DOI: 10.11817/j.issn.1672-7207.2021.04.007

基于Gabor小波的汽车金属材料表面微小缺陷快速识别

周李洪1, 2,龚金科2,李兵3

(1. 湖南大学 机械与运载工程学院,湖南 长沙,410082;

2. 湖南机电职业技术学院 汽车工程学院,湖南 长沙,410151;

3. 合肥工业大学 电气与自动化工程学院,安徽 合肥,30009)

摘要:引入Gabor小波方法去除光照干扰,实现汽车金属材料表面微小缺陷的快速识别。通过改进Otsu阈值分割法对缺陷图像进行分割,对缺陷图像实行进一步处理去除光照干扰;利用模拟测试法得到Gabor滤波器运行中的最佳参数,对样本汽车金属材料表面微小缺陷图像进行Gabor模板卷积操作,获取边缘图像;针对边缘图像实行加权马氏距离计算,对边缘轮廓特征进行增强;通过连通区域标记检索并标记汽车金属材料表面的缺陷,实现汽车金属材料表面微小缺陷的快速识别。研究结果表明:Gabor小波的缺陷识别方法缺陷识别率高,能够准确识别横向划伤、纵向划伤以及网纹等缺陷,具有较高的可行性。

关键词:Gabor小波;汽车金属材料;加权马氏距离;改进Otsu阈值分割

中图分类号:TG115 文献标志码:A

文章编号:1672-7207(2021)04-1099-10

Rapid identification of micro defects on surface of automotive metal materials based on Gabor wavelet

ZHOU Lihong1, 2, GONG Jinke2, Li Bing3

(1. School of Mechanical and Transportation Engineering, Hunan University, Changsha 410082, China;

2. School of Automotive Engineering, Hunan Mechanical and Electrical Polytechnic, Changsha 410151, China;

3. School of Electrical and Automation Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: Gabor wavelet method was introduced to remove the illumination interference and realize the rapid recognition of micro defects on the surface of automotive metal materials. The improved Otsu threshold segmentation method was used to segment the defect image, and the defect image was further processed to remove the light interference. The simulation test method was used to get the best parameters in the operation of Gabor filter, and the Gabor template convolution operation was performed on the sample automobile metal material surface micro defect image to obtain the edge image. The weighted Mahalanobis distance was calculated for the edge image, and the edge contour feature was enhanced. The defects on the surface of automotive metal materials were retrieved and marked by the connected region marking, so as to realize the rapid recognition of micro defects on the surface of automotive metal materials.The results show that the Gabor wavelet defect recognition method has high recognition rate, and can accurately identify the defects such as horizontal scratch, vertical scratch and mesh, so it has high feasibility.

Key words: Gabor wavelet; automotive metal materials; weighted Mahalanobis distance; improved Otsu threshold segmentation

在生产力水平迅速发展和工业技术、工艺水平不断提高的背景下,金属材料已广泛应用于社会发展的各个行业中,同时发挥了非常重要的作用。其中,汽车金属材料在加工时,会不可避免地出现一些缺陷,如铸造时生成的气孔、表层黏砂和夹砂等,还有锻造时的表层裂纹等。在材料整个使用周期中,在时间不断延长、气候和环境等一系列因素影响下,腐蚀和疲劳等不足也逐渐产生。此类缺陷会对材料整体使用寿命和力学特性等产生直接影响。一些微小缺陷的发展会造成材料失效同时出现断裂,因此,汽车金属材料表面微小缺陷的无损检测成为了急需解决的问题。国内无损检测起步相对较晚,但是整体发展很迅速。近年来,人们采用超声波、光声和机器视觉等多种手段进行了相应研究[1-2]。无损检测指的是以不破坏对象正常使用功能为前提条件,使用现代化技术与设备对因材料缺陷造成的异常进行检测,以此得到缺陷信息的检测技术,其能够减少及消除金属材料隐患。该技术为工业发展过程中不可或缺的有效工具,在提高生产力和促进国家发展中具有重要的现实意义[3-4]。李萍等[5]提出了一种基于深度学习的缺陷识别方法,通过卷积神经网络模型获得汽车金属材料表面缺陷特征,通过深度学习对汽车金属材料表面特征进行分析,提升了对汽车金属材料微小缺陷识别的适应性,但是缺陷类型判断效果不佳。兰红等[6]提出了三维灰度矩阵的汽车金属材料缺陷识别方法,通过图像灰度矩阵对样本图像空间特征进行分割,通过三维灰度矩阵构画等值线图,结合全局搜索与局部搜索方法确定材料表面凹凸区域位置,实现对微小裂纹缺陷精确定位。此方法能够有效提升缺陷识别率,但是抗干扰效果不佳。因此,为了有效地识别汽车金属材料表面缺陷,并进行及时处理,本文作者提出基于Gabor小波的汽车金属材料表面微小缺陷快速识别方法,利用Gabor小波技术对光照干扰进行处理,通过改进Otsu阈值分割方法对汽车金属材料表面微小缺陷图像进行分割,然后,通过Gabor模板卷积操作获取图像边缘,实现汽车金属材料表面微小缺陷的快速识别。

1 基于Gabor小波的汽车金属材料表面微小缺陷识别

1.1 汽车金属材料缺陷图像分割

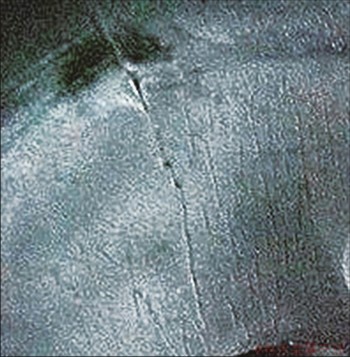

为了提取图像中的缺陷,首先对图像进行分割,引入Otsu阈值分割法对图像进行分割。该分割法可称作最大类间方差法,其运行原理为将原始图像基于灰度划分成目标与背景2个类别,同时使其类间的方差最大化。该算法的整个过程在图像一维直方图中执行。当获取图像一维直方图后,算法执行时与图像尺寸没有相关性,由此执行效率非常高。图1所示为汽车金属材料表面缺陷图。

图1 汽车金属材料表面缺陷图

Fig. 1 Surface defects of automotive metal materials

假设图像中灰度 的像素占据整个图像的比例为

的像素占据整个图像的比例为 ,整幅图像灰度均值

,整幅图像灰度均值 ,以

,以 为阈值对缺陷图像

为阈值对缺陷图像 进行分类,分别为

进行分类,分别为 和

和 ,2个类别占据的比例为

,2个类别占据的比例为

(1)

(1)

2个类别各自的灰度均值为

(2)

(2)

传统Otsu算法目标函数 是

是 和

和 这2个类别的类间方差,表示形式为

这2个类别的类间方差,表示形式为

(3)

(3)

式中: 为

为 类缺陷图像类别占比;

类缺陷图像类别占比; 为

为 类缺陷图像类别占比;

类缺陷图像类别占比; 为

为 类缺陷图像灰度初始值;

类缺陷图像灰度初始值; 为

为 类缺陷图像灰度初始值。

类缺陷图像灰度初始值。

能够使式(3)获取最大值的 就是分割阈值,从数学上证明式(3)最大化的目标函数

就是分割阈值,从数学上证明式(3)最大化的目标函数 的表达式为

的表达式为

(4)

(4)

其中,最佳阈值 可利用下式得到:

可利用下式得到:

(5)

(5)

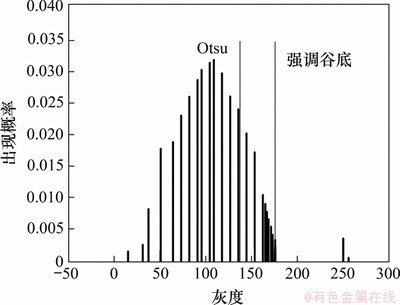

图2所示为缺陷图像的灰度直方图。从图2可以看出:直方图具有单峰性特征,不具备显著性双峰特征,使用Otsu算法获得的阈值通常不在谷底部位,因此,传统Otsu算法无法获取理想的图像分割结果。

图2 缺陷图像的灰度直方图

Fig. 2 Gray histogram of defect image

针对上述问题提出改进Otsu算法,对图像进行分割。汽车金属材料表面微小缺陷属于小目标,因此,表面缺陷在图像中占据的比例非常低,导致图像直方图呈近单峰特征。根据分割阈值处在谷底的特征,通过强调谷底条件下的改进Otsu算法实现图像分割。该算法与传统Otsu算法最大的不同体现在目标函数上,改进算法目标函数 的表示形式为

的表示形式为

(6)

(6)

由式(6)可知,该目标函数添加了权重参数 。其中,

。其中, 越小,则表示出现概率越小,其在目标函数中占据的权重就越大,由此该目标函数能够确保阈值一直处在谷底,使占据图像比例相对大的背景可以被忽视,占据比例较小的缺陷目标可以被提取[7-8]。

越小,则表示出现概率越小,其在目标函数中占据的权重就越大,由此该目标函数能够确保阈值一直处在谷底,使占据图像比例相对大的背景可以被忽视,占据比例较小的缺陷目标可以被提取[7-8]。

综上可知,改进Otsu算法执行步骤如下。

步骤1:遍历图像中所有像素,统计图像一维灰度,并对各灰度出现概率进行计算。

步骤2:遍历所有灰度 ,利用式(6)计算相应目标函数。

,利用式(6)计算相应目标函数。

步骤3:在所有目标函数中寻找最大值,该最大值相应灰度 就是分割阈值。

就是分割阈值。

步骤4:将灰度比阈值低的像素灰度设置成0,剩下灰度设置为255,获取分割之后汽车金属材料表面图像的二值化图像。

1.2 缺陷识别

对上述缺陷图像进行分割后,将Gabor小波与马氏距离法结合,可快速识别汽车金属材料表面微小缺陷。

1.2.1 Gabor小波变换

Gabor滤波器(带通滤波器)具有频率选择与方向选择等特征。因Gabor小波变换窗口函数为1个固定值,假设将小波函数用在变换过程中,能够以高分辨率分析频域与时间域[9-10]。图像的边缘特征为畸变像素点构成的集合,Gabor小波函数能够捕捉到对应空间部位、频率及方向选择性的像素数据对缺陷边缘进行识别。利用Gabor小波实现缺陷识别,不仅可以去除噪声,而且可以很好地保留缺陷纹理特征。

利用直接由频域构建Gabor小波二维的卷积模板,提取相同尺度下的8个方向上特征图像实现二维边缘图像重构[11]。

假设在笛卡尔坐标系中,方向和尺度分别为 和

和 的二维Gabor小波函数

的二维Gabor小波函数 表示形式为

表示形式为

(7)

(7)

式中: ,代表图像的像素点坐标;

,代表图像的像素点坐标; 代表相应值欧式范数[12];

代表相应值欧式范数[12]; 为图像像素点的散布函数;

为图像像素点的散布函数; 为高斯窗口波长变化函数,它能够控制高斯窗口整体宽度、振荡部分波长和方向。

为高斯窗口波长变化函数,它能够控制高斯窗口整体宽度、振荡部分波长和方向。

(8)

(8)

式中: 为滤波器采样频率;

为滤波器采样频率; 为最大的采样频率;

为最大的采样频率; 为频域范围内核函数间隔因子[13];

为频域范围内核函数间隔因子[13]; ,

, 为图像灰度函数,该值反映了滤波器整体方向选择性。

为图像灰度函数,该值反映了滤波器整体方向选择性。

根据式(7)可知,Gabor小波函数 为

为 上的一个复值函数[14],

上的一个复值函数[14], 为缺陷图像像素离散域,

为缺陷图像像素离散域, 为缺陷图像类间方差集合,利用实部

为缺陷图像类间方差集合,利用实部 、虚部

、虚部 有

有

(9)

(9)

式中: 为利用Gabor小波函数和图像

为利用Gabor小波函数和图像 之间卷积所得虚部函数。设定图像中1点

之间卷积所得虚部函数。设定图像中1点 ,利用Gabor小波描述

,利用Gabor小波描述 位置周边图像特征,则缺陷图像卷积函数

位置周边图像特征,则缺陷图像卷积函数 可表示为

可表示为

(10)

(10)

其中: 代表卷积操作;

代表卷积操作; 为点

为点 位置汽车金属材料表面微小缺陷图像卷积。在图像边缘定义中,

位置汽车金属材料表面微小缺陷图像卷积。在图像边缘定义中, 为图像周边像素灰度的阶跃变化,或者是屋顶状变化像素构建的集合,图像边缘点为一种信号突变点或者奇异点[15-16],因此,能够利用下式描述图像Gabor特征集合

为图像周边像素灰度的阶跃变化,或者是屋顶状变化像素构建的集合,图像边缘点为一种信号突变点或者奇异点[15-16],因此,能够利用下式描述图像Gabor特征集合 ,即

,即

(11)

(11)

根据上述Gabor小波特性,该集合 能够捕捉图像不同频率和方向下边缘,还有局部明显特征,此类突变或奇异点构成的组合就是目标缺陷区域。

能够捕捉图像不同频率和方向下边缘,还有局部明显特征,此类突变或奇异点构成的组合就是目标缺陷区域。

1.2.2 马氏距离法

马氏距离法能够描述数据协方差距离,为得到2个未知样本集合相似程度的可靠方法。因汽车金属材料微小缺陷存在的特征,传统欧式距离法仅对图像中2点间距离进行计算,结果误差较大,容易受外界干扰[17]。当协方差矩阵为 时,缺陷图像中随机2点x和y的马氏距离函数服从正态分布。针对根据

时,缺陷图像中随机2点x和y的马氏距离函数服从正态分布。针对根据 个样本

个样本 构建的样本空间

构建的样本空间 ,

, 为样本在空间的分布密度,随机样本点和样本均值

为样本在空间的分布密度,随机样本点和样本均值 之间马氏距离

之间马氏距离 的计算式为

的计算式为

(12)

(12)

其中:

(13)

(13)

(14)

(14)

利用马氏距离能够增强图像边缘像素点的基本特征,并使缺陷兴趣区域像素点变得更为显著。传统马氏距离只是对整个图像协方差矩阵进行计算,对于兴趣区域、背景图像不进行划分,并且夸大了变化比较微小的像素,导致误检率较高[18]。经综合考虑,采用加权马氏距离实现图像增强处理。

在样本空间范围内, 为特征维数,则当原灰度样本点和样本均值

为特征维数,则当原灰度样本点和样本均值 时,将相关参数代入式(12),获得马氏距离计算公式:

时,将相关参数代入式(12),获得马氏距离计算公式:

(15)

(15)

式中: 为灰度矩阵。

为灰度矩阵。

如果 为正定阵,那么存在

为正定阵,那么存在 使式(16)成立:

使式(16)成立:

(16)

(16)

式中: 为

为 的特征值;

的特征值; 列向量是对应单位特征向量;

列向量是对应单位特征向量; 为缺陷图像边缘像素特征向量。综上,

为缺陷图像边缘像素特征向量。综上, 维空间范围内的点

维空间范围内的点 与样本均值

与样本均值 之间加权马氏距离表达式为

之间加权马氏距离表达式为

(17)

(17)

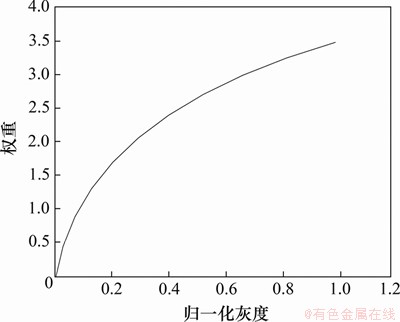

加权之后图像中不同像素点权重见图3。

图3 加权后图像中不同像素点权重

Fig. 3 Weighting values of different pixels in weighted image

分析图3可知:归一化灰度与权重具有相关性,当归一化灰度为0.2时,权重为1.5,当归一化灰度为0.6时,权重为3.0;归一化灰度越大,权重增加越缓慢。

1.2.3 缺陷识别

在缺陷识别过程中,先对图像实行预处理,其中包含图像均衡化以及同态滤波等,以此去除光照产生的影响。利用模拟测试法得到Gabor滤波器运行中的最佳参数,对样本汽车金属材料表面微小缺陷图像进行Gabor模板卷积操作,获取边缘图像。针对边缘图像进行加权马氏距离计算,增强边缘轮廓特征。最后通过连通区域标记,检索并同时标记汽车金属材料表面的缺陷,实现缺陷识别。

综合Gabor滤波器自身组成特性,选择运行参数时,一般考虑的是频域空间[19-20]。在此,利用模拟试验机法,从整体到局部,设定在其他参数均为最优的前提下,剖析单个因素对图像边缘纹理产生的影响。其中,对Gabor函数提取图像边缘产生影响的主要参数包含卷积模板尺寸、最大的采样频率和空间频率以及滤波器模板大小等。

在Gabor卷积模板尺寸选择中,当模板由16像素*16像素顺次增加到128像素*128像素时,对应的滤波器形状也会发生变化。在Gabor卷积模板范围不断增加下,对应Gabor卷积核非零部分变得越来越小,表示其提取到的特征不断趋向细节特征。由此,要基于具体应用选取合适Gabor核函数窗。

假设最大样本采集频率为 ,那么得到的边缘纹理非常细腻,特征十分显著,但是容易受到噪声影响;假设空间频率为

,那么得到的边缘纹理非常细腻,特征十分显著,但是容易受到噪声影响;假设空间频率为 ,那么得到的边缘纹理相对模糊,且细节特征显著性不强。因此,实验确定最大样本采集频率为

,那么得到的边缘纹理相对模糊,且细节特征显著性不强。因此,实验确定最大样本采集频率为 ,而空间频率取为

,而空间频率取为 。

。

当滤波器尺度(滤波算子的空间作用范围,对于高斯类算子指其均方差)相对小,则提取到的特征比较细腻,但受噪声影响。在尺度不断增加下,边缘细节会逐渐丢失,还会产生偏移现象。除此之外,多尺度会大大增加整体计算量。

加权马氏距离在阈值化之后,得到的边缘存在细微毛刺,利用设定阈值将毛刺去除会出现误检毛刺。经模拟可知,若阈值过小则会导致得到的边缘较粗糙,增加了误检率。若阈值过大,则导致边缘过于细腻,漏检率会偏高,并且容易受噪声影响。经测试,最佳阈值约为0.6。

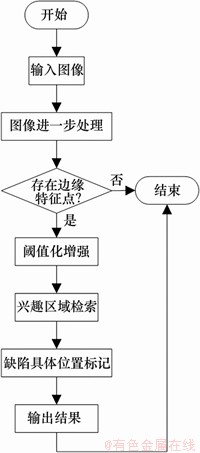

在缺陷图像分割基础上,进行如下步骤。

步骤1:输入带有缺陷并分割完成的图像,对图像进行进一步处理。

步骤2:构建二维Gabor小波函数。在指定尺度和不同方向下,构建8个方向上的Gabor卷积模板,并针对各方向下模板和缺陷图像进行Gabor卷积操作,得到8个卷积图像,然后利用逆滤波实现图像复原,获取Gabor提取到的边缘图像。

步骤3:利用步骤2得到汽车金属材料表面微小缺陷边缘图像,对总灰度均值 进行计算。得到图像各像素点灰度

进行计算。得到图像各像素点灰度 ,并构建权重函数。对加权像素数据集合进行计算,对协方差矩阵进行重新估计。

,并构建权重函数。对加权像素数据集合进行计算,对协方差矩阵进行重新估计。

步骤4:基于加权马氏距离计算式获取任意灰度样本和总样本之间差值,以增强图像边缘特征。

步骤5:利用连通区域标记法实现兴趣区域检索和标注。引入2次扫描法,在第一次扫描时赋予不同 值,二次扫描时对相邻连通区域

值,二次扫描时对相邻连通区域 值进行同化。最后在原图像中标记缺陷具体位置。图4所示为缺陷识别流程示意图。

值进行同化。最后在原图像中标记缺陷具体位置。图4所示为缺陷识别流程示意图。

图4 缺陷识别流程示意图

Fig. 4 Schematic diagram of defect identification

2 实验结果与分析

在验证基于Gabor小波的汽车金属材料表面微小缺陷快速识别方法有效性过程中,将实验平台搭建在Matlab上,对汽车空调压缩机表面缺陷进行实验检测,以验证所提技术实用性。压缩机缸体由灰铁(N0.35)铸造而成,其长×宽×高为370 mm×230 mm×180 mm。实验数据来源于某汽车生产厂家,共采集了横向划伤、纵向划伤和网纹等几种缺陷图像数据,原始图像像素为732×287。为了实验方便,在原始图像中截取128×128带有缺陷的区域,共得样本为1 356个,其中1个样本中可能含有多种类型缺陷。

2.1 缺陷识别结果

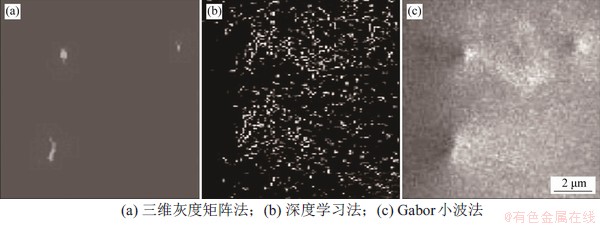

为了验证缺陷识别效果,采用三维灰度矩阵法、深度学习法以及Gabor小波法对汽车金属材料缺陷进行识别,得到放大10 000倍后的电镜识别结果如图5所示。

图5 不同方法的缺陷识别效果

Fig. 5 Defect recognition effect of different methods

由图5可知:采用不同方法所得检索效果不同。采用三维灰度矩阵法识别出的缺陷图像清晰度明显较低,只能在检测结果中看见较为明显的3个缺陷,但是缺陷是凹陷还是凸起无法确定,缺陷识别效果不佳;采用深度学习法识别出的缺陷图像比较模糊,可能是受到了噪声的影响,缺陷识别效果较差。而图5(c)中的缺陷识别图像结果清晰度较高,能够有效确定缺陷位置,同时可以区分缺陷类型,说明Gabor小波法具有较好的识别效果。

2.2 缺陷识别正确率对比

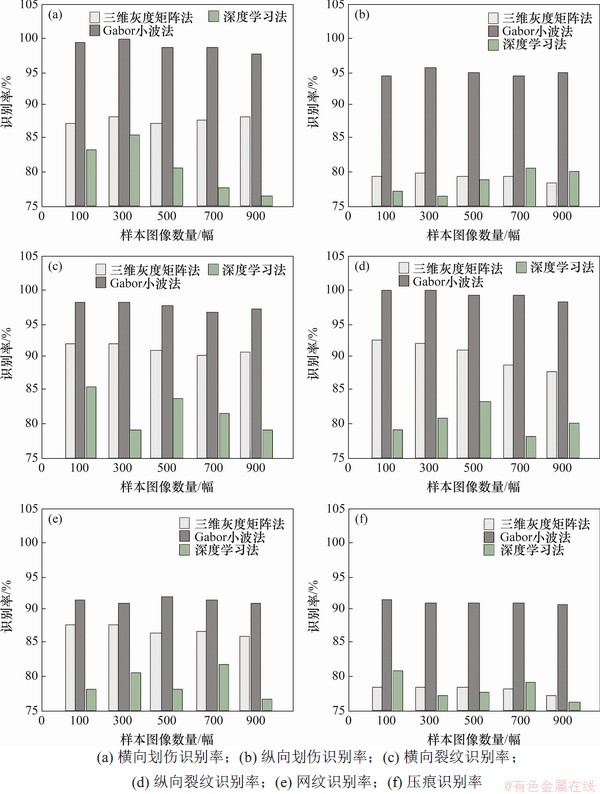

利用不同方法对比结果验证所提方法正确性,所得结果见图6。

图6 缺陷识别正确率

Fig. 6 Defect recognition accuracy

由图6(a)可知:采用不同方法所得横向划伤识别率不同;当样本图像数量为100幅时,三维灰度矩阵法的横向划伤识别率为87%,Gabor小波法的横向划伤识别率为99.5%,深度学习法的横向划伤识别率为83%;当样本图像数量增加到900幅时,三维灰度矩阵法的横向划伤识别率为89%,Gabor小波法的横向划伤识别率为98%,深度学习法的横向划伤识别率为77%。采用本文方法所得横向划伤识别率一直较高。

由图6(b)可知:不同方法的纵向划伤识别率不同;当样本图像数量为300幅时,三维灰度矩阵法的纵向划伤识别率为79%,Gabor小波法的纵向划伤识别率为94.9%,深度学习法的纵向划伤识别率为77%;当样本图像数量增加到900幅时,三维灰度矩阵法的纵向划伤识别率为78%,Gabor小波法的纵向划伤识别率为95%,深度学习法的纵向划伤识别率为80%。本文方法的纵向划伤识别率较高。

由图6(b)~(f)可知:本文方法的横向裂纹识别率、纵向裂纹识别率、网纹识别率以及压痕识别率比其他2种传统方法的高,说明这种方法很好地解决了由于微小变化导致的误检问题,增强了汽车金属材料表面微小缺陷边缘特征,提高了缺陷识别率。

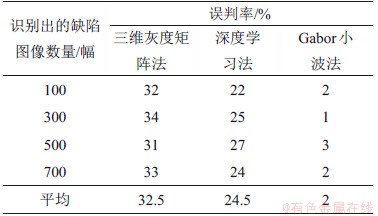

在上述基础上检测不同方法对金属缺陷的误判率,结果如表1所示。

表1 不同方法的缺陷误判率

Table 1 Defect misjudgment rates by different methods

由表1可知:当识别出的缺陷图像数量为100幅时,三维灰度矩阵法的缺陷误判率为32%,深度学习法的缺陷误判率为22%,Gabor小波法的缺陷误判率为1%;在700幅缺陷图像中,三维灰度矩阵法的平均缺陷误判率为32%,深度学习法的平均缺陷误判率为22%,Gabor小波法的平均缺陷误判率为1%。采用本文方法所得缺陷误判率比其他2种方法的低,缺陷识别效果好。

2.3 缺陷识别用时对比

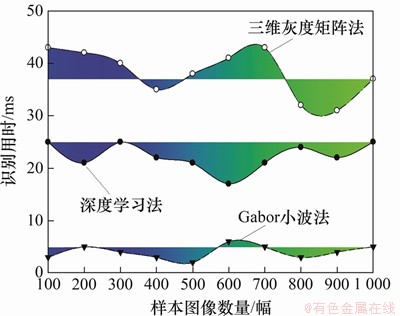

采用sigmaplot软件获得上述3种方法的缺陷识别用时,结果如图7所示。

图7 缺陷识别用时

Fig. 7 Defect identification time

由图7可知:当样本图像数量为200幅时,三维灰度矩阵法的缺陷识别用时为42 ms ,深度学习法的缺陷识别用时为21 ms,Gabor小波法的缺陷识别用时为5 ms;当样本图像数量为800幅时,三维灰度矩阵法的缺陷识别用时为32 ms ,深度学习法的缺陷识别用时为24 ms,Gabor小波法的缺陷识别用时为3 ms。本文方法的缺陷识别用时始终较短,说明本文方法的识别效率最高,实现了汽车金属材料表面微小缺陷快速识别。

3 结论

1) 汽车金属材料缺陷高精度检测是提高车辆质量的必要手段,为此,提出基于Gabor小波的汽车金属材料表面微小缺陷快速识别方法。以图像分割结果为基础,结合Gabor小波和加权马氏距离,实现缺陷识别。

2) 采用本文方法所得缺陷识别图像结果清晰度较高,能够有效确定缺陷位置,同时可以区分缺陷类型,说明Gabor小波法具有较好的识别效果。

3) 本文方法的横向裂纹识别率、纵向裂纹识别率、网纹识别率以及压痕识别率都明显高于其他2种传统方法,有效地解决了由于微小变化导致的误检问题,增强了汽车金属材料表面微小缺陷边缘特征,提升了缺陷识别率。

参考文献:

[1] 李茂东, 林晓辉, 杨波, 等. 非金属防腐层分层缺陷超声导波检测[J]. 中国测试, 2018, 44(6): 22-27.

LI Maodong, LIN Xiaohui, YANG Bo, et al. Detection on delamination damage of nonmetallic erosion resistant coating based on ultrasonic guided waves[J]. China Measurement & Test, 2018, 44(6): 22-27.

[2] 王琦, 张超. 模式识别的汽车轮毂铸件缺陷检测技术研 究[J]. 铸造技术, 2017, 38(12): 2889-2891.

WANG Qi, ZHANG Chao. Research on defects detection technology of automobile hub casting based on pattern recognition[J]. Foundry Technology, 2017, 38(12): 2889-2891.

[3] 汤勃, 孔建益, 伍世虔. 机器视觉表面缺陷检测综述[J]. 中国图象图形学报, 2017, 22(12): 1640-1663.

TANG Bo, KONG Jianyi, WU Shiqian. Review of surface defect detection based on machine vision[J]. Journal of Image and Graphics, 2017, 22(12): 1640-1663.

[4] 张驰, 栾亦琳, 罗志伟, 等. 扩散焊接头缺陷超声C扫描检测能力分析[J]. 焊接学报, 2016, 37(9): 83-86.

ZHANG Chi, LUAN Yilin, LUO Zhiwei, et al. Analysis of ultrasonic C-scan detectability on diffusion bonding joint[J]. Transactions of the China Welding Institution, 2016, 37(9): 83-86.

[5] 李萍, 宋波, 毛捷, 等. 深度学习在超声检测缺陷识别中的应用与发展[J]. 应用声学, 2019, 38(3): 458-464.

LI Ping, SONG Bo, MAO Jie, et al. Application and development of defect recognition using deep learning in ultrasonic testing[J]. Journal of Applied Acoustics, 2019, 38(3): 458-464.

[6] 兰红, 方治屿. 3维灰度矩阵的钢板缺陷图像识别[J]. 中国图象图形学报, 2019, 24(6): 859-869.

LAN Hong, FANG Zhiyu. Image recognition of steel plate defects based on a 3D gray matrix[J]. Journal of Image and Graphics, 2019, 24(6): 859-869.

[7] 唐庆菊, 刘俊岩, 王扬, 等. 基于模糊C均值聚类和Canny算子的红外图像边缘识别与缺陷定量检测[J]. 红外与激光工程, 2016, 45(9): 281-285.

TANG Qingju, LIU Junyan, WANG Yang, et al. Infrared image edge recognition and defect quantitative determination based on the algorithm of fuzzy C-means clustering and Canny operator[J]. Infrared and Laser Engineering, 2016, 45(9): 281-285.

[8] 高世鹰, 王东, 倪培君, 等. 基于涡流技术的铝合金焊丝表面缺陷在线检测系统研究[J]. 兵器材料科学与工程, 2016, 39(5): 120-124.

GAO Shiying, WANG Dong, NI Peijun, et al. On-line detection technology of surface defects for high performance aluminum alloy welding wire[J]. Ordnance Material Science and Engineering, 2016, 39(5): 120-124.

[9] 黄刚. 基于超声透射时差法的金属棒缺陷检测研究[J]. 仪器仪表学报, 2016, 37(4): 818-826.

HUANG Gang. Research on defect detection system for material based on ultrasonic transmission method[J]. Chinese Journal of Scientific Instrument, 2016, 37(4): 818-826.

[10] 田舒平, 解瑞东, 李涤尘, 等. 激光金属成形缺陷在线检测方法及热场仿真[J]. 西安理工大学学报, 2019, 35(2): 212-218.

TIAN Shuping, XIE Ruidong, LI Dichen, et al. A defects detection method for laser metal deposition and thermal fields simulation[J]. Journal of Xi'an University of Technology, 2019, 35(2): 212-218.

[11] 张振林, 范孟豹, 曹丙花, 等. 碳纤维复合材料分层缺陷的超声相控阵检测方法[J]. 科学技术与工程, 2018, 18(18): 43-47.

ZHANG Zhenlin, FAN Mengbao, CAO Binghua, et al. Characterization of delamination defects in carbon fiber reinforced plastics using ultrasonic phased array testing[J]. Science Technology and Engineering, 2018, 18(18): 43-47.

[12] 余力, 吕俊男, 杜伟, 等. 金属材料三维断裂韧度厚度效应的有限元模拟[J]. 固体力学学报, 2018, 39(2): 170-181.

YU Li, LU Junnan, DU Wei, et al. The elucidation of thickness effect of three-dimensional fracture toughness by using the finite element method[J]. Chinese Journal of Solid Mechanics, 2018, 39(2): 170-181.

[13] 甄光楠, 付振坡, 毕殿阁, 等. 钢锭轧制材料分层缺陷形成机理及控制研究[J]. 炼钢, 2019, 35(4): 71-75.

ZHEN Guangnan, FU Zhenpo, BI Diange, et al. Study on formation mechanism and control of layered defects in ingot rolling materials[J]. Steelmaking, 2019, 35(4): 71-75.

[14] 李新城, 唐永春, 朱伟兴, 等. 超细晶钢热轧板表面开裂型缺陷成因探析及其表征与控制[J]. 材料热处理学报, 2016, 37(9): 100-104.

LI Xincheng, TANG Yongchun, ZHU Weixing, et al. Surface crack defect analysis of hot-rolled ultra-fine grain slab and its characterization and control[J]. Transactions of Materials and Heat Treatment, 2016, 37(9): 100-104.

[15] 孙博学, 刘骁, 龚先政, 等. 汽车用金属材料的生态设计实践[J]. 中国材料进展, 2016, 35(3): 197-204.

SUN Boxue, LIU Xiao, GONG Xianzheng, et al. Practicing eco-design in metal materials for automobile[J]. Materials China, 2016, 35(3): 197-204.

[16] BIAN Wenjuan, LIN Yue, WANG Ting, et al. Direct identification of surface defects and their influence on the optical characteristics of upconversion nanoparticles[J]. ACS Nano, 2018, 12(4): 3623-3628.

[17] ZHANG Hui, JIN Xiating, WU Q M J, et al. Automatic visual detection system of railway surface defects with curvature filter and improved Gaussian mixture model[J]. IEEE Transactions on Instrumentation and Measurement, 2018, 67(7): 1593-1608.

[18] ZHENG Xiaoling. Automatic identification technology for surface defects of aluminum castings based on machine vision[J]. Journal of Liming Vocational University, 2018(3): 78-83.

[19] 李海洋, 李巧霞, 王召巴, 等. 金属材料表面缺陷的激光超声检测技术[J]. 火力与指挥控制, 2019, 44(8): 61-64.

LI Haiyang, LI Qiaoxia, WANG Zhaoba, et al. Study on laser ultrasonic testing of metal material surface defects[J]. Fire Control & Command Control, 2019, 44(8): 61-64.

[20] 高兴宇, 钟平, 李志松, 等. 基于自模板重构与NSCT的汽车内饰件表面缺陷检测方法研究[J]. 计算机应用与软件, 2019, 36(3): 57-61.

GAO Xingyu, ZHONG Ping, LI Zhisong, et al. Surface defect detection of automobile interior parts based on self-template reconstruction and nsct[J]. Computer Applications and Software, 2019, 36(3): 57-61.

(编辑 刘锦伟)

收稿日期: 2020 -06 -21; 修回日期: 2020 -08 -03

基金项目(Foundation item):国家自然科学基金资助项目(51777050);湖南省自然科学基金资助项目(2019JJ70064) (Project(51777050) supported by the National Natural Science Foundation of China; Project(2019JJ70064) supported by the Natural Science Foundation of Hunan Province)

通信作者:龚金科, 教授, 博士生导师, 从事动力机械及工程学科研究; E-mail: gongjinke@126.com

引用格式: 周李洪, 龚金科, 李兵. 基于Gabor小波的汽车金属材料表面微小缺陷快速识别[J]. 中南大学学报(自然科学版), 2021, 52(4): 1099-1108.

Citation: ZHOU Lihong, GONG Jinke, Li Bing. Rapid identification of micro defects on surface of automotive metal materials based on Gabor wavelet[J]. Journal of Central South University(Science and Technology), 2021, 52(4): 1099-1108.