DOI: 10.11817/j.issn.1672-7207.2020.02.005

Cu质量分数对Al-1.0Mg-1.0Si-0.6Mn合金显微组织和性能的影响

刘名鑫1, 2,邓运来1, 3,张臻2, 3,唐建国1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 轻合金研究院,湖南 长沙,410083;

3. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:利用硬度测试、室温拉伸实验、晶间腐蚀实验、电化学腐蚀实验、SEM和TEM等方法,研究Cu质量分数对Al-1.0Mg-1.0Si-0.6Mn合金显微组织与性能的影响。研究结果表明:随着Al-1.0Mg-1.0Si-0.6Mn合金中Cu质量分数由0.01%逐渐增加至1.12%,其达到峰值时效所需时间逐渐减少,且峰值时效(T6态)硬度明显增加;随着Cu质量分数的增加,峰时效状态合金的抗拉强度由357.7 MPa逐渐增加至452.2 MPa,抗拉强度提升94.5 MPa,这是因为随着Cu质量分数增加,晶内析出相数量逐渐增多且尺寸逐渐减小,使得沉淀强化效果逐渐增强;Cu质量分数增加使粗大相AlFeMnSi的数量逐渐增加,腐蚀电流密度显著增大,合金的断后伸长率和抗晶间腐蚀性能呈下降趋势。

关键词:Cu质量分数;Al-1.0Mg-1.0Si-0.6Mn合金;抗拉强度;析出相;抗晶间腐蚀性能;粗大相

中图分类号:TG146.2+1;TG115.5 文献标志码:A

文章编号:1672-7207(2020)02-0309-10

Effect of Cu mass fraction on microstructures and properties of Al-1.0Mg-1.0Si-0.6Mn alloys

LIU Mingxin1, 2, DENG Yunlai1, 3, ZHANG Zhen2, 3, TANG Jianguo1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Light Alloy Research Institute, Central South University, Changsha 410083, China;

3. State Key Laboratory of High Performance Complex Manufacturing, Central South University,Changsha 410083, China)

Abstract: The effect of Cu mass fraction on the microstructures and properties of Al-1.0Mg-1.0Si-0.6Mn alloy was studied by means of hardness test, tensile test, intergranular corrosion test, electrochemical corrosion test, SEM and TEM. The results show that the time required to reach peak aging decreases gradually and the hardness in T6 status increases obviously with the increase of Cu mass fraction. The tensile strength increases from 357.7 MPa to 452.2 MPa, i. e. the strength increases by 94.5 MPa. The reason is that the number of precipitates in the alloys increases and the size of precipitates becomes smaller gradually with the increase of Cu mass fraction, which enhances the precipitation-strengthening effect. However, the number of the coarse phases such as AlFeMnSi increases gradually and the corrosion current density increases dramatically. The elongation rate after fracture and the intergranular corrosion resistance of the alloys show a descending trend.

Key words: Cu mass fraction; Al-1.0Mg-1.0Si-0.6Mn alloy; tensile strength; precipitated phase; intergranular corrosion resistance; coarse phase

在全球节能减排和环境保护的背景下,结构材料的轻量化已经成为趋势[1]。Al-Mg-Si合金 (6000系列)是一种可热处理强化铝合金,具有密度低、强度中等、耐蚀性能优良、焊接性能和成型性能好等优点,在建筑、航空航天、交通等领域有着广泛的应用[2-3]。而现今社会各领域对轻质材料的需求量不断增加,6000系列铝合金有望成为轻质结构材料的首选材料[1]。随着现代科技的发展,建筑、军工、航空航天、轨道交通等领域对于轻质材料的综合性能提出了越来越高的要求,这就需要开发出高性能铝合金并对其进行优化。研究表明,合理的热处理制度及合金元素Cu可以提高Al-Mg-Si合金的综合性能[4-5]。关于合金元素Cu对Al-Mg-Si合金的作用,国内外已经有很多研究,其中主要涉及添加Cu之后合金的析出序列研究、析出相结构研究[6-8]。如CHAKRABARTI等[7]研究了Al-Mg-Si合金和Al-Mg-Si-Cu合金的相平衡、亚稳相及析出序列,发现当这些合金包含一定Cu元素时,平衡相中会出现Q相,在析出过程中出现Q'相。DING等[8]认为Cu加入6000系合金中,其脱溶序列为:过饱和固溶体→原子团簇→GP区→β'',L/S/C,QP,QC→β',Q'→Q。其中亚稳相Q'主要出现在过时效阶段,呈板条状,L相为Q'的预析出相,对硬化效果有显著影响。也有研究者认为Cu元素可大幅度改善合金的时效硬化行为,金曼等[9]将透射电镜与三维原子探针结合,研究了Cu元素对Al-Mg-Si合金时效过程中富Cu原子团簇的形成及长大的影响,结果表明Cu元素的存在促进了合金时效初期GP区的形成,加快了时效硬化行为。虽然Cu元素对铝合金的影响一直是国内外研究热点,且Cu元素对6000系铝合金的影响已有一定研究[6-9],但添加Cu的质量分数一般不超过0.6%,而本文在Al-1.0Mg-1.0Si-0.6Mn合金的基础上最多添加了质量分数为1.1%的Cu,这就为高质量分数Cu元素对6000系铝合金组织和性能的影响的研究提供了一定参考。为了适应人们对于高性能6000系铝合金的需求,本文作者以Al-1.0Mg-1.0Si-0.6Mn合金热轧板材为对象,研究Cu质量分数对Al-1.0Mg-1.0Si-0.6Mn合金的力学性能及腐蚀性能的影响,并通过扫描电镜、透射电镜等显微观察技术,分析Cu质量分数的变化对Al-1.0Mg-1.0Si-0.6Mn合金显微组织的影响并揭示其性能变化机理,以期为进一步优化6000系铝合金提供指导。

1 实验

1.1 实验材料和热处理工艺

实验采用合金的名义成分为Al-1.0Mg-1.0Si-xCu-0.60Mn-0.20Fe(x=0,0.20%,0.60%,1.10%,质量分数)。以纯度为99.2%的工业纯铝、纯度为99.0%的纯镁、Al-50Cu以及Al-30Si和75%Mn剂等中间合金为原料,制备Cu质量分数不同的4种合金,得到合金实际化学成分如表1所示。将4种合金铸锭经520 ℃均匀化退火处理24 h后,在550 ℃下由40.0 mm厚热轧成3.5 mm厚的板材,空冷至室温,然后在550 ℃下固溶处理1 h并淬火至室温,最后对4种合金板材进行180 ℃人工时效处理。

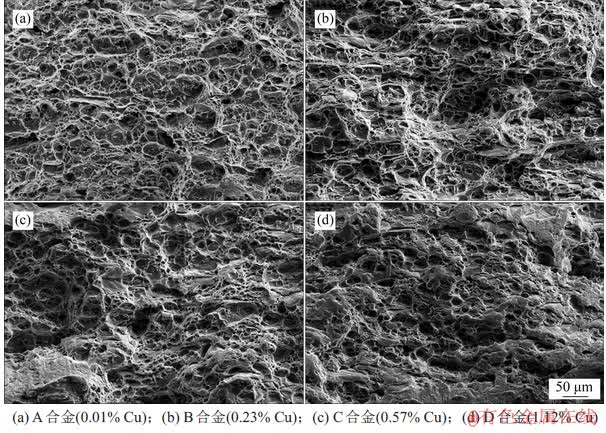

表1 实验合金的实际化学成分(质量分数)

Table 1 Actual chemical composition of alloys %

1.2 实验方法

分别对4种合金板材人工时效过程进行维氏硬度测试,硬度测试在200 HVS-5型显微硬度计上进行,试验载荷为29.4 N,加载时间为15 s,每个样件每次测试5个点,取其平均值作为测定结果。

室温拉伸参照GB/T 228.1—2010标准执行,在DDL-100电子万能拉伸机上进行室温拉伸试验,拉伸速率为2 mm/min;晶间腐蚀试验参照ASTM G110标准执行,将试样浸泡在标准晶间腐蚀溶液(57 g/L NaCl+10 mL/L H2O2+H2O)中,实验温度为35 ℃,浸泡时间为24 h,而后取出水洗吹干,并在OLYMPUS GX71金相显微镜下沿横截面观察晶间腐蚀深度;采用Multi Autolab M204电化学工作站测量循环极化曲线(cyclic polarization curve),试样的电化学测试采取三电极体系,以试样为工作电极,以Pt片作为辅助电极,饱和甘汞电极(SCE)为参比电极。试样的电化学测试面积为1 cm2,电化学测试介质为3.5%(质量分数)的NaCl溶液,实验温度为25 ℃。循环极化曲线扫描电位的范围为-1.3~0 V。

采用ZEISS MA10扫描电子显微镜(SEM)观察室温拉伸断口形貌及板材材料的第二相分布。在TECNAI G2 20型透射电子显微镜下对合金材料的析出相进行微观观察,其中加速电压为200 kV,将试样打磨至薄样后采用电解双喷减薄,其中双喷液为30%硝酸(HNO3)+70%甲醇(CH3OH)混合液(体积分数)。本文中室温拉伸、晶间腐蚀、电化学腐蚀、SEM和TEM试样均取峰值时效(T6)状态时的试样。

2 实验结果

2.1 力学性能

2.1.1 时效硬化行为

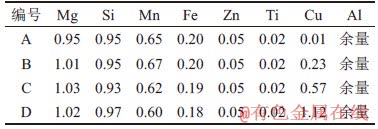

图1所示为不同Cu质量分数的4种合金淬火后立即进行180 ℃人工时效处理的硬化曲线。从图1可以看出:随时效时间增加,4种合金均呈现出相似规律,即在3~10 h时效初期阶段维氏硬度(HV)达到峰值,随后合金维氏硬度开始缓慢降低,进入过时效阶段;除此之外,Cu质量分数对合金的峰值硬度和峰值时间有显著的影响,A,B,C和D合金峰值维氏硬度分别为105.6,117.6,129.6和136.7,硬度逐渐升高,达到峰值的时间分别为8,6,5和3 h,峰值时效时间提前,即硬化速率得到提高。这说明随Cu质量分数增加,合金的时效硬化行为可得到提高。

图1 180 ℃时效处理后合金硬度变化曲线

Fig. 1 Hardness curves of different alloys aged at 180 ℃

2.1.2 室温拉伸

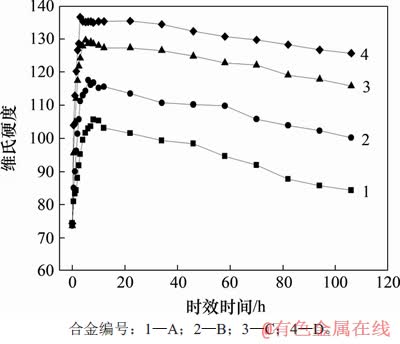

图2所示为不同Cu质量分数的4种合金T6状态下的室温拉伸曲线及拉伸性能。由图2可知:在T6状态下,A,B,C和D合金的抗拉强度分别达到357.7,392.3,431.1和452.2 MPa,屈服强度分别为342.5,374.3,394.7和398.8 MPa,伸长率分别为13.7%,12.1%,11.7%,11.0%。可见:随着Cu质量分数的增加,合金的抗拉强度和屈服强度均逐渐提高,而其断后伸长率减小。

图2 不同Cu质量分数合金的室温拉伸曲线及拉伸性能

Fig. 2 Tensile curves and tensile properties of alloys with different Cu mass fractions at room temperature

2.1.3 拉伸断口分析

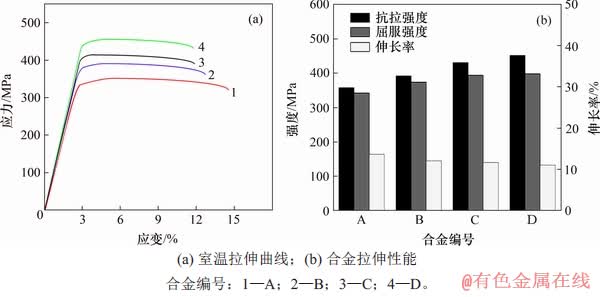

图3所示为不同Cu质量分数合金室温拉伸断口的SEM图片。从图3可以得出:整体来看,不同Cu质量分数的实验合金的室温拉伸断口上分布着大小、深浅不一的韧窝,均属于典型的韧性断裂。当Cu质量分数较低时(Cu质量分数分别为0.01%和0.23%),断口表面大部分都是一些均匀的韧窝,具有韧性断裂的特征,A合金断口表面几乎都由较深的韧窝占据,且部分大韧窝里面包含小韧窝;B合金表面的韧窝相比A合金较少较浅;Cu质量分数较高的C和D合金(Cu质量分数分别为0.57%和1.12%),其断口表面韧窝边缘出现一些台阶状撕裂棱,开始具备一些脆性断裂的特征,但还是以韧性断裂为主,而Cu质量分数最高的D合金比C合金撕裂棱的面积更大,说明Cu质量分数为1.12%的D合金的脆性断裂程度比Cu质量分数为0.57%的C合金大。总的来说,随着Cu质量分数的增加,实验合金韧窝所占的比例越来越小,且韧窝变得越来越浅,说明Cu质量分数的增加反而降低了合金的塑性,这与室温拉伸结果中伸长率的变化规律一致。

图3 不同Cu质量分数合金拉伸断口SEM照片

Fig. 3 SEM images of tensile fracture of alloys with different Cu mass fractions

2.2 腐蚀性能

2.2.1 晶间腐蚀

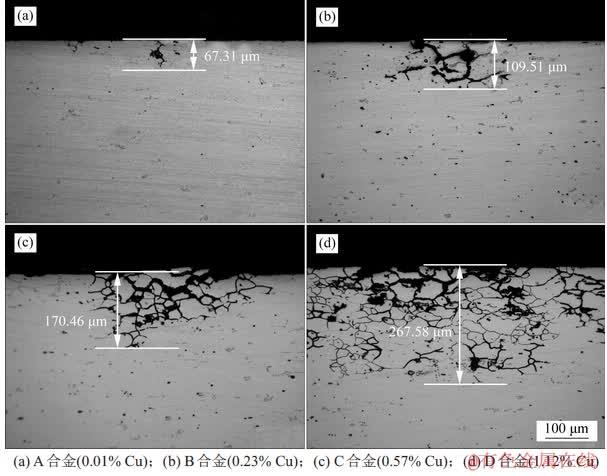

Cu质量分数不同的4种T6态合金的晶间腐蚀试样在金相显微镜下的断面观察如图4所示。从图4可以看出:4种合金均发生了不同程度的晶间腐蚀现象。随着Cu质量分数的增加,腐蚀沿晶界扩展,且逐渐深入合金内部,晶间腐蚀程度越来越大,特别是D合金(Cu质量分数为1.12%),整个视野内均呈现晶间腐蚀现象;且部分晶粒开始脱落。对4种合金的最大腐蚀深度进行测量可知:A,B,C和D合金的最大腐蚀深度分别为67.31,109.51,170.46和267.58 μm,最大腐蚀深度逐渐增大。结合4种合金的腐蚀特征可以得出:Cu质量分数对Al-Mg-Si合金的晶间腐蚀抗性产生显著影响,随Cu质量分数增加,合金的抗晶间腐蚀性能下降。

图4 晶间腐蚀实验后合金断面照片

Fig. 4 Cross-sectional pictures of alloys after intergranular corrosion test

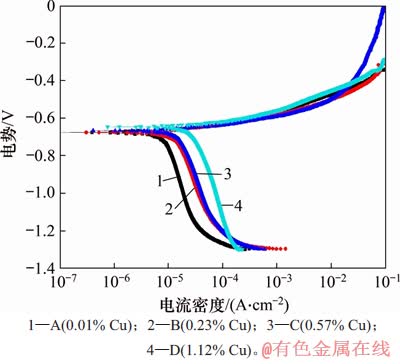

图5 不同Cu质量分数下合金动电位极化曲线

Fig. 5 Potentiodynamic polarization curves of alloys with different Cu mass fractions

2.2.2 电化学腐蚀

图5所示为T6态实验合金在3.5% NaCl(质量分数)溶液中的极化曲线,通过软件对极化曲线进行拟合的腐蚀结果如表2所示。通过图5可以看出腐蚀过程中均未发生钝化现象。由表2可知A,B,C和D合金的腐蚀电位变化不大;而随着Cu质量分数增加,A,B,C和D合金的腐蚀电流密度分别为8.843×10-6,1.236×10-5 ,1.555×10-5和2.558×10-5 A/cm2,腐蚀电流密度呈现出了不断升高的趋势,而腐蚀电流密度可以表征材料腐蚀的速率,腐蚀电流密度越大,腐蚀速率越高。由此可知:随Cu质量分数的增加,合金腐蚀速率增大,耐蚀性能降低。这与晶间腐蚀实验的结果相一致。

表2 不同Cu质量分数下合金的极化曲线拟合结果

Table 2 Fitting results of polarization curves of alloys with different Cu mass fractions

3 分析与讨论

3.1 Cu质量分数对力学性能的影响

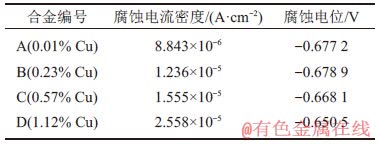

Al-Mg-Si-Cu合金属于可热处理强化合金,因此,其组织与性能必定与时效过程中的析出相类型、大小、分布、数量等有着不可分割的关系。当Al-Mg-Si-Cu合金中Cu质量分数较低时,一般认为在时效过程中的脱溶序列为SSS过饱和固溶体→球状的GP区→针状β''相→棒状β'相→片状β相(Mg2Si);当Cu质量分数较高时,此系列合金的析出序列就会发生较大改变,析出过程也更为复杂,一般认为Cu质量分数较高的Al-Mg-Si-Cu时效析出序列为:SSS过饱和固溶体→GP区→针状β''相→棒状β'相+板条状含Q'相→片状β相(Mg2Si)+圆形Q相[8,10-12]。可见其中主要是在时效析出过程中出现了Q系列相尤其是Q'相,可与β''相一起阻碍位错运动,对合金起着一定的强化作用。

图6所示为Cu质量分数不同的T6态Al-1.0Mg-1.0Si-0.6Mn合金沿[100]Al方向的晶内明场像。从图6可以看出:4种合金在晶内主要析出的是针状和圆状的细小第二相。这种析出相可判断为β''相,因为6000系铝合金中β''相的惯析方向为<100>Al,析出时在这3个晶向上相互垂直,因此,沿[100]Al方向观察时便会出现圆状(径向)和针状(轴向)这2种形貌特征(见图6(a)中1和2),且β''相与基体共格,具备最大的强化作用,一般在合金的峰值时效析出,其衍射斑纹为“十字型”[12](见图6(a)插图所示)。另外,可以明显地观察到A,B和C合金晶内析出相类型不发生改变,均只出现β''相,只是随Cu质量分数增加,β''数量逐渐增加且尺寸逐渐减小。而D合金晶内的β''相的数量相比C合金略有增加,尺寸也相差不大,但在D合金晶内还发现一种形貌为板条状的析出相(见图6(d)中3和4),应为含Cu相Q'相[7-8]。从图6(d)可以看出:相应衍射花样除了β''相形成的“十字型”衍射斑外,还出现了较明显的Q'相斑点[7](见图6(d)中白色箭头所指)。

从图1中4种合金的时效硬化行为来看,Cu质量分数越大,合金的硬化速率较快,这是因为Cu质量分数增加使GP区的形核位置数量增加[9],促进强化相β''相的形成,从而提高了合金的时效硬化速率。金曼等[9]通过TEM和3DAP等手段证实了添加元素Cu可以促进原子团簇和GP区的形成,加快β''相的析出,只是并没有改变Mg和Si原子的物质的量比,且Cu元素具有降低析出相激活能的作用[13],这也说明添加Cu能够加快时效相析出。而在时效过程中,Cu原子倾向于在Q'相和基体的界面处形成偏聚,这种偏聚能抑制析出相的粗化,使合金保持较高的强度和热稳定性[11],且Cu原子越多,这种作用越显著,这也是析出相数量增加而尺寸减小的原因。由图6可知:随着Cu质量分数增加,晶内析出相的数量逐渐增加,且析出相尺寸减小。根据沉淀强化理论可知,时效析出相数量越多、尺寸越小,则强化作用越大,故Cu质量分数越高,合金的强度和硬度均升高。此外,Cu质量分数为1.12%的D合金与C合金(0.57% Cu)的晶内β''相的状态相差不大,但D合金晶内出现了β''相和Q'相共存的现象,Q'相尺寸较大且与基体半共格,对合金也有一定的强化效果,故D合金的强度和硬度最高。实验合金伸长率逐渐减小,这是因为合金元素Cu质量分数高的合金,其粗大第二相和析出相数量多,而粗大第二相往往是合金中裂纹的萌生处,易导致合金断裂韧性较差;而且合金在固溶时效这些热处理过程中,除了固溶处理时未溶入Al基体的粗大第二相之外,还有时效处理时细小的强化相沉淀析出(见图6)。张国君等[14]认为虽然析出相可以提高合金的强度,但是易于引起应力集中,从而降低合金的塑性和韧性。如图3所示,Cu质量分数增加,合金断口形貌发生了变化,韧窝变浅,出现越来越多的撕裂棱平台,这是因为第二相的存在阻碍了位错运动,易于造成应力集中,进而促进裂纹的萌生,塑性降低。

3.2 Cu质量分数对腐蚀性能的影响

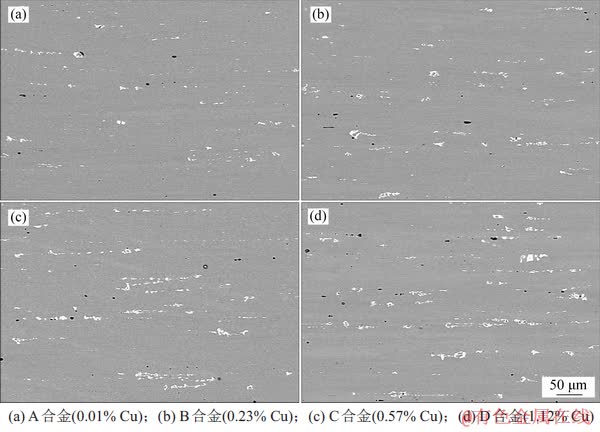

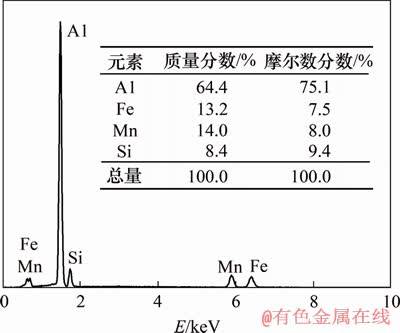

图7所示不同Cu质量分数的4种T6态合金的扫描电子显微图片。从图7可见:合金基体中主要存在白色第二相(黑色状为打磨抛光过程中粗大相脱落留下的孔洞),在基体中呈点状、块状和链状分布。经能谱分析(见图8),白色第二相主要含Al,Si,Mn和Fe这4种元素,其摩尔数分数分别为75.1%,9.4%,8.0%和7.5%,应为AlFeMnSi相[15]。AlFeMnSi相是一种难熔的杂质相,其熔点较高,一般温度下很难固溶于Al基体;其热稳定性很高,在常规热处理过程中不会发生太大变化,高温下也不会发生粗化。利用Image J软件对图中第二相的面积占比进行统计,得出A,B,C和D合金中AlFeMnSi相的面积占比分别为1.02%,1.50%,1.78%和1.93%。由此可知:随着Cu质量分数的增加,合金基体中AlFeMnSi相的数量增加。这是因为Cu的存在可占据Al基体中的过饱和空位等,增大合金的过饱和度,降低Mg和Si等溶质原子的溶解度,合金元素更容易偏聚形核、析出并长大成尺寸粗大相[16],Cu质量分数越高,则未能溶解的分布在基体上的AlFeMnSi相的数量越多。

图6 不同Cu质量分数下合金的晶内明场像及衍射斑点

Fig. 6 Bright field image in interior of grain of alloys with different Cu mass fractions

图7 不同Cu质量分数下合金SEM照片

Fig. 7 SEM images of alloys with different Cu mass fractions

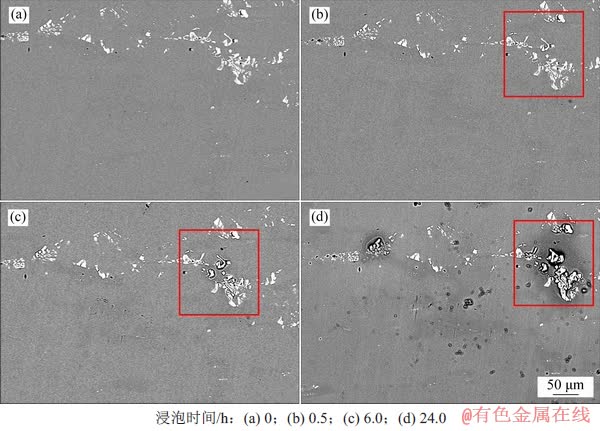

研究表明[17],粗大相对合金的晶间腐蚀产生一定影响。这些在固溶过程中未溶的粗大相与Al基体的化学成分不同,因此,两者之间存在一定的电位差,当电位差达到一定值时,便会形成腐蚀微电池,导致合金容易发生点蚀。图9所示为B合金在标准晶间腐蚀液中浸泡不同时间的腐蚀形貌图,由图9可以看出:在浸泡腐蚀前期(0.5 h),部分AlFeMnSi相的周围基体发生轻微点蚀,在粗大相周围留下环型的点蚀坑(图9(b));随着浸泡时间的延长(6和24 h),基体发生的溶解越来越严重(图9(c)和(d)),点蚀坑越来越大,且发生腐蚀的部位越来越多。由此可知在腐蚀过程中Al基体一直充当阳极发生溶解,而AlFeMnSi相则充当阴极不溶解。这与文献[18]中粗大相AlFeMnSi相的腐蚀电位比Al基体的高,Al基体充当阳极发生溶解的结果一致。Cu质量分数增加,造成的粗大AlFeMnSi相增多(如图7所示),进而导致合金发生点蚀的可能性增加,而晶间腐蚀和点蚀往往存在着十分密切的关系[19]。当点蚀发生在晶界时,腐蚀沿着蚀坑壁的晶界优先形成晶间腐蚀;当点蚀发生在晶内且点蚀严重时,则通过基体的溶解,腐蚀沿着点蚀坑壁扩展到晶界处,引发晶间腐蚀。因此,Cu质量分数的增加将降低合金的抗晶间腐蚀性能。

图8 第二相能谱

Fig. 8 EDS of the second phase

图9 浸泡不同时间后AlFeMnSi颗粒的腐蚀形貌

Fig. 9 Corrosion morphologies of AlFeMnSi constituent particles after immersing for different time

4 结论

1) 随Cu质量分数增加,合金达到峰值时效的时间缩短,合金的时效硬化速率加快,T6态合金的硬度提高。

2) 随Cu质量分数增加,T6态实验合金的析出相数量增多而尺寸减小,强度不断升高,而第二相的数量增加造成其伸长率降低。

3) 添加Cu元素可降低合金的耐蚀性能,Cu质量分数增加可导致合金粗大第二相的数量更多,进而造成合金抗晶间腐蚀性能降低。

4) 当Cu质量分数较低时(低于0.57%),合金的晶内析出相为β''相;当Cu质量分数达到1.12%时,晶内出现Q'相,与β''相共存;随Cu质量分数升高,析出相的数量增加且尺寸减小。

参考文献:

[1] SUN Wenlong, CHEN Xiaokai, WANG Lu. Analysis of energy saving and emission reduction of vehicles using light weight materials[J]. Energy Procedia, 2016, 88: 889-893.

[2] POZNAK A, MARCEAU R K W, SANDERS P G. Composition dependent thermal stability and evolution of solute clusters in Al-Mg-Si analyzed using atom probe tomography[J]. Materials Science and Engineering: A, 2018, 721: 47-60.

[3] 贾志宏, 丁立鹏, 吴赛楠, 等. 汽车车身用6000系铝合金板材微观组织与热处理工艺的研究进展[J]. 材料工程, 2014(12): 104-113.

JIA Zhihong, DING Lipeng, WU Sainan, et al. Research progress on microstructure and heat treatment process of 6000 series aluminum alloy sheets for automobile body[J]. Journal of Materials Engineering, 2014(12): 104-13.

[4] GAO Guanjun, HE Chen, LI Yong, et al. Influence of different solution methods on microstructure, precipitation behavior and mechanical properties of Al-Mg-Si alloy[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(5): 839-847.

[5] 何立子, 陈彦博, 崔建忠, 等. Cu含量对一种新型Al-Mg-Si合金晶间腐蚀的影响[J]. 腐蚀科学与防护技术, 2004, 16(3): 129-133.

HE Lizi, CHEN Yanbo, CUI Jianzhong, et al. Effect of Cu content on intergranular corrosion of a novel Al-Mg-Si alloy[J]. Corrosion Science and Protection Technology, 2004, 16(3): 129-133.

[6] SUNDE J K, MARIOARA C D, VAN HELVOORT A T J , et al. The evolution of precipitate crystal structures in an Al-Mg-Si(-Cu) alloy studied by a combined HAADF-STEM and SPED approach[J]. Materials Characterization, 2018, 142: 458-469.

[7] CHAKRABARTI D J, LAUGHLIN D E. Phase relations and precipitation in Al–Mg–Si alloys with Cu additions[J]. Progress in Materials Science, 2004, 49(3/4): 389-410.

[8] DING Lipeng, JIA Zhihong, ZHANG Zhiqing, et al. The natural aging and precipitation hardening behaviour of Al-Mg-Si-Cu alloys with different Mg/Si ratios and Cu additions[J]. Materials Science and Engineering: A, 2015, 627: 119-126.

[9] 金曼, 邵光杰. Cu对6082Al-Mg-Si合金时效初期析出相的影响[J]. 中国有色金属学报, 2009, 19(1): 1-7.

JIN Man, SHAO Guangjie. Effect of Cu on Precipitates in the Early Stage of Aging of 6082Al-Mg-Si Alloy[J]. Chinese Journal of Nonferrous Metals, 2009, 19(1): 1-7.

[10] DING Lipeng, JIA Zhihong, NIE Jianfeng, et al. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy[J]. Acta Materialia, 2018, 145: 437-450.

[11] MATSUDA K, TEGURI D, UETANI Y, et al. Cu-segregation at the Q′/α-Al interface in Al–Mg–Si–Cu alloy[J]. Scripta Materialia, 2002, 47(12): 833-837.

[12] 杨文超. Al-Mg-Si-Cu系6005A合金的时效硬化行为及析出相的微观结构表征[D]. 长沙: 中南大学材料科学与工程学院, 2011: 59-62.

YANG Wenchao. Age Hardening Behavior and Microstructure Characterization of Precipitated Phase of 6005A Alloy in Al-Mg-Si-Cu System[D]. Changsha: Central South University.School of Materials Science and Engineering, 2011: 59-62.

[13] 李 海, 王秀丽, 史志欣, 等. Al-Mg-Si-(Cu)铝合金在连续升温中的析出行为[J]. 中国有色金属学报, 2011, 21(9): 2028-2034.

LI Hai, WANG Xiuli, SHI Zhixin, et al. Precipitation behaviors of Al-Mg-Si-(Cu) aluminum alloys during continuous heating[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2028-2034.

[14] 张国君, 袁生平, 王瑞红, 等. 粗大第二相及时效析出相对Al-Mg-Si合金延性断裂的耦合影响[J]. 中国有色金属学报, 2009, 19(11): 1894-1901.

ZHANG Guojun, YUAN Shengping, WANG Ruihong, et al. Coupled effect of constituents and precipitates on the ductile fracture of Al-Mg-Si alloy[J]. Journal of Chinese Nonferrous Metals, 2009, 19(11): 1894-1901.

[15] 刘胜胆, 陈小连, 张端正, 等. 固溶温度对6082铝合金显微组织与性能的影响[J].中国有色金属学报, 2015, 25(3): 582-588.

LIU Shengdan, CHEN Xiaolian, ZHANG Duanzheng, et al. Effect of solution temperature on microstructure and properties of 6082 aluminum alloy[J].The Chinese Journal of Nonferrous Metals, 2015, 25(3): 582-588.

[16] 廖郁国, 韩晓祺, 曾苗霞, 等. Cu元素对7XXX系列铝合金再结晶的影响[J]. 上海金属, 2014, 36(3):25-28.

LIAO Yuguo, HAN Xiaoqi, ZENG Miaoxia, et al. Effect of Cu on Recrystallization of 7XXX series aluminium alloys[J]. Shanghai Metal, 2014, 36(3): 25-28.

[17] 李海, 孟林, 王芝秀, 等. 残留结晶相对Al-Mg-Si-Cu合金晶间腐蚀行为的影响[J]. 中国有色金属学报, 2012, 22(12): 3300-3306.

LI Hai, MENG Lin, WANG Zhixiu, et al. Effect of residual constituents on intergranular corrosion behavior of Al-Mg-Si-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3300-3306.

[18] BIRBILIS N, BUCHHEIT R G. Electrochemical characteristics of intermetallic phases in aluminum alloys[J]. Journal of the Electrochemical Society, 2005, 152(4): B140.

[19] GUILLAUMIN V, MANKOWSKI G. Localized corrosion of 6056 T6 aluminium alloy in chloride media[J].Corrosion Science, 2000, 42(1): 105 -125.

(编辑 伍锦花)

收稿日期: 2019 -05 -26; 修回日期: 2019 -08 -26

基金项目(Foundation item):国家重点研发计划项目(2016YFB0300901);国家自然科学基金资助项目(51705539)(Project(2016YFB0300901) supported by the National Key R&D Program of China; Project(51705539)supported by the National Natural Science Foundation of China)

通信作者:唐建国,博士,副教授,从事高性能铝合金材料设计与制备研究;E-mail: jgtang@csu.edu.cn