文章编号:1004-0609(2013)S1-s0445-07

热处理对Ti46Αl4Nb1Cr0.2B合金相和等温热压缩行为的影响

郭险峰,孔凡涛,陈玉勇

(哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:通过改变TiAl合金的相分布,实现在低温区对TiAl合金的热加工。TiAl合金经过不同热处理过程得到不同的相分布,随后在共析温度下对合金进行等温压缩,观察应力和组织变化,利用退火消除变形组织。经6 ℃/min升温,在1 340 ℃保温15 min,并空冷处理后的合金和经12 ℃/min升温,在1 340 ℃保温15 min,并空冷处理后的合金的最大应力比合金铸锭的小,而且试件没有开裂。在α相转变温度附近对等温压缩后的合金进行退火,合金的变形组织消失,而在再结晶温度附近进行退火的合金的变形组织没有完全消失。相的分布可以影响TiΑl合金在低温区的热加工性能,而完全消除变形组织应在α相转变温度附近进行退火。

关键词:TiAl合金;热处理;相;应力;流线组织;再结晶

中图分类号:TG146.2 文献标志码:A

Effects of heat treatment on phase and isothermal compression behavior of Ti46Αl4Nb1Cr0.2B alloy

GUO Xian-feng, KONG Fan-tao, CHEN Yu-yong

(School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: Hot workability of TiAl alloys at low temperatures was improved by changing the phase distribution of TiAl alloys. The alloys were compressed below eutectoid temperature and annealed. The stress and microstructure were observed by scanning electron microscope. TiAl alloy has different phase distributions after different heat treatments. The maximum stress of ingot is higher than that of alloy which has been heated with cooling rate of 6 ℃/min and treated in 1 340 ℃ for 15 min and finally cooled in air to RT as well as alloy which has been heated with cooling rate of 12 ℃/min and treated in 1 340 ℃ for 15 minutes and cooled to RT during isothermal compression process. The crack is not observed in these alloys. The deformation microstructure of alloy disappears after annealing near α phase transition temperature and can be observed after annealing near the recrystallization temperature. The phase distribution affects hot workability of alloy at low temperatures and the annealing near α phase transition temperature completely eliminates the deformation microstructure.

Key words: TiAl alloy; heat treatment; phase; stress; streamline microstructure; recrystallization

TiAl合金与传统耐高温结构材料相比,具有高的比刚度、良好的抗蠕变性、优异的阻燃性能、低密度等优势,因此被视为一种具有广阔应用前景的新型轻质耐高温合金[1-4]。通过对TiAl合金高温变形行为和热加工性能的研究[5-8],可以在理解TiAl合金的高温变形行为和热加工性能基础之上控制合金热加工过程,从而得到满意的热加工产品,但是由于TiAl合金在高温区具有良好塑性,TiAl合金的热加工多在高温区间进行等温加工,对设备的热加工能力要求高,热加工成本也比较昂贵。相分布和组织可以影响TiAl合金的变形行为和性能[9-10],热处理是改变TiAl合金相分布和组织常采用的可以规模化使用的有效方法,得到了广泛的研究[11-15]。然而,热处理的研究大多限于探讨相变机理和在高温加工区改变TiAl合金的相分布和组织对热加工性能的影响,对低温区改变TiAl合金相分布和组织对合金低温区热加工性能影响研究却较少。因此,本文作者研究通过热处理改变TiAl合金的相分布和组织以提高TiAl合金在低温区的变形能力,保证TiAl合金在低温区热加工的顺利进行,降低TiAl合金热加工对设备的要求。

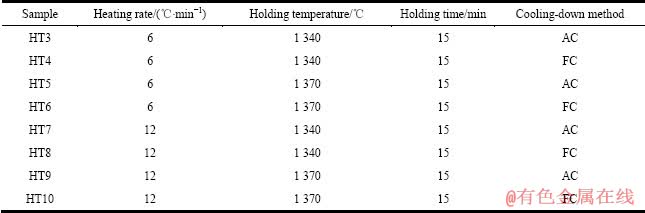

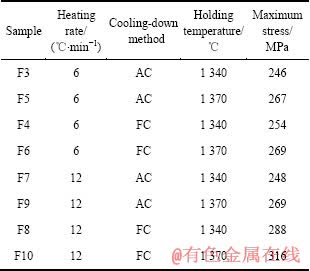

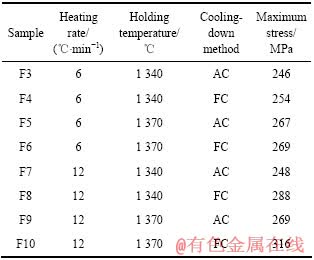

1 实验

通过真空电弧熔炼技术熔炼Ti46Αl4Nb1Cr0.2B合金纽扣锭,熔炼进行5次以保证合金锭的成分均匀,并利用扫描电镜观察合金的相分布。通过DTΑ测定Ti46Αl4Nb1Cr0.2B合金的α相转变温度为Tα= (1 355±5) ℃。为了保证在热处理后能得到不同的热处理组织,热处理的保温温度选择在α相变温度的两侧,热处理工艺参数列于表1中。采取空冷(AC)和炉冷 (FC) 2种冷却方式,热处理工艺和热处理件的编号相同,按HT3到HT10排列。

等温压缩的温度定在共析温度以下,但不能太低,以防止因温度过低导致压缩件开裂,选择1 100 ℃作为热压缩温度。Gleeble-1500热物理模拟机能够保证在1 100 ℃温度下,试件的中部和端部在压缩前后的温度差不超过5 ℃,保温时间为20 s以保证试件温度均匀,升温速度为10 ℃/s,压缩时间为60 s,应变速率为0.01 s-1,应变量为60%,压缩完成后在空气中冷却。标号HT3、HT4、HT5、HT6、HT7、HT8、HT9和HT10的热处理件在等温压缩后标号分别改为F3、F4、F5、F6、F7、F8、F9和F10。铸态件等温压缩后的压缩件标号为Fzj。

对压缩件进行后续退火选择3种工艺,列于表2中。第1种工艺是让试件在α单相区停留,得到单一相,然后炉冷至室温,使α单相分解得全层片组织,通过相变调整成分分布和组织形态。第2种工艺是将试件在略低于α单相区的温度下保温一段时间,使α和γ相达到平衡,增加α相的体积分数,同时由于在两相区,晶粒不会快速长大,然后再加热到α单相区短时停留,剩余的γ相分解,因为在单相区停留的时间较短,所以可以避免晶粒过度长大。第3种工艺是将试件在再结晶温度和共析温度之间的区域进行再结晶退火,得到再结晶组织。选择在等温压缩中最大应力小的F3和F5分别采取第1和第2种热处理工艺进行后续退火,选择在等温压缩中最大应力最大的F10采取第3种热处理工艺进行后续退火,后续退火后的试件编号分别为FHT3、FHT7和FHT10。

表1 热处理工艺参数

Table 1 Process parameters of heat treatment

表2 后续退火工艺参数

Table 2 Process parameters of finish annealing

2 结果分析与讨论

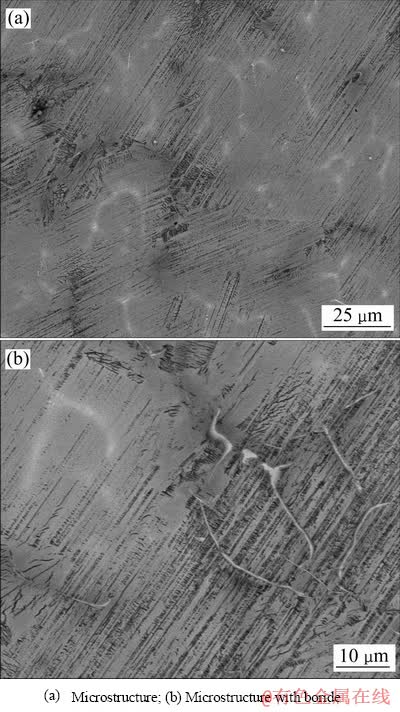

合金的铸态组织如图1所示,铸态组织为全片层组织,枝晶组织明显。B在两相TiΑl合金的α和γ相中的固溶度非常低,分别为0.003%和0.011%左右,B在TiΑl合金中主要是以高熔点的TiB2相的方式存在,硼化物呈弯曲细长的线状,分布于α2+γ两相层片晶团内或晶界。

图1 Ti46Αl4Nb1Cr0.2B合金铸态组织

Fig. 1 Cast structures of Ti46Αl4Nb1Cr0.2B alloy

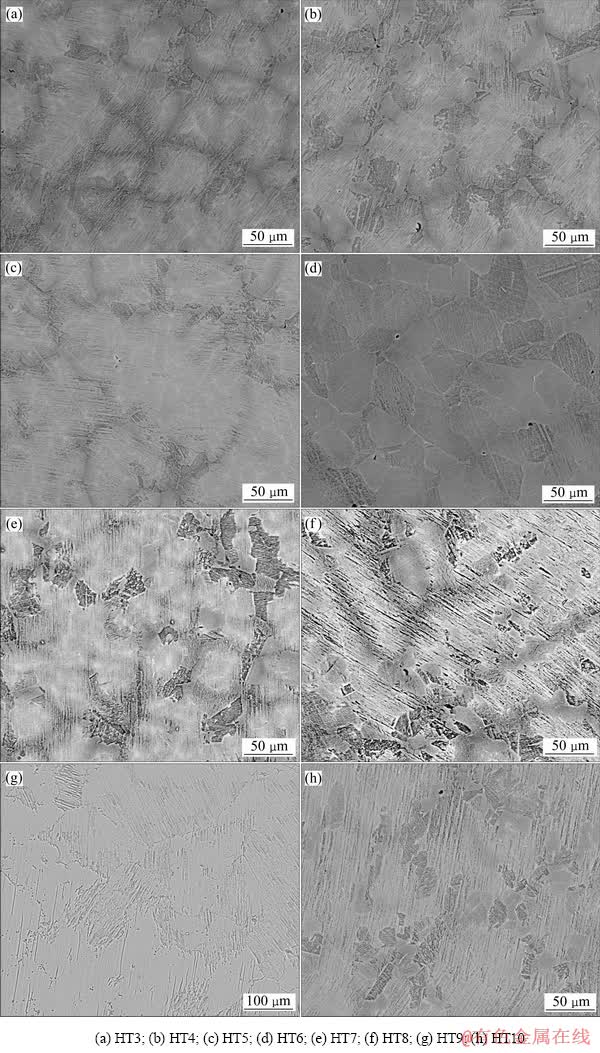

图2所示为经过各热处理工艺处理后合金的组织形貌。经6 ℃/min升温,1 340 ℃保温15 min,空冷处理后,由于枝晶间有较大的Αl偏析,高Αl的γ相在枝晶间析出,其直径在10~30 μm之间,层片晶团的直径为100~200 μm。在1 340 ℃时,合金处于α2+γ两相区,根据杠杆原理,平衡态组织中γ相的体积分数较少,又因为降温速度较快,所以较大程度上保留了高温时组织的相体积分数。经6 ℃/min升温,1 340 ℃保温15 min,随炉冷却处理后,合金中γ相的分数相对于HT3明显增多,这是冷却方式不同引起的结果。随炉冷却时,冷却速度缓慢,相的转变可以在近平衡态的情况下进行,根据相图和杠杆原理,在平衡状态下的合金室温组织中γ相较多。γ相晶粒直径在45~60 μm之间,层片团的直径为100~150 μm。经6 ℃/min升温,1 370 ℃保温15 min,空冷处理后,因为升温速度缓慢,所以,合金组织在前期转变比较充分,在空冷的情况下,降温速度快得到极少的γ相。在1 370 ℃ 时,合金处于α单相区,晶粒有所长大,层片团直径在200~300 μm之间,γ相直径在10~15 μm之间。合金经6 ℃/min升温,1 370 ℃保温15 min,随炉冷却处理后,形成双态组织。层片团直径在30~50 μm之间,γ相晶粒直径也在30~50 μm之间。合金经12 ℃/min升温,1 340 ℃保温15 min,空冷处理后,组织形态与HT3相近。合金经12 ℃/min升温,1 340 ℃保温15 min,随炉冷却处理后,层片团粗大,γ相连续析出。合金经12 ℃/min升温,1 370 ℃保温15 min,空冷处理后,得到全片层组织,层片团直径在150~300 μm之间。合金经12 ℃/min升温,1 370 ℃保温15 min,随炉冷却处理后,γ相在层片团中连续析出,相互接触,层片团被分割包围。层片团直径在150~200 μm之间,而γ相直径在30~45 μm之间。

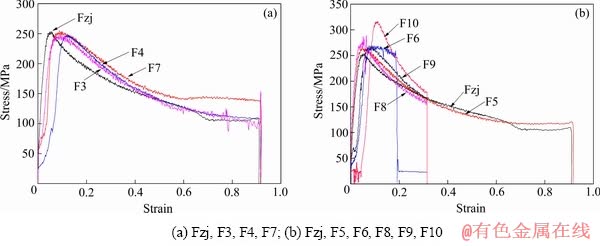

等温压缩后,Fzj、F3、F6和F10侧面有一道较深裂纹,F4、F7和F8侧面完整,F5侧面有多条细裂纹,F9侧面开裂。在应变速率为0.01 s-1、1 100 ℃下压缩时,F4、F7和F8等试件的塑性好,F5的次之,而Fzj、F3、F6和F10的塑性较差,F9的塑性最差。

图3所示为各个试件等温压缩应力—应变曲线。F3和F7的最大应力值大致相等,F7的应力值略大于F3的,它们都小于铸件的最大应力值。F4的最大应力值同铸件的非常接近,F10的最大应力值在所有试件中最大,F8的次之,F6、F5和F9的最大应力值大致相等,F6和F9相当,F5略小,但它们都小于F8的最大应力值,并且大于铸件的最大应力值。

升温速率、保温温度和冷却方式对合金等温压缩的最大应力的影响对比在表3、表4和表5中列出。通过对比,发现在升温速度影响中出现2次最大应力值相近的情况,说明此次实验中升温速度对合金最大应力值影响较小,可能是实验中的升温速度差别不大造成的。虽然如此,但也能看到升温速度6 ℃/min下的最大应力值比12 ℃/min下的要小。保温温度越低,则得到的最大应力值越小。空冷条件下得到的最大应力值比炉冷方式下得到的要小。

图2 热处理后的组织

Fig. 2 Microstructures after heat treatment

图3 等温压缩应力—应变曲线

Fig. 3 Isothermal compression stress—strain curve

表3 升温速率对最大应力的影响

Table 3 Effects of heating rate on maximum stress

表4 保温温度对最大应力的影响

Table 4 Effects of holding temperature on maximum stress

表5 冷却方式对最大应力的影响

Table 5 Effects of cooling-down method on maximum stress

结合前面对合金热处理组织的描述,空冷情况下得到含有一定数量γ相的组织,保温温度低的情况下则得到层片团较少的组织,而在6 ℃/min条件下没有出现全片层和γ相连续析出并接触的组织。这表明等温压缩前的组织形态影响到合金的热加工性能。综合以上分析,合金试样中最大应力值最小的应该是升温速率为6 ℃/min、保温温度为1 340 ℃、空冷处理条件下的试样,而符合此条件的HT3的最大应力值确实在所有试样中最小。

合金经压缩后会有明显的流线组织,为进一步热加工带来不利的影响,后续退火是对流线组织进行调整的手段。后续退火FHT3、FHT7和FHT10后合金的组织分别如图4所示。后续退火FHT3后,试件的组织为全片层,流线型组织完全消失,在层片团之间还有少量的γ相存在,组织的成分分布不均匀,可能是由于降温速度较慢,在降温过程中先发生了α到α+γ的转变。层片团的直径在100~200 μm之间。后续退火FHT7的组织为全片层组织,层片团之间极少有等轴γ相存在,几乎全部为层片组织。层片团直径在100~200 μm之间,FHT3的层片团直径相近,说明由于B元素的添加可以有效防止合金在单相区晶粒的过度长大。试件FHT10等温压缩时的最大应力最大,再结晶的驱动力也大,经后续退火FHT10后,出现大量的再结晶晶粒。再结晶晶粒虽然大量出现,但晶粒不完整,而流线型组织依然存在,再结晶很不充分。这可能因为:一是再结晶的保温温度较低,不能提供足够的再结晶转变能量;二是保温时间较短,再结晶转变需要时间,转变不完全;三是试件的变形量不够,导致再结晶的驱动力不足。即使该试件再结晶充分,也比较难消除再结晶晶粒按原流线方向排列的特征,因为再结晶晶粒长大后,各晶粒长大的环境是均等的。

图4 后续退火的组织

Fig. 4 Microstructure after finish annealing

3 结论

1) 采用不同的热处理工艺,TiΑl合金可以得到不同的相分布,而通过对Ti46Αl4Nb1Cr0.2B合金等温压缩的研究,发现压缩前层片团和γ相的分布可以影响TiΑl合金热加工性能,层片团和γ相的配合可以降低TiΑl合金热加工温度。

2) 在再结晶温度附近进行后续退火,不能完全消除合金等温压缩产生的流线组织,而在α相转变温度附近进行退火,合金的流线组织完全消除,形成全片层组织。

REFERENCES

[1] CLEMENS H, SMARSLY W. Light-weight intermetallic titanium aluminides-status of research and development[J]. Euro Superalloys, 2010, 278: 551-556.

[2] APPEL F, BROSSMANN U, CHRISTOPH U, EGGERT S, JANSCHEK P, LORENZ U, MULLAUER J, OEHRING M, PAUL J D H. Recent progress in the development of gamma titanium aluminide alloys[J]. Advanced Engineering Materials, 2000, 2(11): 699-720.

[3] CLEMENS H, KESTLER H. Processing and applications of intermetallic gamma-TiAl-based alloys[J]. Advanced Engineering Materials, 2000, 2(9): 551-570.

[4] CLEMENS H, LORICH A, EBERHARDT N, GLATZ W, KNABL W, KESTLER H. Technology, properties and application of intermetallic γ-TiAl based alloys[J]. Zeitschrift Fur Metallkunde, 1999, 90(8): 569-580.

[5] GERLING R, SCHIMANSKY F P, STARK A, BARTELS A, KESTLER H, CHA L, SCHEU C, CLEMENS H. Microstructure and mechanical properties of Ti45Al5Nb+(0-0.5C) sheets[J]. Intermetallics, 2008, 16(5): 689-697.

[6] APPEL F, OEHRING M, PAUL J D H, KLINKENBERG C, CARNEIRO T. Physical aspects of hot-working gamma-based titanium aluminides[J]. Intermetallics, 2004, 12(7/9): 791-802.

[7] 李慧中, 李 州, 刘 咏, 张 伟, 王海军. TiAl基合金的高温塑性变形行为[J]. 中国有色金属学报, 2010, 20(1): 79-85.

LI Hui-zhong, LI Zhou, LIU Yong, ZHANG Wei, WHANG Hai-jun. Plastic deformation behavior of TiAl based alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 79-85.

[8] 孔凡涛, 张树志, 陈玉勇. Ti-46Al-2Cr-4Nb-Y合金的高温变形及加工图[J]. 中国有色金属学报, 2010, 20(S1): s233-s236.

KONG Fan-tao, ZHANG Shu-zhi, CHEN Yu-yong. Hot deformation and processing map of Ti-46Al-2Cr-4Nb-Y[J], The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s233-s236.

[9] 郭建亭, 周兰章, 李谷松. 高温结构金属间化合物及其强韧化机理[J]. 中国有色金属学报, 2011, 21(1): 1-34.

GUO Jian-ting, ZHOU Lan-zhang, LI Gu-song. High temperature structural intermetallics and their strengthening- softening mechanisms[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 1-34.

[10] CHEN Yu-yong, LI Bao-hui, KONG Fan-tao. Microstructural refinement and mechanical properties of Y-bearing TiAl alloys[J]. Journal of Alloys and Compounds, 2008, 457(1/2): 265-269.

[11] DING Xian-fei, LIN Jun-pin, ZHANG Lai-qi, CHEN Guo-liang. Effects of heat treatment on microstructure of directionally solidified Ti-45Al-8Nb-(W, B, Y) alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 26-31.

[12] MARKOVSKY P E, SEMIATIN S L. Microstructure and mechanical properties of commercial-purity titanium after rapid (induction) heat treatment[J]. Journal of Materials Processing Technology, 2010, 210(3): 518-528.

[13] KOSCIELNA A, SZKLINIARZ W. Effect of cyclic heat treatment parameters on the grain refinement of Ti-48Al-2Cr-2Nb alloy[J]. Materials Characterization, 2009, 60(10): 1158-1162.

[14] 苏美科, 郑立静, 张 虎. 热处理对铸态TiAl基合金组织细化的影响[J]. 材料热处理学报, 2010, 31(9): 99-103.

SU Mei-ke, ZHENG Li-jing, ZHANG Hu. Microstructure refinement of cast TiAl alloy by heat treatment[J]. Transactions of Materials and Heat Treatment, 2010, 31(9): 99-103.

[15] 齐立春, 李臻熙, 黄 旭, 曹京霞. 均匀化热处理对TiAl合金铸造组织的影响[J]. 宇航材料工艺, 2010, 3: 63-66.

QI Li-chun, LI Zhen-xi, HUANG Xu, CAO Jing-xia. Effect of homogenizing treatment on microstructure of cast TiAl alloys[J]. Aerospace Materials & Technology, 2010, 3: 63-66.

(编辑 何运斌)

基金项目:国家自然科学基金资助项目(51371064,51074058);国家重点基础研究发展计划资助项目(2011CB605502)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:陈玉勇,教授,博士;电话:0451-86418802;E-mail: yychen@hit.edu.cn