Mg-Gd-Y-Nd-Zr合金铸锭的均匀化

许 轲1, 2,蔡兴科1, 2,吴利辉1, 2,杨 柳1, 2,邓运来1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410012)

摘 要:采用光学金相、差热分析、扫描电镜、能谱分析和拉伸试验等方法,对比研究Mg-Gd-Y-Nd-Zr合金铸锭非平衡凝固组织熔点(539 ℃)以下(520 ℃)和先于520 ℃保温再在非平衡凝固组织熔点以上(560 ℃)保温这2种不同均匀化制度对合金组织和力学性能的影响。结果表明:Mg-Gd-Y-Nd-Zr合金采用520 ℃保温均匀化后,尽管伪共晶基本消除,但残留较多富稀土粒子,进一步采用560 ℃保温均匀化后,不仅非平衡组织能在较短的时间内消除,而且富稀土粒子相明显减少,伸长率提高50%以上;减少熔炼时形成游离稀土粒子和在高于非平衡凝固组织熔点以上保温均匀化是提高该合金伸长率的有效途径。

关键词:镁合金;稀土;热处理;显微组织;力学性能

中图分类号:TG249.9 文献标识码:A 文章编号:1672-7207(2009)05-1240-05

Homogeneity of Mg-Gd-Y-Nd-Zr alloy as-cast

XU Ke1, 2, CAI Xing-ke1, 2, WU Li-hui1, 2, YANG Liu1, 2, DENG Yun-lai1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Changsha 410012, China)

Abstract: The influence of two different homogenization heat treatment, one at temperature below the melting point of pseudo-eutectic (MPPE, 539 ℃) and another include treating below MMPE followed by treating above MPPE, on the microstructures and mechanical properties of Mg-Gd-Y-Nd-Zr alloy was investigated with OM, DTA, SEM, EDS and tensile test. The results show that, almost all the pseudo-eutectics disappear after the homogenization heat-treatment at 520 ℃, but some rare-earth-rich particles remain. While after the further homogenization heat-treatment at 560 ℃, the amount of rare-earth particles decreases dramatically. Therefore, the elongation rate of the two-stage homogenized samples increases by 50% with the decrease of the rare-earth-rich particles. This reveals that decreasing the dissociatived rare-earth particles and being homogeneity-heat-treated at temperature more than the MPPE are effective ways to improve the elongation of the present Mg-Gd-Y-Nd alloy.

Key words: magnesium alloy; rare-earth; heat-treatment; microstructure; mechanical property

镁合金具有密度低、比强度高、阻尼性能好、容易切削加工等优点,在航天和航空工业中得到了广泛应用[1-2]。添加稀土不仅可以明显提高镁合金的高温力学性能,而且能改善镁合金的韧性、铸造性能、焊接性能和耐蚀性等性能[3-4],如国内外广泛使用的WE54,WE43合金(MG-Y-Nd系)[5]和ZM6(Mg-Nd-Zn系)等。Mg-Gd-Y-X系合金具有比WE54,WE43和ZM6合金更好的高温性能[6-9],但铸锭(件)的室温伸长率偏低。研究者一般都在该合金铸锭(件)非平衡凝固温度以下进行均匀化[10-13],而对更高温度对铸造Mg-Gd-Y合金组织和性能影响的研究并不多。为此,本文作者先在合金铸锭的非平衡凝固组织熔点以下保温,然后加热到非平衡凝固组织熔点以上保温并进行均匀化,研究合金组织和力学性能,以便为探索Mg-Gd-Y-X系合金铸锭的新型均匀化提供参考。

1 实 验

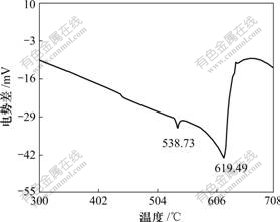

合金名义成分为Mg-8Gd-4Y-1Nd-0.6Zr,在普通电阻炉中用铁坩埚进行合金熔炼,合金元素Gd,Y,Nd和Zr以中间合金的形式加入纯镁熔体。熔体经精炼、静置后在铁模中凝固获得铸锭。从铸锭上割取热分析样品,采用美国Perkin Elmer 公司的DTA7型差热分析仪进行差热分析。升温速度为10 ℃/min,测试过程采用氩气保护。根据DTA分析结果确定非平衡凝固组织的熔点温度约为539 ℃ (图1)。在铸锭上切取d12 mm×11 mm的试棒放入箱式电阻炉内,采用2种不同制度进行均匀化处理。一种制度为试棒加热到520 ℃后,分别保温8,16和24 h,然后,从炉内取出空冷(以下分别标记为NT8,NT16和NT24);另一种制度为将试棒加热到520 ℃保温8 h的试块转入560 ℃的箱式电阻炉内,分别保温2,4和6 h,然后,从炉内取出空冷(以下分别标记为HT2,HT4和HT6)。

试样经砂纸磨光和机械抛光处理后,以苦味酸为腐蚀剂腐蚀抛光的试样表面,腐蚀时间为5~10 s,然后,用清水将金相表面清洗干净。用吹风机吹干腐蚀好的试样表面在XJP-6A型立式光学显微镜和Sirion场发射扫描电镜上观察显微组织。

图1 铸锭试样的差热分析曲线

Fig.1 DTA curve of Mg-Gd-Y-Nd-Zr alloy as-cast

采用直径×长度为8 mm×40 mm的短比例试样在CSS44100电子万能试验机上按照GB/T 228—2002进行室温拉伸试验测试力学性能。

2 结果与分析

2.1 铸锭的显微组织

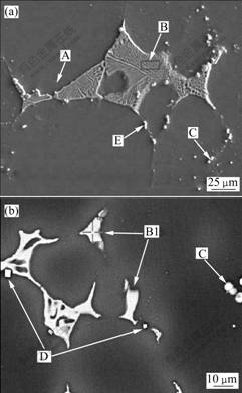

图2所示为铸锭样品苦味酸腐蚀后的二次电子像。结合能谱分析结果可以看出,铸锭样品的显微组织很不均匀,除α-Mg固溶体(标记为A)外,还存在4种类型的显微组织(分别标记为B,C,D和E),其EDS分析结果见表1。其中:B为非平衡凝固伪共晶,C为富锆(Zr-Rich)相粒子,D为富稀土(RE-Rich)初生粒子相,E为游离的稀土元素固溶体(α(Gd+Y+Nd))相(下文中简记为α-RE),也呈粒子状。Zr-Rich相粒子主要分布在基体晶粒中,非平衡凝固组织与枝晶界面上也能寻找到Zr-Rich相粒子,Zr-Rich粒子的这种分布有利于细化镁合金铸锭晶粒尺寸[14]。游离的RE-Rich相与α-RE固溶体主要分布在非平衡凝固组织(B)与枝晶界面上。根据SEM背散射电子像的成像原理,可以从图2(b)中分辨出非平衡凝固组织是由呈骨骼状的RE-Rich凝固结构(B1)和α(Mg)固溶体组成的伪共晶,从衬度上可以初步判断骨骼状的RE-Rich凝固结构(B1)与游离的RE-Rich初生相(D)具有不同的成分。

(a) 低倍;(b) 高倍

图2 Mg-Gd-Y-Nd-Zr合金铸锭试样的SEM像

Fig.2 SEM images of Mg-Gd-Y-Nd-Zr alloy as-cast

图2(a)中非平衡凝固组织(B)的划线框中EDS测试的平均稀土元素(Gd,Y和Nd)的总含量(表1中的B)明显高于合金中稀土元素名义成分含量,而图2(b)中骨骼状的凝固显微组织(B1)的合金元素的总含量比图2(a)中划线框中的含量更高。结合图2所示的显微组织特征与DTA分析结果(图1)可知,本研究所得铸锭中基体熔点约为619 ℃,伪共晶的熔点温度约为539 ℃,低于文献[15]报道的Mg-Gd-Y三元平衡相图共晶温度(547 ℃)。

表1 铸锭试样能谱分析结果

Table 1 EDAX analysis results of Mg-Gd-Y-Nd-Zr alloy as-cast

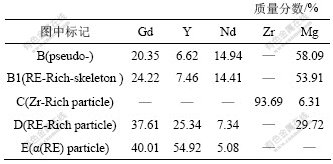

2.2 铸锭均匀化热处理后的显微组织

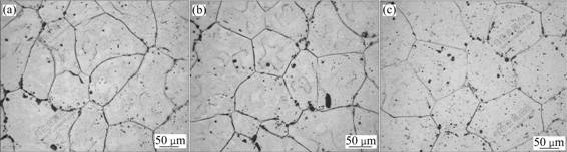

Mg-Gd-Y-Nd-Zr合金在520 ℃保温不同时间的显微组织见图3。从图3可以看出,NT8试样中有少量非平衡凝固组织,枝晶间隙上有大量的RE-Rich粒子相(图3(a)),NT16样品中枝晶间隙仍分布着大量的粒子相,另外,有极少数的伪共晶组织没有消除(图3(b)),NT24样品中未见明显的伪共晶组织,枝晶间隙模糊不清,晶界变得清晰,但晶界和枝晶间隙仍有大量粒子相(图3(c))。可见,用520 ℃保温的均匀化制度(NT)时,由于非平衡凝固组织中偏聚的稀土化元素扩散速度较慢,需要较长的时间才能溶入基体,基本消除非平衡凝固组织,但初生粒子相很难溶入基体。

进一步升温到560 ℃,分别保温不同时间进行均匀化热处理样品的显微组织如图4所示。从图4可以看出,所有HT处理试样中均未见非平衡凝固组 织,随着保温时间的延长,平直且三叉相交型晶界变得越来越清晰,与NT处理制度相比,粒子相数量明显减少。另外,不能相交且模糊不清的枝晶间隙逐步消失,随着枝晶间隙的消失,在晶内可清晰地分辩出原先分布在枝晶间隙中不能溶解的粒子相。

(a) NT12; (b) NT24; (c) NT48

图3 Mg-Gd-Y-Nd-Zr合金于520 ℃保温不同时间的显微组织

Fig.3 Microstructures of Mg-Gd-Y-Nd-Zr alloy heated at 520 ℃

(a) HT2; (b) HT4; (c) HT6

图4 Mg-Gd-Y-Nd-Zr合金于560 ℃保温不同时间的显微组织

Fig.4 Microstrucutres of Mg-Gd-Y-Nd-Zr alloy heated at 560 ℃ for different times

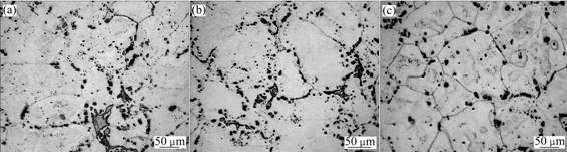

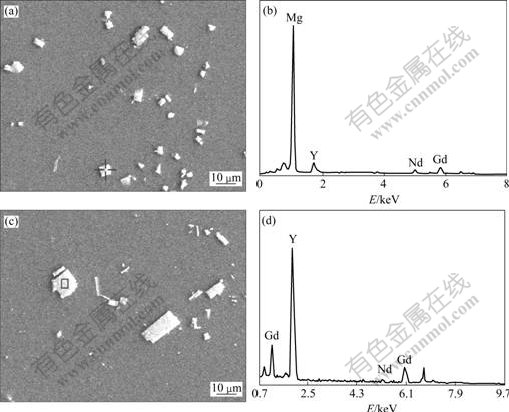

(a), (b) HT24; (c), (d) HT6

图5 Mg-Gd-Y-Nd-Zr合金不同均匀化处理试样的SEM像

Fig.5 SEM images of Mg-Gd-Y-Nd-Zr alloy by different homogeneity heat-treatments

HT6处理试样中RE-Rich粒子相基本上被消除,主要剩下α(RE)粒子。上述结果表明,在稀土元素总含量较高的Mg-Gd-Y-X系合金中(如本文中稀土元素名义总含量达13%),应在熔炼与铸造过程中避免形成游离的α(RE)粒子,这种粒子很难由均匀化消除,显然对铸锭(件)的力学性能产生不利影响。

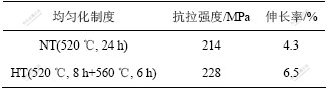

2.3 力学性能

经NT和HT这2种制度均匀化处理后试样的室温拉伸力学性能如表2所示。可见,NT处理试样的室温拉伸强度与伸长率都分别比HT处理试样的拉伸强度和伸长率低,HT处理提高伸长率50%以上。在铸锭非平衡凝固组织熔点以下约20 ℃进行的NT均匀化处理,虽然基本消除了凝固伪共晶,但由于晶内与晶界存在大量RE-Rich初生相和α-RE相粒子,降低了固溶强化效果,伸长率的提高幅度也有限。而进一步在非平衡凝固组织熔点以上约20 ℃进行HT均匀化处理,不仅消除了凝固伪共晶,而且基本消除了RE-Rich初生相粒子,只剩下少量α-RE相粒子,相应地,增强了固溶强化效果,同时,也明显提高了伸长率。由此可见,在铸锭中消除α-RE相粒子和采用HT均匀化处理,能有效提高该合金试样的力学性能。

表2 不同热处理状态合金的力学性能

Table 2 Mechanical properties of sample by NT and HT homogeneity heat-treatment

3 结 论

a. 名义成分为Mg-8Gd-4Y-1Nd-0.6Zr的镁合金在铁模中凝固形成枝晶不发达,溶质浓度明显高于平均浓度的非平衡凝固伪共晶组织,其熔点温度约为539 ℃,在枝晶间隙还会形成游离的RE-Rich初生相和α(Gd+Y+Nd))相粒子。

b. 在铸锭非平衡凝固组织熔点以下约20 ℃进行均匀化处理,虽然基本消除了凝固伪共晶,但由于晶内与晶界存在大量RE-Rich初生相和α(Gd+Y+Nd)相粒子,降低了固溶强化效果,且不会明显提高伸长率。

c. 经过较低温度处理后,进一步在铸锭非平衡凝固组织熔点以上约20 ℃进行均匀化处理,不仅消除了凝固伪共晶,而且基本消除了RE-Rich初生相粒子,增强了固溶强化效果,同时可使伸长率提高50%。

参考文献:

[1] Alves H, Koster U, Aghion E, et al. Environmental behavior of magnesium and magn-esium alloys[J]. Materials Technology, 2001, 16(2): 110-126.

[2] Baghni I M, Wu Y S, Li J Q, et al. Mechanical properties and potential applications of magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(6): 1253-1259.

[3] Nie J F, Gao X, Zhu S M. Enhanced age hardening response and creep resistance of Mg-Gd alloys containing Zn[J]. Scripta Materialia, 2005, 53(9): 1049-1053.

[4] Apps P J, Karimzadeh H, King J K. Precipitation reactions in magnesium-rare earth alloys containing yttrium, gadolinium or dysprosium[J]. Scripta Materialia, 2003, 48: 1023-1028.

[5] Nie J F, Muddle B C. Characterisation of strengthening precipitate phases in a Mg-Y-Nd alloy[J]. Acta Materialia, 2000, 48(8): 1691-1703.

[6] 张新明, 陈健美. 高强耐热稀土镁合金: CN 200610031169.9 [P]. 2006-07-19.

ZHANG Xin-ming, CHEN Jian-mei. High tensile and heat resisting alloy: CN 200610031169.9[P]. 2006-07-19.

[7] Suzuki M, Sato H, Maruyama K. Creep behavior and deformation microstructures of Mg-Y alloys at 550 K[J]. Materials Science and Engineering A, 1998, 252(2): 248-255.

[8] 张新明, 陈健美, 邓运来, 等. Mg-Gd-Y-(Mn, Zr)合金的显微组织和力学性能[J]. 中国有色金属学报, 2006, 16(2): 219-226.

ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai, et al. Microstructures and mechanical properties ofMg-Gd-Y-(Mn, Zr) magnesium alloys[J]. The Chinese Journal of Nonferrous Metal, 2006, 16(2): 219-226.

[9] 陈健美, 张新明, 邓运来, 等. 镁合金熔炼的热力学[J]. 中南大学学报: 自然科学版, 2006, 37(3): 427-432.

CHEN Jian-mei, ZHANG Xin-ming, DENG Yun-lai, et al. Thermodynamics of melding and refining of magnesium alloys[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 427-432.

[10] 马志新, 张家振, 李德富, 等. 铸态Mg-Gd-Y-Zr镁合金均匀化工艺研究[J]. 特种铸造及有色合金, 2007, 27(9): 659-662.

MA Zhi-xing, ZHANG Jia-zheng, LI De-fu, et al. Investigation on homogeneity of Mg-Gd-Y-Nd-Zr alloy as cast[J]. Special Casting & Nonferrous Alloys, 2007, 27(9): 659-662.

[11] 张新明, 肖 阳, 陈健美, 等. 挤压温度对Mg-9Gd-4Y-0.6Zr合金组织与力学性能的影响[J]. 中国有色金属学报, 2006, 16(3): 518-523.

ZHANG Xin-ming, XIAO Yang, CHEN Jian-mei, et al. Influence of extrusion temperature on microstructures and mechanical properties of Mg-9Gd-4Y-0.6Zr alloy[J]. The Chinese Journal of Nonferrous Metal, 2006, 16(3): 518-523.

[12] ZHONG Ying-ying, XU Shu-fang, ZHANG Xin-ming, et al. Measurement of creep stress exponent of Mg-Nd-Zn-Zr alloy at room temperature by nano-indentation method[J]. Materials Science Forum, 2007, 546/549: 509-511.

[13] 肖 阳, 张新明, 邓运来. Mg-9Gd-4Y-0.6Zr析出相在高温拉伸中的相变[J]. 特种铸造及有色合金, 2007, 27(11): 829-831.

XIAO Yang, ZHANG Xin-ming, DENG Yun-lai. Phase Transformation of Mg-9Gd-4Y-0.6Zr in tension at high tempreture[J]. Special Casting and Nonferrous Alloys, 2007, 27(11): 829-831.

[14] Peng Z K, Zhang X M, Chen J M, et al. Grain refining mechanism in Mg-Gd-4Y alloy by Zircomnium[J]. Mater Sic & Tech, 2005, 21(6): 722-726.

[15] Drits M E, Rokhlin L L, Nikitina N I, et al. State diagram of the Mg-Y-Gd system in the range rich in magnesium[J]. Metally, 1983(5): 178-181.

收稿日期:2008-09-04;修回日期:2008-12-18

基金项目:国家基础研究项目(5133001E)

通信作者:邓运来(1969-),男,湖南常德人,副教授,从事材料组织性能及加工研究;电话:0731-88830265;E-mail: luckdeng@mail.csu.edu.cn