文章编号:1004-0609(2010)08-1605-07

热压烧结法制备Cf/TiC/Cu复合材料的组织及性能

黄向东,刘桂香,叶学青,李 强

(福州大学 材料科学与工程学院,福州350108)

摘 要:采用热压烧结法制备Cf/TiC/Cu复合材料,研究Cf/TiC/Cu复合材料的界面反应原理及微观形貌,以及碳纤维(Cf)含量对复合材料密度、强度等性能的影响。结果表明:Cu-C-Ti 三元体系在低于1 100 ℃时,溶解在铜液中的钛原子与碳纤维接触发生反应,在碳纤维表面形成以TiC为主相的过渡层。该过渡层靠近铜液的一侧可能覆盖着一层钛铜化合物膜,TiC通过该膜层与铜紧密结合在一起,改善铜与碳纤维的界面结合,因此有利于提高Cf/TiC/Cu复合材料的性能。在钛含量不变的情况下,随碳纤维含量(质量分数)的增加,材料性能有所降低,当碳纤维含量为5%时,Cf/TiC/Cu复合材料的综合性能最好,其电阻率低达0.054 μΩ·m,平行于压力方向的抗弯强度为237.90 MPa,垂直于压力方向的抗弯强度为237.44 MPa。

关键词:短碳纤维;复合材料;热压烧结;抗弯强度

中图分类号:TB331 文献标志码:A

Microstructures and properties of Cf/TiC/Cu composites prepared by hot-pressed sintering

HUANG Xiang-dong, LIU Gui-xiang, YE Xue-qing, LI Qiang

(College of Materials Science and Engineering, Fuzhou University, Fuzhou 350108, China)

Abstract: The Cf/TiC/Cu composites were prepared by the hot-pressed sintering. The mechanism of interface reaction between copper and carbon fiber(Cf) and the microstructure of composites were studied. The effects of Cf content on the density and bending strength of Cf/TiC/Cu composites were investigated. The results indicate that the transition layer with TiC as the main phase surrounding the carbon fiber is generated due to the reaction between titanium dissolved in the liquid copper and carbon in the ternary system of Cu-C-Ti. A film of Ti-Cu compounds maybe covers the side of the transition layer near the liquid copper, which tightly combines TiC with copper and improves the combination between copper and carbon fiber, thus the properties of Cf/TiC/Cu composites are improved. When the Ti content is certain, the properties of Cf/TiC/Cu composites get worse with the Cf content(mass fraction) increasing. When the Cf content is 5%, the synthetic properties of Cf/TiC/Cu composites are the best, the resistivity is 0.054 μΩ·m, the bending strength parallel to the pressure direction is 237.90 MPa, and the bending strength perpendicular to the pressure direction is 237.44 MPa.

Key words: short carbon fiber; composite materials; hot-pressed sintering; bending strength

C/Cu复合材料不仅导电性及导热性与纯铜相近,而且具有良好的抗电弧侵蚀和抗磨损能力等优点,已被广泛应用于电子元件材料、滑动材料、 触头材料、 集成电路散热板及耐磨器件等领域,是一种具有广泛应用前景的新型材料[1-3]。制备C/Cu复合材料关键在于将铜渗透到碳纤维或石墨颗粒之间,使铜碳相紧密结合。但液态铜在高温下与碳既不润湿也不反应[4],铜与碳不能自然结合在一起。将铜粉、碳粉混合,常温模压成型,然后在低于铜熔点的温度下处理,使铜粉烧结,但由于铜碳之间没有结合,材料性能很差[5]。如果在高于铜熔点的温度下处理,则铜碳完全分离,根本不能制成复合材料。为了解决这个问题,通常采取两种方法使铜碳紧密结合。一种方法是在碳纤维或碳颗粒表面镀铜(电镀或化学镀)[6, 13-19],利用外加电场或化学势的力量使铜离子移至碳表面并还原沉积成铜原子形成金属铜层,这层金属铜完全依附于碳表面生成,因此包裹情况良好。但铜与碳间没有化学结合,仅是物理接触,机械互锁,界面结合力小。另一种方法是在铜基体中添加钛等活性合金元素[7-13],在铜与碳之间形成过渡层,以此来改善铜液对碳的润湿效果。渗铜法[9-10]制备铜碳复合材料便是利用此原理。添加钛等活性元素不仅使铜液能包裹碳纤维或碳颗粒,而且通过过渡层使铜和碳之间产生化学结合力,因此,不仅解决了碳铜紧密接触的问题,同时过渡层的化学结合使碳铜界面结合力增大,更有助于提高复合材料的力学性能。

镀铜(电镀或化学镀)法制备C/Cu复合材料工艺比较繁琐,如姚广春研究组[14-20]在镀铜前都要对碳纤维或石墨颗粒进行预处理,一般为去胶→粗化→中和→敏化→活化→还原等工序。镀铜的镀液或对纤维预处理的化学药品都会污染环境,危害人们健康。而在利用添加钛元素的渗铜法制备C/Cu复合材料时由于含有钛的铜液从表面渗入C/C复合材料,随渗入深度的增加,渗入金属熔液中的钛含量不断消耗,愈来愈少,液体金属的渗透能力逐渐变差,这样很容易导致渗透不均匀出现渗透梯度问题,制备的C/Cu复合材料性能不均匀,尤其是对尺寸较大的制品更是如此。

本文作者利用特种陶瓷制备工艺中常用的热压烧结法来制备Cf/TiC/Cu复合材料,研究Cf/TiC/Cu复合材料的界面反应原理及微观形貌,以及不同碳纤维添加量对复合材料密度、气孔率、强度等性能的影响。

1 实验

1.1 实验材料

二维碳纤维布由宜兴市新维碳纤维织造有限公司生产,3K,单丝直径约为7 μm,密度为1.76 g/cm3。铜粉由北京有色金属研究院金属粉末中心提供,粒度为50 μm,密度为8.90 g/cm3,熔点为1 084 ℃。钛粉由宝鸡市华泰钛粉有限公司生产,粒度为74 μm,密度为4.51 g/cm3,熔点为1 668 ℃。

1.2 制备工艺

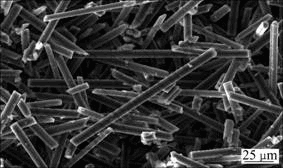

首先将碳纤维布磨碎,制成如图1所示的碳纤维粉末,再与铜粉、钛粉混合均匀,然后装入石墨模具中。碳纤维、钛粉和铜粉的质量及质量分数见表1。采用沈阳威泰科技发展有限公司的真空气氛热压烧结炉烧结试样,最高加热温度为1 100 ℃,加压压力为25 MPa,达到设定温度及保压时间后随炉冷却。

图1 磨碎碳纤维形貌

Fig.1 Micro-morphology of short carbon fibers

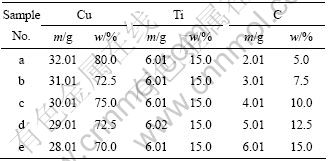

表1 烧结前原料的质量及质量分数

Table 1 Mass and mass fraction of raw materials before sintering

1.3 测试

采用日本理学D/max UltimaⅢ型X射线衍射仪分析复合材料的物相,铜靶,Kα辐射,扫描角度范围为10?~100?,扫描速率为4 (?)/min。试样经研磨抛光后,采用XL30ESEM型环境扫描电镜进行形貌分析。采用上海正阳仪表厂制造的QJ84型数字直流电桥测试复合材料的电阻。采用CMT-6104型电子万能试验机三点弯曲法测试样品的抗弯强度,试样尺寸为3 mm×4 mm×36 mm,跨距为30 mm,加载速度为0.5 mm/min。利用阿基米德原理测试样密度。

2 结果与讨论

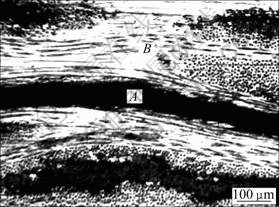

2.1 Cf/TiC/Cu复合材料的截面显微组织

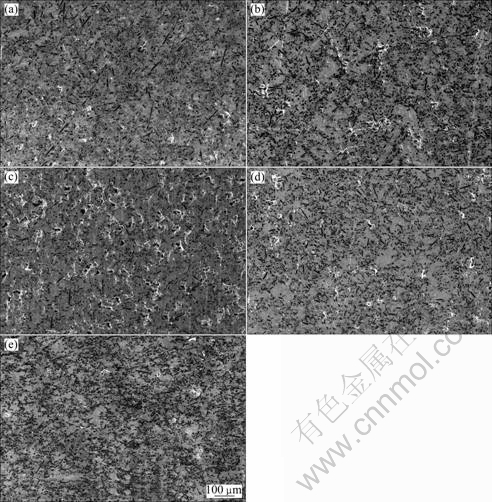

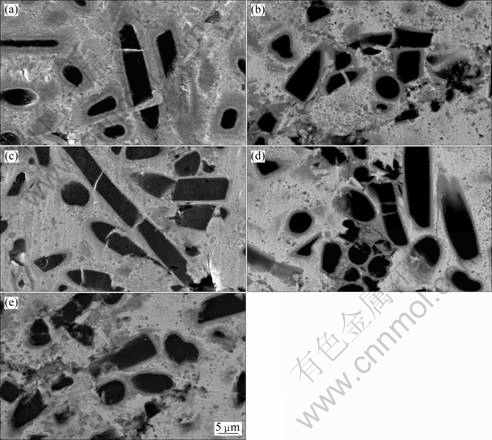

本课题组前期利用碳纤维布来制作Cf/Cu复合材料[21],发现铜钛熔液很难完全渗透碳纤维布,导致Cf/Cu复合材料易分层,如图2所示。图2中A区碳纤维没有浸入铜液,B区铜液浸入良好,导致材料总体性能较差。为了克服这种问题,本研究利用短碳纤维来制作Cf/Cu复合材料,按碳纤维含量(质量分数,%)不同制得复合材料,其显微组织如图3所示。从图3可以看出,纤维分布均匀,没有分层现象,黑色圆点或椭圆状、棒状相为碳纤维,灰色相为铜,碳纤维分布均匀,周围完全被铜所填充。由此可以推断,铜液对碳纤维润湿良好,界面致密、结合良好,没有孔洞,这有利于提高复合材料的强度。

图2 钛含量为9.1%的复合材料的SEM像[21]

Fig.2 SEM image of composites with Ti content of 9.1% [21]

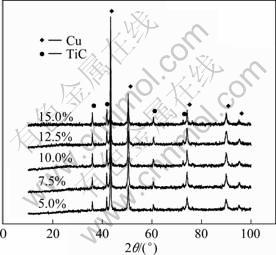

2.2 Cf/TiC/Cu复合材料的XRD物相分析

图4 所示为不同碳纤维含量的Cf/TiC/Cu复合材料经研磨粉碎后的XRD谱。从图4可以看出铜和TiC的衍射峰,说明钛与碳反应生成了TiC;而且TiC衍射峰随Cf含量的增加,其峰强有所增加。当碳纤维含量大于10%后,TiC衍射峰的强度增加不明显,这是因为随着Cf含量的增加,钛接触更多的碳,生成的TiC的量就会相应地增加,当碳纤维含量(大于10%)达到一定程度后,几乎所有的钛都参与了反应,所以TiC的含量不再增加。所有的样品中均没有检测到碳的衍射峰,这可能是因为:一方面碳与钛反应消耗一部分碳;另一方面碳纤维是乱层石墨结构,结晶不好,所以其衍射峰也不强,当碳纤维含量少时,XRD不易检测到。由于铜与钛反应生成铜钛化合物的量也可能比较少,因此XRD谱中未能检测到其衍射峰。由于没有其他杂质的衍射峰,因此,可推测烧结后复合材料的主相为铜、TiC和碳,没有剩余的钛或剩余的钛含量很少。

图3 不同碳纤维含量的复合材料SEM像

Fig.3 SEM images of composites with different Cf contents: (a) 5.0%; (b) 7.5%; (c) 10.0%; (d) 12.5%; (e) 15.0%

图4 不同碳纤维含量的Cf/TiC/Cu复合材料的XRD谱

Fig.4 XRD patterns of Cf/TiC/Cu composites with different Cf contents

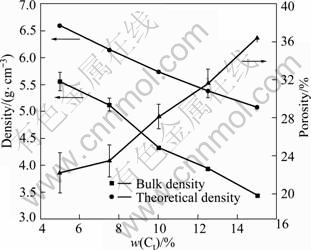

2.3 Cf/TiC/Cu复合材料的密度和孔隙率

图5所示为不同碳纤维含量的Cf/TiC/Cu复合材料密度和实测孔隙率图。由图5可以看出,Cf/TiC/Cu复合材料的密度随着碳纤维含量的增加而逐渐减小,理论密度与实际密度变化趋势一致。因为碳纤维的密度(1.67 g/cm3)远小于Cu(8.90 g/cm3)的密度,在样品添加原料总质量不变,钛的相对含量一样的前提下,碳纤维相对含量增加时, 铜的相对含量就会减小,所以制成的Cf/Cu复合材料的密度就会减小。由图4可知,随碳纤维含量的增加,复合材料的致密度降低,孔隙率升高。这可能有三方面的原因:一是短碳纤维的杂乱堆积,有些碳纤维垂直于压力方向,有些平行于压力方向,而平行于压力方向的碳纤维起支撑作用,阻碍压实致密,因此,致密度随着碳纤维含量的增加而逐渐减小,孔隙率升高;二是随着碳纤维含量的增加,混合过程中纤维更容易团聚,形成架桥效应,形成局部碳纤维为主、铜钛粉很少的区域,高温时需铜液渗透较长距离来填满碳纤维间的孔隙,但由于渗流液中钛含量的变化,可能会导致铜液浸入不足,该碳纤维团聚区中心就会形成较多的细孔,使样品致密度降低,孔隙率升高;最后,也可能是最主要的因素,即铜、碳的热膨胀系数相差较大。20 ℃时,铜和碳的线膨胀系数分别为17.5×10-6和-0.5×10-6 K-1,即使高温下碳纤维之间都被铜液充盈,在随后的冷却过程中由于两者收缩幅度的巨大差异,铜碳会出现分离的倾向。由于铜碳通过TiC过渡层产生很强的化学键结合,因此在保持铜碳界面不分离的情况下,铜金属内部会出现微小的缩孔,就像一般金属铸件中常出现的冷却缩孔一样。由于碳纤维含量少时,碳纤维对铜的收缩限制较小,产生的缩孔相对少;碳纤维含量高时,碳纤维对铜收缩的限制作用强,缩孔的产生相对较多,因此,随碳纤维含量增加,材料致密度下降,孔隙率升高。

图5 Cf/TiC/Cu复合材料的密度和空隙率与碳纤维含量的关系

Fig.5 Relationships among density, porosity and Cf content of Cf/TiC/Cu composites

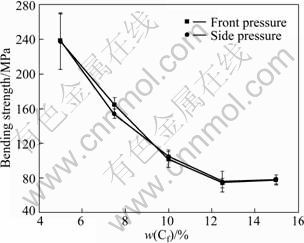

2.4 Cf/TiC/Cu复合材料的抗弯强度

图6所示为复合材料的抗弯强度与碳纤维含量的关系。由图6可以看出,Cf/TiC/Cu复合材料的抗弯强度随着碳纤维含量的增加而总体呈下降趋势,在碳纤维含量由2.5%增加到10.0%时,抗弯强度减小幅度很大,几乎成线性变化;从图6还可以看出,平行于压力方向的抗弯强度为237.90 MPa,垂直于压力方向的抗弯强度为237.44 MPa。抗弯强度之所以随着碳纤维含量的增加而减小,主要是因为复合材料随着碳纤维含量的增加而致密度降低,孔隙率升高。

图6 复合材料的抗弯强度与碳纤维含量的关系

Fig.6 Relationship between bending strength and Cf content of composites

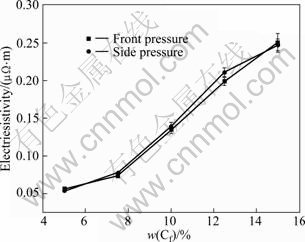

2.5 Cf/TiC/Cu复合材料的电阻率

图7所示为复合材料的电阻率与碳纤维含量的关系。由图7可以看出,Cf/TiC/Cu复合材料的电阻率随着碳纤维含量的增加而逐渐增大,垂直于压力方向与平行于压力方向的电阻率变化趋势相同,且数值几乎相等。这是因为铜的电导率为57.21×106 S/m,碳纤维的电导率为4.2×106 S/m,碳纤维的导电性远小于铜的。另外,碳纤维的存在割断了基体铜的连续性,造成铜的晶格点阵产生畸变,同时复合材料内部存在大量晶界[22],所以随着碳纤维含量的增加,电阻率增大。

3 讨论

图8所示为不同碳纤维含量的复合材料显微组织。从图8可以看出,黑色相(碳纤维)与灰色相(铜) 之间出现了明显的过渡层,该过渡层把碳纤维与铜紧密地连接在一起,且碳纤维含量越少时,该过渡层越厚,碳纤维逐渐增多时,该过渡层就会变薄一些。因为在C-Cu-Ti系统中,溶解在铜液中的钛最容易与碳反应生成TiC[2],紧密地附着在碳的周围形成过渡层,所以该过渡层应该是以TiC或以TiC为主。在钛含量不变的情况下,由于碳纤维含量增多,每根碳纤维周围的钛含量相对减少,因此该过渡层变薄。从图8还可以看出,该过渡层与铜之间的界面结合良好,没有任何孔洞。

图7 复合材料的电阻率与碳纤维含量的关系

Fig.7 Relationship between resistivity and Cf content of composites

图8 不同碳纤维含量的复合材料显微组织

Fig.8 Microstructures of composites with different Cf contents: (a) 5.0%; (b) 7.5%; (c) 10.0%; (d) 12.5%; (e) 15.0%

在制备Cf/Cu复合材料时,由于铜液对碳不浸润,表面张力会阻止铜液包裹碳纤维,热压后铜都被挤出石墨模具,碳纤维间没有铜存在。此外,按照文献[23]的报道,纯铜与TiC不润湿,在1 100、1 130和1 170 ℃时的润湿角分别为126?、115?和105?。但本文作者在制备Cf/TiC/Cu复合材料时,最高热压温度为1 100 ℃,此时铜液中的钛与碳纤维反应生成TiC过渡层,而且铜与TiC过渡层的界面结合良好。这说明有钛存在时,铜液可润湿TiC,形成了很好的铜基碳纤维复合材料,其原因很值得进行深入探讨。

从TiC的生成过程看,溶解在铜液中的钛原子随铜液流动,在接触到碳纤维时,生成热力学更稳定的TiC,这一过程是逐步进行的,即最靠近碳纤维表面的金属液中的钛原子与碳纤维反应生成TiC,生成的TiC层不断增厚,最终阻碍在金属液中的钛原子继续流动到碳纤维处,这样靠近TiC层处的金属液中仍然有少量钛原子存在。如果TiC晶体表面最外层原子是钛原子时,那么它和金属液中的钛原子具有很好的亲和性,形成金属键结合;如果TiC晶体表面最外层原子是碳原子时,必然会吸附铜液中的钛原子,形成部分离子键、部分共价键的C-Ti结合。也就是说,这种环境下生成的TiC晶体靠近金属液一侧的表面应该是钛原子层,该钛原子层可能与铜液中的铜原子形成铜钛化合物,由此与铜润湿,形成很好的结合。BRANDES [24]考察的是铜在碳化钛固体表面的润湿情况,所用的TiC是预先制备好的,其表面为钛原子或碳原子的机会均等,铜原子与碳原子不亲和,因此得到铜与TiC不润湿的结论。

综上所述,可得出一个有意义的新观点:铜钛熔液靠近碳材料时,在碳材料表面生成TiC层,TiC层靠近金属液一侧的表面原子都是钛原子,并可能与铜液中的铜原子形成铜钛化合物膜,通过铜钛共格使TiC与铜很好地结合在一起。这一观点还有待于进一步的研究证实。

4 结论

1) 在热压烧结过程时,于Cu-C-Ti三元系统中,钛与碳最易反应生成TiC。TiC包覆在碳纤维周围,形成原位生成碳芯碳化钛纤维。

2) 复合材料的碳纤维分布均匀,碳与铜通过过渡层紧密结合在一起,界面结合良好。在碳纤维含量为5.0%时,综合性能最好,电阻率低达0.054 μΩ·m,平行于压力方向的抗弯强度为237.9 MPa,垂直于压力方向的抗弯强度为237.44 MPa。

3) 在钛添加量不变的情况下,随碳纤维含量的增加,材料性能有所降低。

4) TiC可能通过钛铜化合物膜与铜保持很好的结合。

REFERENCES

[1] GEFFROY P M, CHATIER T, SILVAIN J F. Preparation by tape casting and hot pressing of copper carbon composites films[J]. European Ceramic Society, 2007, 27: 291-299.

[2] LIANG Y H, WANG H Y, YANG Y F, WANG Y Y, JIANG Q C. Evolution process of synthesis of TiC in the Cu-Ti-C system[J]. Alloys and Compounds, 2008, 452: 298-303.

[3] EVEN C, ARIEU C, ENISSET J M. Powder roite processing of carbon fibres reinforced titanium matrix composites[J]. Composites Science and Technology, 2008, 68: 1273-1281.

[4] SINGH M, SHPARGEL T P, MORSCHER G N, ASTHANA R. Active metal brazing and characterization of brazed joints in titanium to carbon-carbon composites[J]. Materials Science and Engineering A, 2005, 412: 123-128.

[5] 张钦钊. 石墨粒度及其表面化学镀铜对铜-石墨复合材料性能的影响[D]. 福州: 福州大学, 2004.

ZHANG Qin-zhao. The effect of graphite particle size on the properties of copper-graphite composites made with copper-coated and uncoated graphite powders via electroless copper plating[D]. Fuzhou: Fuzhou University, 2004.

[6] JAHAZI M, ALILIAN F J. The influence of thermochemical treatments on interface quality and properties of copper/ carbon-fibre composites[J]. Composites Science and Technology, 1999, 59: 1969-1975.

[7] OKU T, KURUMADA A, SOGABE T, OKU T, HIRAOKA T, KURODA K. Effects of titanium impregnation on the thermal conductivity of carbon/copper composite materials[J]. Journal of Nuclear Materials, 1998, 257: 59-66.

[8] SINGH M, SHPARGEL T P, MORSCHER G N, ASTHANA R. Active metal brazing and characterization of brazed joints in titanium to carbon-carbon composites[J]. Materials Science and Engineering A, 2005, 412: 123-128.

[9] SINGH M, ASTHANA R. Characterization of brazed joints of C-C composite to Cu-clad-Molybdenum[J]. Composites Science and Technology, 2008, 68: 3010-3019.

[10] 易振华, 易茂中, 冉丽萍, 杨 琳. 添加钛对炭/炭复合材料渗铜的影响[J]. 中国有色金属学报, 2006, 16(7): 1214-1218.

YI Zhen-hua, YI Mao-zhong, RAN Li-ping, YANG Lin. Influence of adding Ti on molten copper infiltration into C/C composites[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1214-1218.

[11] OKU T. Effects of titanium addition on the microstructure of carbon/copper composite materials[J]. Solid State Communications, 2007, 141: 132-135.

[12] BRENDEL A, POPESCU C, SCHURMANN H, BOLT H. Interface modification of SiC-fiber/copper matrix composites by applying a titanium interlayer[J]. Surface & Coatings Technology, 2005, 200: 161-164.

[13] 胡 锐, 李海涛, 薛祥义, 李金山, 寇洪超, 常 辉. Ti 对 C/Cu 复合材料界面润湿及浸渗组织的影响[J]. 中国有色金属学报, 2008, 18 (5): 840-844.

HU Rui, LI Hai-tao, XUE Xiang-yi, LI Jin-shan, KOU Hong-chao, CHANG Hui. Effect of Ti on interface wettability and microstructure of C/Cu composites prepared by infiltration[J]. The Chinese Journal of Nonferrous Metals, 2008, 18 (5): 840-844.

[14] 高 嵩, 姚广春. 化学镀铜前碳纤维预处理的研究[J]. 材料保护, 2005, 38(7): 43-45.

GAO Song, YAO Guang-chun. Pretreatment of carbon fiber for electroless copper plating [J]. Material Protection, 2005, 38(7): 43-45.

[15] 杨连威, 刘振刚, 姚广春. 碳纤维镀铜的研究[J]. 材料科学与工艺, 2005, 13(6): 620-622.

YANG Lian-wei, LIU Zhen-gang, YAO Guang-chun. The research of depositing copper on carbon fiber[J]. Materials Science and Technology, 2005, 13(6): 620-622.

[16] 高 嵩, 姚广春. 碳纤维表面镀铜的镀液稳定性[J]. 材料与冶金学报, 2005, 4(4): 317-320.

GAO Song, YAO Guang-chun. Stability of electroless plating solution for Cu plating on carbon fiber[J]. Journal of Materials and Metallurgy, 2005, 4(4): 317-320.

[17] 高 嵩, 姚广春. 影响碳纤维表面镀铜速率的因素[J]. 材料保护, 2005, 38(4): 32-34.

GAO Song, YAO Guang-chun. Factors affecting the copper deposition rate on carbon fiber[J]. Material Protection, 2005, 38(4): 32-34.

[18] 高 嵩, 姚广春. 硼酸涂覆法防止C-Cu复合丝氧化问题[J]. 复合材料学报, 2007, 24(1): 60-64.

GAO Song, YAO Guang-chun. Oxidation problem of C-Cu fiber prepared by using boric acid[J]. Acta Materiae Compositae Sinica, 2007, 24(1): 60-64.

[19] 杨连威, 姚广春. 石墨粉化学镀铜工艺的研究[J]. 材料保护, 2004, 37(6): 20-22.

YANG Lian-wei, YAO Guang-chun. Electroless copper plating technology for graphite powder [J]. Material Protection, 2004, 37(6): 20-22.

[20] YANG Lian-wei, YAO Guang-chun, LU Yang. Research on new and high performance electric locomotive pantograph slide Plate[J]. Materials Review, 2005, 19(11): 136-139.

[21] 刘桂香, 黄向东, 郑振环, 李 强. 热压烧结一步制备C/Cu复合材料的组织和性能研究[J]. 复合材料学报, 2010, 27(1): 73-78.

LIU Gui-xiang, HUANG Xiang-dong, ZHENG Zhen-huan, LI Qiang. Microstructure and properties of Cf/Cu composites prepared by one-step hot-pressing sintering[J]. Acta Materiae Compositae Sinica, 2010, 27(1): 73-78.

[22] 龙卧云, 丁晓坤, 杨晓华, 林智群, 任文辉, 李雪松. 碳纤维增强铜基复合材料的性能研究[J]. 理化检验-物理分册, 2006, 42(8): 379-381.

LONG Wo-yun, DING Xiao-kun, YANG Xiao-hua, LIN Zhi-qun, REN Wen-hui, LI Xue-song. Study of properties of carbon fiber reinforced copper matrix composites[J]. Physical and Chemical Testing-Physical Volumes, 2006, 42(8): 379-381.

[23] CONTREAS A. Wetting of TiC by Al-Cu alloys and interfacial characterization[J]. Colloid and Interface Science, 2007, 311: 159-170.

[24] BRANDES E A. Smithells metals reference book[M]. 7th ed. American: Butteruorth-HeinemanLtd, 1992: 244

(编辑 何学锋)

基金项目:福州大学科技发展基金资助项目(2006-XQ-01);福州大学人才基金资助项目(XJY-0305)

收稿日期:2009-05-25;修订日期:2009-09-15

通信作者:黄向东,副教授,博士;电话:13509354015;E-mail:huang_xdong@fzu.edu.cn