共沉淀法制备高比表面积的铟锡氧化物超细粉末

古映莹1, 刘雪颖1, 谭 坚1, 李 丹1, 杨天足2, 赖琼琳2

(1.中南大学 化学化工学院, 湖南 长沙, 410083;

2.中南大学 冶金科学与工程学院, 湖南 长沙, 410083)

摘要: 采用化学共沉淀法制备铟锡氧化物超细粉末, 并用差热分析仪测定铟锡氧化物前驱体的分解温度、 用X射线衍射分析其晶型, 用透射电镜观察颗粒的大小和形貌, 用自动吸附仪测量颗粒的比表面积; 对分散剂的添加及添加方式、 煅烧温度等因素对产品性能的影响也进行研究。 研究结果表明: 在抽滤洗涤共沉淀凝胶时用Na2SiO3做分散剂润洗, 然后在700℃下煅烧2h, 可以得到粒度为20~30nm、 比表面积达150m2/g、 分布均匀、 结晶性好的铟锡氧化物超细粉末。

关键词: 超细粉末; 共沉淀法; 铟锡氧化物; 比表面积

中图分类号:TQ584 文献标识码:A 文章编号: 1672-7207(2005)05-0837-04

Preparation of ultra-fine indium tin oxide powders with high specific surface areas by co-precipitation method

GU Ying-ying1, LIU Xue-ying1, TAN Jian1, LI Dan1, YANG Tian-zu2, LAI Qiong-lin2

(1. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

2. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The ultra-fine indium tin oxide (ITO) powders were prepared by chemistry co-precipitation method. The decomposable temperature of the indium trihyoxide for ITO was measured by differential thermal analysis techniques; the crystal structure of the ITO powders was analyzed by X-ray diffractometry; the particles size and appearance were observed by transmission electron microscopy; the powders specific surface areas were measured by automatic absorption technique. The synthesis conditions influencing the properties of the products, such as dispersant Na2SiO3 and appendent methods, and the calcination temperature were investigated. With large specific surface area of 150m2/g, small particle size of 20-30nm, the good particle distribution and fine crystallization ultra-fine ITO powders were obtained under the conditions of the sintering at 700℃ for 2h after the indium trihyoxide for ITO was washed by dispersant Na2SiO3 in filtration.

Key words: ultra-fine powder; co-precipitation; indium tin oxide; specific surface area

近年来, 人们对纳米材料的基本机理(例如尺寸效应、 材料的应用)进行了大量的研究[1, 2]。 氧化铟是一种N型宽禁带半导体(Eg=3.5 eV), 按m(In2O3)∶m(SnO2)=9∶1掺Sn之后就得到铟锡氧化物(ITO)[3]。 铟锡氧化物在许多方面得到应用, 例如电学材料、 透明电极材料、 太阳能电池材料、 电致发光材料等, 特别是铟锡氧化物纳米晶体粉末在屏幕显示技术方面有广泛的应用[4, 5]。 目前, 世界上的发达国家如日本、 美国、 法国等将一半左右的铟用于制备ITO材料[6]。 因此, 研究ITO超细粉体的制备具有重要的意义。

制备ITO粉末的方法有多种, 如化学共沉淀法[7]、 溶胶-凝胶法[8]、 减压-挥发氧化法[9]、 熔体雾化-燃烧法和液雾氧化燃烧法等[10]。 其中化学共沉淀法是以金属或金属盐为原料, 在溶液中以共沉淀的方式制备ITO复合粉末, 具有设备普通, 流程简单, 产品粒度能调控, 颗粒均匀, 成本相对较低的优点, 成为目前纳米粉体制备的主要手段之一。 为此, 本文作者采用化学共沉淀法, 通过控制反应条件制备纳米ITO粉体。

1 实 验

1.1 试剂和仪器

试剂为: 金属铟(99.99%), SnCl4·5H2O, H2SO4, Na2CO3, 均为分析纯。

仪器为: 差热分析仪(CRY-1P, 上海精密科学仪器有限公司); 自动吸附仪(ZXF-06, 西北化工研究院); X-射线衍射仪(SIMENS·D50, 日本); 透射电镜仪(H-800, 日本)。

1.2 ITO超细粉体的制备

首先, 将金属铟在硫酸中溶解, 然后, 将所得In2(SO4)3溶液和SnCl4溶液按m(In2O3)∶m(SnO2)=9∶1混合, 在恒温水浴槽中于70℃下反应。 在高速搅拌下匀速滴加1 mol/L碳酸钠溶液, 调节pH值到7, 继续搅拌30 min, 使沉淀完全。 将得到的共沉淀前驱体抽滤、 洗涤、 干燥、 煅烧、 研磨, 即可获得ITO超细粉末。

1.3 ITO粉体的表征

将制得的ITO超细粉末用X射线衍射仪进行物相分析; 用差热分析仪测定前驱体的分解温度; 采用BET法测定粉末的比表面积; 用电子显微镜观察粉末的平均粒径及形貌。

2 结果与讨论

2.1 共沉淀前驱体的差热分析

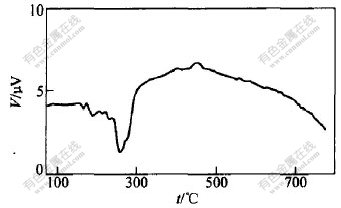

为了确定ITO共沉淀前驱体的煅烧温度, 将共沉淀前驱体进行差热分析(DTA)。 在空气气氛, 升温速度为10℃/min的差热条件下得到的差热分析(DTA)曲线如图1所示。 图1中, 70~200℃过程为吸附水以及其他残余溶剂挥发过程, 200~350℃ 为前驱体的吸热分解过程。 可知前驱体在400℃就已经完全分解。 铟锡氢氧化物在300℃煅烧1 h后逐渐由非晶态转变为晶态结构[11], 所以, 在后续的煅烧工艺中选定共沉淀前驱体的煅烧温度为400~800℃。

图 1 ITO共沉淀前驱体的DTA曲线图

Fig. 1 DTA curve of indium trihydroxide for ITO by co-precipitation

2.2 煅烧温度

由共沉淀前驱体的差热分析结果可知, 共沉淀前驱体在400℃即已经完全分解, 故在研究煅烧温度对ITO粉末性能的影响时, 将制得的ITO前驱体干胶粉分别在400, 500, 600, 700和800℃下煅烧2 h, ITO粉末的X射线衍射图谱如图2所示。

图 2 不同煅烧温度下所得ITO粉末的XRD图谱

Fig. 2 XRD patterns of ITO powders prepared at different sintering temperature

由图2可知, 在500℃时煅烧即可得到结晶性较好的粉末, 3个样品都为立方In2O3结构, 出现的衍射峰均为In2O3的特征衍射峰, 未出现SnO2的衍射峰。 与In2O3标准谱图比较, 所得的谱图的衍射峰略有偏差, 这说明制得的铟锡氧化物并不是In2O3与SnO2的简单混合物, 而是在反应中Sn4+占据部分In3+的位置而生成具有立方In2O3结构的固溶体, 这与文献[12]报道的结果一致。 随着煅烧温度的升高, 峰的强度明显减弱, 这可能是随着煅烧温度升高, Sn4+在In2O3中形成的空位取代增加的原因[13]。

化学共沉淀法制备的ITO粉体的特有颜色为淡绿色[9]。 实验发现在400℃、 500℃和600℃下煅烧得到的粉末均为淡黄色, 在700℃和800℃下煅烧得到的ITO粉末均为淡绿色。 随煅烧温度的不同而生成颜色不同的ITO粉体, 其原因是不同的温度提供的热动力不同, 所以生成的ITO粉体的颜色不同[14] 。 因此, 煅烧温度选择为700℃。

2.3 分散剂

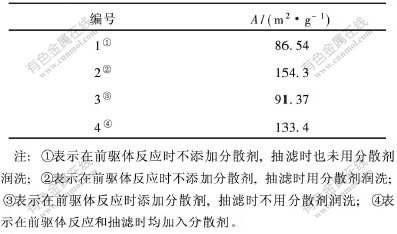

分散剂的加入可改善沉淀过程中的新核生成和晶核生长。 为了研究分散剂对产品粒径的影响, 参照有关资料并结合实验情况, 认为添加有机试剂不可取, 况且, 添加有机试验还会提高成本和产生新的污染[9]。 因此, 选用一种常用的无机盐——硅酸钠为分散剂, 研究其分散性能以及添加方式对ITO粉末比表面积的影响, 结果如表1所示。

表 1 不同条件下所得ITO粉的比表面积

Table 1 Specific surface areas of ITO powders prepared under different conditions

由表1可知: 2号、 3号和4号样品的比表面积均大于1号样品的比表面积, 其中2和4号样品尤为明显。 可见, 添加分散剂硅酸钠有利于生成比表面积大的ITO粉末。

本实验采用了4种分散剂添加方式, 由表1可知, 2号样品的比表面积明显大于1号样品的比表面积; 4号样品的比表面积也明显大于3号样品的比表面积。 可见在抽滤时用含分散剂的溶液润洗, 其分散效果更佳, 更有利于生成比表面积大的ITO粉末。

硅酸钠是一种强碱弱酸盐, 水解反应如下:

Na2SiO3+2H2O=2Na++2OH-+H2SiO3,H2SiO3=H++HSiO-3,HSiO-3=H++SiO2-3。

当加入硅酸钠作分散剂时, 粉体的比表面积与没有加任何添加剂制得的粉体的比表面积相比增大将近1倍。 这主要是由水化性很强的HSiO-3和硅酸胶粒以物理吸附的方式吸附包裹在粉体颗粒上, 以阻止颗粒在随后的煅烧过程中发生二次团聚。 同时体系中的SO2-4对金属离子的吸引力比较大, 有利于球形粒子的形成, 而球形粒子具有更大的比表面积, 活性更高。

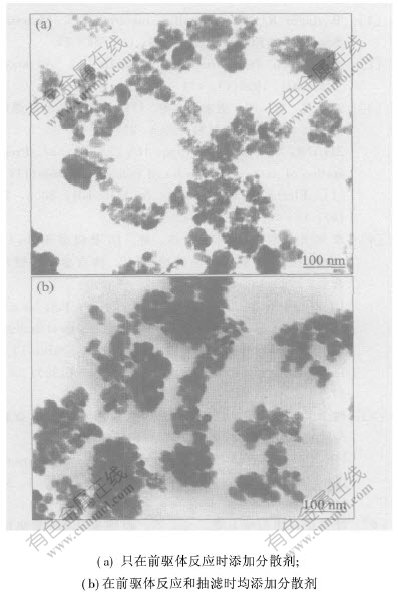

2.4 ITO粉末的透射电镜分析

采用电子显微镜观察ITO超细粉末的晶体形貌, 结果如图3所示。

图 3 在700℃煅烧2 h的ITO粉末的TEM图

Fig. 3 TEM images of ITO powders sintered at 700℃ for 2 h

在有分散剂时所得ITO粉末的形貌为球形, 颗粒大致呈单分散状态, 粒度分布均匀, 其平均粒径为20 nm。

3 结 论

a. 以金属铟、 SnCl4·5H2O为原料, 以Na2CO3作沉淀剂, Na2SiO3为分散剂, 通过化学共沉淀法制备出粒径小、 粒度分布均匀、 比表面积大、 结晶性好的纳米级的ITO粉体。

b. 以Na2SiO3为分散剂, 共沉淀前驱体在700℃煅烧2h, 可得到粒径为20~30nm、 比表面积为130~150m2/g的ITO超细粉体, 该粉体粒子呈球形、 分散性好。

参考文献:

[1]Birringor R. Nanocrystalline materials[J]. Materials Science and Engineering, 1989, 117: 33-34.

[2]Glieter H. Nanostructured materials[J]. Advanced Materials, 1992(4): 474-481.

[3]张贤高, 贺平, 贾志杰, 等. ITO纳米粉体的低温制备[J]. 电子元件与材料, 2004, 23(6): 44-45.

ZHANG Xian-gao, HE Ping, JIA Zhi-jie, et al. Preparation of nano-sized powder of indium tin oxide(ITO)[J]. Electronic Components & Materials, 2004, 23(6): 44-45.

[4]李风光, 刘东平, 邓培, 等. 纳米级球形In2O3(SnO2)粉末的制备及性能研究[J]. 稀有金属与硬质合金, 1999(138): 15-17.

LI Feng-guang, LIU Dong-ping, DENG Pei, et al. Preparation of nanometer dispersive spherical indium tin oxide powder by liquid chemical coprecipitation[J]. Rare Metals and Cemented Carbides, 1999(138): 15-17.

[5]何小虎, 韦莉. 铟锡氧化物及其应用[J]. 稀有金属与硬质合金, 2003, 31(4): 51-57.

HE Xiao-hu, WEI Li. In-tin oxide and its applications[J]. Rare Metals and Cemented Carbides, 2003, 31(4): 51-57.

[6]段学臣, 陈振华, 周立, 等. 超细氧化铟-氧化锡(ITO)复合粉末的研制与结构特性[J]. 稀有金属, 1998, 22(5): 396-399.

DUAN Xue-chen, CHEN Zhen-hua, ZHOU Li, et al. Preparation and structural characterization of In2O3-SnO2(ITO) ultrafine composite powder[J]. Chinese Journal of Rare Metals, 1998, 22(5): 396-399.

[7]张艳峰, 张久兴. 化学共沉淀法制备纳米ITO粉体及结构表征[J]. 功能材料, 2003, 34(5): 573-574.

ZHANG Yan-feng, ZHANG Jiu-xing. Preparation and characterization of nanosized indium tin oxide powders by chemical co-precipitation method[J]. Functional Materials, 2003, 34(5): 573-574.

[8]Kim S S, Choi S Y, Park C G, et al. Transparent conductive ITO thin films through the sol-gel process using metal salts[J]. Thin Solid Films, 1999, 374: 155-160.

[9]于汉芹. ITO超细粉末的研制[J]. 有色矿冶, 2000(16): 35-38.

YU Han-qin. Investigation and preparation of ITO ultrafine powder[J]. Non-ferrous Metal and Metallurgy, 2000(16): 35-38.

[10]陈世柱, 尹志民, 胡林轩. 用液雾氧化燃烧工艺制备SnO2/In2O3纳米粉[J]. 中国有色金属学报, 1997, 7(4): 94-96.

CHEN Shi-zhu, YIN Zhi-min, HU Lin-xuan. Atomizing-combustion technique for preparation of SnO2/In2O3 nanosized powder[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 94-96.

[11]余萍, 杨觉明, 陈平. 热处理温度对铟锡氧化物纳米粉显微结构的影响[J]. 西安工业学院学报, 2002, 22(4): 332-335.

YU Ping, YANG Jue-ming, CHEN Ping. Effect of heat treatment temperature on microstructure of nano-powders of indium tin oxide[J]. Journal of Xi’an Institute of Technology, 2002, 22(4): 332-335.

[12]YANG Hua, HAN Sang-do, WANG Li, et al. Preparation and characterization of indium-doped tin dioxide nanocrystalline powders[J]. Materials Chemistry and Physics, 1998(56): 153-156.

[13]Udawatte C P, Yanagisawa K. Sintering of free hydrothermally indium tin oxide powders in air[J]. Journal of Solid State Chemistry, 2000(154): 444-450.

[14]张永红, 陈明飞. 热处理对制备纳米氧化铟锡(ITO)粉末的影响[J]. 金属热处理, 2003, 28(2): 18-20.

ZHANG Yong-hong, CHEN Ming-fei. Influence of the heat treatment on nanoscale indium tin oxide powder[J]. Heat Treatment of Metals, 2003, 28(2): 18-20.

收稿日期:2005-01-09

基金项目: 国家“十五”攻关西部开发科技行动计划资助项目(2001BA901A09)

作者简介:古映莹(1962-), 女, 湖南长沙人, 硕士, 教授, 从事功能材料的研究

论文联系人: 古映莹, 女, 教授; 电话: 0731-8879616(O); E-mail: guyy02@163.com