纤维素基湿度控制材料的制备与表征

李鑫1, 2,冯伟洪1,卢其明1,夏启斌2

(1. 华南农业大学 理学院,广东 广州,510642;

2. 华南理工大学 化学化工学院,广东省绿色化学产品技术重点实验室,广东 广州,510640)

摘 要:以甲基纤维素作为接枝共聚的原料合成纤维素基湿度控制材料,并加入CaCl2和异丙基丙烯酰胺改善其吸放湿性能;通过间歇式吸附/脱附进行吸、放湿动力学实验与恒温脱附实验,采用热重分析(TG-DTA)和红外光谱(FTIR)表征改性复合材料的热稳定性及其结构。研究结果表明:该类材料具有吸湿量较大、易再生和稳定性高的特性,CaCl2改性材料在相对湿度为100%的最大湿容量为1.45 g/g,吸湿平衡时间约160 h;而相对湿度为90%达到湿平衡的样品放湿需约60 h,在80 ℃恒温烘箱中脱附40%仅需10 min。加入异丙基丙烯酰胺后材料的放湿速率明显增大,且所有材料在300 ℃以下具有较强的热稳定性。

关键词:甲基纤维素;温敏性;异位脱附;吸放湿性能

中图分类号:TQ326.4 文献标志码:A 文章编号:1672-7207(2010)04-1327-07

Synthesis and characterization of

cellulose humidity control materials

LI Xin1, 2, FENG Wei-hong1, LU Qi-ming1, XIA Qi-bin2

(1. The College of Science, South China Agriculture University, Guangzhou 510642, China;

2. The Guangdong Provincial Laboratory of Green Chemical Technology, College of Chemical Engineering and Energy, South China University of Technology, Guangzhou 510640, China)

Abstract: Cellulose humidity control materials were synthesised by methyl cellulose as a graft copolymerization of raw materials, and CaCl2 and NIPAm were added into the materials to improve the moisture absorption and desorption performance, and then kinetic experiments of moisture absorption/release on the humidity-controlling composite materials were carried out with the help of batch adsorption/desorption experiment. The thermal decomposition temperature and structure of humidity-controlling composite material were estimated separately by means of TG-DTA and FTIR, and the effects of the moisture absorption/release of humidity-controlling composite material were discussed. The results show that the product has higher hygroscopic capability, easier regeneration and better heat stability. The time of the product modifies by CaCl2 to reach its humidity-controlling balance is about 160 h, the hygroscopic capacity of the product is 1.45 g/g. At the same time, it’s about 60 h to release humidity from the product at 90%, and it only takes 10 min to desorbed 40% of adsorbed water in the 80 ℃ oven. What’s more, the releasing humidity rate of the product modified by NINPAm increases greatly, and the thermal decomposition temperature of the product is about 300 ℃.

Key words: methyl cellulose; thermosensitivity; desorption; moisture absorption and release properties

高吸水树脂是近年来国内外发展起来的一种新型功能高分子材料,按其合成原料划分,可分为淀粉类、纤维素类和合成聚合物类3类。这3类高吸水材料不仅可以高效吸收自身质量几倍乃至几千倍的液态水,而且对水蒸气也有一定的吸湿作用,其吸湿功能已引起研究者高度关注[1-2]。但是一般的高分子吸湿材料都存在吸放湿速度慢、吸放湿量小、脱湿能耗大[3]等缺点,如何提高高分子材料吸放湿的响应性是目前研究的热点。其中,纤维素类高吸水树脂原料由于来源丰富、价格低廉,同时具有良好的水溶性,可生物降解、无毒性、较强的抗盐性、可再生性、价格便宜、易得和使用寿命长等优点[4-6],具有广阔的市场前 景[7-8]。因此,本文作者尝试利用温敏性纤维素醚材料合成异位湿度控制材料,借助温敏性材料的低临界溶解温度(Lower critical solution temperature,LCST)[9]的特性(即当温度高于LCST时,发生体积相变,把水挤出体系)对该湿度控制进行异位脱附,可以大大降低放湿脱附能耗,同时加入无机盐材料进行复合,改善其吸放湿性能。

因此,本实验以甲基纤维素(methyl cellulose, MC)、丙烯酰胺(Acrylic amide, AM)、异丙基丙烯酰胺(N-Isopropyl acrylamide, NIPAM)及无水氯化钙(CaCl2)为原料,采用水溶液聚合法分别合成出有机高分子和有机高分子/无机盐复合材料。通过测定它们吸、放湿速率与脱附速率,并比较其吸湿性能和特点,为进一步研究开发新型吸湿材料提供参考。

1 实验部分

1.1 实验药品和仪器

主要试剂和材料:丙烯酸(AR)、丙烯酰胺(AR)及无水氯化钙(AR),均为天津市科密欧化学试剂有限公司生产;甲基纤维素(AR),国药集团化学试剂有限公司生产;异丙基丙烯酰胺(AR),日本Kohjin公司生产。

实验仪器:红外光谱仪(AVATAR 360 FT-IR,美国Nicolet公司制造);差热热重联用仪(DTG-60,日本Shimadzu公司制造);电子分析天平(AB204,梅特勒托利多仪器有限公司制造)。

1.2 实验原理

(1) 链引发:

→

→

(2) 甲基纤维素接枝共聚见图1。

(3) 加入CaCl2进行多元复合共混。

图1 甲基纤维素接枝共聚反应式

Fig.1 Reacting pattern of methyl cellulose graft copolymerization

1.3 实验方法

1.3.1 复合调湿材料的制备

将质量比为5?5的甲基纤维素与丙烯酰胺单体(若用异丙基丙烯酰胺单体,则甲基纤维素与异丙基丙烯酰胺单体的质量比为9?1)和N,N-亚甲基双丙烯酰胺(质量分数为0.5%)用一定量的去离子水溶于三口瓶中,在通入N2保护下机械搅拌15 min,并加入质量分数为1%的过硫酸铵,继续冲入氮气搅拌15 min,混合均匀后于70 ℃中水浴加热,反应数小时后得到水凝胶,静置过夜,再在80 ℃烘箱中烘干至恒重,粉碎、过35.5 μm筛后得白色粉状产品。以甲基丙烯酸甲酯和异丙基丙烯酰胺为单体所得的2种样品分别记为PAM-MC和PNIPAM-MC。若以丙烯酰胺为单体,在加入质量分数为1%的过硫酸铵的同时加入适量CaCl2溶液,所得最终样品记为PAM-MC/CaCl2[10]。

1.3.2 吸湿性能的测定

称取0.20 g样品放入预先已称重的称量瓶中,并分别放入恒温(25 ℃)恒湿的双蒸水及饱和金属盐溶液的密封环境中静置,每种溶液对应一个具体的相对湿度[11],让其中的凝胶粉体在恒温恒湿环境中自然吸湿。检测开始时,每小时称量1次样品质量,6 h后每6 h称重1次,直至恒重,按下式计算吸湿率:

W =[(m1-m2-0.2)/0.2]×100%

式中:m1为在恒温恒湿环境中吸湿至湿平衡后的凝胶及称量瓶整体质量;m2为空称量瓶的质量;0.2为吸湿前的复合调湿材料质量。

1.3.3 放湿性能的测定

将处于饱和硝酸钾溶液(相对湿度为90%)的环境中达到湿平衡后的样品置于放有氯化锂的恒温(25 ℃)恒湿(相对湿度10%)封闭环境中静置。检测开始时,每小时称量1次样品质量,6 h后每6 h称1次,直至恒质量为止。

1.3.4 恒温脱附的测定

将处于双蒸水(相对湿度为100%)环境中达到湿平衡后的样品置于恒温烘箱中(80 ℃),每隔10 min称量样品质量一次,直至恒重。

1.3.5 热重检测

以Shimazu DTG-60型差热热重联用仪对样品进行检测,样品用量为2~4 mg,氮气气氛,升温速度为25 ℃/min,扫描范围为20~500 ℃。

1.3.6 红外光谱表征

用Nicolet AVATAR 360 FT-IR型红外光谱仪记录样品的红外光谱图,扫描100次,分辨率为2 cm-1。粉末状样品采用压片机制样法制备,采用FW-4A型压片机压片,压片压力为20 MPa。

2 结果与讨论

2.1 纤维素吸湿复合材料的吸湿等温曲线

图2所示为室温下纤维素吸湿复合材料的吸湿等温线。可见:在中低湿度下,二元高分子材料吸湿量较低,最低只有10%,因为高分子材料由甲基纤维素组成,具有一定的疏水性。而加入CaCl2的PAM-MC/CaCl2三元复合材料,吸湿率明显提高30%,这是由于CaCl2本身易吸湿潮解,CaCl2潮解时可以与H2O发生可逆化学反应,生成复杂的结晶水合物CaCl2·H2O,CaCl2·2H2O,CaCl2·4H2O 和CaCl2·6H2O,进一步潮解还可以形成饱和盐溶液,从而使复合材料可以容纳较多水分。因此,在中低湿度下,CaCl2改性的复合材料具有较大的湿容量[12]。在高湿环境下,二元复合材料最高吸湿率只有40%,吸湿量也不高,经CaCl2改性的三元复合材料吸湿率明显提高。

1—PNIPAM-MC; 2—PAM-MC; 3—PAM-MC/CaCl2

图2 室温下纤维素吸湿复合材料的吸湿等温曲线

Fig.2 Moisture absorption isotherm of moisture absorption materials at room temperature

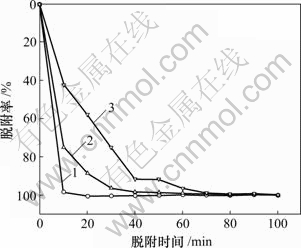

2.2 恒温脱附结果与分析

图3所示为双蒸水(相对湿度为100%)环境中达到湿平衡后的样品置于恒温烘箱中(80 ℃)脱附曲线。从图3可见:脱附速度较快,其中有3个样品在20 min左右便脱附60%以上,这与制备的材料具有温敏性有关。当甲基纤维素处于低温时,大分子为水分子包围而形成笼状结构,温度升高所施加的热量将会使水分子和MC之间的氢键断裂,笼状的超分子结构被破坏,水分子从氢键作用的束缚下释放出来成为自由水分子,而甲基纤维素大分子链上的疏水甲基基团则暴露出来,这就使得疏水结合成为可能。如果同一个分子链上的甲基发生疏水结合,则这种分子内的作用将使整个分子呈现卷绕状。然而,升温导致链段运动加剧,分子内的疏水作用不稳定,分子链由卷绕状态变成伸展状,此时,分子间的疏水作用开始占据主导;当温度逐渐升高时,越来越多的氢键发生断裂,从笼状结构中脱离出来的纤维素醚分子也越来越多,距离较近的大分子之间通过疏水作用聚集在一起而形成一种疏水聚集体,从而进行异位脱附[13]。比较2个二元温敏材料,可以看出PNIPAM-MC的脱附速率明显比PAM-MC的要快,10 min脱附95%以上,这是因为组成材料的NIPAm其低临界溶解温度(LCST)为32 ℃左右,而MC的LCST约80 ℃,所以,PNIPAm-MC的相变温度明显比PAM-MC的低,脱附速率较快。而PAM-MC/CaCl2的吸附量最大。从图2可以看出:在0~10 min,直线的脱附斜率明显比10~40 min的要大。这是由于PAM-MC/CaCl2在相变下,前期发生体积相变,进行异位脱附,把体系内部分水分子挤出,易于脱附。而后期因为复合材料有一定的亲水基团,在氢键作用下,剩余的水分子不容易脱附,需要在原位脱附,所以,脱附速率较慢。

1—PNIPAM-MC; 2—PAM-MC; 3—PAM-MC/CaCl2

图3 不同温敏性复合材料恒温脱附曲线

Fig.3 Desorption curve of different thermo-sensitivity composite materials at constant temperature

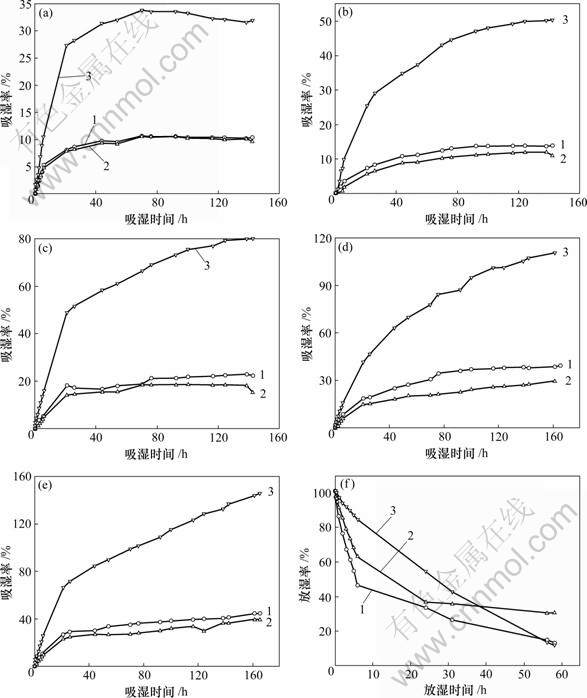

2.3 纤维素湿度控制材料的吸、放湿曲线

图4所示为不同相对湿度下温敏吸湿复合材料的吸附及解吸附动力学曲线。由图4(a)~(e)可见:加入CaCl2的PAM-MC/CaCl2的吸湿动力曲线的斜率较三元复合样品吸湿动力学曲线的要大,达到湿平衡的时间要短,各湿度下吸湿速率都得到进一步提升。在相对湿度为100%时,平衡吸湿量为145%,明显要比其他2类二元复合材料的平均吸湿率要高。这是由于甲基纤维素富含亲水性基团[14-15],具有大量吸水的潜力,在CaCl2的共同作用下,水分子在高分子中逐步扩散,颗粒表面结合的水分子逐渐增多,导致颗粒内外渗透压差增大,促使水分子的扩散逐步进行,所以,有较大吸湿容量。从图4(f)所示的解吸附动力学曲线可以看出:3个样品的放湿速率都较快,在24 h左右,放湿率达到50%以上。在二元温敏材料中,以PNIPAM-MC放湿速度最快,这与该材料体系中的疏水基团较多有关,放湿较容易;而PAM-MC/CaCl2的吸湿量最大,但放湿速率也较快,24 h时放湿率为43%,是因为CaCl2的结晶盐及其饱和盐溶液所对应的饱蒸汽压(相当于相对湿度33%)与放湿时的外界环境湿度(相对湿度为10%)始终保持着较大的放湿推动力,而且PAM-MC/CaCl2具有一定疏水基团,保湿能力不强,有利于水分释放。因此,将无机盐加入到高分子吸湿材料中,在不影响其放湿速率的情况下,可以大大提高复合材料的吸湿速率。同时,高分子树脂网状结构又避免了单纯氯化钙干燥剂潮解的问题,有利于材料的循环使用。

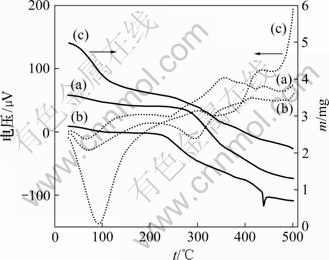

2.4 纤维素材料的热重分析

图5所示为TG-DTA各种复合吸湿材料样品的热重曲线。从图5可以看出:3个样品在0~100 ℃都有1个较大的吸热峰,其失重率为17%~25%,这是由于样品体系内有部分水分子,复合材料具有温敏性,吸热发生相变。在300~350 ℃之间都出现了较明显的能量变化,复合材料键开始发生断裂,说明材料开始分解。而在350~490 ℃热失重曲线陡降,是样品在高温下分解所致,其失重率为30%~40%。由此可见:本产品在300 ℃之后才开始分解,在有机物中具有较高的分解温度,表明产品具有了较好热稳定性。

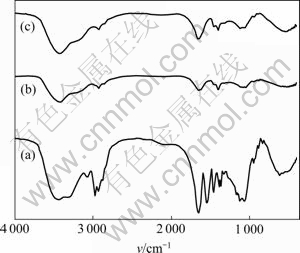

2.5 纤维素材料的红外表征分析

图6所示为各种纤维素吸湿材料样品的红外光谱。从图6可见:在3 250~3 625 cm-1处峰有1个非常明显的宽而强的吸收峰,这是—NH和—OH伸缩振动峰;而在2 973 cm-1出现较强的—CH3伸缩振动峰,1 640 cm-1和1 532 cm-1处的峰为酰胺Ⅰ和酰胺Ⅱ的吸收峰[16],1 372 cm-1出现的峰是典型的—CH(CH3)的弯曲振动峰;1 068 cm-1处的峰属于纤维素分子中醚键的伸缩振动峰[17]。图6(b)与图6(c)的红外光谱基本相似,两者都有相同的基本特征峰;而图6(a)的红外光谱在1 500 cm-1到1 200 cm-1出现比较多的特征峰,为—CH3和—CH(CH3)的弯曲振动峰。由此推断反应所得样品为NIPAM,AM,MC及CaCl2所组成的复合材料。

相对湿度/%: (a) 35; (b) 55; (c) 75; (d) 90; (e) 100; (f) 10

1—PNIPAM-MC; 2—PAM-MC; 3—PAM-MC/CaCl2

图4 不同相对湿度下纤维素吸湿复合材料的吸附及解吸附动力学曲线

Fig.4 Dynamics curve of moisture absorption/release on moisture absorption materials at different relative humidities

(a) PNIPAM-MC; (b) PAM-MC; (c) PAM-MC/CaCl2

图5 各种复合吸湿材料样品的热重曲线

Fig.5 TG-DTA spectra of moisture absorption materials

(a) PNIPAM-MC; (b) PAM-MC; (c) PAM-MC/CaCl2

图6 各种复合吸湿材料样品的红外光谱图

Fig.6 FTIR spectra of moisture absorption materials

3 结论

(1) 无水CaCl2改性的纤维素及适度控制材料,在中低湿下(相对湿度<80%),其湿容量增加1倍,吸湿速率增加3倍;而在相对湿度为100%时,最大湿容量为1.45 g/g,吸湿平衡时间约160 h;但其在相对湿度为10%时,放湿速率及80 ℃的恒温脱附速率均与未用CaCl2改性的湿度控制材料相比要小。

(2) 异丙基丙烯酰胺温敏材料改性的纤维素基湿度控制材料在整个湿度范围内,其吸湿速率及平衡吸湿量变化不大,但其在相对湿度为10%时,放湿速率及80 ℃的恒温脱附速率均明显比未用异丙基丙烯酰胺改性的湿度控制材料的放湿速率及脱附速率大。

(3) 各类有机吸湿材料成功地进行复合,复合产品在350 ℃之后才开始强烈分解,具有较强的热稳 定性。

参考文献:

[1] 王志玉, 刘作新. 高吸水树脂的性能及其在农业上的应用[J]. 土壤通报, 2004, 35(3): 352-356.

WANG Zhi-yu, LIU Zuo-xin. Properties of super water absorbent polymers and their applications in agriculture[J]. Chinese Journal of Soil Science, 2004, 35(3): 352-356.

[2] 李仲谨, 李小燕, 郭焱. 农用高吸水性树脂及其研究进展[J]. 高分子材料科学与工程, 2006, 22(3): 16-20.

LI Zhong-jin, LI Xiao-yan, GUO Yan. Agricultural super absorbent polymers and their development[J]. Polymer Materials Science & Engineering, 2006, 22(3): 16-20.

[3] 侯国艳, 冀志江, 王静, 等. 调湿材料的国内外研究概况[J]. 材料导报, 2008, 22(18): 78-82.

HOU Guo-yan, JI Zhi-jiang, WANG Jing, et al. Domestic and abroad research status of humidity-control[J]. Materials Materials Review, 2008, 22(18): 78-82.

[4] 李万芬, 汪超, 陈国锋, 等. 魔芋葡甘聚糖接枝丙烯酸共聚物超强吸湿剂的扩散吸湿特性研究[J]. 材料科学与工程学报, 2007, 25(2): 276-280.

LI Wan-fen, WANG Chao, CHEN Guo-feng, et al. Study on the SAPs moisture-absorption characteristics of konjac glucomannan-acrylic acid copolymer[J]. Journal of Materials Science and Engineering, 2007, 25(2): 276-280.

[5] 吴文娟. 纤维素系高吸水性树脂的研究进展[J]. 纤维素科学与技术, 2006, 14(4): 57-61.

WU Wen-juan. Research progress of super absorbent resin from cellulose[J]. Journal of Cellulose Science and Technology, 2006, 14(4): 57-61.

[6] Athawale V D, Rathi S C. Synetheses and characteration of starch-poly(methacrylic acid) graft copolymer[J]. Journal of Applied Polymer Science, 1997, 166: 1339-1703.

[7] 王迎军, 葛建华, 郑裕东. 二步加热交联法制备羧甲基纤维素基高吸水材料[J]. 化学工程, 2005, 33(5): 50-52.

WANG Ying-jun, GE Jian-hua, ZHENG Yu-dong. Carboxymethyl-cellulose superabsorbent materials prepared by two-step heating process[J]. Chemical Engineering, 2005, 33(5): 50-52.

[8] 李仲谨, 穆瑞花, 宋俊. 纤维素系高吸水性树脂的制备工艺及其发展方向[J]. 陕西师范大学学报: 自然科学版, 2006, 34(6): 55-58.

LI Zhong-jin, MU Rui-hua, SONG Jun. Preparation technics and development heading of the cellulose super absorbent resin[J]. Journal of Shaanxi Normal University: Natural Science Edition, 2006, 34(6): 55-58.

[9] 宋江莉, 王秀芬. LCST类水凝胶开关效应的研究进展[J]. 化学进展, 2004, 16(1): 56-59.

SONG Jiang-li, WANG Xiu-fen. Advances of LCST-hydrogels applied as a molecular switch[J]. Progress In Chemistry, 2004, 16(1): 56-59.

[10] 李鑫, 朱敏斌, 卢其明, 等. CaCl2改性聚丙烯酸基调湿材料的制备与表征[J]. 四川大学学报: 工程版, 2009, 41(2): 155-161.

LI Xin, ZHU Min-bin, LU Qi-ming, et al. Synthesis and characterization of poly acrylic acid humidity-controlling composite material modified by CaCl2[J]. Journal of Sichuan University: Engineering Science Edition, 2009, 41(2): 155-161.

[11] 姚海林, 杨洋, 程平, 等. 膨胀土壤标准吸湿含水率及其试验方法[J]. 岩土力学, 2004, 26(6): 856-859.

YAO Hai-lin, YANG Yang, CHENG Ping, et al. Standard moisture absorption water content of soil and its testing standard[J]. Rock and Soil Mechanics, 2004, 25(6): 856-859.

[12] 李鑫, 李忠, 刘宇, 等. 金属盐改性对硅胶的水蒸气吸附性能影响[J]. 离子交换与吸附, 2005, 2(5): 391-396.

LI Xin, LI Zhong, LIU Yu, et al. The effect of surface modification by different metal salt solutions on the hygroscopic property of silica gels[J]. Ion Exchange and Adsorption, 2005, 2(5): 391-396.

[13] 贾晓辉. 羟丙基甲基纤维素热引发水凝胶的制备与性能研究[D]. 上海: 东华大学材料科学与工程学院, 2008: 62-78.

JIA Xiao-hui. Reparation and study of performance of thermal induced HPMC hydrogel[D]. Shanghai: Donghua University. College of Material Science and Engineering, 2008: 62-78.

[14] 马凤国, 宋镠毅, 多英全, 等. 羧甲基纤维素与丙烯酸和丙烯酰胺共聚接枝研究[J]. 高分子材料科学与工程, 2003, 19(1): 81-83.

MA Feng-guo, SONG Liu-yi, DUO Ying-quan, et al. Acrylic acid and acrylamide graft on the sodium carboxymethylcellulose[J]. Polymeric Materials Science and Engineering, 2003, 19(1): 81-83.

[15] 林莹, 蒋国强, 昝佳, 等. 甲基纤维素温敏水凝胶的凝固及体外释药特性[J]. 清华大学学报: 自然科学版, 2006, 46(6): 836-838.

LIN Ying, JIANG Guo-qiang, ZAN Jia, et al. Physical and in vitro release properties of methylcellulose-based thermo- sensitive hydrogels[J]. Journal of Tsinghua University: Science and Technology, 2006, 46(6): 836-838.

[16] 姜宇, 刘守信, 房喻, 等. 纳米TiO2/聚N-异丙基丙烯酰胺复合水凝胶的合成及其表征[J]. 化学学报, 2007, 65(21): 2437-2442.

JIANG Yu, LIU Shou-xin, FANG Yu, et al. Synthesis and characterization of nano-TiO2/poly(N-isopropyl-acrylamide) composite hydrogels[J]. Acta Chimica Sinica, 2007, 65(21): 2437-2442.

[17] 魏娜, 陈玉磊, 蒋腊生, 等. 二芳基大环冠醚共轭8-差劲基喹啉的合成及光致发光性质[J]. 有机化学, 2008, 28(10): 1729-1734.

WEI Na, CHEN Yu-lei, JIANG La-sheng, et al. Synthesis and photoluminescence properties of novel bisphenylene crown ether conjugated quinolin-8-ol and their complexes[J]. Chinese Journal of Organic Chemistry, 2008, 28(10): 1729-1734.

收稿日期:2009-09-03;修回日期:2009-12-10

基金项目:广东省绿色化学产品技术重点实验室开放基金资助项目(GC200805);广东省科技计划项目(2008B02000048);华南农业大学校长基金资助项目(2008K014)

通信作者:李鑫(1979-),男,河南南阳人,博士,讲师,从事能源与环境材料的研究;电话:020-85280323;E-mail: xinliscau@126.com

(编辑 任楚威)