文章编号: 1004-0609(2006)02-0205-08

Mg-5Zn-3Al-0.2Mn铸造合金的组织和室温力学性能

杨光昱, 介万奇, 郝启堂

(西北工业大学 材料科学与工程学院, 西安 710071)

摘 要: 研究了砂型铸造Mg-5Zn-3Al-0.2Mn合金的显微组织, 发现其主要相组成为δ -Mg基体相和τ(Mg32(Al, Zn)49)化合物相, τ相以半连续网状骨骼形态沿δ相的晶界分布。 实验合金中加入少量Sr, Ti, B元素后, 合金组织细化, τ相形态转变为断续的短条状或粒状, 并且分布更加均匀。 在本实验条件下, 当炉前加入0.06%Ti、 0.012%B、 0.1%Sr时, 合金的组织形态得到显著改善, 合金的室温力学性能最佳。 不同温度下对Mg-5Zn-3Al-0.2Mn合金进行的固溶处理实验发现, 在335℃固溶17h淬火后, 合金的室温抗拉强度和塑性得到了大幅度提高; 在343℃固溶17h淬火后, 合金组织完全转变为单相固溶体, 合金的室温力学性能较好, σb为245MPa, δ为12%。

关键词: 铸造镁合金; 显微组织; 室温力学性能; 变质; 固溶处理

中图分类号: TG146.4 文献标识码: A

Microstructures and room temperature

mechanical properties of Mg-5Zn-3Al-0.2Mn casting alloy

YANG Guang-yu, JIE Wan-qi, HAO Qi-tang

(College of Materials Science and Engineering,

Northwestern Polytechnic University, Xi′an 710071, China)

Abstract: The as-cast microstructures of sand-casting magnesium alloys Mg-5Zn-3Al-0.2Mn were studied, which was found to contain δ -Mg and τ(Mg32(Al, Zn)49) phases. By adding trace elements Sr, Ti and B into the melt of the alloys, the primary grain of δ -Mg is refined, meanwhile the morphology of τ phase is changed from semi-netted shape to short rods or spheres, and the distribution of τ phase tends to be more homogeneous. In the case of additions of 0.06%Ti, 0.012%B, and 0.1%Sr, δ -Mg grain is greatly refined and the best room temperature mechanical properties are gotten. It is also found that the ultimate strength and the elongation of Mg-5Zn-3Al-0.2Mn alloy greatly increase when the alloy is quenched after annealed at higher temperature. The microstructure of Mg-5Zn-3Al-0.2Mn alloy is transformed from binary phase microstructure into δ -Mg solid solution due to the dissolution of τ phase after annealed at 343℃ for 17h, and meanwhile the mechanical properties reach the maximum values, i.e., σb 245MPa, δ 12%.

Key words: casting magnesium alloy; microstructures; room temperature mechanical properties;refinement; solid solution treatment

铸造镁合金具有低密度、 高比强度、 较低的刚性和较大的冲击功吸收等独特的优点, 目前在汽车、 航空航天、 电子等领域得到日益广泛的应用[1-3]。

通常, 铸造镁合金分为标准类镁合金、 高强度类镁合金和耐热类镁合金[4, 5]。 在Mg-Al-Zn系镁合金中, 高Al(5%~10%)低Zn(0.2%~3%)类合金的研究目前已比较充分, 如AZ91, AZ92, AZ63, AZ81, AM100A等均是以此为基础而发展出来的[3, 5]。 由于这类合金的σ0.2较低, 各国一直在努力发展高σ0.2的合金, 即高强镁合金。

高强度类镁合金目前主要是Mg-Zn-Zr系合金, 其优点在于具有较高的抗拉强度和较高的屈服强度, 但热裂与缩松倾向较为严重。 由于Zr的熔点高、 化学活性高、 可与镁合金液中的Fe、 Al、 Si、 Mn等元素优先形成化合物而沉淀, 在镁合金液中溶解度小, 所以该系列镁合金的熔炼工艺较为复杂, 熔炼时易产生Zr的偏析, 在铸造生产中存在比较严重的夹杂问题。 Zr夹杂可以使合金的强度和塑性下降20%以上[4, 6]。

虽然Al在Mg-Zn-Zr中是杂质元素。 然而Al和Zn一样, 都是镁合金中最常用的固溶强化元素, 并且Al能够改善合金的铸造性能。 Zn能够增加合金熔体的流动性, 但Zn量增加也会加大镁合金的缩松倾向[5, 7]。 因此, 研究Mg-Zn-Al三元相图中高Zn低Al侧合金的组织和室温力学性能具有重要意义。

研究表明[ 8, 9], 晶粒细化对提高镁合金铸件的性能至关重要。 晶粒细化能够减小缩松倾向, 提高镁合金的气密性、 耐蚀性和力学性能。 尤其对于冷速很慢的砂型铸造合金, 细化合金晶粒、 改善合金组织中第二相的分布形态, 对于生产出高性能的优质铸件无疑是一项关键技术。

本文作者在研究Mg-5Zn-3Al-0.2Mn合金砂型铸造组织结构的基础上, 进一步探索Sr、 Ti、 B元素对组织和力学性能的影响。 同时, 研究固溶处理对该合金室温力学性能的影响。

1 实验

1.1 实验合金的制备

实验合金的熔炼在12kg电阻坩锅炉中进行。 实验合金的成分范围(质量分数): 4.8%~5.5% Zn, 2.6%~3.5% Al、 0.15%~0.25% Mn、 〈0.016% Fe、 余量为Mg。 熔炼在RJ-6溶剂保护下进行。 Zn和Al以纯金属(99.9%)的形式加入, Mn、 Ti和Sr分别以中间合金Al-10%Mn、 Al-5%Ti-1%B、 Al-10%Sr形式加入。 合金精炼好后, 在高于760℃加Al-10%Sr或Al-5%Ti-1%B变质处理。 在高于760℃保温30min以上, 再次精炼, 静置8min。 在745℃时分别浇铸成标称尺寸为d10mm×50mm的金相试样, d12mm×50mm的标准砂型拉力试棒。 各炉次实验合金的成分化验结果列于表1。

表1 实验合金的化学成分

Table 1 Chemical composition of experimental alloys (mass fraction, %)

1.2 实验方法

实验合金常温力学性能的测试在CSS1220型电子万能拉力实验机上进行, 每组测试3根试样, 结果采用其平均值。 合金成分分析采用电感耦合等离子体发射光谱(ICP)分析方法。 金相试样用3%的硝酸酒精溶液腐蚀。 显微组织观察采用XJL-02型光学显微镜和LEO1455VP型扫描电子显微镜(SEM)。 微区成分分析采用Oxford Inca型能量色散谱仪(EDS)。 合金组成相分析采用X射线衍射(XRD, Cu靶, Kα谱线)和微区成分分析相结合的方法进行。 X射线衍射仪型号为D/MAX2400型。 合金的相变点测定采用DSC方法在DSC-2910差示量热分析仪上进行。 实验合金的热处理在箱式炉中进行, 恒温区温度均匀性为±5℃。

2 结果与讨论

2.1 实验合金的微观组织分析

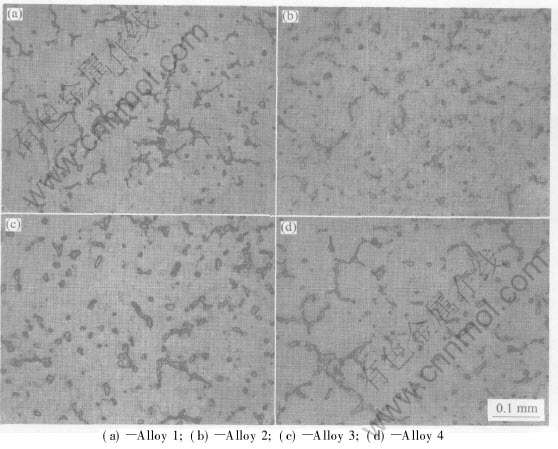

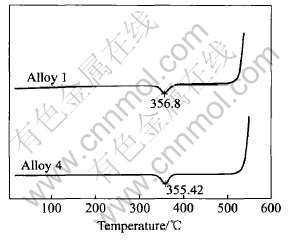

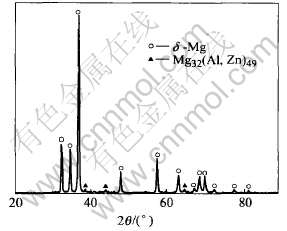

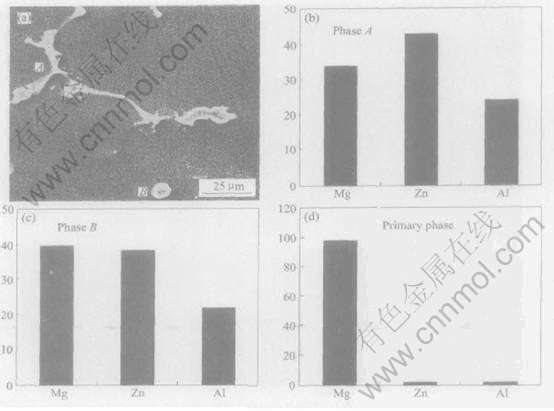

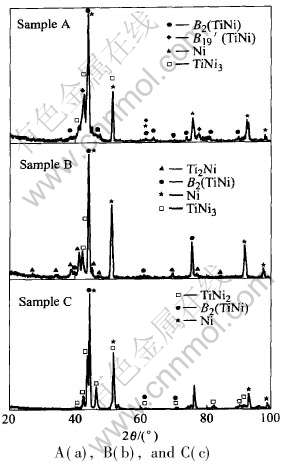

图1所示为实验合金的典型显微组织。 为了分析实验合金的相组成, 分别对1号合金和4号合金试样进行了DSC分析, 结果见图2。 可见1号和4号合金均由两相组成。 对1号合金进一步的X射线衍射分析(见图3)和EDS分析(见图4)显示, 1号合金的主要相组成为: δ -Mg基体相和τ(Mg32(Al, Zn)49)化合物。 图4(a)中A, B两种形态的第二相均为τ相。 由于2号、 3号合金的主要成分与1号合金的一致, 4号合金虽然含有0.16%Sr, 但其DSC分析曲线与1号合金的一致, 相变点相同。 因此断定, 1号至4号合金的主要相组成均为: δ -Mg基体相和τ(Mg32(Al, Zn)49)相。

图1 实验合金的铸态显微组织

Fig.1 Microstructures of as-cast experimental alloys

图2 1号和4号合金的DSC曲线

Fig.2 DSC curves of alloys 1 and 4

图3 1号合金的X射线衍射谱

Fig.3 XRD pattern of alloy 1

由图1可以观察到, 4种实验合金组织中的第二相形态彼此不同。 1号合金组织中的τ相呈现相边界极不规则的半连续网状骨骼形态, τ相分布较为不均匀。 2号合金的τ相呈现断续骨骼状或粒状, τ相分布较为不均匀。 3号合金的τ相形态则呈现短棒条状或粒状, 粒状τ相的数量较2号增多, τ相的边界较1号、 2号合金更为光滑园整, 合金晶粒细小。 对于4号合金, τ相分布比1号合金均匀, 组织形态的变化没有3号合金大, 粒状τ相的数量较1号增多, 晶粒略有细化。 同时还观察到, 3号和4号合金的第二相局部都出现了较明显的层片状组织, 4号合金的这种现象更为明显(见图5)。 以上观察说明, Sr、 Ti、 B对Mg-5Zn-3Al-0.2Mn合金的第二相有明显的变质作用。

2.2 实验合金的室温力学性能

图4 1号合金的SEM照片和EDS分析结果

Fig.4 SEM image and EDS analysis results of alloy 1

图5 4号合金的SEM照片、 C区域的EDS分析结果以及线扫描分析结果

Fig.5 SEM photo (a), EDS analysis resultsof zone C(b) and line scanning analysis results(c) of alloy 4

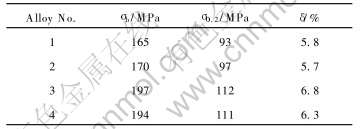

表2所列为实验合金的砂型铸造铸态室温力学性能。 可以看到3号和4号合金的力学性能得到了较大幅度提高, 合金的屈服强度明显增加。 而2号合金的力学性能则略有改善, 但不明显。

表2 砂型铸造铸态实验合金的室温力学性能

Table 2 Mechanical properties of sand-cast specimen at room temperature

2.3 Sr、 Ti、 B对合金组织和性能影响的机理

为了分析Sr对合金组织的影响机理, 对4号合金试样图5(a)中的C区域作了EDS分析, 结果见图5(b)。 发现合金的层片状组织中含有Sr, 其中黑色层片状相为基体相, 含Sr高达0.65%(EDS分析结果省略)。 而合金基体相及园点状τ相中不含Sr。 为了进一步确定Sr的分布情况, 对4号合金进行了线扫描分析, 结果见图5(c)。 发现Sr元素主要分布在黑白层片状组织间的过渡区域。 这说明合金凝固时, Sr可能富集在τ相生长表面, 形成一层薄膜, 该薄膜抑制了τ相的长大, 从而形成了层片状组织。

研究表明[10, 11], Ti对于镁合金为表面活性元素, 它一般分布在晶界上。 合金在凝固时, Ti元素在τ相凝固前沿富集, 抑制了三元相τ的生长, 从而使半连续网状的τ相变为棒状或粒状。 所以在2号、 3号合金加入Ti后, 第二相τ的形态发生了变化。

Johnson确立的溶质晶粒细化理论认为[12, 13], 偏析倾向大的溶质和有效的形核质点是晶粒细化必不可少的两个因素。 溶质偏析使生长晶粒的液固表面前沿产生成分过冷区, 从而阻碍了晶粒生长, 并提供了激活成分过冷区内形核质点的驱动力。 而形核质点的形核能力决定了凝固开始及成分过冷区内有效晶核的数量。

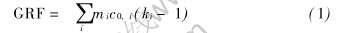

溶质元素的作用可以用生长抑制因子(GRF)来表示[12]:

式中 mi为二元相图中液相线斜率; c0, i为合金中溶质元素的原始含量; ki为溶质的分凝因数。 表3列出根据二元相图确定的镁合金中Zr、 Ca、 Sr、 Ce、 Y等溶质元素的生长抑制系数m(k-1)。

表3 镁合金中溶质元素的生长抑制系数[14]

Table 3 Growth restriction parameter for alloying element in magnesium[14]

与Zr、 Ca等元素相比, Sr的GRF值较小。 但Sr的GRF值较Ce、 Y等元素为高。 因此, Sr虽具有一定的晶粒细化能力, 但较弱, 这和4号合金的组织观察结果是一致的。 Sr细化晶粒的原因可能是由于其吸附在生长晶粒表面形成一层薄膜, 该薄膜阻碍了晶粒长大并提供了较多的时间使镁合金液中更多的碳化物、 TiB2等形核质点被激活所致。

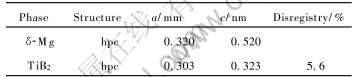

而合金异质形核能力取决于形核基底与结晶相间的界面能, 失配度则是决定界面能的主要因素。 新相在固相衬底上形核应满足低指数晶面的失配度小于15%的条件[11-13]。 表4所列为TiB2形核质点和δ -Mg基体相的晶体结构、 晶格常数及TiB2的(0001)面和δ -Mg的(0001)面的晶格失配度。 可以看出, TiB2为密排六方结构, 其晶格常数与δ -Mg的晶格常数比较接近, 其熔点tm为2980℃, 所以在合金液中以固态质点存在; TiB2的(0001)面和δ -Mg的(0001)面的晶格失配度为5.6%, 所以TiB2的(0001)面可作为δ -Mg相的异质形核基底, 促进合金的异质形核。 因此2号和3号合金的组织出现了细化。 而另一方面, Sr元素在镁合金中的溶解度极低, 它在凝固界面的富集, 阻止了晶粒的长大, 所以Sr对于Ti元素的细化具有促进作用。 同时, 合金细化剂的加入存在一个最佳量的问题, 太少则

表4 TiB2和δ -Mg的晶体结构、晶格常数[13, 15]及(0001)TiB2面和(0001)δ -Mg面的晶格失配度

Table 4 Crystal structure and lattice parameters of TiB2 and δ -Mg[13, 15], and calculated disregistry between (0001)TiB2 and (0001)δ -Mg

不能形成足够的形核质点而使细化作用很弱, 太多则形核核心聚集沉淀而失去形核核心。 在本次实验中, 3号合金的Sr、 Ti、 B加入量为最佳, 这从合金的力学性能和组织形态上可以得到证明。

镁合金的屈服强度和晶粒尺寸的关系可用Hall-Petch关系表示为[15]

对于镁合金, 式(2)中的系数k=280~320MPa·μm1/2。 铝合金的k=68MPa·μm1/2, 因而与铝合金相比, 镁合金的细化更能有效提高合金的强度。 3号合金的晶粒度最小, 同时第二相形态光滑圆整, 分布均匀, 所以其强度和塑性最好, 尤其是合金的屈服强度得以较大的提高。 而4号合金的形态和晶粒度为次好, 所以性能也仅次于3号合金。

2.4 实验合金的固溶热处理强化和组织转变

由于Mg-Zn-Al系合金具有极强的固溶强化效果, 因此对1号实验合金的拉力试棒进行了固溶处理。 根据图2所示合金的DSC分析曲线可知, 1号合金的固相线温度约为356.8℃。 对于一般镁合金, 为了获得最大的过饱和固溶度, 淬火加热温度通常只比固相线低10℃左右, 但有时为了防止合金局部过烧, 所以有时将固溶温度要调得更低一些。 为了摸索实验合金适宜的固溶温度, 制定了以下不同固溶温度: 323, 335, 343和350℃。 考虑到镁合金原子扩散能力弱, 为了保证τ相充分固溶, 需要较长的加热时间, 因此实验合金的保温时间定为17h。 为防止铸件过烧, 采取了分段加热方式, 在290℃下保温2.5h, 然后再逐步升温到固溶温度, 进行保温, 再直接淬于70~80℃的热水中。

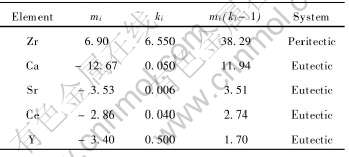

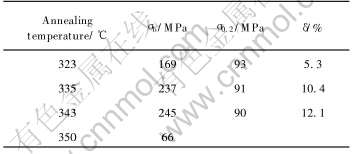

图6所示为不同固溶温度下1号实验合金的淬火组织。 表5列出不同淬火温度下1号实验合金淬火后的力学性能。 可以看到, 在同样加热时间下, 随着固溶温度的提高, 合金组织中τ相固溶量逐步增加。 在323℃固溶处理后, 晶界上的粒状和细小的τ相大部分消失, 合金的力学性能较铸态略有提高。 而335℃固溶处理后, τ相的溶解量达到80%以上, σb和δ大幅提高, 分别达到237 MPa和10.4%。

一般认为, 铸造合金中的化合物约有85%固溶时, 合金便具有最大的强度极限[5]。 实验合金在343℃固溶后, 组织中的第二相τ完全消失(见图 [CM(22]6(c)), 合金的力学性能为最好, 但与335℃的固

图6 1号合金在不同淬火温度下热处理的显微组织

Fig.6 Microstructures of quenched alloy 1 after annealing at different temperatures

表5 1号合金在不同固溶温度保温17h后淬火的室温力学性能

Table 5 Mechanical properties of quenched alloy 1 after 17h annealing at different temperatures

溶合金的力学性能相比较, 提升幅度极小。 由于在水中淬火的合金微观结构的特点就是没有清楚的晶界[5], 所以合金的腐蚀金相中没有出现象通常镁合金在空气中淬火时组织腐蚀后所出现的清晰晶界。 而在350℃下进行固溶处理的合金组织(见图6(d)), 在晶界汇合处发生了多边化熔汇现象, 合金的晶界明显粗化, 这是典型的过烧组织特征[4, 5]。 此时, 合金的力学性能急剧恶化。 可以发现, 1号实验合金的完全固溶温度区间很窄, 所以合金如果在固溶态下使用, 采用335℃的固溶温度比较合适。

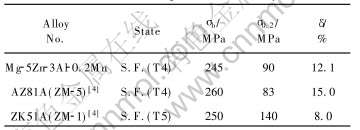

表6列出实验合金T4态的力学性能与AZ81A、 ZK51A合金的室温力学性能对比。 可以看出, 实验合金T4态的室温抗拉强度与这两种合金的基本相当, 其屈服强度低于ZK51A合金, 但高于AZ81A合金。 塑性高于ZK51A合金, 但低于AZ81A合金。

表6 实验合金和AZ81A、ZK51A合金的室温力学性能的对比

Table 6 Comparison of mechanical properties at room temperature among AZ81A, ZK51A and experimental alloys

3 结论

1) Mg-5Zn-3Al-0.2Mn砂铸合金的主要相组成为δ -Mg基体相和τ(Mg32(Al, Zn)49)化合物相。 τ相以半连续网状分布在δ -Mg的晶界上。

2) Mg-5Zn-3Al-0.2Mn合金中加入少量Sr, Ti, B时, 组织发生了细化, τ相由半连续网状向断续的短条状或粒状转变, 分布趋于均匀。 在本实验条件下, 当在炉前加入0.06%Ti、 0.012%B、 0.1%Sr时, 合金组织形态得到最大改善, 合金室温力学性能最佳。

3) 不同温度下Mg-5Zn-3Al-0.2Mn合金的固溶热处理实验发现, 在335℃固溶17h淬火后, 合金的室温抗拉强度和塑性得到了大幅提高。 在343℃固溶17h淬火后, 组织完全转变为固溶体, 力学性能较好, σb为245MPa, δ为12%。

REFERENCES

[1]Brulower P M. Automotive die casting magnesium reviving up for the 21st century[J]. Die Casting Engineering, 1997, 41(3): 68-70.

[2]余琨, 黎文献, 王日初. 变形镁合金的研究、 开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu. Application and development of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[3]Lou A A. Resent magnesium alloy development for elevated temperature application[J]. International Materials Reviews, 2004, 49(1): 13-30.

[4]陆树荪, 顾开道, 郑来苏. 有色铸造合金及熔炼[M]. 北京: 国防工业出版社, 1983.

LU Shu-xun, GU Kai-dao, ZHENG Lai-su. Foundry and Melting of Nonferrous Alloys[M]. Beijing: Defense Industry Press, 1983.

[5]Портни К И, Лебедев А А. 镁合金手册[M]. 林裴, 译. 北京: 冶金工业出版社, 1966.

Портни К И, Лебедев А А. Handbook of Magnesium Alloys[M]. LIN Pei, transl. Beijing: Metallurgical Industry Press, 1966.

[6]Raynor G V. The Physical Metallurgy of Magnesium and Its Alloys[M]. Oxford: Pergamon, 1959.

[7]Matucha K H. Structure and Properties of Nonferrous Alloys(Vol8)[M]. Germany: VCH, 1996.

[8]Kurota K, Mabuchi M, Higashi K. Review processing and mechanical properties of fine-grained magnesium alloys[J]. Journal of Materials Science, 1999, 34: 2255-2262.

[9]Dahle K, Lee C A. Nave D Y. Mark, et al. Development of the sa-cast microstructure in magnesium-aluminum alloys[J]. Journal of Light Metals, 2001(1): 61-72.

[10]杨光昱, 郝启堂, 介万奇. 微量Ti对Mg-9Al合金显微组织和性能的影响[J]. 稀有金属与工程, 2005, 34(3): 380-384.

YANG Guang-yu, HAO Qi-tang, JIE Wan-qi. Effects of trace Ti on the microstructure and properties of casting Mg-9Al magnesium alloy[J]. Rare Metals Materials and Engineering, 2005, 34(3): 380-384.

[11]王迎新, 杨明珊, 李立明. Al5TiB对Mg-8Zn-4Al-0.3Mn合金的显微组织的影响[J]. 机械工程材料, 2003, 27(9): 36-39.

WANG Ying-xin, YANG Ming-shan, LI Li-ming. Effects of Al5TiB on microstructures of Mg-8Zn-4Al-0.3Mn magnesium alloy[J]. Materials for Mechanical Engineering, 2003, 27(9): 36-39.

[12]刘子利, 沈以赴, 李子全. 铸造镁合金的晶粒细化技术[J]. 材料科学与工程学报, 2004, 22(1): 146-149.

LIU Zi-li, SHEN Yi-fu, LI Zi-quan. Review of the grain refinement technology of cast magnesium alloys[J]. Journal of Materials Science & Engineering, 2004, 22(1): 146-149.

[13]Mark E, David S J. Grain refinement of aluminum alloys[J]. Metall Mater Trans A, 1999, A30(6): 1613-1633.

[14]Yousuke T, Norio K, Tetsuichi M. Grain refining mechanism and structure of Mg-Zr alloy[J]. Journal of Japan Institute of Light Metal, 1998, 48: 185-189.

[15]胡赓祥, 钱苗根. 金属学[M]. 上海: 科学技术出版社, 1980.

HU Geng-xiang, QIAN Miao-gen. Metallurgy of Metals[M]. Shanghai: Science and Technology Press, 1980.

(编辑陈爱华)

基金项目: 国家重大基础研究发展规划资助项目(G2000067202)

收稿日期: 2005-06-02; 修订日期: 2005-08-22

作者简介: 杨光昱(1967- ), 男, 高级工程师, 博士研究生

通讯作者: 杨光昱, 电话: 029-88494276; 传真: 029-88494276; E-mail: seniorygy.student@sina.com