文章编号:1004-0609(2008)06-0967-07

等温温度对半固态2024合金部分重熔组织的影响

王顺成,李元元,陈维平,潘国如

(华南理工大学 机械工程学院,广州510640)

摘 要:分别在固液两相区620和 630 ℃以及液相线以上640和650 ℃对半固态2024合金坯料进行等温加热,利用光学显微镜和金相图像分析系统,研究等温温度对半固态坯料部分重熔组织的影响。结果表明:坯料等温温度越高,液相形成速度越快,重熔后晶粒越细小。在液相线以上温度等温加热比在固液两相区温度等温加热时,坯料重熔后晶粒明显细小,但球化程度略低。组织演变机理分析表明,提高等温温度,液相形成速度加快导致晶粒合并受到一定的抑制是晶粒细化的主要原因,而保温时间的缩短则是晶粒球化程度降低的原因。

关键词:半固态金属;部分重熔;等温温度;组织演变

中图分类号:TG 146.21 文献标识码:A

Effect of isothermal temperature on microstructure of

semi-solid 2024 alloy during partial remelting

WANG Shun-cheng, LI Yuan-yuan, CHEN Wei-ping, PAN Guo-ru

(School of Mechanical Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: The semi-solid 2024 alloy billets were isothermally reheated at 620, 630, 640 and 650 ℃, respectively. The effect of isothermal temperature on the microstructure of semi-solid billet during partial remelting was studied by optical microscopy and metallographic image analysis system. The results show that the higher the isothermal temperature is, the quicker the formation rate of liquid phase is and the finer the grains are. The grains of semi-solid billet isothermally reheated over liquidus temperatures 640 and 650 ℃ are much finer than those at solidus-liquidus zone temperatures 620 and 630 ℃, but the spheroidization degree is slightly lower. It is indicated that through the analysis of microstructural evolution mechanism, the restraining of grains coalescence and the shortening of holding time by accelerating the formation rate of liquid phase are the reasons of grains refinement, and the shortening of holding time is the reason of grains spheroidization degree lowering.

Key words: semi-solid metal; partial remelting; isothermal temperature; microstructural evolution

半固态金属成形技术具有提高铸件致密度、延长模具寿命和实现高速近终成形等优点。半固态金属成形工艺包括流变成形和触变成形,目前研究和应用较多的是触变成形,包括半固态坯料的制备、部分重熔和触变成形3个技术环节[1-3]。

半固态坯料的制备是触变成形的基础,制备方法目前已有很多,如机械搅拌、电磁搅拌、应变诱发熔化激活和喷射沉积等[1-3]。低过热度浇注法制备半固态坯料工艺简单,无需特殊设备,生产效率高,可大大降低坯料制备成本,近年来受到广泛关注[4-6]。

半固态坯料部分重熔在触变成形中具有承上启下作用,其目的首先是使坯料获得一定的液相分数,其次还要使坯料的非枝晶组织进一步转变为球形晶粒组织[2-3]。目前广泛采用的部分重熔工艺是在固液两相区范围内的等温二次加热工艺,SEO等[7-8]研究了坯料原始组织状态及其制备工艺对坯料等温部分重熔组织的影响,LIU等[9-11]研究了等温温度和保温时间对坯料等温部分重熔组织的影响。坯料部分重熔过程中,伴随着晶粒的球化,晶粒还会长大,在两相区等温加热虽然可实现长时间的保温,确保晶粒得到充分的球化,但晶粒粗化也十分明显,而晶粒粗化也会降低坯料的触变性能,同时还会恶化成形件的力学性能[12-14]。

本文作者采用低过热度浇注法制备半固态2024合金坯料,尝试将等温温度扩展到液相线以上温度对半固态坯料进行等温加热,研究等温温度对半固态坯料部分重熔组织的影响。

1 实验

实验材料为2024合金,用纯铝锭、纯镁锭、Al-50Cu和Al-10Mn合金熔炼配制,熔炼设备为15 kW电阻炉和石墨坩锅,熔炼温度为760 ℃。采用低过热度浇注法制备半固态坯料,熔体经精练、静止和扒渣后于650 ℃浇注到水冷铁模中,铸成40 mm×200 mm×200 mm的坯料。在ARL4460光电直读光谱仪上测定坯料成分为(质量分数,%):Cu 4.26,Mg 1.44,Mn 0.34,Si 0.085,Fe 0.105,Cr 0.002,Ni 0.008,Zn 0.011,Al 余量。坯料内部组织主要为细小的玫瑰状晶粒,如图1所示。坯料最后加工成d15 mm×20 mm的圆柱试样用于部分重熔实验。

图1 半固态2024合金坯料的原始组织

Fig.1 Original microstructure of semi-solid 2024 alloy billet

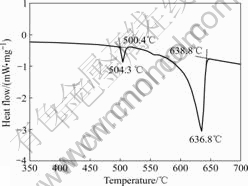

在NETZSCH STA449C综合热分析仪上对坯料进行差示扫描量热分析(DSC),DSC曲线如图2所示,采用外推始、终点法[15],确定坯料的固相线和液相线温度分别为500.4和638.8 ℃。根据DSC结果,选取等温温度分别为620、630、640和650 ℃。

图2 半固态2024合金坯料的DSC曲线

Fig.2 DSC curve of semi-solid 2024 alloy billet

二次加热设备为7 kW旋风箱式热处理炉。实验前在试样中心预先钻d 2 mm×10 mm的小孔,并插入K型热电偶用于测量试样温度变化,温度数据收集采用MCGS温度智能测控实验系统记录。热处理炉加热到预定温度后放入试样,并开始记录试样温度,到达预定的加热保温时间后取出试样水淬。

试样经磨制、抛光并用混合酸溶液(1 mL HF+1.5 mL HCl+2.5 mL HNO3+95 mL H2O)腐蚀后,在OLYMPUS金相显微镜下进行组织观察,用OLYCIA金相图像分析系统统计分析试样液相分数、晶粒的等积圆直径(2(A/π)1/2,A为晶粒截面积)和等效圆度(P2/(4πA),P为晶粒周长)。

2 结果与讨论

2.1 半固态2024合金的升温曲线

图3所示为半固态2024合金坯料分别在620、630、640和650 ℃等温加热时的升温曲线。由图可见,不同温度等温加热,坯料升温速度都是先快后慢。温度达到504 ℃后,由于共晶相的熔解吸热,曲线都出现一个短暂的平台,这与DSC结果一致(图2)。随后继续升温,由于α(Al)相开始熔解吸热以及坯料温度与炉温温差逐渐减小,升温速度都逐渐减慢,坯料温度最后都达到预定炉温开始进入等温保温。由图3还可看出,等温温度越高,坯料升温速度越快,相同加热时间时,坯料温度也越高。

图3 半固态2024合金坯料的等温加热升温曲线

Fig.3 Heating-up curves of semi-solid 2024 alloy billet isothermally reheated at various temperatures

2.2 等温温度对部分重熔组织的影响

图4~7所示为半固态2024合金坯料分别在620、630、640和650 ℃等温加热不同时间时的组织。坯料液相分数、晶粒平均等积圆直径和平均等效圆度随加热时间的变化曲线如图8所示。由图4~7可知,不同温度等温加热,坯料液相分数都随加热时间的延长而增加,首先是晶界上低熔点共晶相发生熔解,在晶间形成少量液相,随后固相晶粒外围发生部分熔解,液相继续增加。随着等温温度的提高,由于坯料升温速度加快以及坯料温度的提高,液相形成速度明显加快,相同加热时间时,坯料液相分数也越高。特别是等温温度提高到液相线以上640和650 ℃后,坯料重熔速度明显加快,低熔点共晶相迅速熔解,并通过固液界面溶质扩散促进固相晶粒外围的迅速熔解,导致液相分数迅速增加(见图8(a))。

图4 半固态2024合金坯料620 ℃等温加热不同时间时的组织

Fig.4 Microstructures of semi-solid 2024 alloy billet isothermally reheated at 620 ℃ for different times: (a) 30 min; (b) 60 min; (c) 120 min; (d) 180 min

图5 半固态2024合金坯料630 ℃等温加热不同时间时的组织

Fig.5 Microstructures of semi-solid 2024 alloy billet isothermally reheated at 630 ℃ for different times: (a) 30min; (b) 60 min; (c) 90 min; (d) 120 min

半固态坯料部分重熔,晶粒的长大和球化是固液界面张力作用下的一个自发过程,驱动力是系统界面自由能的降低[9-11]。低过热度浇注半固态2024合金坯料原始组织主要为细小的玫瑰状晶粒,圆整度较差 (见图1)。从图4~7可知,坯料在不同温度等温加热,由于同一玫瑰晶晶臂具有更加相匹配的晶粒位向[16],首先是玫瑰晶晶臂之间发生合并,其次是晶粒之间继续发生合并,导致晶粒数量迅速减少,而晶粒则迅速长大和等轴化。晶粒同时还发生Ostwald熟化,即在表面张力作用下,晶粒高曲率部位溶质发生熔解并向低曲率部位沉积,导致大晶粒继续长大,小晶粒则逐渐熔解变小甚至消失,而晶粒形态则逐渐趋于球 形[17]。从图4~7还可知,由于晶粒合并导致晶粒内部都包裹许多细小的液相池[18],随着加热时间的延长,晶内液相也通过扩散迁移而逐渐聚集长大。

从图8可知,不同温度等温加热,晶粒平均等积圆直径都随加热时间的延长而增大,加热初期大约前30 min,由于等温温度越高,坯料温度越高,晶粒长大速度随等温温度的提高略有加快,但30 min之后,晶粒长大速度则随等温温度的提高而逐渐下降(见图8(b))。晶粒平均等效圆度值随加热时间的延长而逐渐下降,且等温温度越高,晶粒平均等效圆度值下降速度越快。

图6 半固态2024合金坯料640 ℃等温加热不同时间时的组织

Fig.6 Microstructures of semi-solid 2024 alloy billet isothermally reheated at 640 ℃ for different times: (a) 20 min; (b) 40 min; (c) 60 min

图7 半固态2024合金坯料650 ℃等温加热不同时间时的组织

Fig.7 Microstructures of semi-solid 2024 alloy billet isothermally reheated at 650 ℃ for different times: (a) 20 min; (b) 30 min; (c) 40 min

图8 半固态2024合金坯料不同温度等温加热时液相分数、晶粒平均等积圆直径和平均等效圆度随加热时间的变化曲线

Fig.8 Variation curves of liquid fraction (a), grain average equal-circle diameter (b) and grain average equivalent roundness (c) with heating time of semi-solid 2024 alloy billet isothermally reheated at various temperatures

SANNES等

[2, 16]在研究半固态坯料部分重熔组织演化时发现,晶粒长大速率是随液相分数的增大而降低,并提出在低液相率时,晶粒合并是整个晶粒长大粗化的主要机制,而在高液相率时,晶粒Ostwald熟化是晶粒长大粗化的主要机制。这是因为晶粒的合并是强烈依赖于相邻晶粒之间的连接程度,液相分数越高,相邻晶粒数量则越少,晶粒之间的连接程度则越低,晶粒发生合并就越困难,从而导致晶粒长大速度下降。从图4~7可知,不同温度等温加热时,加热初期液相分数都比较低,晶粒通过合并导致晶粒都迅速长大,随着液相分数的增加,晶粒出现熔断分离,晶间液相相互贯通形成液相网络,晶粒之间的连接程度大大降低,即晶粒合并受到了一定的抑制,此时晶粒长大速度都逐渐下降(见图8(b))。

随着等温温度的提高,晶粒长大速度下降越快,坯料部分重熔后晶粒越细小,特别是当等温温度提高到液相线以上640和650 ℃以后,坯料重熔后晶粒明显细小,但晶粒圆度略有下降,作者认为这与等温温度越高,液相形成速度越快对晶粒合并抑制越早以及保温时间缩短有关。从图4可知,坯料在两相区温度620 ℃等温加热,液相形成速度比较缓慢,在加热初期相当长一段时间内,液相分数都比较低,晶粒连接紧密并互相堆砌,晶粒通过合并导致晶粒不断长大,而晶粒球化速度则十分缓慢,晶粒主要呈等轴状,随着液相明显增加后,晶粒再通过Ostwald熟化,晶粒逐渐趋于球形。620 ℃等温加热180 min后,此时大部分晶粒都已呈球形,但晶粒粗化也十分明显,部分晶粒尺寸达到200 μm以上(见图4(d))。从图5~7可看到,随着等温温度的提高,由于坯料升温速度加快以及坯料温度提高,液相形成速度逐渐加快,特别是当等温温度提高到液相线以上640和650 ℃以后,液相形成速度明显加快。一方面,液相形成速度加快,导致晶粒发生熔断分离越早,晶间液相网络形成越早,即晶粒合并长大受到抑制越早,从而降低了晶粒的长大速度;另一方面,等温温度越高,液相形成越快,加热保温时间则越短,因此,坯料重熔后晶粒越细小。

从图8(c)还可看到,随着等温温度的提高,晶粒平均等效圆度值下降越快,即晶粒球化速度越快。等温温度越高,液相形成速度越快。一方面,液相迅速增加导致晶粒迅速熔断分离,多边形晶粒因有较大的比表面积而具有较高的界面自由能,在表面张力作用下,晶粒迅速球化以降低界面自由能;另一方面,晶粒的Ostwald熟化是一个溶质扩散过程,温度越高,溶质扩散速度越快,因此,晶粒球化速度越快。当等温温度提高到液相线以上640和650 ℃后,虽然晶粒球化速度加快,但是由于保温时间大大缩短,晶粒未能获得充分的熟化,因此,重熔后晶粒球化程度整体上略有降低。

从上述分析可知,半固态金2024合金坯料部分 重熔,提高等温温度,不但可加快坯料液相形成速度,同时还可适当抑制晶粒的粗化并加速晶粒的球化,这对于进一步提高坯料的重熔效率、重熔后的触变性能以及成形件的力学性能都是有利的。但等温温度也不宜过高,否则,由于保温时间的大幅度缩短会导致晶粒球化程度的降低。

3 结论

1) 半固态2024合金等温加热,等温温度越高,坯料液相形成速度越快,部分重熔后晶粒越细小,但球化程度略有降低。

2) 适当提高坯料等温温度,加快液相形成速度对晶粒的合并长大具有一定的抑制作用,有利于部分重熔晶粒组织的细化和球化。

REFERENCES

[1] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J]. Metall Trans A, 1991, 22: 957-981.

[2] FAN Z. Semisolid metal processing[J]. Int Mater Rev, 2002, 47(2): 49-85.

[3] 罗守靖, 姜巨福, 杜之明. 半固态金属成形研究的新进展、工业应用及其思考[J]. 机械工程学报, 2003, 39(11): 52-60.

LUO Shou-jing, JIANG Ju-fu, DU Zhi-ming. New research development, industrial application and some thinking of semi-solid metal forming[J]. Chinese Journal of Mechanical Engineering, 2003, 39(11): 52-60.

[4] EASTON M A, KAUFMANN H, FRAGNER W. The effect of chemical grain refinement and low superheat pouring on the structure of NRC castings of aluminium alloy Al-7Si-0.4 Mg[J]. Mater Sci Eng A,2006, 420: 135-143.

[5] LASHKARI O, NAFISI S, GHOMASHCHI R. Microstructural characterization of rheo-cast billets prepared by variant pouring temperatures[J]. Mater Sci Eng A,2006, 441: 49-59.

[6] LIU Zheng, MAO Wei-min, ZHAO Zheng-duo. Effect of pouring temperature on semi-solid slurry of A356 Al alloy prepared by weak electromagnetic stirring[J]. Trans Nonferrous Met Soc China,2006, 16(1): 71-76.

[7] 李元东, 郝 远, 陈体军, 马 颖. 原始组织对半固态AZ91D镁合金重熔行为的影响[J]. 中国有色金属学报, 2004, 14(3): 366-371.

LI Yuan-dong, HAO Yuan, CHEN Ti-jun, MA Ying. Effects of different primary microstructure on melting behavior of semi-solid AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 366-371.

[8] SEO P K, KANG C G. The effect of raw material fabrication process on microstructural characteristics in reheating process for semi-solid forming[J]. J Mater Process Technol, 2005, 162(5): 402-409.

[9] 乐启炽, 崔建忠, 路贵民, 欧 鹏. 两相区铸造AZ91D半固态坯料的部分重熔工艺与组织演变[J]. 中国有色金属学报, 2003, 13(6): 1488-1493.

LE Qi-chi, CUI Jian-zhong, LU Gui-min, OU Peng. Microstructure evolution and partially remelting processing two-phase-region casting AZ91D semisolid slurry ingot[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1488-1493.

[10] MAO Wei-min, CUI Cheng-lin, ZHAO Ai-min, SUN Feng, ZHONG Xue-you. Dynamical coarsening processes of microstrucures in non-dendritic AlSi7Mg alloy remelted in semi-solid state[J]. Trans Nonferrous Met Soc China, 2000, 10(1): 25-28.

[11] 周 全, 杨院生, 唐军立, 胡壮麒. 脉冲电场下制备AZ91D 镁合金部分重熔过程的组织演变[J]. 中国有色金属学报, 2006, 16(8): 1417-1422.

ZHOU Quan, YANG Yuan-sheng, TANG Jun-li, HU Zhuang-qi. Microstructure evolution of magnesium alloy AZ91D prepared by electric current pulse discharge during partial remelting[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1417-1422.

[12] LASHKARI OMID, GHOMASHCHI R. The implication of rheology in semi-solid metal processes: An overview[J]. J Mater Process Technol,2007, 182(3): 229-240.

[13] PARK C, KIN S, LEE Y. Effect of microstructure on tensile behavior of thixoformed 357-T5 semisolid Al alloy[J]. Metall Mater Trans A, 2004, 35: 1407-1410.

[14] 谭建波, 邢书明, 李立新. 半固态A356合金微观组织特征对充型能力的影响[J], 中国有色金属学报, 2006, 16(4): 612-617.

TAN Jian-bo, XING Shu-ming, LI Li-xin. Influences of microstructure characteristics of semi-solid A356 alloy on filling ability[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 612-617.

[15] 刘振海, 徐国华, 张洪林. 热分析仪器[M]. 北京: 化学工业出版社, 2006.

LIU Zhen-hai, XU Guo-hua, ZHANG Hong-lin. Thermal analysis apparatus[M]. Beijing: Chemical Industry Press, 2006.

[16] TZIMAS E, ZAVALIANGOS A. Evolution of near-equiaxed microstructure in the semisolid state[J]. Mater Sci Eng A, 2000, 289: 228-240.

[17] KANG M K, KIM D Y, HWANG N M. Ostwald ripening kinetics of angular grains dispersed in a liquid phase by two-dimensional nucleation and abnormal grain growth[J]. J Euro Ceramic Soc,2002, 22(5): 603-612.

[18] CHEN T J, HAO Y, SUN J. Formation of liquid pools entrapped within solid grains of ZA27 alloys during partial remelting[J]. J Mater Sci Technol, 2002, 18(6): 481-483.

基金项目:中国博士后科学基金资助项目(20060400749);华南理工大学博士后创新科学基金资助项目

收稿日期:2007-09-11;修订日期:2007-12-22

通讯作者:王顺成,博士;电话:020-87112948-306;E-mail:wangsc76@sina.com

(编辑 何学锋)