高压扭转纳米结构Al-Mg铝合金的微观结构演变和位错组态

来源期刊:中国有色金属学报(英文版)2014年第12期

论文作者:刘满平 蒋婷慧 谢学锋 刘 强 李雪峰 Hans J. ROVEN

文章页码:3848 - 3857

关键词:Al-Mg铝合金;大塑性变形;高压扭转;位错组态;晶粒细化;变形机制

Key words:Al-Mg aluminum alloy; severe plastic deformation; high pressure torsion; dislocation configurations; grain refinement; deformation mechanism

摘 要:利用透射电镜(TEM)和高分辨透射电镜(HRTEM)研究高压扭转大塑性变形纳米结构Al-Mg合金的微观结构演变和位错组态。结果表明:对尺寸小于100 nm的晶粒,晶内无位错,其晶界清晰平直;而尺寸大于200 nm的大晶粒通常由几个亚晶或位错胞结构组成,其局部位错密度高达1017 m-2。这些位错是1/2á110?型60°位错,且往往以位错偶和位错环的形式出现。在高压扭转Al-Mg合金的超细晶晶粒中,用HRTEM同时观察到分别由0° 纯螺型位错和60° 混合位错分解产生的Shockley部分位错而形成的微孪晶和层错。这些直接证据证实,通常存在于FCC纳米晶中由晶界发射部分位错而产生孪晶和层错的变形机制,同样可以存在于超细晶FCC金属中。基于实验结果,分析了高压扭转Al-Mg合金中的局部高密度位错、位错胞、非平衡晶界、层错和孪晶等对晶粒细化的作用,提出了相应的晶粒细化机制。

Abstract: Microstructure evolution and dislocation configurations in nanostructured Al–Mg alloys processed by high pressure torsion (HPT) were analyzed by transmission electron microscopy (TEM) and high-resolution TEM (HRTEM). The results show that the grains less than 100 nm have sharp grain boundaries (GBs) and are completely free of dislocations. In contrast, a high density of dislocation as high as 1017 m-2 exists within the grains larger than 200 nm and these larger grains are usually separated into subgrains and dislocation cells. The dislocations are 60° full dislocations with Burgers vectors of 1/2á110? and most of them appear as dipoles and loops. The microtwins and stacking faults (SFs) formed by the Shockley partials from the dissociation of both the 60° mixed dislocation and 0° screw dislocation in ultrafine grains were simultaneously observed by HRTEM in the HPT Al–Mg alloys. These results suggest that partial dislocation emissions, as well as the activation of partial dislocations could also become a deformation mechanism in ultrafine-grained aluminum during severe plastic deformation. The grain refinement mechanism associated with the very high local dislocation density, the dislocation cells and the non-equilibrium GBs, as well as the SFs and microtwins in the HPT Al-Mg alloys were proposed.

Trans. Nonferrous Met. Soc. China 24(2014) 3848-3857

Man-ping LIU1, Ting-hui JIANG1, Xue-feng XIE1, Qiang LIU1, Xue-feng LI1, Hans J. ROVEN2,3

1. School of Materials Science and Engineering, Jiangsu Province Key Laboratory of Materials Tribology, Jiangsu University, Zhenjiang 212013, China;

2. Department of Materials Science and Engineering, Norwegian University of Science and Technology, Trondheim 7491, Norway;

3. Center for Advanced Materials, Qatar University, P.O. Box 2713, Doha, Qatar

Received 17 October 2013; accepted 5 November 2014

Abstract: Microstructure evolution and dislocation configurations in nanostructured Al–Mg alloys processed by high pressure torsion (HPT) were analyzed by transmission electron microscopy (TEM) and high-resolution TEM (HRTEM). The results show that the grains less than 100 nm have sharp grain boundaries (GBs) and are completely free of dislocations. In contrast, a high density of dislocation as high as 1017 m-2 exists within the grains larger than 200 nm and these larger grains are usually separated into subgrains and dislocation cells. The dislocations are 60° full dislocations with Burgers vectors of 1/2<110> and most of them appear as dipoles and loops. The microtwins and stacking faults (SFs) formed by the Shockley partials from the dissociation of both the 60° mixed dislocation and 0° screw dislocation in ultrafine grains were simultaneously observed by HRTEM in the HPT Al–Mg alloys. These results suggest that partial dislocation emissions, as well as the activation of partial dislocations could also become a deformation mechanism in ultrafine-grained aluminum during severe plastic deformation. The grain refinement mechanism associated with the very high local dislocation density, the dislocation cells and the non-equilibrium GBs, as well as the SFs and microtwins in the HPT Al-Mg alloys were proposed.

Key words: Al-Mg aluminum alloy; severe plastic deformation; high pressure torsion; dislocation configurations; grain refinement; deformation mechanism

1 Introduction

Over the last two decades, severe plastic deformation (SPD) techniques have been widely used to produce bulk nanostructured materials with unusual properties that are very attractive for various structural and functional applications [1-5]. It is well known that Al-Mg alloys belong to an important class of non-heat treatable alloys (the 5xxx series) [6]. Recent works have shown that Mg addition in SPD aluminium alloys enhances their properties such as the work hardening rate, dynamic strain aging effect, thermal stability, dislocation generation, grain refinement and thus the strength and ductility [7,8]. In addition, Al-Mg alloys are often used for studying the well-known serrated yielding or Portevin-Le  (PLC) effect and the associated plastic instabilities evident during tensile flow [9]. Therefore, the binary SPD Al–Mg alloys have attracted substantial interest, both for fundamental research and technological development. High pressure torsion (HPT) is one of the most promising SPD techniques because it has the potential to produce nanostructures with grain size less than 100 nm [10]. However, the genesis of the structural features in HPT-processed Al–Mg alloys is not yet fully understood. These features are quite complex and the presence of microtwins and stacking faults (SFs), non-equilibrium grain boundaries (GBs), full and partial dislocations, dipoles, severe lattice distortions and other nanostructures in these materials may have profound effects on the grain refinement and deformation mechanisms and the mechanical behavior [11-21].

(PLC) effect and the associated plastic instabilities evident during tensile flow [9]. Therefore, the binary SPD Al–Mg alloys have attracted substantial interest, both for fundamental research and technological development. High pressure torsion (HPT) is one of the most promising SPD techniques because it has the potential to produce nanostructures with grain size less than 100 nm [10]. However, the genesis of the structural features in HPT-processed Al–Mg alloys is not yet fully understood. These features are quite complex and the presence of microtwins and stacking faults (SFs), non-equilibrium grain boundaries (GBs), full and partial dislocations, dipoles, severe lattice distortions and other nanostructures in these materials may have profound effects on the grain refinement and deformation mechanisms and the mechanical behavior [11-21].

Deformation twinning has never been observed in coarse-grained aluminum either at high shock pressures or by deformation close to 0 K owing to its high stacking fault energy. But both simulations and experiments suggest that deformation twinning and SFs could occur in aluminum under certain circumstances (e.g. with a sufficiently small grain size). Deformation twinning in aluminum has been reported by YAMAKOV et al [13], who observed several deformation twins in molecular dynamics (MD) simulations of nanocrystalline aluminum under tensile deformation. ZHU et al [14] further provided direct experimental evidence confirming the MD predictions of deformation twinning in cryogenically ball-milled Al-7.6% Mg (mole fraction) alloy. At the same time our works also reported experimental observation of microtwins and SFs in HPT Al-Mg alloys [11,12]. However, it is still not very clear how the grain refinement and deformation mechanisms are related to the formation of the microtwins and SFs in the nanograined Al-Mg alloys.

Another important structural feature in nanostructured SPD materials is non-equilibrium GBs [1]. Non-equilibrium GB is a concept which was first initiated in 1970s by GRABSKI et al [4] and was experimentally confirmed by VALIEV et al [20] and HUANG et al [21]. VALIEV et al [2] suggested that non-equilibrium GBs in SPD metals may have a strong effect on grain-boundary processes such as sliding, diffusion/GB migration or interaction with lattice dislocations. Recent experiments demonstrated that non-equilibrium GB is capable of producing materials exhibiting extraordinary combinations of both high strength and high ductility [3]. Although the roles of non-equilibrium GBs in SPD metals are considered in a number of reports, there still maintains an unsatisfactory fit between this structural feature and the grain refinement/deformation mechanisms.

In the present work, three binary Al-Mg alloys and a commercial AA5182 alloy were subjected to HPT at room temperature. Microstructure evolution and dislocation configurations in the HPT processed materials were comparatively investigated by transmission electron microscopy (TEM) and high- resolution TEM (HRTEM). Grain refinement mechanism of the HPT Al-Mg alloys was proposed and deformation mechanism involved in the alloys during HPT was discussed according to the TEM observations.

2 Experimental

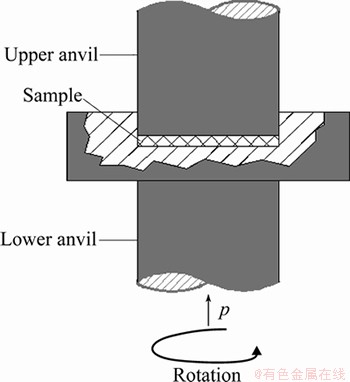

Three binary Al-Mg alloys (with 0.5%, 1.0% and 2.5% Mg) and a commercial AA5182 alloy (Al-4.1Mg- 0.35Mn-0.13Si-0.32Fe, %) were received as rods with diameter of 20 mm in the as-cast and homogenized condition. The samples cut from the rods with diameter of 20 mm and thicknesses of 0.5 and 2.0 mm were subjected to HPT to 5 and 10 turns, respectively, with a rotation speed of 1 r/min under a pressure of 6 GPa at room temperature (see Fig. 1). The deformed HPT samples had dimensions of 0.2 mm (5 turns) and 0.6 mm (10 turns) in thickness. Using the equations in Ref. [5], the calculated equivalent strains at the outer edge of the HPT samples were about 906 (5 turns) and 604 (10 turns). The structural features were performed by both conventional TEM and HRTEM with both JEM-2010 and JEOL-2010F TEM operated at 200 kV. The JEOL 2010F TEM was equipped with a field emission gun and scanning TEM detectors. This microscope has a point- resolution of 0.23 nm. Small disks with diameter of 3 mm for TEM were punched from the outer edge of these HPT samples. Thin TEM foils were prepared from the small disks by means of disc grinding, dimpling and finally ion polishing with Ar+ at an accelerating voltage of 3 kV.

Fig. 1 Schematic diagram of device used for high pressure torsion

3 Results and analysis

3.1 Deformation structures

The grain size and its distribution in the HPT Al–Mg alloys have been quantitatively measured by dark-field TEM technique in our previous work [6]. The average grain sizes of the HPT-processed Al-0.5Mg, Al-2.5Mg and AA5182 are about 265, 86 and 71 nm, respectively. For the HPT Al-0.5Mg alloy, the grain size varies from 50 to 580 nm. By comparison, the microstructure in the AA5182 alloy exhibits a grain size ranging in 10-180 nm. Theses results indicate that the size distributions in all the four alloys are not uniform and grains with different sizes coexist. The microstructures are characterized by a log-normal size distribution and the grain size distributions may become more uniform as the Mg content increases.

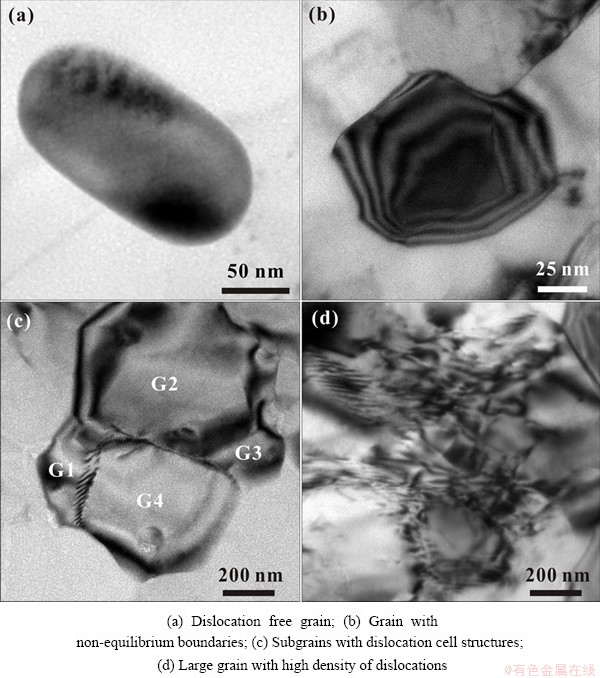

It is widely known that deformation structures in face-centered cubic (FCC) materials are very complex [12]. Different deformation structures such as dislocation-free grains, non-equilibrium GBs, dislocation cell and subgrain structures, low-angle GBs (LAGBs), high angle grain boundaries (HAGBs), stacking faults (SFs) and nanotwins may coexist in the HPT Al-Mg alloys. Figure 2 shows a typical deformed microstructure observed in the HPT Al-0.5Mg alloy together with a selected area diffraction (SAD) pattern. The pattern exhibits diffraction rings typical for nanostructured materials, indicating random orientations. The significant feature in the microstructure is that many grains with different sizes and orientations are simultaneously formed within a very large grain as highlighted with dotted lines in Fig. 2. Most of these grains are subgrains with dislocation cell structures and the GBs between these cell boundaries are LAGBs. Some GBs between very small grains with ~ 100 nm in size (as marked with the asterisks in Fig. 2) are HAGBs and these very small grains may have sharp grain boundaries and could be completely free of dislocations.

Fig. 2 TEM image of typical deformed microstructure observed in HPT Al-0.5Mg alloy together with SAD pattern

As mentioned above, the grains having a size less than 100 nm usually have sharp GBs and are free of dislocations. Another example of such grains observed in the HPT Al-1.0 Mg alloy is shown in Fig. 3(a). As seen in Fig. 3(a), it is apparent that these extremely fine grains have sharp boundaries and show a large difference in diffraction contrast with the neighboring grains. No dislocations, no subgrains or dislocation cell structures were clearly observed within these grains. It is suggested that the very small grains formed are grains separated by HAGBs and the grain interior and boundaries are free of dislocations and many of the grains have clearly defined boundaries. Such straight and narrow grain boundaries are believed to be in an equilibrium state and are HAGBs, which could have been formed by continuous dynamic recovery under large strain [19].

Another interesting feature in the deformed alloys is the non-equilibrium GBs which frequently were observed in the grains on the order of 100-500 nm. An example of such non-equilibrium GBs observed in the HPT Al-0.5 Mg alloy is shown in Fig. 3(b). In this micrograph the boundaries are curved and the inclined GB image contains light-and-dark broadened bands. This observation is very similar to the results reported in Refs. [16,18]. The strong spreading of thickness extinction contours in Fig. 3(b) indicates high elastic stresses near the non-equilibrium boundaries. Boundaries with high energy and long range stresses could be caused by the absorption of a large number of lattice dislocations [20].

As an important deformation structure, subgrains with dislocation cell structures were often found inside some larger grains of 100-1000 nm. A typical observation is shown in Fig. 3(c) observed in the HPT Al-1.0 Mg alloy, where the larger grain ~1000 nm is divided by sub-boundaries into four smaller subgrains with size of about 200 nm as marked G1-G4, respectively. As described further below, the misorientation across these cell boundaries increases with further plastic straining, and eventually becomes large enough to transform through LAGBs to HAGBs [21]. It should be noted that the GBs of the grain in Fig. 3(c) also have configurations of typical non- equilibrium GBs as seen in Fig. 3(b).

In addition, a number of larger grains with 200-1000 nm in size contain a high density of dislocations, suggesting that these larger grains are heavily strained. As shown in Fig. 3 (d) (HPT Al–1.0 Mg alloy), a high density of dislocations is clearly visible within the larger grains and the dislocation distribution is random and chaotic. These chaotically distributed dislocations are believed to be rearranged to form subgrains and dislocation cell structures with LAGBs during subsequent processing. It is interesting to note that the boundaries of the larger grains do not appear to be straight, but very irregular (see Fig. 3(d)). Such grains usually exhibit poor intergranular image contrast and the grain boundaries are very diffuse or non-homogeneous [18]. This indicates a high level of internal stress and elastic distortion in the crystal lattice due to the presence of a locally high dislocation density at the boundaries.

Fig. 3 TEM images of typical grain structures observed in HPT Al-Mg alloys

3.2 Dislocation configurations and grain boundary structures

As determined above by the quantitative X-ray diffraction (XRD) measurements, the average dislocation densities in the HPT alloys are in the range of 0.37×1014–4.97×1014 m–2 [6]. However, extensive HRTEM observations revealed that local dislocation densities at grain boundary and triple junction areas might be as high as 1017 m-2, which are 2-3 orders of magnitude larger than the average values. An example of such HRTEM results is shown in Fig. 4. These HRTEM images are observed from a GB area inside a 300 nm larger grain in the HPT Al–0.5Mg alloy. Figure 4(a) shows the  HRTEM image of the GB area with the fast Fourier transform (FFT) pattern inset transformed from this image and Fig. 4(b) shows an inverse Fourier image transformed from the FFT pattern in Fig. 4(a) using the (000) and pair of

HRTEM image of the GB area with the fast Fourier transform (FFT) pattern inset transformed from this image and Fig. 4(b) shows an inverse Fourier image transformed from the FFT pattern in Fig. 4(a) using the (000) and pair of  . As shown in Fig. 4(b), a very high density of dislocations is found near the GB. The local dislocation density measured from Fig. 4(b) is as high as 2.43×1017 m-2. The dislocations in Fig. 4(b) are 60° perfect dislocations on the

. As shown in Fig. 4(b), a very high density of dislocations is found near the GB. The local dislocation density measured from Fig. 4(b) is as high as 2.43×1017 m-2. The dislocations in Fig. 4(b) are 60° perfect dislocations on the  plane with Burgers vectors of 1/2<110>. Most dislocations in Fig. 4(b) appear as dipoles (marked by ellipses). The dipoles are in fact dislocation loops with elongation along one direction so that they look like a pair of single dislocations with opposite Burgers vectors [22]. In addition, interstitial loops (marked by black circles) and vacancy loops (marked by white circles) also exist near the GB (see Fig. 4(b)). The formation mechanism of the dipoles and their effect on plastic deformation is still unknown [23,24]. However, it is reasonable to believe that such dipoles could be formed due to a very high local stress resulted from the significant plastic deformation. The introduction of dipoles near GBs is likely to increase the stored elastic energy [25] and makes the GB energy higher.

plane with Burgers vectors of 1/2<110>. Most dislocations in Fig. 4(b) appear as dipoles (marked by ellipses). The dipoles are in fact dislocation loops with elongation along one direction so that they look like a pair of single dislocations with opposite Burgers vectors [22]. In addition, interstitial loops (marked by black circles) and vacancy loops (marked by white circles) also exist near the GB (see Fig. 4(b)). The formation mechanism of the dipoles and their effect on plastic deformation is still unknown [23,24]. However, it is reasonable to believe that such dipoles could be formed due to a very high local stress resulted from the significant plastic deformation. The introduction of dipoles near GBs is likely to increase the stored elastic energy [25] and makes the GB energy higher.

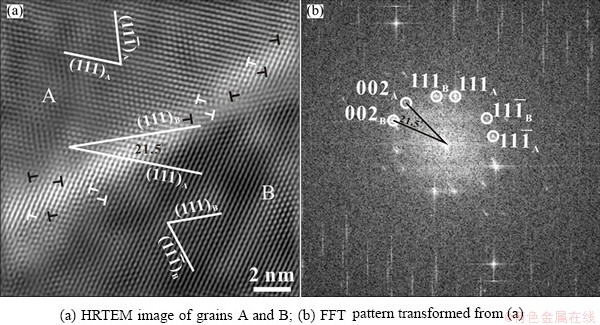

Our previous HRTEM observations have revealed that the LAGBs in the HPT alloys can be in either non-equilibrium or equilibrium state. As usual, the HAGBs in the conventional metals and alloys are believed to be in an equilibrium state and are equilibrium GBs. In fact, the equilibrium HAGBs also exist in the HPT alloys as a high order Σ=9 HAGB confirmed by HRETM in our previous work [12]. However, some special non-equilibrium HAGBs were frequently characterized by HRETM in the HPT alloys. An example of such non-equilibrium HAGBs is shown in Fig. 5. Figure 5 (a) shows an HRTEM  image observed in the HPT Al-0.5Mg alloy and Fig. 5(b) shows a FFT pattern directly transformed from the HRTEM image of Fig. 5(a). Note that dislocations on {111}A and {111}B planes in Fig. 5(a) are indicated with white and black ‘T’, respectively. As shown in Fig. 5, the GB plane is almost straight. The neighboring grains A and B share a common

image observed in the HPT Al-0.5Mg alloy and Fig. 5(b) shows a FFT pattern directly transformed from the HRTEM image of Fig. 5(a). Note that dislocations on {111}A and {111}B planes in Fig. 5(a) are indicated with white and black ‘T’, respectively. As shown in Fig. 5, the GB plane is almost straight. The neighboring grains A and B share a common  axis and have a misorientation of about 21.5°, which transcends the limiting angle 15° for that of a LAGB. It is clearly seen that many 60° dislocations with Burgers vector of the 1/2<110> type are present on two (111) planes at the GB. The Burgers vector of the GB dislocations is still a lattice vector, which is not the case for an HAGB [26]. In addition, the severe lattice distortion is also visible in the vicinity of the GB (see Fig. 5(a)). Therefore, it is reasonable to believe that such grains with so severe lattice distortion and extreme density of dislocations are still in a high energy state albeit the GB plane is almost straight. In other words, the HAGB between the two grains can be referred to as a non-equilibrium GB, which is in contrast to the equilibrium Σ=9 HAGB reported in our previous work [12].

axis and have a misorientation of about 21.5°, which transcends the limiting angle 15° for that of a LAGB. It is clearly seen that many 60° dislocations with Burgers vector of the 1/2<110> type are present on two (111) planes at the GB. The Burgers vector of the GB dislocations is still a lattice vector, which is not the case for an HAGB [26]. In addition, the severe lattice distortion is also visible in the vicinity of the GB (see Fig. 5(a)). Therefore, it is reasonable to believe that such grains with so severe lattice distortion and extreme density of dislocations are still in a high energy state albeit the GB plane is almost straight. In other words, the HAGB between the two grains can be referred to as a non-equilibrium GB, which is in contrast to the equilibrium Σ=9 HAGB reported in our previous work [12].

Fig. 4 HRTEM  images of HPT Al-0.5Mg alloy

images of HPT Al-0.5Mg alloy

Fig. 5 HRTEM  images of non-equilibrium HAGB in HPT Al-0.5Mg alloy

images of non-equilibrium HAGB in HPT Al-0.5Mg alloy

3.3 Extended dislocations and stacking faults

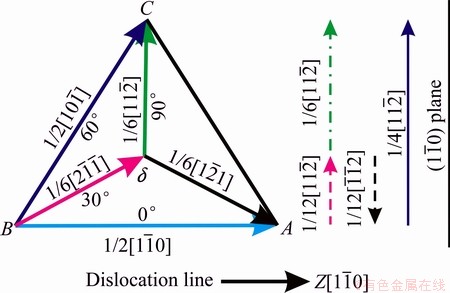

It is well known that Thompson tetrahedron is a convenient notation for describing all the perfect and partial dislocations and dislocation reactions in FCC metals [27]. In FCC metals, a perfect dislocation with Burgers vector of the 1/2<110> type usually dissociates into two Shockley partial dislocations with a stacking fault between them forming an extended dislocation [28]. The Shockley partials have Burgers vector of the 1/6<112> type. Assuming that the electron beam and the dislocation line are parallel to  , the end-on dislocation BC with Burgers vector 1/2

, the end-on dislocation BC with Burgers vector 1/2 has a 60° angle with the dislocation line and the end-on dislocation BA with Burgers vector 1/2

has a 60° angle with the dislocation line and the end-on dislocation BA with Burgers vector 1/2 is parallel to the dislocation line (see Fig. 6). Therefore, the perfect dislocations BC and BA are a 60° mixed dislocation and a 0° screw dislocation, respectively. Both the 60° mixed dislocation and the 0° screw dislocation can dissociate into two Shockley partials with a stacking fault. As shown in Fig. 6, the expression for the dissociation of a 60° dislocation 1/2

is parallel to the dislocation line (see Fig. 6). Therefore, the perfect dislocations BC and BA are a 60° mixed dislocation and a 0° screw dislocation, respectively. Both the 60° mixed dislocation and the 0° screw dislocation can dissociate into two Shockley partials with a stacking fault. As shown in Fig. 6, the expression for the dissociation of a 60° dislocation 1/2  will be

will be

1/2 → 1/6

→ 1/6 +1/6

+1/6  ,i.e., BC→Bδ+δC (1)

,i.e., BC→Bδ+δC (1)

where 1/6 and 1/6

and 1/6 are the Burgers vector of a 30° Shockley partial and a 90° Shockley partial, respectively. Correspondingly, the dissociation of a 0° screw dislocation 1/2

are the Burgers vector of a 30° Shockley partial and a 90° Shockley partial, respectively. Correspondingly, the dissociation of a 0° screw dislocation 1/2 is

is

1/2 →1/6

→1/6 +1/6

+1/6 , i.e., BA→Bδ+δA (2)

, i.e., BA→Bδ+δA (2)

where 1/6 and 1/6

and 1/6 are the Burgers vector of two 30° Shockley partials with the same magnitude but in different directions. In the dissociation process, stacking faults and twins can be formed [29].

are the Burgers vector of two 30° Shockley partials with the same magnitude but in different directions. In the dissociation process, stacking faults and twins can be formed [29].

Fig. 6 Thompson tetrahedron projected along Dδ

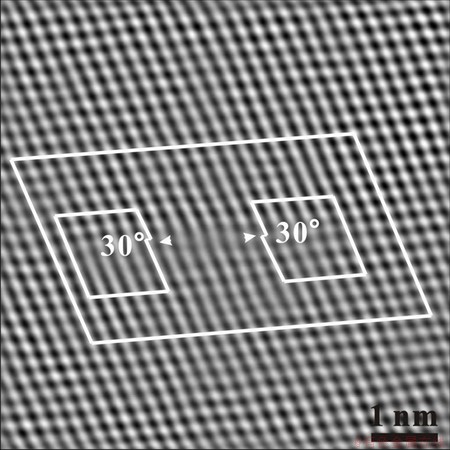

Interestingly, the above extended dislocations dissociated from both the 60° mixed dislocation and the 0° screw dislocation have been directly observed by HRTEM in the HPT Al-Mg alloys. Figure 7 shows a  HRTEM micrograph of an end-on extended dislocation dissociated from the 60° mixed dislocation observed inside a grain with a size of about 500 nm in the HPT AA5182 alloy. As shown in Fig. 7, when a Burgers circuit was drawn around the whole extended dislocation, i.e. involving both partials, one can get the Burgers vector projected onto the

HRTEM micrograph of an end-on extended dislocation dissociated from the 60° mixed dislocation observed inside a grain with a size of about 500 nm in the HPT AA5182 alloy. As shown in Fig. 7, when a Burgers circuit was drawn around the whole extended dislocation, i.e. involving both partials, one can get the Burgers vector projected onto the  plane to be 1/4

plane to be 1/4 . This Burgers vector is the projection of the 60° mixed dislocation onto the

. This Burgers vector is the projection of the 60° mixed dislocation onto the  plane as the solid-up-arrow line shown in right in Fig. 6. Therefore, it can be concluded that this extended dislocation was formed by a dissociation from a 60° dislocation with Burgers vector 1/2

plane as the solid-up-arrow line shown in right in Fig. 6. Therefore, it can be concluded that this extended dislocation was formed by a dissociation from a 60° dislocation with Burgers vector 1/2 . Note that the magnitude of the extended dislocation 1/4

. Note that the magnitude of the extended dislocation 1/4 b =(

b =( /4) a=0.2478 nm, where a (0.4049 nm) is the lattice parameter, which is almost equal to the spacing of {111} atomic planes, 0.2338 nm. Similarly, if Burgers circuits of the two Shockley partials, starting and ending at the fault, were drawn as indicated in Fig. 7. One can easily determine the 90° Shockley and 30° Shockley partials, respectively, by their projected vectors onto

/4) a=0.2478 nm, where a (0.4049 nm) is the lattice parameter, which is almost equal to the spacing of {111} atomic planes, 0.2338 nm. Similarly, if Burgers circuits of the two Shockley partials, starting and ending at the fault, were drawn as indicated in Fig. 7. One can easily determine the 90° Shockley and 30° Shockley partials, respectively, by their projected vectors onto  plane as indicated by the arrows in Fig. 7. The projected vectors of the two partials are 1/6

plane as indicated by the arrows in Fig. 7. The projected vectors of the two partials are 1/6 and 1/12

and 1/12 as shown by the dash-dot and dashed up-arrow lines in right in Fig. 6, respectively. According to the micrograph, it can be determined that a stacking fault between the two partials is formed and the width of the SF is about 5.0 nm.

as shown by the dash-dot and dashed up-arrow lines in right in Fig. 6, respectively. According to the micrograph, it can be determined that a stacking fault between the two partials is formed and the width of the SF is about 5.0 nm.

Fig. 7 HRTEM  image of end–on 60° dislocation dissociated into 30° and 90° partials, connected by stacking fault in HPT AA5182 alloy

image of end–on 60° dislocation dissociated into 30° and 90° partials, connected by stacking fault in HPT AA5182 alloy

An example of an end-on extended dislocation dissociated from the 0° screw dislocation is shown in Fig. 8. This  HRTEM micrograph was observed inside a grain with a size of about 200 nm in the HPT Al-2.5Mg alloy. The Burgers circuit around the whole extended dislocation in Fig. 8 reveals that the Burgers vector projected onto the

HRTEM micrograph was observed inside a grain with a size of about 200 nm in the HPT Al-2.5Mg alloy. The Burgers circuit around the whole extended dislocation in Fig. 8 reveals that the Burgers vector projected onto the  plane to be zero length. According to the Thompson tetrahedron in Fig. 6, the projection of the 0° screw dislocation onto the

plane to be zero length. According to the Thompson tetrahedron in Fig. 6, the projection of the 0° screw dislocation onto the  plane is zero. Therefore, it is reasonable to believe that the extended dislocation in Fig. 8 was formed by a dissociation from a 0° screw dislocation with Burgers vector 1/2

plane is zero. Therefore, it is reasonable to believe that the extended dislocation in Fig. 8 was formed by a dissociation from a 0° screw dislocation with Burgers vector 1/2 . When Burgers circuits of the two partials were drawn as indicated in Fig. 8, one can easily identify that the two partials are 30° Shockley partials. Their projected vectors onto the

. When Burgers circuits of the two partials were drawn as indicated in Fig. 8, one can easily identify that the two partials are 30° Shockley partials. Their projected vectors onto the  plane are 1/12

plane are 1/12 and 1/12

and 1/12 as shown by the dashed up-arrow and down-arrow lines in right in Fig. 6, respectively. The two Shockley partials are of the same magnitude but in opposite directions on the projection plane

as shown by the dashed up-arrow and down-arrow lines in right in Fig. 6, respectively. The two Shockley partials are of the same magnitude but in opposite directions on the projection plane  , as indicated by the arrows in Fig. 8. It is suggested that the stacking fault between the two partials is an intrinsic one [28] and the width of the SF is about 3 nm.

, as indicated by the arrows in Fig. 8. It is suggested that the stacking fault between the two partials is an intrinsic one [28] and the width of the SF is about 3 nm.

Fig. 8 HRTEM  image of end–on screw dislocation dissociated into two 30° partials, connected by stacking fault in HPT Al-2.5Mg alloy

image of end–on screw dislocation dissociated into two 30° partials, connected by stacking fault in HPT Al-2.5Mg alloy

4 Discussion

4.1 Grain refinement mechanism

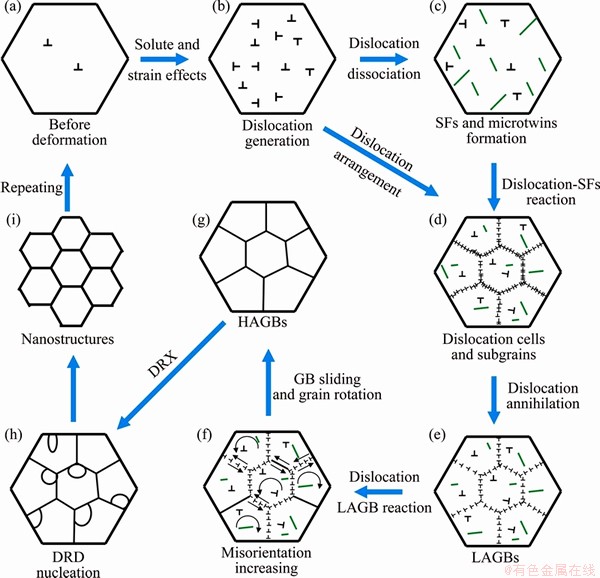

The mechanism of grain refinement of Al-Mg alloys during HPT can be illustrated in Fig. 9 based on both the present TEM observations and the mechanisms of grain refinement during SPD proposed in Refs. [30-34]. During the HPT processing with repeated turns, more and more dislocations are generated in grain interiors and at grain boundaries due to the solute effect and large strain (see Figs. 9(a) and (b)). As a result, dislocation cells and subgrains typical in the form of non-equilibrium GBs with excess dislocations appear within larger grains (see Fig. 2, Figs. 3(c) and (d), Fig. 5, Fig. 9(d)). At the same time, high-density SFs and microtwins (see Figs. 7 and 8) are formed inside grains and in the vicinity of GBs resulting from dissociated dislocations (see Fig. 9(c)). The formation of SFs and microtwins could also have a positive effect on the division of the grains/sub-grains (see Figs. 9(c) and (d)). As the dislocation density achieves some critical value with increasing strain, the misorientation across these sub-boundaries increases due to the dislocation annihilation/ accumulation (see Figs. 9(d) and (e)). When the density of the excess dislocations continuously rises with further plastic straining, the misorientation eventually becomes large enough to transform through LAGBs (see Fig. 9(e)) to HAGBs (see Fig. 9(f)) due to the interaction of LAGBs with dislocations and the planar defects. Simultaneously, the GB sliding and the grain rotation occurring during SPD further facilitates the transformation of LAGBs into HAGBs (see Figs. 9(f) and (g)). In addition, the HPT process would also engage deformation heating [35]. Once the local temperature is higher than the recrystallization temperature, dynamic recrystallization (DRX) takes place (see Fig. 9(h)). As a result, equiaxed nano-sized grains form in the regions where the highest strain is generated (see Fig. 9(j)).

Therefore, the grain refinement mechanism in these HPT alloys is summarized by the following sequent stages: 1) continuously generation of high-density dislocations resulting from the effects of solute and large strain; 2) grain division from repeated appearance of dislocation cells and subgrains with the help of the dislocation generation/reservoir; 3) formation of high-density SFs and microtwins with the dissociated dislocations; 4) gradual transformation of dislocation cells and subgrains through LAGBs into HAGBs due to dislocation annihilation/accumulation, the interaction of LAGBs with dislocations and the planar defects, as well as the GB sliding and the grain rotation occurring during SPD; 5) acquisition of equiaxed nano-sized grains as a result of both the grain division and dynamic recrystallization.

Fig. 9 Schematic illustration of grain refinement mechanism of Al-Mg alloys during HPT

4.2 Deformation mechanism

Both the present TEM observations and our previous works reveal that different deformation structures including dislocation-free grains, non- equilibrium GBs, dislocation cell and subgrain structures, LAGBs, HAGBs, SFs and nanotwins coexist in the HPT Al-Mg alloys. As such, the deformation mechanism of the Al-Mg alloys under HPT probably involves deformation twinning and stacking faults, GB sliding and grain rotation, as well as non-equilibrium GBs. In particular, deformation twinning and stacking faults are of great importance in grain refinement of Al-Mg alloys during HPT.

As suggested by the models of ASARO et al [36] and ZHU et al [37,38], as well as the MD simulations [39], deformation twinning and SFs resulting from partial dislocation emissions from GBs can only become a preferred deformation mode in nanocrystalline aluminum with grain sizes in the range of 10-50 nm. However, both the present HRTEM observations (see Figs. 7 and 8) and our previous works provide direct evidences of the activation of partial dislocations in ultrafine-grained (UFG) aluminum. The generation of partial dislocations from such GBs results in the formation of stacking faults and deformation twins within ultrafine grains as observed in the present alloy. These results suggest that partial dislocation emission from GBs in FCC metals could also become a deformation mechanism in UFG aluminum (e. g. 100-500 nm) during SPD.

5 Conclusions

1) The TEM and HRTEM observations in the HPT Al-Mg alloys show that the grains less than 100 nm have sharp GBs and are completely free of dislocations. In contrast, a high density of dislocation as high as 1017 m-2 exists within the grains larger than 200 nm and these larger grains are usually separated into subgrains and dislocation cells. The dislocations are 60° full dislocations with Burgers vectors of 1/2<110> and most of them appear as dipoles and loops.

2) The GBs in the HPT Al-Mg alloys can either be in the non-equilibrium or the equilibrium state. High angle non-equilibrium GBs with a high density of extrinsic dislocations are characterized by HRETM.

3) The microtwins and SFs formed by the Shockley partials from the dissociation of both the 60° mixed dislocation and 0° screw dislocation with Burgers vectors of 1/2<110> type have been simultaneously observed by HRTEM in ultrafine grains in the HPT Al-Mg alloys. These results suggest that microtwins and SFs formed by partials, as well as the activation of partial dislocations could also become a deformation mechanism in ultrafine-grained aluminum during SPD.

4) The roles of the very high local dislocation density, the dislocation cells and the non-equilibrium GBs, as well as the SFs and microtwins in grain refinement during HPT were analyzed and the grain refinement mechanisms associated with these structural features were proposed.

References

[1] SABIROV I, MURASHKIN M Y, VALIEV R Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development [J]. Mater Sci Eng A, 2013, 506: 1-24.

[2] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Prog Mater Sci, 2000, 45(2): 103-189.

[3] VALIEV R Z, Enikeev N A, LANGDON T G. Towards superstrength of nanostructured metals and alloys produced by SPD [J]. Kovove Mater, 2011, 49: 1-9.

[4] GRABSKI M W, KORSKI R. Grain boundaries as sinks for dislocations [J]. Philos Mag, 1970, 22: 707-715.

[5] ZHILYAEV A P, LANGDON T G. Using high-pressure torsion for metal processing: Fundamentals and applications [J]. Prog Mater Sci, 2008, 53(6): 893-979.

[6] LIU M P, ROVEN H J, MURASHKIN M Y, VALIEV R Z. Structure and mechanical properties of nanostructured Al-Mg alloys processed by severe plastic deformation [J]. J Mater Sci, 2013, 48: 4681-4688.

[7] ZHANG J W, STARINK M J, GAO N, ZHOU W L. Effect of Mg addition on strengthening of aluminium alloys subjected to different strain paths in high pressure torsion [J]. Mater Sci Eng A, 2011, 528(4-5): 2093-2099.

[8] ZHA M, LI Y J, MATHIESEN R H,  R, ROVEN H J. Achieve high ductility and strength in an Al-Mg alloy by severe plastic deformation combined with inter-pass annealing [J]. Mater Sci Eng A, 2014, 598: 141-146.

R, ROVEN H J. Achieve high ductility and strength in an Al-Mg alloy by severe plastic deformation combined with inter-pass annealing [J]. Mater Sci Eng A, 2014, 598: 141-146.

[9]  Z, CHINH N Q, LENDVAI J, HORITA Z, LANGDON T G. Effect of indentation size on plastic deformation processes in ultrafine-grained Al-3%Mg alloy [J]. Mater Sci Forum, 2002, 396(2): 1073-1078.

Z, CHINH N Q, LENDVAI J, HORITA Z, LANGDON T G. Effect of indentation size on plastic deformation processes in ultrafine-grained Al-3%Mg alloy [J]. Mater Sci Forum, 2002, 396(2): 1073-1078.

[10] LIU Man-ping, SUN Shao-chun, ROVEN H J, YU Ying-da, ZHANG Zhen, MURASHKIN M, VALIEV R Z. Deformation defects and electron irradiation effect in nanostructured Al-Mg alloy processed by severe plastic deformation [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1810-1816.

[11] LIU M P, ROVEN H J, MURASHKIN M, VALIEV R Z. Structural characterization by high-resolution electron microscopy of an Al-Mg alloy processed by high-pressure torsion [J]. Mater Sci Eng A, 2009, 503: 122-125.

[12] LIU M P, ROVEN H J, Liu X T, MURASHKIN M, VALIEV R Z,  T, BALOGH L. Special nanostructures in Al-Mg alloys subjected to high pressure torsion [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2051-2056.

T, BALOGH L. Special nanostructures in Al-Mg alloys subjected to high pressure torsion [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2051-2056.

[13] YAMAKOV V, WOLF D, PHILLPOT S R, GLEITER H. Dislocation-dislocation and dislocation-twin reactions in nanocrystalline Al by molecular dynamics simulation [J]. Acta Mater, 2003, 51(14): 4135-4147.

[14] ZHU Y T, LIAO X Z, WU X L. Deformation twinning in bulk nanocrystalline metals: Experimental observations [J]. JOM, 2008, 60(9): 60-64.

[15] LIU M P, ROVEN H J, YU Y D. Deformation twins in ultrafine grained commercial aluminum [J]. Int J Mater Res, 2007, 98(3): 184-190.

[16] LIU M P, ROVEN H J, YU Y D, WERENSKIOLD J C. Deformation structures in 6082 aluminium alloy after severe plastic deformation by equal-channel angular pressing [J]. Mater Sci Eng A, 2008, 483-484: 59-63.

[17] LIU M P, ROVEN H J. High density hexagonal and rhombic shaped nanostructures in a fcc aluminum alloy induced by severe plastic deformation at room temperature [J]. Appl Phys Lett, 2007, 90(8): 083115.

[18] SU J Q, NELSON T W, STERLING C J. Grain refinement of aluminum alloys by friction stir processing [J]. Philos Mag, 2006, 86: 1-24.

[19] KAIBYSHEV R, SHIPILOVA K, MUSIN F, MOTOHASHI Y. Continuous dynamic recrystallization in an Al-Li-Mg-Sc alloy during equal-channel angular extrusion [J]. Mater Sci Eng A, 2005, 396: 341-351.

[20] VALIEV R Z, GERTSMAN V Y, KAIBYSHEV O A. Grain boundary structure and properties under external influences [J]. Phys Status Solidi, 1986, 97(1): 11-51.

[21] HUANG J Y, ZHU Y T, JIANG H, LOWE T C. Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening [J]. Acta Mater, 2001, 49(9): 1497-1505.

[22] LIAO X Z, HUANG J Y, ZHU Y T, ZHOU F, LAVERNIA E J. Nanostructures and deformation mechanisms in a cryogenically ball-milled Al-Mg alloy [J]. Philos Mag, 2003, 83(26): 3065-3075.

[23] WU X L, MA E, ZHU Y T. Deformation defects in nanocrystalline nickel [J]. J Mater Sci, 2007, 42(5): 1427-1432.

[24] MA E, SHEN T D, WU X L. Nanostructured metals: Less is more [J]. Nature Mater, 2006, 5(7): 515-516.

[25] MURAYAMA M, HOWE J M, HIDAKA H, TAKAKI S. Atomic-level observation of disclination dipoles in mechanically milled, nanocrystalline Fe [J]. Science, 2002, 295: 2433-2435.

[26] HUANG J Y, LIAO X Z, ZHU Y T, ZHOU F, LAWERNIA E J. Grain boundary structure of nanocrystalline Cu processed by cryomilling [J]. Philos Mag, 2003, 83(12): 1407-1419.

[27] HULL D, BACON D J. Introduction to dislocations [M]. Oxford: Butterworth-Heinemann, 2001: 91.

[28] QIN L C, LI D X, KUO K H. An HREM study of the defects in ZnS [J]. Philos Mag A, 1986, 53: 543-555.

[29] WU X L, ZHU Y T. Partial-dislocation-mediated processes in nanocrystalline Ni with nonequilibrium grain boundaries [J]. Appl Phys Lett, 2006, 89: 031922.

[30] LIU M P, ROVEN H J, Liu X T,  T, BALOGH L, MURASHKIN M, VALIEV R Z. Grain refinement in nanostructured Al-Mg alloys subjected to high pressure torsion [J]. J Mater Sci, 2010, 45: 4659-4664.

T, BALOGH L, MURASHKIN M, VALIEV R Z. Grain refinement in nanostructured Al-Mg alloys subjected to high pressure torsion [J]. J Mater Sci, 2010, 45: 4659-4664.

[31] VALIEV R Z, ESTRIN Y, HORITA Z. Producing bulk ultrafine- grained materials by severe plastic deformation [J]. JOM, 2006, 58(4): 33-39.

[32] TAO N R, WU X L, SUI M L, LU J, LU K. Grain refinement at the nanoscale via mechanical twinning and dislocation interaction in a nickel-based alloy [J]. J Mater Res, 2004, 19: 1623-1629.

[33] SUN H Q, SHI Y N, ZHANG M X, LU K. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy [J]. Acta Mater, 2007, 55: 975-982.

[34] SAKAI T, BELYAKOV A, KAIBYSHEV R, MIURA H, JONAS J J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions [J]. Prog Mater Sci, 2014, 60: 130-207.

[35] ZHILYAEV A P, GARCIA-INFANTA J M, CARRENO F, LANGDON T G, RUANO O A. Particle and grain growth in an Al-Si alloy during high-pressure torsion [J]. Scripta Mater, 2007, 57: 763-765.

[36] ASARO R J, KRYSL P, KAD B. Deformation mechanism transitions in nanoscale fcc metals [J]. Philos Mag Lett, 2003, 83(12): 733-743.

[37] ZHU Y T, LIAO X Z, SRINIVASAN S G, ZHAO Y H, BASKES M I, ZHOU F, LAVERNIA E J. Nucleation and growth of deformation twins in nanocrystalline aluminum [J]. Appl Phys Lett, 2004, 85: 5049-5051.

[38] ZHU Y T, LIAO X Z, SRINIVASAN S G, LAVERNIA E J. Nucleation of deformation twins in nanocrystalline face-centered- cubic metals processed by severe plastic deformation [J]. Appl Phys Lett, 2005, 98: 034319.

[39] YAMAKOV V, WOLF D, PHILLPOT S R, GLEITER H. Deformation twinning in nanocrystalline Al by molecular-dynamics simulation [J]. Acta Mater, 2002, 50: 5005-5020.

刘满平1,蒋婷慧1,谢学锋1,刘 强1,李雪峰1,Hans J. ROVEN2, 3

1. 江苏大学 材料科学与工程学院,江苏省材料摩擦学重点实验室,镇江 212013;

2. Department of Materials Science and Engineering, Norwegian University of Science and Technology, Trondheim 7491, Norway;

3. Center for Advanced Materials, Qatar University, P.O. Box 2713, Doha, Qatar

摘 要:利用透射电镜(TEM)和高分辨透射电镜(HRTEM)研究高压扭转大塑性变形纳米结构Al-Mg合金的微观结构演变和位错组态。结果表明:对尺寸小于100 nm的晶粒,晶内无位错,其晶界清晰平直;而尺寸大于200 nm的大晶粒通常由几个亚晶或位错胞结构组成,其局部位错密度高达1017 m-2。这些位错是1/2<110>型60°位错,且往往以位错偶和位错环的形式出现。在高压扭转Al-Mg合金的超细晶晶粒中,用HRTEM同时观察到分别由0° 纯螺型位错和60° 混合位错分解产生的Shockley部分位错而形成的微孪晶和层错。这些直接证据证实,通常存在于FCC纳米晶中由晶界发射部分位错而产生孪晶和层错的变形机制,同样可以存在于超细晶FCC金属中。基于实验结果,分析了高压扭转Al-Mg合金中的局部高密度位错、位错胞、非平衡晶界、层错和孪晶等对晶粒细化的作用,提出了相应的晶粒细化机制。

关键词:Al-Mg铝合金;大塑性变形;高压扭转;位错组态;晶粒细化;变形机制

(Edited by Xiang-qun LI)

Foundation item: Project (BK2012715) supported by the Basic Research Program (Natural Science Foundation) of Jiangsu Province, China; Project (14KJA430002) supported by the Key University Science Research Project of Jiangsu Province, China; Project (50971087) supported by the National Natural Science Foundation of China, China; Projects (11JDG070, 11JDG140) supported by the Senior Talent Research Foundation of Jiangsu University, China; Project (hsm1301) supported by the Foundation of the Jiangsu Province Key Laboratory of High-end Structural Materials, China; Project (Kjsmcx2011004) supported by the Foundation of the Jiangsu Province Key Laboratory of Materials Tribology, China

Corresponding author: Man-ping LIU; Tel: +86-511-88780192; E-mail: manping-liu@263.net; manpingliu@ujs.edu.cn

DOI: 10.1016/S1003-6326(14)63542-1