文章编号: 1004-0609(2006)10-1736-07

镁铝合金处理GCr15轴承钢夹杂物的变质

王 博, 姜周华, 姜茂发

(东北大学 材料与冶金学院, 沈阳 110004)

摘 要: 分别采用3种不同镁含量的镁铝合金对GCr15轴承钢液进行了夹杂物变质处理, 分析了实验过程中全氧值的变化, 并利用光学显微镜、 扫描电镜和能谱仪分析了试样中夹杂物的尺寸、 形貌和化学成分。 结果表明: 经镁铝合金处理后, GCr15轴承钢中的全氧值显著降低, 夹杂物由大尺寸、 形状不定的氧化铝颗粒转变为尺寸细小、 球形的镁铝尖晶石颗粒。 含镁量为16.55%的3#镁铝合金夹杂物变质效果最明显, 钢中夹杂物多为镁铝尖晶石和氧化镁, 其中96.23%的夹杂物直径小于3μm。 因此, 镁铝合金夹杂物变质处理有利于改善轴承钢浇注和提高轴承钢疲劳寿命。

关键词: GCr15轴承钢; 镁铝合金; 夹杂物; 变质处理

中图分类号: TG113.1 文献标识码: A

Inclusion modification in GCr15 bearing steel

with Al-Mg alloy treatment

WANG Bo, JIANG Zhou-hua, JIANG Mao-fa

(School of Materials and Metallurgy,

Northeastern University, Shenyang 110004, China)

Abstract: The molten GCr15 bearing steel was modified by three types of Al-Mg alloys. Firstly, the total oxygen content value was measured, then the inclusion size, shape and chemical composition were analyzed by optical microscopy, SEM and EDX. The results show that, after treated by Al-Mg alloy, the total oxygen content descends remarkably and the alumina inclusion with big size and different shapes transform into spinel with small size and spherical shape. The optimal effect of inclusion modification is acquired after treated by 3# Al-Mg alloy containing 16.55% Mg, most of the inclusions in steel are spinel and magnesia, and the size of 96.23% inclusions is less than 3μm. So, the inclusion modification treated by Al-Mg alloy can improve casting and fatigue life of bearing steel.

Key words: GCr15 bearing steel; Al-Mg alloy; inclusion; modification treatment

轴承钢生产工艺是以Al作为主要脱氧剂的, 用Al脱氧成本低且可以获得较低的溶解氧含量[1], 但是脱氧产物Al2O3容易聚集成簇状的Al2O3, 夹杂不易上浮去除, 残留在钢中的Al2O3夹杂物在轧制过程中沿轧制方向碎裂为链状夹杂物带, 其尖锐的棱角易引发形成空穴和成为应力源, 对轴承钢的疲劳寿命产生危害[2]。 且在轴承钢浇注过程中, Al2O3夹杂物也是造成水口堵塞的主要原因之一。

目前, 控制轴承钢中Al2O3夹杂物数量主要有两种工艺措施: 高碱度LF渣精炼以及使用新型脱氧剂对Al2O3夹杂物进行变质处理。 高碱度渣精炼虽然可以有效地减少钢中Al2O3夹杂物的数量, 但同时会形成铝酸钙类夹杂物, 此类夹杂物同样对轴承钢疲劳寿命有害[3-5]。 目前, 国内外研究者尝试采用Mg、 Ba等碱土金属对轴承钢夹杂物进行变质处理, 以获得形状和尺寸都比较理想的复合夹杂物, 从而提高轴承钢疲劳寿命。

Saxena[6-7]对镁合金的研究结果表明, 镁能使Al2O3和MnS夹杂物变性。 镁可以使簇状Al2O3夹杂变成尺寸细小、 边缘圆滑的Al2O3·MgO夹杂物, 且其在轧制过程中不易引发形成空穴和成为应力源。 尖晶石夹杂物被能变形的硫化物所包裹, 这种多相的夹杂物对钢的疲劳性能有害程度较小。 使用Al-Mg合金处理钢液, 使得轴承钢棒材(d65mm)的疲劳寿命提高了4.5倍。 周得光等[8]的实验结果表明, 微量镁能改善轴承钢的性能, 当钢中镁含量增加到0.002%~0.003%, 其抗拉强度和屈服强度增加5%, 塑性基本保持不变。

本文作者通过实验考察了镁铝合金对钢中Al2O3夹杂物的变质效果, 并通过相应分析手段研究了其作用机理。 由于镁蒸汽压在1600℃高达1.927MPa[9], 直接向钢液喂纯镁会导致镁大量汽化逸出, 因此本文作者以镁铝合金包芯线方式喂入钢液。 镁铝合金可以显著降低镁的活度[10], 减小镁的逸出, 从而提高镁的收得率。

1 实验

1.1 钢料和渣料准备

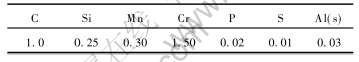

实验用钢铁料为GCr15轴承钢轧材棒料, 化学成分如表1所列。

表1 GCr15轴承钢成分

Table 1 Chemical composition of GCr15 bearing steel (mass fraction, %)

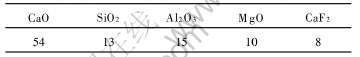

实验所用渣料由化学纯试剂配置而成, 为高碱度精炼渣系, 其中w(CaO)/w(SiO2)=4.15, 具有良好的夹杂物吸附能力, 其成分如表2所列。

表2 实验炉渣成分

Table 2 Chemical composition of prepared slag (mass fraction, %)

1.2 镁铝合金的制备

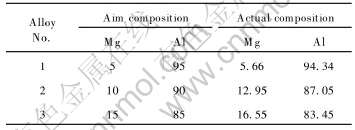

新日铁室兰厂[11]进行的镁铝合金夹杂物变质实验证明: 镁含量小于5%的镁铝合金不能充分对Al2O3进行改质, 而镁含量大于70%的镁铝合金则会导致反应激烈, 造成钢液喷溅。 本研究中镁含量选取5%~20%为考察区间, 炼制的镁铝合金成分如表3所列。

表3 镁铝合金的化学成分

Table 3 Chemical composition of Al-Mg alloy (mass fraction, %)

考虑到镁在炼制过程中的损耗, 镁的配入量略大。 镁铝合金包芯线制作步骤如下:

1) 将纯镁和纯铝小块按照表3中目标含量的比例, 称量100g放入石墨坩埚混合;

2) 将石墨坩埚放入MoSi2炉中, 炉口用石棉封闭, 炉管中通氩气保护;

3) 升温至800℃时, 用钼丝搅拌均匀, 恒温20min后停电, 氩气保护气氛下随炉冷却;

4) 清除合金表面的氧化物, 破碎成粉状, 取1g粉料以薄铁片封装, 制作成包芯线。

1.3 实验步骤

本研究共进行了4组坩埚实验, 依次为非镁铝合金处理的精炼渣实验(空白实验)及合金1、 2和3的处理实验。 实验在MoSi2电阻炉内进行, 以d65mm×80mm电熔MgO坩埚盛装钢料, 采用B型热电偶测温, 实验操作步骤如下:

1) 装入1kg钢料, 给电升温, 炉膛内通入氩气保护, 流量为6L/min;

2) 升温至1600℃恒温, 待钢料熔清后, 插入0.5g铝进行沉淀脱氧;

3) 加入成分如表2的渣料80g, 渣料熔化后分批加入SiC粉进行渣面扩散脱氧, 反应开始计时;

4) 反应30min后, 用d6mm石英管抽取样品1#;

5) 插入镁铝合金包芯线, 进行夹杂物变质处理(空白实验省略此步骤);

6) 30min后, 抽取样品2#;

7) 反应结束, 待炉子冷却至室温后取出钢锭, 利用线切割方法制作尺寸为d6mm×30mm的样品3#;

8) 将所有试样放置在马弗炉中于900℃恒温6h, 随炉冷却, 进行退火处理。

2 结果与讨论

2.1 镁铝合金处理对全氧的影响

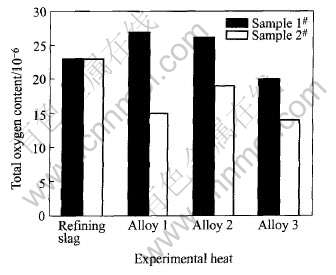

对每炉实验的样品1#和样品2#作全氧分析, 结果如图1所示。

图1 镁铝合金处理后全氧含量的变化

Fig.1 Variety of total oxygen content after Al-Mg alloy treatment

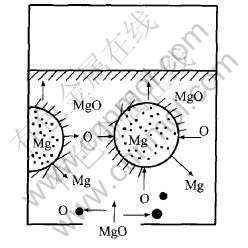

由图1可知, 经镁铝合金处理后, 钢中全氧含量呈显著下降趋势, 而未经镁铝合金处理的炉次, 全氧含量没有变化。 主要是由于铝脱氧30min后, 大颗粒Al2O3迅速上浮排除, 细小的Al2O3颗粒则容易团聚为簇状, 这种簇状结构Al2O3中心夹带钢液, 上浮困难, 从而残留在钢液中; 而喂入镁铝合金后钢中形成了镁蒸汽, 镁气泡在逸出时搅拌钢液有利于夹杂物的上浮, 且镁气泡的表面不断进行脱氧反应, 脱氧产物吸附在气泡表面最终被带出钢液, 使钢中全氧值降低[12], 其反应机理如图2所示。

2.2 夹杂物形貌和成分分析

图2 镁脱氧过程示意图

Fig.2 Schematic diagram of deoxidation process by magnesium

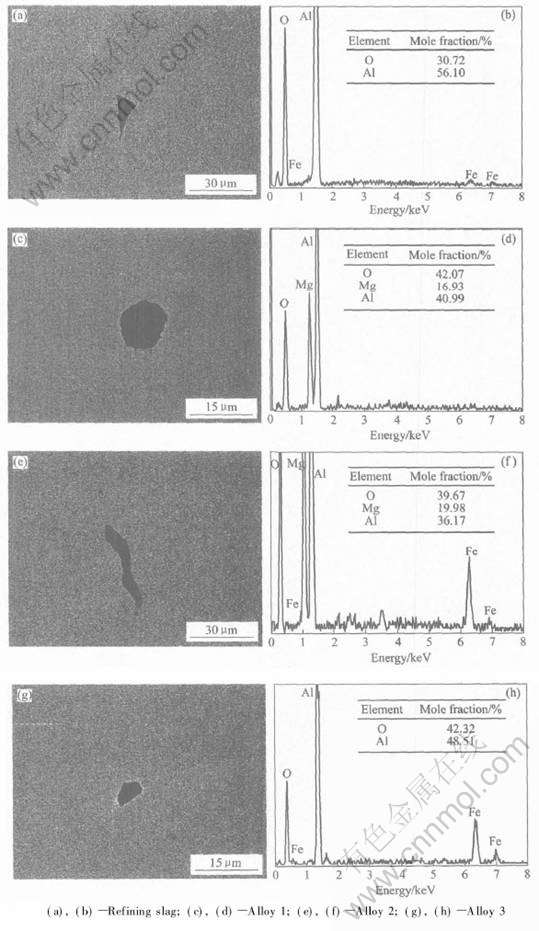

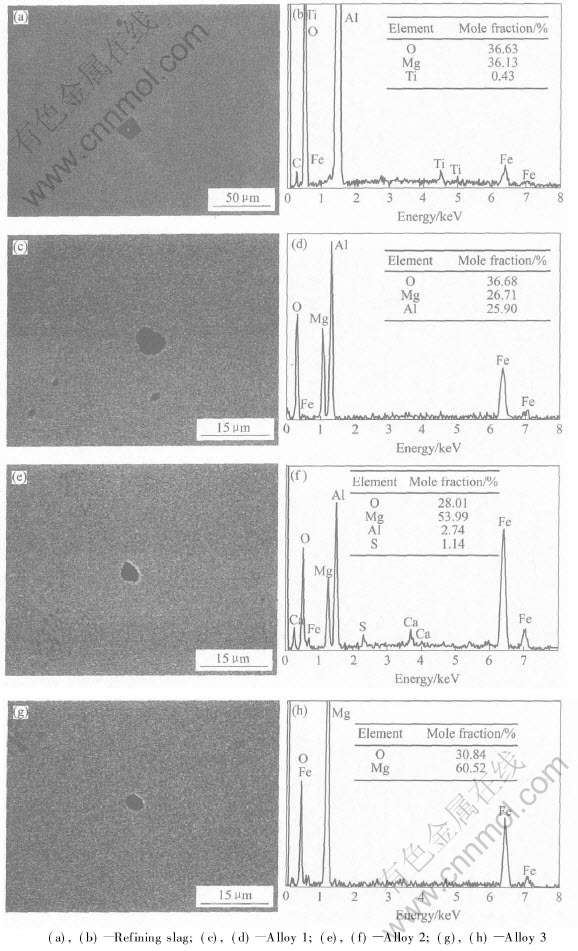

将每炉实验的样品1#和2#加工成d6mm×10mm的钢棒, 将端面打磨、 抛光后, 用扫描电镜及能谱仪对夹杂物的形貌和成分做了分析。 图3所示为每炉实验样品1#中典型夹杂物的扫描电镜照片和能谱分析的元素含量。 图4所示为每炉实验样品2#中典型夹杂物的扫描电镜照片和能谱分析结果。 对比图3和4后可看出, 经镁铝合金处理后, 钢中夹杂物成分、 形貌和尺寸都发生了显著变化。

由样品1#可知, 钢液经铝脱氧30min后, 钢中夹杂物成分以Al2O3为主, 某些夹杂物中复合有较低含量的MgO(其来源应为坩埚或炉渣中氧化镁[5, 13]), 镁铝比低于镁铝尖晶石(摩尔比为1); 观察样品2#, 未经镁铝合金处理的精炼渣实验, 样品2#中夹杂物仍然以Al2O3为主; 而镁铝合金变质处理30min后所取样品2#中没有观察到Al2O3, 夹杂物几乎均为Al2O3·MgO(其镁铝比高于镁铝尖晶石的镁铝比), 有些Al2O3·MgO夹杂物被硫化物包裹, 这与文献[6]中介绍的一致。 尤其是从经合金3处理后的样品2#中观察到了MgO, 这是由于钢中溶解镁含量增加, 镁部分或者完全取代铝脱氧所致。 热力学计算证明[14-15], 当钢中溶解镁含量满足2×10-8〈w[Mg]〈6×10-6时, 就可以生成Al2O3·MgO, 而当溶解镁含量满足w[Mg]>6×10-6时, 就有纯MgO生成。

镁铝合金处理后的镁铝尖晶石夹杂物尺寸细小、 形状接近于球形, 而处理前颗粒较大、 形状不规则。 因此, 采用镁铝合金处理钢液时, 镁、 铝同时参与脱氧反应, 脱氧产物依托钢中质点形核, 产物尺寸细小, 且弥散分布在钢中。

2.3 夹杂物的定量金相分析

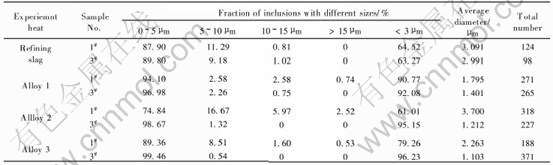

由文献[16-17]可知: 夹杂物尺寸对轴承钢疲劳寿命呈非线性影响, 如果夹杂物数量多且尺寸细小, 轴承钢仍然能获得高的疲劳寿命, 而数量极少的大颗粒夹杂则明显降低轴承钢的疲劳寿命。 一般认为, 直径大于8μm的夹杂物对轴承钢的疲劳寿命会产生危害, 而直径小于3μm的夹杂物几乎是无害的[2, 7]。 为考察镁铝合金处理对夹杂物尺寸分布的影响, 对每炉实验的样品1#和3#作了夹杂物定量金相分析。 将试样打磨、 抛光后, 用LEICAQ5501W图像仪、 DMRME显微镜进行观察, 每个试样观察40个视场。 表4所列为夹杂物在各个尺寸区间分布的统计数据。

图3 样品1#中典型夹杂物扫描电镜及能谱分析结果

Fig.3 Analysis results of SEM and EDX of typical inclusions in sample 1#

图4 样品2#中典型夹杂物扫描电镜及能谱分析结果

Fig.4 Analysis results of SEM and EDX of typical inclusions in sample 2#

表4 夹杂物尺寸分布变化

Table 4 Distribution variety of inclusion size

由表4中可以看出, 经镁铝合金处理后, 大尺寸夹杂物比例减小, 小尺寸夹杂物的比例明显升高, 夹杂物平均直径减小, 而未经镁铝合金处理的精炼渣实验夹杂物尺寸分布变化不明显。 在本研究的考察范围内, 随着镁铝合金中镁含量的增加, 终点样中夹杂物尺寸分布更加优良, 无害夹杂物(直径小于3μm)的比例升高, 夹杂物平均直径减小; 经合金3处理后, 终点样中夹杂物直径均小于5μm, 其中无害夹杂物(直径小于3μm)的含量高达96.23%, 其夹杂物的平均直径为1.103μm, 3项指标均为4组实验中最优。

3 结论

1) 轴承钢液经镁铝合金处理后, 钢中全氧值显著降低, 而未经镁铝合金处理的精炼渣实验钢中全氧值始终稳定在较高水平。

2) 变质处理后, 形状不定的Al2O3夹杂物转变为球形镁铝尖晶石夹杂物, 合金3变质效果最为显著, 钢中生成了MgO; 而精炼渣实验钢中夹杂物自始至终以Al2O3为主。

3) 镁铝合金处理优化了夹杂物的尺寸分布, 大尺寸夹杂物比例明显减小, 小尺寸夹杂物比例升高; 三炉变质实验终点样的夹杂物分布情况优于精炼渣实验的, 经合金3处理样品夹杂物分布情况最佳, 夹杂物尺寸均为0~10μm, 其中96.23%夹杂物的直径小于3μm。

REFERENCES

[1]于赋志, 沈峰满, 刘恒昌. 钢水深脱氧用铝系复合材料的应用与发展[J]. 东北大学学报(自然科学版), 2000, 21(4): 423-426.

YU Fu-zhi, SHEN Feng-man, LIU Heng-chang. Application and development of compound materials with aluminum in deep deoxidization for steelmaking[J]. Journal of Northeastern University(Natural Science), 2000, 21(4): 423-426.

[2]杨建宏, 雷建中, 叶键熠, 等. 轴承钢洁净度对轴承疲劳寿命的影响[J]. 轴承, 2001(5): 28-30.

YANG Jian-hong, LEI Jian-zhog, YE Jian-hui, et al. Effect of cleanness of bearing steel for fatigue life of bearing[J]. Bearing, 2001(5): 28-30.

[3]Yoon B H, Heo K H, Kim J S, et al. Improvement of steel cleanliness by controlling slag composition[J]. Ironmaking and Steelmaking, 2003, 29(3): 215-218.

[4]Rocabois P, Lehmann J, Gatellier C, et al. Non-metallic inclusion entrapment by slags: laboratory investigation[J]. Ironmaking and Steelmaking, 2003, 30(2): 95-100.

[5]于平, 陈伟庆, 冯军, 等. 高碱度渣精炼的轴承钢中夹杂物研究[J]. 钢铁, 2004, 39(7): 21-23.

YU Ping, CHEN Wei-qing, FENG Jun, et al. Investigation of inclusions in bearing steel under refining with high basicity slag[J]. Iron and Steel, 2004, 39(7): 21-23.

[6]Saxena S K. Refining reaction of magnesium in steel at steelmaking temperature[A]. Proceedings International Symposium on the Physical Chemistry of Iron and Steelmaking[C]. Toronto: Conference of Metallurgists, 1982: 17-22.

[7]Saxena S K. Using Magnesium treatment to produce super clean steel with excellent mechanical property[J]. SEAISI, 1997(7): 42-52.

[8]周德光, 傅杰, 李晶, 等. 轴承钢中镁的控制及作用研究[J]. 钢铁, 2002, 37(7): 23-25.

ZHOU De-guang, FU Jie, LI Jing, et al. Study on control and effect of magnesium in bearing steel[J]. Iron and Steel, 2002, 37(7): 23-25.

[9]de Barbadilio J J. Reactivity of magnesium and calcium in liquid steel[A]. De Barbadilio J J, Snape E. Inclusions in steel[C]. USA: American Society for Metals, 1975: 70-99.

[10]路贵民, 刘学山, 蒋冬梅, 等. Al-Mg合金热力学性质的计算[J]. 中国有色金属学报, 1999, 9(2): 381-384.

LU Gui-min, LIU Xue-shan, JIANG Dong-mei, et al. Calculation of thermodynamic properties of liquid Al-Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 381-384.

[11]岑永权. 有效防止钢水中夹杂物聚集长大的方法[J]. 上海金属, 1995, (2): 64.

CEN Yong-quan. Methods for preventing effectively gathering and growing of inclusions in molten steel[J]. Shanghai Metals, 1995, (2): 64.

[12]李阳. 碱土金属合金对钢液脱氧及其夹杂物控制研究[D]. 沈阳: 东北大学, 2003.

LI Yang. Deoxidation with Alkaline Earth Alloys and the Inclusion Control in Molten Steel[D]. Shenyang: Northeastern University, 2003.

[13]Mizuno K. Effects of Al and Ca in ferrosilicon alloysfor deoxidation on inclusion composition in type 304 stainless steel[J]. Iron and Steelmaker, 2001(8): 93-101.

[14]王厚昕. 含钡、 镁新型炼钢脱氧剂的开发研究[D]. 沈阳: 东北大学, 2003.

WANG Hou-xin. Development of New Dioxidizer Bearing Ba and Mg Used in Steelmaking Process[D]. Shenyang: Northeastern University, 2003.

[15]Hiroki O, Hideuki S. Activities in CaO-Al2O3-MgO slags and deoxidation equlibrium of Al, Mg and Ca[J]. ISIJ International, 1996, 36(8): 983-990.

[16]殷瑞钰. 钢的质量现代进展[M]. 北京: 冶金工业出版社, 1995.

YIN Rui-yu. The Advance Development of Steel Quality[M]. Beijing: Metallurgical Industry Press, 1995.

[17]钟顺思, 王昌生. 轴承钢[M]. 北京: 冶金工业出版社, 2000.

ZHONG Shun-si, WANG Chang-sheng. Bearing Steel[M]. Beijing: Metallurgical Industry Press, 2000.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50374029)

收稿日期: 2006-01-09; 修订日期: 2006-06-19

通讯作者: 王 博; 电话: 024-83681478; E-mail: wz8295@163.com