received W-25Re alloy, it is important to explore the relationship between grain size and mechanical properties, which is written in the form of the Hall–Patch equation [24]. Here, hardness version is used instead of flow stress version:

H=H0+KHd-1/2 (2)

where H is the hardness, H0 and KH are material constants related to tungsten alloy itself, and d is the average grain size.

Hall-Patch relationship has been confirmed by many SPD processed materials [25-27]. It is interesting to note that for some samples with grain size below 25 nm [28], the inverse Hall-Patch relationship is more favorable than the traditional one. In this work, the smallest average grain size that could be achieved is around 200 nm, so Fig. 7 is plotted to check the applicability of Hall-Patch relationship. The sintered as-received plate acts as coarse-grained sample. From the result, a clear liner correlation between points from as-received coarse sample to samples 10-revolution HPTed at room temperature and 2.5-revolution HPTed at 573 K could be seen from Fig. 7. The sample processed by HPT for 10 revolutions at 573 K is above the line, and this could be explained with the fact that high temperature could generate more storage energy to postpone saturation stage. The other point below line is due to inhomogeneity of hardness in less revolutions of HPT treatment. From the slope of the experimental line in Fig. 7, the value of KH is estimated to be 442.8.

Fig. 7 Hall-Petch relationship for initial sample and samples processed by HPT

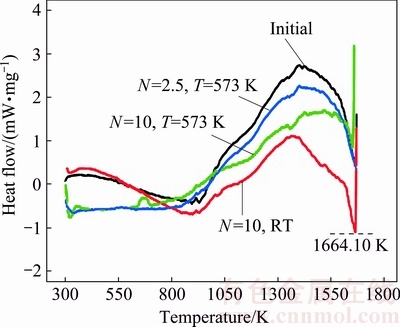

Due to the sintered state of the initial material, it could be noted in Fig. 3(a) that less than 5% HAGBs exist. For HPT-processed samples, as shown in Figs. 3(b-d), the unique shift from HAGBs to LAGBs could be found, especially in Fig. 3(d). Unlike aluminum alloy reported previously [29], as a kind of hard-to- deform material, tungsten alloy will need more energy to activate slip system. It is well established that slip transfer through LAGBs is much easier by comparison with HAGBs and therefore they represent weaker barriers for the movement of lattice dislocations [30]. This phenomenon may be due to the increasing density of grain boundaries, even the average misorientation of grain boundaries (GBs) changes slightly as shown in this work. Admittedly, we could not deny that Hall-Patch relationship is based on pile-up of dislocations against GBs, geometrically necessary dislocations (GNDs) to accommodate the plastic compatibility during the plastic deformation of poly-crystals, GBs as sources and sinks for dislocations, and dislocation avalanche behavior. All these models can lead to the Hall-Patch formula and, as such, they are theoretically equivalent. It is hard to figure out which is the most important factor to cause this unique misorientation stable phenomenon, but by using DSC measurements results (Fig. 8), we could realize that LAGBs are too small to impede the potential dislocation slip.

Fig. 8 DSC curves of W-25Re samples with and without HPT processing

The exothermic peaks are visible for all tested samples, which are commonly representations of energy storage during SPD. The appearance of an exothermic peak in the non-isothermal DSC measurements can be related to recovery and recrystallization phenomena after cold forming [31]. The sample processed by HPT for 10 revolutions at room temperature shows the lowest storage energy, in other words, the highest thermal stability among all samples. It is important to notice that the as-received sample in this work is not powder-based tungsten alloy. It is the sintered plate for industrial application, so there is high residual stress input during the previous manufacturing process. HPT processing promotes the microstructural homogeneity by increasing the number of revolutions. Additionally, as shown in Fig. 6, the sample processed by HPT for 2.5 revolutions has not reached the saturation stage, but DSC curve shows that the sample processed by HPT for 2.5 revolutions has obtained more strain storage energy than the sample processed by HPT for 10 revolutions. Based on the traditional theory for polycrystalline materials processed by plastic deformation, more strain-stored energy indicates larger dislocation density in the sample. It is the driven force to recover and recrystallize and may result in the exothermic peak of DSC curve shifting to lower temperature direction [32]. The dislocation density may be estimated using following equation [31]:

(3)

(3)

where G is the shear modules and b is the value of the Burgers vector.

Therefore, it is reasonably assumed that the samples processed by HPT for 10 revolutions have lower dislocation density than the sample processed by HPT for 2.5 revolutions, which is consistent with previous LAGBs misorientation analysis. LAGBs could not impede the slip system activation with increasing the strain input due to the relatively small crystallographic misalignment across the grain boundaries [30]. As a result, the homogeneity will be increased, and the dislocation density will be declined with increasing the strain.

5 Conclusions

1) The saturation hardness achieved at high strains in HPT processing is dependent upon the microstructural evolution. Rapid strain hardening and following saturation stage are clearly shown.

2) Hall-Patch relationship shows clear correlation among samples processed by HPT for 2.5 revolutions, 10 revolutions and initial coarse sample. The grain size is directly related to the strength. The grain boundaries play a minor role in strengthening, which is confirmed by EBSD and microhardness analysis, and is further validated by DSC measurements.

3) High pressure and increasing revolution of HPT may induce solid solution phase to be separated during processing of W-25Re alloy, which needs further investigation.

Acknowledgements

Authors want to acknowledge great support from Ms. Andrea BACHMAIER and Prof. Reinhard PIPPAN from Erich Schmid Institute of Materials Science for helping us to perform HPT experiments.

References

[1] LEONHARDT T. Properties of tungsten-rhenium and tungsten- rhenium with hafnium carbide [J]. JOM, 2009, 61(7): 68-71.

[2] ROMANELLI F,  J, KAMENDJE R, WATKINS M L, BREZINSEK S, LIANG Y, LITAUDON X, LOARER T, MOREAU D, MAZON D, SAIBENE G, SARTORI F, de VRIES P C. Recent contribution of JET to the ITER physics [J]. Fusion Engineering and Design, 2009, 84(2-6): 150-160.

J, KAMENDJE R, WATKINS M L, BREZINSEK S, LIANG Y, LITAUDON X, LOARER T, MOREAU D, MAZON D, SAIBENE G, SARTORI F, de VRIES P C. Recent contribution of JET to the ITER physics [J]. Fusion Engineering and Design, 2009, 84(2-6): 150-160.

[3] IGITKHANOV Y, JANESCHITZ G. Attenuation of secondary electron emission from divertor plates due to magnetic field inclination [J]. Journal of Nuclear Materials,2001, 290: 99-103.

[4] HIRAI T, PINTSUK G, LINKE J, BATILLIOT M. Cracking failure study of ITER-reference tungsten grade under single pulse thermal shock loads at elevated temperatures [J].Journal of Nuclear Materials,2009, 390(1): 751-754.

[5] LIU R, XIE Z M, HAO T, ZHOU Y, WANG X P, FANG Q F, LIU C S. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized yttria dispersion strengthening [J]. Journal of Nuclear Materials, 2014, 451(1-3): 35-39.

[6] ZHILYAEV A P, LANGDON T G. Using high-pressure torsion for metal processing: Fundamentals and applications [J]. Progress in Materials Science, 2008, 53(6): 893-979.

[7] JITTRAPORN W, KAWASAKI M, LANGDON T G. A comparison of microstructures and mechanical properties in a Cu-Zr alloy processed using different SPD techniques [J]. Journal of Materials Science, 2012, 48(13): 4653-4660.

[8] VALIEV R Z, IVANISENKO Y V, RAUCH E F, BAUDELET B. Structure and deformation behaviour of Armco iron subjected to severe plastic deformation [J]. Acta Materialia, 1996, 44(12): 4705-4712.

[9] FALESCHINI M, KREUZER H, KIENER D PIPPAN R. Fracture toughness investigations of tungsten alloys and SPD tungsten alloys [J]. Journal of Nuclear Materials, 2007, 367-370(26): 800-805.

[10] WEI Q, JIAO T, RAMESH K, MA E, KECSKES L, MAGNESS L, DOWDING R, KAZYKHANOV V, VALIEV R. Mechanical behavior and dynamic failure of high-strength ultrafine grained tungsten under uniaxial compression [J]. Acta Materialia, 2006, 54(1): 77-87.

[11] WEI Q, ZHANG H, SCHUSTER B, RAMESH K, VALIEV R, KECSKES L, DOWDING R, MAGNESS L, CHO K. Microstructure and mechanical properties of super-strong nanocrystalline tungsten processed by high-pressure torsion [J]. Acta Materialia, 2006, 54(15): 4079-4089.

[12] SABIROV I, PIPPAN R. Formation of a W-25%Cu nanocomposite during high pressure torsion [J]. Scripta Materialia, 2005, 52(12): 1293-298.

[13] ZHANG Y, GANEEV A, GAO X, SHARAFUTDINOV A V, WANG J T, ALEXANDROV I V. Influence of HPT deformation temperature on microstructures and thermal stability of ultrafine-grained tungsten [J]. Materials Science Forum, 2008, 584-586: 1000-1005.

[14] MAURIZIO F. A short summary of present knowledge and some experimental observations on the ductility of sub-microcrystalline aluminum alloys [J]. Materials Science Forum, 2009, 633-634: 179-196.

[15] POPOV V V, GRABOVETSKAYA G P, SERGEEV A V, MISHIN I P, TIMOFEEV A N, KOVALENKO E V. Structure and properties of grain boundaries in sub-microcrystalline molybdenum prepared by high-pressure torsion [J]. The Physics of Metals and Metallography, 2010, 109(5): 556-562.

[16] WURSTER S, GLUDOVATZ B, HOFFMANN A, PIPPAN R. Fracture behavior of tungsten-vanadium and tungsten-tantalum alloys and composites [J]. Journal of Nuclear Materials, 2011, 413(3): 166-176.

[17] LEVIN Z S, HARTWIG K T. Hardness and microstructure of tungsten heavy alloy subjected to severe plastic deformation and post-processing heat treatment [J]. Materials Science and Engineering A, 2015, 635: 94-101.

[18] FIGUEIREDO R B, CETLIN P R, LANGDON T G. Using finite element modeling to examine the flow processes in quasi-constrained high-pressure torsion [J]. Materials Science and Engineering A, 2011, 528(28): 8198-8204.

[19] SABBAGHIANRAD S, LANGDON T G. An evaluation of the saturation hardness in an ultrafine-grained aluminum 7075 alloy processed using different techniques [J]. Journal of Materials Science, 2015, 50(12): 4357-4365.

[20] VORHAUER A, PIPPAN R. On the homogeneity of deformation by high pressure torsion [J]. Scripta Materialia, 2004, 51(9): 921-925.

[21] BACHMAIER A, PFAFF M, STOLPE M, ABOULFADL H, MOTZ C. Phase separation of a supersaturated nanocrystalline Cu-Co alloy and its influence on thermal stability [J]. Acta Materialia, 2015, 96: 269-283.

[22] WANG Y B, LIAO X Z, ZHAO Y H, COOLEY J C, HORITA Z, ZHU Y T. Elemental separation in nanocrystalline Cu-Al alloys [J]. Applied Physics Letters, 2013, 102(23): 231912(1-5).

[23] VORHAUER A, PIPPAN R. Microstructure and thermal stability of tungsten based materials processed by means of severe plastic deformation [J]. Materials Science Forum, 2003: 426-432: 2747-2752.

[24] SABIROV I, MURASHKIN M Y, VALIEV R Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development [J]. Materials Science and Engineering A, 2013, 560: 1-24.

[25] LU K. Nanocrystalline metals crystallized from amorphous solids: Nanocrystallization, structure, and properties [J]. Materials Science and Engineering R-Reports, 1996, 16(4): 161-221.

[26] FURUKAWA M, HORITA Z, NEMOTO M, VALIEV R, LANGDON T. Factors influencing the flow and hardness of materials with ultrafine grain sizes [J]. Philosophical Magazine A, 1998, 78(1): 203-215.

[27] GLEITER H. Materials with ultrafine microstructures: retrospectives and perspectives [J]. Nanostructured Materials, 1992, 1(1): 1-19.

[28] MEYERS M A, MISHRA A, BENSON D J. Mechanical properties of nanocrystalline materials [J]. Progress in Materials Science, 2006, 51(4): 427-556.

[29] BAZARNIK P, HUANG Y, LEWANDOWSKA M, LANGDON T G. Structural impact on the Hall-Petch relationship in an Al-5Mg alloy processed by high-pressure torsion [J]. Materials Science and Engineering A, 2015, 626: 9-15.

[30] HANSEN N. Hall-Petch relation and boundary strengthening [J]. Scripta Materialia, 2004, 51(8): 801-806.

[31] SHAHMIR H, NILI-AHMADABADI M, MANSOURI-ARANI M, KHAJEZADE A, LANGDON T G. Evaluating the room temperature ECAP processing of a NiTi alloy via simulation and experiments [J]. Advanced Engineering Materials, 2014, 17(4): 532-538.

[32] LI Y S, TAO N R, LU K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures [J]. Acta Materialia, 2008, 56(2): 230-241.

钱陈豪1,2,贺子阳3,梁 辰4,吉卫喜1,2

1. 江南大学 机械工程学院,无锡 214122;

2. 江南大学 江苏省食品先进制造装备技术重点实验室,无锡 214122;

3. Industrial and Manufacturing System Engineering Department, Iowa State University, Ames, Iowa 50011, United States;

4. School of Engineering, University of Liverpool, Brownlow Hill, Liverpool L69 3GH, United Kingdom

摘 要:研究W-25Re(质量分数,%)合金在7.7 GPa下经历不同温度10圈高压扭转变形(HPT)的微观组织和显微硬度。结果表明,在室温下经历10圈HPT变形的试样平均晶粒尺寸达到了极小值(约0.209 μm);且在室温和573 K温度下经历10圈HPT变形的试样均获得极高的平均硬度(约HV 1200)。通过观察试样的微观结构,并结合Hall-Patch公式进行分析,发现晶粒细化和晶界强化是HPT形变W-25Re合金硬化的主要因素,并推断出烧结态W-25Re试样在HPT过程中存在脆性相析出。

关键词:高压扭转;W-25Re合金;显微组织;Hall-Patch公式;显微硬度演变

(Edited by Bing YANG)

Foundation item: Project (11402264) supported by the National Natural Science Foundation of China; Project (BK20160182) supported by the Natural Science Foundation of Jiangsu Province, China; Projects (JUSRP116027, JUSRP51732B) supported by the Fundamental Research Funds from Jiangnan University, China

Corresponding author: Wei-xi JI; Tel: +86-13861459713; E-mail: qianch@jiangnan.edu.cn; jiweixi@jiangnan.edu.cn

DOI: 10.1016/S1003-6326(17)60290-5