CFRP复杂型面构件的孔隙率超声检测方法

胡宏伟1,李雄兵2,杨岳2,倪培君3,童林军2

(1. 长沙理工大学 汽车与机械工程学院,湖南 长沙,410114;

2.中南大学 CAD/CAM研究所,湖南 长沙,410075;

3. 中国兵器科学研究院宁波分院,浙江 宁波,315103)

摘要:针对碳纤维复合材料(CFRP)复杂型面构件给出一种孔隙率超声自动检测方法:首先对已知孔隙率的CFRP试块进行超声测量,利用相位展开法求得不同孔隙率条件下的相速度,通过相速度与孔隙率之间的内在联系建立CFRP超声检测模型。针对CFRP复杂型面构件先利用超声测距原理采集其表面的坐标信息,根据曲面反求获得其CAD模型,检测路径规划生成探头运动点位;基于多自由度机械手的喷水耦合超声透射法采集超声信号,结合已建立相速度模型计算CFRP复杂型面构件的孔隙率。为验证本文方法的有效性,通过对已测CFRP复杂型面构件进行试片剖切和抛光,利用显微照相法检测其孔隙率。实验结果表明:2种方法的检测结果吻合良好。

关键词:碳纤维复合材料;复杂型面构件;相速度;孔隙率;超声检测

中图分类号:TB332 文献标志码:A 文章编号:1672-7207(2012)04-1315-05

Method of inspecting porosity in CFRP with complex surface by ultrasonic

HU Hong-wei1, LI Xiong-bing2, YANG Yue2, NI Pei-jun3, TONG Lin-jun2

(1. College of Automobile and Mechanical Engineering,

Changsha University of Science and Technology, Changsha 410114, China;

2. CAD/CAM Institute, Central South University, Changsha 410075, China;

3. The Ningbo Branch of Ordnance Science Institute of China, Ningbo 315103, China)

Abstract: An automatic method of inspecting porosity in CFRP (Carbon fiber reinforced plastic) with complex surface by ultrasonic was presented. Through-transmission mode was used to obtain ultrasonic signals of CFRP test blocks with given porosity, and phase-unwrapping method was used to calculate the test blocks phase velocity, and an ultrasonic inspection model based on the relation between phase velocity and porosity was established. The 3D surface data of CFRP with complex surface were obtained by ultrasonic measurement, and then the inspection path was planned after the CAD model had been reconstructed. A multi-degree-of-freedom manipulator was used to acquire ultrasonic signals of CFRP with complex surface, and its porosity was calculated according to the ultrasonic inspection model presented. In order to verify the validity of the presented method, microphotography was used to get the porosity of CFRP with complex surface after block slitting and polishing. The results show that the porosity inspected by the ultrasonic method is in good agreement with that obtained by microphotography.

Key words: CFRP (Carbon fiber reinforced plastic); components with complex surface; phase velocity; porosity; ultrasonic inspection

碳纤维复合材料(CFRP)具有高强度、高硬度和低密度等优越性能,被广泛应用于航空航天、军工、能源等领域[1]。由于其具有独特的制造工艺,在制造的过程中容易形成孔隙、脱粘、分层等缺陷,这些缺陷的存在积累到一定程度就会造成构件性能急剧下 降[2]。随着CFRP的大量应用,其潜在的安全隐患也逐渐显露[3]。可见,准确检测CFRP的内部缺陷尤显迫切。超声无损检测是CFRP内部缺陷的重要检测手段[4],其中脱粘和分层缺陷比较容易检出[5],但检测孔隙缺陷是CFRP超声检测方法中的难点,国内外学者对此开展了大量的研究,如采用衰减法[6]、声阻抗法[7]和背散射法[8]等。现有研究普遍针对标准试件和具有规则几何形状的CFRP构件,且检测的自动化程度不高。而实现复杂型面构件的超声检测,需要充分利用机器人技术、自动控制技术、计算机技术、信号处理技术、CAD/CAM等技术领域的前沿研究与无损检测技术有机结合,这是近年来国内外超声无损检测领域的热点问题与前沿课题[9]。本文作者基于超声测量、建模及检测一体化的思想,通过信号分析建立相速度-孔隙率的超声检测模型,研究一种CFRP复杂型面构件孔隙率自动检测方法。

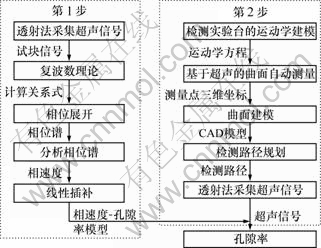

1 检测原理

CFRP中所含孔隙率的不同会导致其密度及声阻抗等参数的改变,从而影响超声波在该材料中传播的相速度,本文在该物理本质的基础上进行研究。CFRP复杂型面构件孔隙率超声自动检测方法分以下2步:第1步基于孔隙率已知的CFRP试块建立相速度—孔隙率超声检测模型;第2步将该模型应用于CFRP复杂型面构件孔隙率的自动超声检测。如图1所示,第1步的具体流程如下:采用透射法对孔隙率已知的试块进行超声检测,分别采集当2个探头之间未插入试块时的参考信号和插入试块时的试块信号。用复波数的概念[10]得出试块中超声波的相速度和衰减的计算关系式,用相位展开法[11]得到参考信号和试块信号的相位谱,并比较两者的相位谱得出试块中超声波的相速度,建立相速度与试块孔隙率之间的关系。

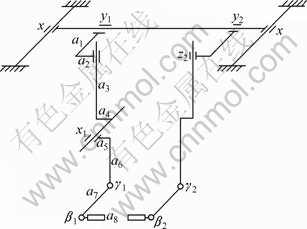

由于超声波具有很强的指向性,超声信号采集时要求声束入射方向与检测点法矢方向保持一致[12],因此,第2步的关键问题是如何准确采集CFRP复杂型面构件的超声信号。采用如图2所示的多自由度机械手实现超声测量及检测一体化,首先对多自由度机械手进行运动学建模,建立其运动学方程,然后按“曲面—曲线—测量点集”策略对构件表面进行测点规划,并通过调整机械手各关节变量使声束对正构件上的检测点,然后利用运动学方程正解获得测量点的三维坐标值,通过曲面反求建立其CAD模型,根据检测需要将构件表面离散若干检测点,利用运动学方程的逆解计算出机械手的各关节变量;最后,根据规划的探头运动点位依次采集超声数据。

图1 孔隙率超声自动检测流程图

Fig.1 Flow chart of porosity ultrasonic inspection

图2 透射法超声测量的系统结构图

Fig.2 System structure of ultrasonic transmission measurement

2 复杂型面构件的超声信号采集

本文所研究的多自由度机械手的原理结构和连杆坐标系如图3所示。左机械手有3个独立的移动副和2个独立的转动副,右机械手有2个独立的移动副和2个独立的转动副。此外,左右手臂还共用1个移动副。其中:左机械手的6个关节变量分别为(x,x1,y1,z1,β1,γ1),右机械手的5个关节变量分别为(x,y2,z2,β2,γ2)。

图3 超声检测机械手杆件坐标系约定

Fig.3 Convention of ultrasonic manipulator frame coordinates

按Denavit-Hartenberg方法[13]建立左机械手臂的运动学方程,其正解见式(1),运动学方法逆解见式(2)。由于左右机械手在结构上只差1个移动关节,所以,两者的运动学建模方法类似。

(1)

(1)

(2)

(2)

式中:a1~a7为结构参量;a8是左侧超声探头的装夹长度;(nx,ny,nz)和(Px,Py,Pz)分别为测量点法矢和坐标值。

基于以上的机械手运动学建模,系统首先利用单探头反射法,通过左机械手控制探头进行仿形测量,根据运动方程的正解获取CFRP复杂型面构件的曲面测量数据,曲面建模后再根据超声检测的工艺要求对曲面进行离散,然后,根据运动方程的逆解得到运动点位,最后控制探头进行超声信号的采集。

3 相速度-孔隙率模型

利用超声透射法采集试块信号及参考信号,用复波数的概念得出试块中超声波的相速度计算关系式,用相位展开法得到参考信号和试块信号的相位谱,并比较两者的相位谱得出试块中超声波的相速度[10]:

(3)

(3)

其中:vw为超声波在水中的传播速度;ω为角频率;h为试块厚度;-Δf(ω)为超声在参考信号和试块信号的相位差。

从待测复杂型面构件同一批成型的碳纤维复合材料中,选用12种不同面积孔隙率(void)的纤维交叉编织层压板分别制作成30 mm×30 mm×4 mm(长×宽×厚)的试块,选用5 MHz纵波平探头透射法采集超声信号,通过上述处理方法获得该批次复合材料在不同频率下的超声波相速度,结果如图4所示。

图4 不同孔隙率下试块的相速度(5 MHz)

Fig.4 Phase velocities of CFRP blocks with different porosities (5 MHz)

Reynolds提出了关于超声波声速v与孔隙率P之间关系模型[14]:

v=v0-kP (4)

其中:v0为超声波在无孔隙复合材料中的传播速度;k为与纤维体积含量相关的常量。为求得系数v0和k,将图4中的数据拟合成一条直线,使得拟合前后声速残差V-v的绝对值之和最小:

(5)

(5)

假设

(6)

(6)

(7)

(7)

有xi+yi=|Vi-vi|。求残差之和最小值,就变成了如下线性规划问题:

(8)

(8)

xi≥0,yi≥0;i=1,2,…,12

可用单纯形法[15]求得v0=2 637.0,k=148.2,该批次复合材料的相速度-孔隙率模型为:

v=2637.0-148.2P (9)

4 结果和讨论

对如图5(a)所示的CFRP复杂型面构件进行试验,首先通过超声测距采集构件表面上的三维坐标,曲面测量结果见图5(b)。然后采用曲面蒙皮方法对测量数据进行CAD模型重构,结果如图5(c)所示。再将曲面离散成有限个检测点,见图5(d)。每个检测点对应1个小图元,在实时超声信号采集时,进行相位展开法计算出每个检测点所对应的超声相速度,并结合已建立的相速度-孔隙率模型获取其孔隙率,最后利用调色板技术对图元进行“着色”,实现CFRP复杂型面构件孔隙率的可视化,检测结果见图5(e)。

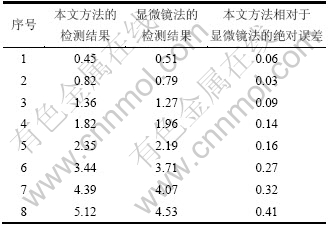

为验证本文方法的有效性,将被测构件进行剖切和抛光,采用显微照相法进行拍照[16],图5 (f)为其中的一个实例(显微镜为江南光学仪器厂生产的XJP-200金相显微镜,显微镜所用摄像头为日本产Panasonic wv-GP240,采用反射方式观察拍照)。通过对照片进行图像分析,以所有孔隙的总面积与断面面积之比表示孔隙率。2种不同方法的实验结果见表1。从表1可以看出:二者误差控制在0.5%以内,尤其是孔隙率小于2.5%时,2种方法的测量结果吻合良好。文本研究对象为CFRP型面型面构件,因此,声束入射面存在不同程度的曲率,导致采集到的超声信号存在漫反射现象;另外,检测系统自身的刚性也是导致系统误差的一部分。需要指出的是:本实验得到的测量结果是针对该批次的纤维交叉编织层压板,不同的复合材料类型和成型工艺,需要通过具体的实验测试和模型进行研究。

表1 2种方法的孔隙率检测结果对比

Table 1 Results contrast of two inspection methods %

图5 CFRP复杂型面构件的孔隙率检测实例

Fig.5 Porosity inspection example of CFRP with complex surface

5 结论

(1) 对已知孔隙率的CFRP试块进行超声测量,利用相位展开法求得不同孔隙率条件下的相速度,通过相速度与孔隙率之间的内在联系建立CFRP超声检测模型。

(2) 利用多自由度机械手实现了CFRP复杂型面构件的超声信号采集,结合已建立相速度-孔隙率模型计算被测构件的孔隙率。

(3) 通过对将被测构件进行剖切和抛光后,采用显微照相法检测其孔隙,对比实验结果表明了本文方法的有效性。

参考文献:

[1] Soutis C. Fibre reinforced composites in aircraft construction[J]. Progress In Aerospace Sciences, 2005, 41(2): 143-151.

[2] Wicklein M, Ryan S, White D M. Hypervelocity impact on CFRP: Testing, material modeling, and numerical simulation[J]. International Journal of Impact Engineering, 2008, 35(12): 1861-1869.

[3] 赵稼祥. 碳纤维复合材料在民用航空上的应用[J]. 高技术纤维与应用, 2003, 28(3): 74-78.

ZHAO Jia-xiang. Application of carbon composite materials for civil aviation[J]. Hi-Tech Fiber & Application, 2003, 28(3): 74-78.

[4] Mouritz A P. Ultrasonic and interlaminar properties of highly porous composites[J]. Journal of Composite Materials, 2000, 34(3): 218-239.

[5] Benammar A, Drai R, Guessoum A. Detection of delamination defects in CFRP materials using ultrasonic signal processing[J]. Ultrasonics, 2008, 48(8): 731-738.

[6] 刘继忠, 蒋志峰, 华志恒. 含孔隙形态分布特征的孔隙率超声衰减测试建模[J]. 航空材料学报, 2006, 26(2): 67-71.

LIU Ji-zhong, JIANG Zhi-feng, HUA Zhi-heng. A morphological study based ultrasonic attenuation model of carbon fiber reinforced plastics porosity testing[J]. Journal of Aeronautical Materials, 2006, 26(2): 67-71.

[7] Birt E A, Smith R A. A review of NDE methods for porosity measurement in fiber reinforced polymer composites[J]. Non-destructive Testing and Condition Monitoring, 2004, 46(11): 681-686.

[8] Grolemund D, Tsai C S. Statistical moments of backscattered ultrasound in porous fiber reinforced composites[J]. IEEE Trans on Ultrasonics Ferroelectrics and Frequency Control, 1998, 45(2): 295-296.

[9] Oraziopo T D, Leo M, Distante A, et al. Automatic ultrasonic inspection for internal defect detection in composite materials[J]. NDT & E International, 2008, 41(2): 145-154.

[10] Jeong H, Hsu D K. Experimental analysis of porosity-induced ultrasonic attenuation and velocity change in carbon composites[J]. Ultrasonics, 1995, 33(3): 195-203.

[11] Ellefsen K J, Cheng C H, Tubman K M. Estimating phase velocity and attenuation of guided waves in acoustic logging data[J]. Geophysics, 1989, 54(8): 1054-1059.

[12] 吴思源, 周晓军, 江健, 等. 超声检测中曲面重构和路径规划方法研究[J] . 浙江大学学报, 2006, 40(5): 763-767.

WU Si-yuan, ZHOU Xiao-jun, JIANG Jian, et al. Research of surface reconstruction and path generation by ultrasonic inspection[J]. Journal of Zhejiang University, 2006, 40(5): 763-767.

[13] Denavit J, Hartenberg R S. A kinematic notation for lower-pair mechanisms based on matrices[J]. J Appl Mech, 1955, 77(2): 215-221.

[14] Reynolds W N, Wilkinson S J. The analysis of fiber reinforced porous composite materials by measurement of ultrasonic wave velocities[J]. Ultrasonics, 1978, 16(4): 159-163.

[15] 申卯兴, 许进. 求解线性规划的单纯形法的直接方法[J]. 计算机工程与应用, 2007, 43(30): 94-96.

SHEN Mao-xing, XU Jin. Direct way of simplex method for solving linear programming model[J]. Computer Engineering and Applications, 2007, 43(30): 94-96.

[16] GB 3365—82, 碳纤维增强塑料孔隙含量检测方法(显微镜法)[S].

GB 3365—82, Standard test method for void content of reinforced plastics(microscopic method)[S].

(编辑 赵俊)

收稿日期:2011-08-05;修回日期:2011-11-04

基金项目:国家自然科学基金资助项目(51005252);湖南省自然科学基金资助项目(10JJ5061);教育部博士点基金资助项目(20100162120042)

通信作者:李雄兵(1977-),男,湖南邵东人,博士,副教授,从事超声无损检测及其自动化研究;电话:0731-82655135;E-mail:lixb_ex@163.com