文章编号:1004-0609(2010)03-0510-06

C/C-Cu复合材料的烧蚀性能及烧蚀机理

冉丽萍,李文军,杨 琳,易茂中

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用真空熔渗技术制备新型C/C-Cu复合材料。采用氧?乙炔焰测试不同时间下C/C-Cu复合材料的抗烧蚀性能,利用XRD、SEM分析材料烧蚀后的物相组成及组织形貌,对C/C-Cu复合材料的烧蚀机理进行研究。结果表明:烧蚀时间对材料的烧蚀率有显著影响,随着时间的延长,材料的质量烧蚀率和线烧蚀率均呈上升趋势;烧蚀后复合材料表面生成氧化物相TiO2和Cu2O,原来的TiC相被TiO2相替代;C/C-Cu复合材料的烧蚀性能优于C/C复合材料的烧蚀性能;C/C-Cu复合材料的氧?乙炔焰烧蚀机制为热氧化烧蚀、热物理烧蚀(升华)和机械冲刷的综合作用。

关键词:C/C-Cu复合材料;烧蚀;烧蚀机理

中图分类号:TB331 文献标识码:A

Ablation properties and ablation mechanism of C/C-Cu composites

RAN Li-ping, LI Wen-jun, YANG Lin, YI Mao-zhong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract:Novel carbon/carbon-copper (C/C-Cu) composites were fabricated by molten infiltration. The ablation characteristics with different ablation times were evaluated under O2-C2H2 ablation conditions. The phase compositions and microstructures of the composites before and after ablation were examined by XRD and SEM. The ablation mechanisms of the composites were discussed. The results show that the ablation time has a great effect on the ablation characteristics. Both the mass ablation rate and linear ablation rate increase with prolonging ablation time. After ablation, the original TiC phase is substituted by TiO2, and Cu2O is formed on the ablation surface of the composites. The ablation properties of the composites are better than those of the carbon/carbon composites. The ablation mechanisms of the C/C-Cu composite under the O2-C2H2 condition are synergistic effect of thermo-oxidation, thermo-physics ablation (sublimation) and mechanical erosion.

Key words: C/C-Cu composites; ablation; ablation mechanism

炭/炭复合材料(C/C)以其密度低、高温强度高、热膨胀系数低、耐烧蚀性好、耐热冲击性能好等一系列优异性能,被认为是理想的喉衬材料,广泛应用 于航天领域,目前已是固体火箭发动机喷管的首选材料[1?7]。但是,C/C复合材料的制备周期长,尤其是在增密后期,大幅度增加了C/C复合材料的制造成本。

钨渗铜材料和石墨渗铜材料中的Cu元素或是起到发汗冷却的作用,或是起到热沉的作用[8?10],都可有效改善材料的烧蚀性能。但是,钨渗铜材料的密度(17.0 g/cm3)太高,石墨渗铜材料的强度低、烧蚀率大,因而,限制了钨渗铜材料和石墨渗铜材料的应用。

目前,俄罗斯采用类似钨渗铜的工艺对C/C复合材料渗铜制成含铜C/C抗烧蚀涂层喉衬材料,经燃气温度3 800 ℃、压力8.0 MPa、工作时间60 s的地面点火试验,烧蚀率较纯C/C材料成倍降低[11?12]。但由于涉及到国防秘密,很难见到实质性的关键技术报道。

因此,本文作者通过活性元素Ti改善熔融Cu与C/C复合材料的润湿性[13?14],采用真空熔渗的方法,将Cu熔融渗入密度为1.5 g/cm3的C/C复合坯体中制备新型的C/C-Cu复合材料,并探讨耐烧蚀C/C和发汗或热沉的Cu复合作为一种新型耐烧蚀材料的可能性。采用氧?乙炔焰对C/C-Cu复合材料进行烧蚀试验,研究烧蚀时间对C/C-Cu复合材料烧蚀性能的影响、烧蚀后的物相和组织变化,探讨C/C-Cu复合材料的烧蚀机理。

1 实验

1.1 C/C-Cu复合材料的制备

以炭纤维针刺整体毡为预制体,通过多次化学气相渗透(CVI)增密获得密度为1.5 g/cm3的C/C复合 坯体,以Cu和Ti合金粉(质量比为9?1)为原料,在真空环境下,熔渗制备密度为2.87 g/cm3的C/C-Cu复合材料。

1.2 烧蚀试验

烧蚀试样的尺寸为d30 mm×10 mm。以氧?乙炔焰为热源对C/C-Cu复合材料试样进行烧蚀,氧气与乙炔混合比例为1.35(体积比);氧气压力为0.4 MPa,乙炔压力为0.095 MPa;试样初始表面距离火焰喷嘴(10±0.2)mm,火焰烧蚀角度为90?,即垂直烧蚀;烧蚀时间分别为10,20和40 s。

1.3 烧蚀性能的表征及组织性能分析

用质量烧蚀率(Rm)和线烧蚀率(Rd)表征材料的烧蚀性能,复合材料的质量烧蚀率和线烧蚀率分别通过下列公式计算:

Rm=(m1?m2)/t (1)

Rd=(d1?d2)/t (2)

式中:m1和m2分别为复合材料烧蚀前、后的质量;d1和d2分别为复合材料烧蚀前、后的厚度;t为复合材料的烧蚀时间。

采用TG328A型分析天秤(精度为0.1 mg)测量材料的质量;用千分尺(精度为0.01 mm)测定材料的厚度;用阿基米德排水法测试试样的体积密度;用RIGAKU?3014 X-ray衍射仪分析复合材料烧蚀前、后物相;用JSM?6360LV SEM观察试样烧蚀后的微观 形貌。

2 结果与讨论

2.1 C/C-Cu复合材料的烧蚀性能

图1所示为C/C-Cu复合材料烧蚀后的宏观形貌。材料表面没有产生宏观的裂纹,即没发生热震破坏,在复合材料的烧蚀中心有一较为明显的烧蚀凹坑。

图1 C/C-Cu复合材料烧蚀40 s后的宏观形貌

Fig.1 Macro morphology of C/C-Cu composites after ablation for 40 s: A—Ablation center; B—Transitional field between ablation center and sample rim; C—Ablation rim

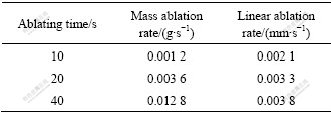

C/C-Cu复合材料烧蚀不同时间的烧蚀结果如表1所列。结果表明:随着时间的延长,C/C-Cu复合材料的质量烧蚀率和线烧蚀率均有增加。当烧蚀时间从10 s延长到20 s时,材料的质量烧蚀率增加200%,线烧蚀率增加57%;当烧蚀时间由20 s增加到40 s时,质量烧蚀率增加达256%,而线烧蚀率仅增加15%。这主要是因为Cu的比热容(380 J/(kg·K))和热导率(401 W/(m·K))都很大,在烧蚀过程中,复合材料的表面温度不会急剧升高到Cu的熔点(1 083 ℃)和沸点(2 330 ℃),而是需要一个过程,因此,烧蚀10 s时复合材料的质量烧蚀率较低,随着烧蚀时间的延长,复合材料的表面温度达到并超过Cu的沸点,这时伴随Cu的大量挥发,复合材料的质量烧蚀率急剧增大;随着Cu的挥发,复合材料的表面由Cu层转变为C/C层,而C/C比Cu耐烧蚀得多,因此,复合材料的线烧蚀率随着烧蚀时间的延长增加较为缓慢。总的来说,随着烧蚀时间的延长,C/C-Cu复合材料的烧蚀率增大。

表1 C/C-Cu复合材料烧蚀不同时间的烧蚀性能

Table 1 Ablation properties of C/C-Cu composites after ablation for different times

为了比较熔渗制备C/C-Cu复合材料的烧蚀性能,实验检测了与坯体密度相同(1.51 g/cm3)和较高密度(1.75 g/cm3)的C/C复合材料的烧蚀性能。图2所示为3种复合材料的线烧蚀率随时间的变化规律。结果表明,对于C/C复合材料,低密度的试样比高密度的烧蚀率高,且随时间的延长,低密度的试样的线烧蚀率不断增大,这主要是因为低密度C/C材料的孔隙多,材料强度低,抗高速气流冲击能力弱;但无论是密度为1.51 g/cm3还是1.75 g/cm3的C/C复合材料,其线烧蚀率都高于C/C-Cu复合材料的,这主要是因为Cu相在烧蚀过程挥发能够有效降低复合材料表面的温度。在烧蚀40 s后,熔融渗透Cu制备C/C-Cu复合材料具有比C/C复合材料更优异的抗烧蚀性能。

图2 3种复合材料的线烧蚀率

Fig.2 Linear ablation rates of three kinds of composites: (a) C/C-Cu composite; (b) C/C composite with density of 1.51 g/cm3; (c) C/C-Cu composite with density of 1.75 g/cm3

2.2 C/C-Cu复合材料烧蚀前、后的物相变化

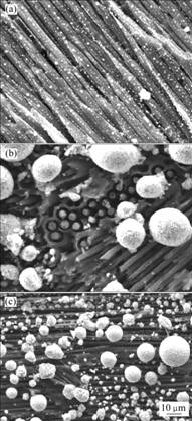

图3所示为C/C-Cu复合材料烧蚀前的SEM形貌,其中图3(a)所示为复合材料内部的微观形貌。可以看出,在炭基体和炭纤维周围的孔隙中都已经填满一种白亮物质,经能谱分析该物质主要为Cu,Cu在材料内部形成网状的连续相;图3(b)所示为C/C-Cu复合材料烧蚀前的表面微观形貌,大块的Cu覆盖在炭纤维表面。图4所示为烧蚀20 s后的微观形貌。由图4可知,已看不到大块的Cu相存在,且炭纤维较烧蚀前变细变尖,呈针尖状。

图3 C/C-Cu复合材料的SEM像

Fig.3 SEM images of C/C-Cu composites: (a) Section; (b) Surface

图4 C/C-Cu复合材料烧蚀20 s后的SEM像

Fig.4 SEM image of C/C-Cu composites after ablation for 20 s

为了研究C/C-Cu复合材料烧蚀后的表面物相组成,对烧蚀前、烧蚀20 s和烧蚀40 s的复合材料进行X射线衍射分析,结果如图5所示。可以看出,复合材料烧蚀前主要存在C相、Cu相和TiC相;烧蚀后,复合材料以C基体和残余的Cu相为主,生成了新氧化相TiO2和Cu2O,而TiC相则被新生成的TiO2相所覆盖。与烧蚀20 s的复合材料相比,烧蚀40 s的复合材料的残余Cu相和生成的新相TiO2均有较大幅度的降低,且没有出现Cu2O的峰,说明烧蚀40 s后,复合材料中 Cu相大量挥发,新生成的TiO2在燃气流的冲刷下也有较多流失。由于Cu相的大量流失,造成复合材料表面含Cu较少,使得在冷却过程中生成的Cu2O含量较少,复合材料烧蚀较为严重,这与表1的结果相符。

图5 C/C-Cu复合材料烧蚀前后的XRD图谱

Fig.5 XRD patterns of ablated surface of C/C-Cu composites: (a) Pre-ablation; (b) After ablation for 20 s; (c) After ablation for 40 s

2.3 C/C-Cu复合材料的烧蚀机理

图6所示为C/C-Cu复合材料在氧?乙炔焰下烧蚀40 s的SEM像。烧蚀后的C/C-Cu复合材料表面可以分为3个区域:烧蚀中心区、烧蚀中心与边缘过渡区、边缘区(分别对应图1的A、B、C),不同区域的烧蚀情况存在很大差异。

图6(a)所示为C/C-Cu复合材料距离火焰最近的烧蚀中心区的微观烧蚀形貌,此处C/C-Cu复合材料的烧蚀最为严重,可以看到大量呈针尖状的炭纤维裸露在表面,没有看到Cu的存在,在纤维表面残留一些白色颗粒。经能谱分析可知这些颗粒含有Ti和O这2种元素,结合图5(c)可知白色颗粒为TiO2。在烧蚀中心区,C/C-Cu复合材料的表面温度远高于Cu的熔点和沸点,故此处的Cu处于完全挥发状态,因而,在炭纤维表面没有Cu的存在,但是Cu的蒸发潜热(?Hv=5 284 kJ/kg)很高,因此,在Cu挥发的同时带走大量的热量,即起到“发汗冷却”的作用,使得C/C-Cu复合材料的表面温度降低到远低于炭纤维的升华温度(3 100 ℃)和TiC的熔点(3 067 ℃),有效地提高复合材料的烧蚀性能。另外,由于氧?乙炔火焰为氧化焰(氧气和乙炔的流量比为1.35),没有熔化的TiC按下列反应[15?16]与氧气反应生成TiO2:

TiC+O2→TiO+CO2 (3)

4TiO+O2→2Ti2O3 (4)

2Ti2O3+O2→4TiO2 (5)

图6 C/C-Cu复合材料烧蚀后不同部位的SEM像

Fig.6 SEM images of different places of C/C-Cu composites after ablation: (a) Ablation center; (b) Transitional field between ablation centre and sample rim; (c) Ablation rim

在烧蚀中心,温度高于TiO2的熔点(1 840 ℃)和沸点(2 227 ℃)[15],在高速燃气流剧烈地冲击复合材料表面的情况下,TiO2大部被高速气流带走,少部分留在炭基体和炭纤维表面,烧蚀中心区炭基体和炭纤维裸露于燃气流中,受到燃气流氧化和冲刷,炭基体和炭纤维烧蚀严重。在烧蚀中心区,C/C-Cu复合材料的烧蚀机制主要为升华、氧化和机械冲刷。

图6(b)所示为C/C-Cu复合材料烧蚀中心与边缘的过渡区微观烧蚀形貌。可以看到炭纤维和炭基体有轻微的烧蚀痕迹,在炭纤维表面有球状颗粒形成,经能谱分析得知,该球状颗粒为Cu。与烧蚀中心相比,该区域内到达复合材料表面的温度有所降低,没有达到Cu的沸点,Cu以熔融状态存在。由于Cu与C/C复合材料不润湿,大部分熔融的Cu被燃气吹离复合材料表面,仅有少部分Cu保留下来。在冷却过程中,这些熔融的Cu在表面张力下收缩成球状颗粒。在烧蚀中心与边缘的过渡区,C/C-Cu复合材料的烧蚀机制以对熔融Cu和基体炭的机械冲刷为主。

图6(c)所示为C/C-Cu复合材料烧蚀边缘区的微观烧蚀形貌。由于烧蚀时间较长,烧蚀边缘区的温度也超过了Cu的熔点,复合材料的烧蚀形貌与过渡区的相似。但是,从图6(c)中可以看到大量不规则的颗粒,经能谱分析含有Ti、O和少量的Cu元素。结合图5可知这些颗粒为TiO2和Cu2O的混合物。这主要是此区距离烧蚀中心最远,受到气流的冲刷最小,这些颗粒才大量地保存下来。在烧蚀边缘区,C/C-Cu复合材料的烧蚀机制主要是复合材料的氧化烧蚀。

3 结论

1) 烧蚀时间对C/C-Cu复合材料的烧蚀性能影响很大,随烧蚀时间的延长,其质量烧蚀率呈倍数增加,而线烧蚀率增加较为平稳。

2) 复合材料在烧蚀前主要存在C相、Cu相和TiC相;烧蚀后,复合材料以C基体和残余的Cu相为主, 且新增加氧化相TiO2和Cu2O,TiC相被新生成的氧化相覆盖。

3) 在氧?乙炔火焰烧蚀下,C/C-Cu复合材料的烧蚀机制是热氧化烧蚀、热物理烧蚀(升华)和机械冲刷的综合作用,且C/C-Cu复合材料不同区域的烧蚀机制有明显不同。

REFERENCES

[1] PAULMIER T, BALAT-PICHELIN M, le QUEAU D. Structural modifications of carbon-carbon composites under high temperature and ion irradiation[J]. Appl Surf Sci, 2005, 243: 376?393.

[2] 尹 建, 张红波, 熊 翔, 黄伯云. 针刺整体毡C/C复合材料整体喉衬烧蚀分析[J]. 中国有色金属学报, 2006, 16(9): 1539?1544.

YIN Jian, ZHANG Hong-bo, XIONG Xiang, HUANG Bo-yun. Analysis on ablation performance of bulk-needled-felt reinforced carbon composites throat[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1539?1544.

[3] SU Jun-ming. Research and development of C/C composites for nozzles[J]. Carbon Sci Technol, 2001, 1(1): 6?11.

[4] TANG Su-fang, DENG Jing-yi, LIU Wen-chuan, YANG Ke. Mechanical and ablation properties of 2D-carbon/carbon composites pre-infiltrated with a SiC filler[J]. Carbon, 2006, 44: 2877?2882.

[5] YIN Jian, XIONG Xiang, ZHANG Hong-bo, MENG Song-he. Microstructure and ablation performances of dual-matrix carbon/carbon composites[J]. Carbon, 2006, 44: 1690?1694.

[6] BLANCO C, CASAL E, GRANDA M, MENENDEZ R. Influence of fiber-matrix interface on the fracture behavior of carbon-carbon composites[J]. J Eur Ceram Soc, 2003, 23(15): 2857?2866.

[7] LUO R Y, LIU T, LI J S, ZHANG H B, CHEN Z J, TIAN G L. Thermophysical properties of carbon/carbon composites and physical mechanism of thermal expansion and thermal conductivity[J]. Carbon, 2004, 42: 2887?2895.

[8] 陈林泉, 王书贤, 张胜勇, 侯 晓. 石墨渗铜喉衬材料烧蚀机理分析[J]. 固体火箭技术, 2004, 27(1): 57?59.

CHEN Lin-quan, WANG Shu-xian, ZHANG Sheng-yong, HOU Xiao. Study on the erosion mechanism of copper-infiltrated graphite throat insert[J]. Journal of Solid Rocket Technology, 2004, 27(1): 57?59.

[9] 陈林泉, 王书贤, 张胜勇, 侯 晓. 石墨渗铜喉衬材料烧蚀机理与工程计算[J]. 科学技术与工程, 2004, 4(3): 211?213.

CHEN Lin-quan, WANG Shu-xian, ZHANG Sheng-yong, HOU Xiao. Erosive principle and engineering calculation of copper-impregnated graphite throat insert material[J]. Science Technology and Engineering, 2004, 4(3): 211?213.

[10] 苏君明, 陈林泉, 王书贤, 侯 晓, 李桂林. 石墨渗铜候衬的烧蚀特性[J]. 固体火箭技术, 2004, 27(1): 69?72.

SU Jun-ming, CHEN Lin-quan, WANG Shu-xian, HOU Xiao, LI Gui-lin. The erosive property of copper-infiltrated graphite throat insert[J]. Journal of Solid Rocket Technology, 2004, 27(1): 69?72.

[11] 王其坤, 胡海峰, 简 科, 陈朝辉, 郑文伟, 马青松. 先驱体转化法制备2D Cf/SiC-Cu复合材料及其性能[J]. 新型炭材料, 2006, 21(2): 151?155.

WANG Qi-kun, HU Hai-feng, JIAN Ke, CHEN Zhao-hui, ZHENG Wen-wei, MA Qing-song. Preparation and properties of 2D Cf/SiC-Cu composites produced by precursor infiltration and pyrolysis[J]. New Carbon Materials, 2006, 21(2): 151?155.

[12] 简 科, 陈朝辉, 胡海峰, 王其坤, 马青松. 2D Cf/SiC-Cu复合材料的制备和性能[J]. 中国有色金属学报, 2005, 15(12): 1933?1937.

JIAN Ke, CHEN Zhao-hui, HU Hai-feng, WANG Qi-kun, MA Qing-song. 2D Cf/SiC-Cu composites fabricated by precursor pyrolysis[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1933?1937.

[13] 易振华, 易茂中, 冉丽萍, 杨 琳. 添加钛对炭/炭复合材 料渗铜的影响[J]. 中国有色金属学报, 2006, 16(7): 1214?1218.

YI Zhen-hua, YI Mao-zhong, RAN Li-ping, YANG Lin. Influence of adding Ti on molten copper infiltration into C/C composites[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1214?1218.

[14] 冉丽萍, 易茂中, 王朝胜, 易振华, 杨 琳. 不同载荷和对偶下C/C-Cu复合材料的摩擦磨损性能[J]. 中南大学学报: 自然科学版, 2007, 38(4): 595?601.

RAN Li-ping, YI Mao-zhong, WANG Chao-sheng, YI Zhen-hua, YANG Lin. Wear behavior of C/C-Cu composites under different loads and couples parts[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 595?601.

[15] 宋桂明, 孟庆昌, 王玉金, 周 玉. TiC和ZrC颗粒增强钨 基复合材料的烧蚀研究[J]. 固体火箭技术, 2001, 24(2): 48?53.

SONG Gui-ming, MENG Qing-chang, WANG Yu-jin, ZHOU Yu. Ablation of tungsten matrix composites reinforced by TiC and ZrC particles[J]. Journal of Solid Rocket Technology, 2001, 24(2): 48?53.

[16] 宋桂明, 武 英, 白厚善, 王玉金, 周 玉, 雷廷权. TiC颗粒增强钨基复合材料的烧蚀性能[J]. 中国有色金属学报, 2000, 10(3): 313?317.

SONG Gui-ming, WU Ying, BAI Hou-shan, WANG Yu-jin, ZHOU Yu, LEI Ting-quan. Ablation of TiC particle-reinforced tungsten matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(3): 313?317.

基金项目:国家重点基础研究发展规划资助项目(2006CB600906);湖南省重点科技支撑计划资助项目(2007KG2017)

收稿日期:2009-08-25;修订日期:2009-12-10

通信作者:冉丽萍,副教授;电话:0731-88830894;E-mail: rlp101@126.com

(编辑 杨 华)