文章编号:1004-0609(2013)S1-s0398-05

热处理工艺对新型抗疲劳低成本钛合金组织和性能的影响

费 跃,朱知寿,王新南,李 静,李 军,商国强,祝力伟

(北京航空材料研究院,北京 100095)

摘 要:采用金相显微镜观察新型抗疲劳低成本钛合金双重退火和普通退火后的显微组织,测试合金的拉伸性能、断裂韧性和疲劳性能等力学性能。结果表明:与普通退火相比,双重退火可以使组织均匀化更加充分,并可通过调整第一重退火温度来获得网篮组织和片层组织。网篮组织具有更好的强度和塑性匹配,随着第一重退火温度的升高,其强度降低、塑性升高;片层组织强度和塑性较低,但抗疲劳性能更加突出。合金采用普通退火获得的网篮组织具有良好的强度-塑性-韧性-疲劳性能匹配,并且随着退火温度的升高,强度和疲劳极限降低,但其组织均匀性有待进一步提高。

关键词:抗疲劳钛合金;双重退火;普通退火;显微组织;力学性能

中图分类号:TG146 文献标志码:A

Influence of heat treatment processes on microstructure and mechanical properties of new fatigue resistance and low cost titanium alloy

FEI Yue, ZHU Zhi-shou, WANG Xin-nan, LI Jing, LI Jun, SHANG Guo-qiang, ZHU Li-wei

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The microstructures of a new fatigue resistance and low cost titanium alloy by double annealing and single annealing were investigated and the mechanical properties such as tensile, fracture toughness and fatigue property were studied. The results show that double annealing is better than single annealing in favor of the homogeneity of microstructure. Basket-weave microstructure and lamellar microstructure can be obtained by adjusting the temperature of the first step annealing. The matching of strength and ductility for basket-weave microstructure is better, in addition, the strength decreases and the plastic increases with increasing temperature of the first step annealing. The fatigue property for lamellar microstructure is higher than basket-weave microstructure, but the strength and ductility are a litter lower. Basket-weave microstructure which can be obtained after single annealing has a better matching of strength, plastic, fracture toughness and fatigue property, in addition, the strength and fatigue property decrease with increasing annealing temperature, however, the homogeneity of microstructure should be further improved.

Key words: fatigue resistance titanium alloy; double annealing; single annealing; microstructure; mechanical properties

随着新一代飞机的跨越式高速发展,钛合金因具有密度小、比强度高、抗腐蚀性能突出、耐高温、焊接性能好等优异综合性能而得到大量应用,以满足飞机高可靠性、长寿命和高机动性的设计与应用目标[1-6]。然而与铝、钢铁等合金相比,钛合金的成本较高,从而限制了钛合金的更广泛应用。因此,低成本钛合金的研究已经越来越引起世界各国的重视,它们纷纷研制出新型低成本钛合金。如采用廉价合金元素设计成功的Ti62S、Ti-LCB、Ti-0.05Pd-0.3Co、Ti12LC、Ti8LC等合金[1, 7-11]。

Ti-Al-Mo-Cr-Zr-Si钛合金是北京航空材料研究院新近研发的具有自主知识产权的一种新型抗疲劳低成本钛合金。该合金不但成本低,而且具有良好的强度、塑性、韧性的匹配,同时具有优异的疲劳性能,均优于Ti-6Al-4V钛合金[12-14]。该合金有望替代Ti-6Al-4V等同级别钛合金在飞机主要承力结构件上的应用;且由于该合金成本较低,还可在兵器、航天及民用等领域得到推广应用。

本文作者通过采用不同的热处理工艺,研究双重退火和普通退火温度对该合金锻件组织和性能的影响,从而改善和挖掘合金的性能潜力,为合金主导热工艺的制定提供可靠的理论和实验依据。

1 实验

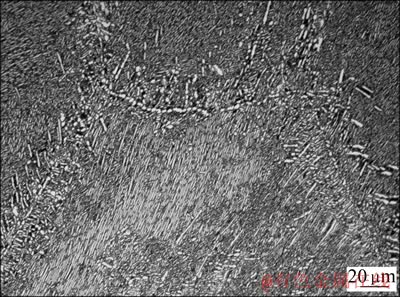

实验所用Ti-Al-Mo-Cr-Zr-Si合金铸锭采用三次真空自耗电弧炉熔炼而成,经过开坯、改锻后,采用准β锻造工艺锻造成锻件,其组织特征如图1所示。从图中可以看出,合金锻态组织非常细小,但组织均匀性较差。合金β晶界处形成了细小的颗粒状α相,部分颗粒状α相沿着晶界长大并发生相互接合;晶界附近形成的部分颗粒状α相向晶粒内部长大,形成相互平行的细小板条状α相;晶粒内部存在大量相互平行或交织的细小板条状α相。

图1 Ti-Al-Mo-Cr-Zr-Si合金锻态组织特征

Fig. 1 Microstructure of forged Ti-Al-Mo-Cr-Zr-Si alloy

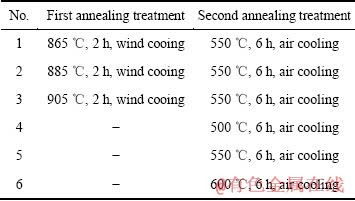

用金相法测得该合金的相变点温度为915~920 ℃。对Ti-Al-Mo-Cr-Zr-Si合金锻件切取试样后,进行热处理,热处理制度如表1所列。

利用LEICA DMI3000 M 型光学显微镜观察该合金在采用不同热处理工艺后的显微组织。利用INSTRON5887型电子万能试验机测定该合金的室温拉伸性能,利用MTS810型疲劳试验机测定该合金的断裂韧度和疲劳极限。

表1 热处理工艺

Table 1 Heat treatment processes

2 结果与讨论

2.1 热处理工艺对合金显微组织的影响

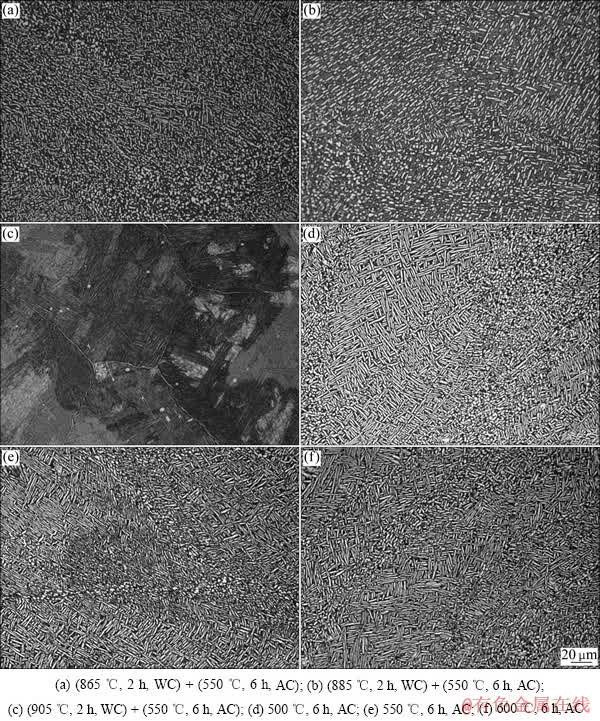

新型抗疲劳低成本Ti-Al-Mo-Cr-Zr-Si合金锻件经过不同的热处理后,其显微组织如图2所示。从图中可以看出,该合金经双重退火后,组织均匀性明显改善。当第一重退火温度为865和885 ℃(见图2(a)和 (b))时,晶界消失,随着第一重退火温度的升高组织变化不明显,都形成细小的网篮组织。当第一重退火温度升高到905 ℃时(见图2(c)),组织发生明显变化,形成典型的片层组织,晶粒内部存在少量的颗粒状α相。该合金经普通退火后(如图2(d)~(f)),组织为典型的网篮组织,与锻态组织相比,均匀性有所改善,但仍存在晶粒状α相聚集的β晶界。并且随着退火温度的升高,板条状α相有粗化的趋势。通过以上的观察可以发现,该合金无论采用双重退火还是普通退火,获得的组织都非常细小,从而有利于获得良好的力学性能。

图2 Ti-Al-Mo-Cr-Zr-Si合金经不同热处理工艺后的显微组织

Fig. 2 Microstructures of Ti-Al-Mo-Cr-Zr-Si alloy processed by different heat treatments

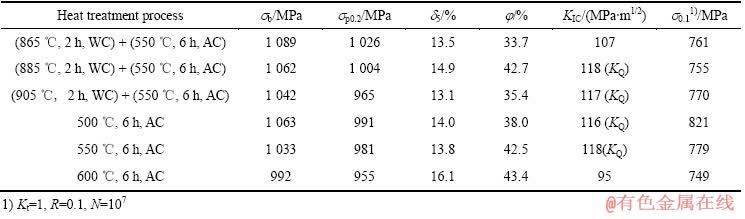

表2 不同热处理工艺下Ti-Al-Mo-Cr-Zr-Si合金的室温力学性能

Table 2 Room-temperature mechanical properties of Ti-Al-Mo-Cr-Zr-Si alloy by different heat treatment processes

2.2 热处理工艺对合金力学性能的影响

新型抗疲劳低成本Ti-Al-Mo-Cr-Zr-Si合金锻件采用不同热处理工艺后的力学性能如表2所列。由表2可知,采用双重退火工艺,合金抗拉强度σb>1 000 MPa,并且随着第一重退火温度的升高而降低;伸长率δ5保持在13%以上;断裂韧度KIC或KQ达到100 MPa·m1/2以上,屈服强度σp0.2达到950 MPa以上,断面收缩率φ达到3.5%以上;疲劳极限σ0.1>750 MPa,并且片层组织的疲劳极限稍高于网篮组织,这是由于合金晶粒细小,并且α片层集束细小,保证了片层组织具有较高的疲劳极限[15]。合金采用普通退火工艺,强度随着退火温度的升高而降低;塑性仍保持在13%以上;断裂韧度KIC(KQ)>90 MPa;疲劳极限σ0.1>740 MPa。与双重退火相比,采用普通退火获得的组织强度和塑性稍低,断裂韧性相当,疲劳性能较好。该合金采用双重退火,σ0.1/σb可达到0.7;采用普通退火,σ0.1/σb可达到0.75以上,说明该合金在保证具有良好的强度、塑型、韧性匹配的同时,还具有突出的抗疲劳性能。

3 结论

1) 对新型抗疲劳低成本钛合金采用双重退火工艺处理,可以使组织充分均匀化。当第一重退火温度低于相变点温度以下30 ℃时,形成网篮组织,具有较高的强度、塑型、韧性匹配,并且强度和疲劳极限随着第一重退火温度的升高而降低,塑性随着第一重退火温度的升高而升高。当第一重退火温度升高到相变点以下10℃左右时,合金形成片层组织,强度和塑性有所降低,但具有较高的疲劳极限。

2) 对新型抗疲劳低成本钛合金采用普通退火工艺处理,形成典型的网篮组织,并且随着退火温度的升高,板条状α相有粗化的趋势,强度和疲劳极限随着退火温度的升高而降低。

REFERENCES

[1] 周武装, 郭晓光, 谢湘云, 王向东. 钛合金手册[M]. 北京: 化学工业出版社, 2012: 6-7, 336.

ZHOU Wu-zhuang, GUO Xiao-guang, XIE Xiang-yun, WANG Xiang-dong. Titanium handbook [M]. Beijing: Chemical Industry Press, 2012: 6-7, 336.

[2] BOYER R R. An overview on the use of titanium in the aerospace industry [J]. Materials Science and Engineering A, 1996, 213: 103-114.

[3] 赵永庆, 李月璐, 吴 欢, 冯 亮, 朱康英, 刘彩利. 低成本钛合金研究[J]. 稀有金属, 2004, 28(1): 66-69.

ZHAO Yong-qing, LI Yue-lu, WU Huan, FENG Liang, ZHU Kang-ying, LIU Cai-li. Research on low cost titanium alloys [J]. Chinese Journal of Rare Metals, 2004, 28(1): 66-69.

[4] 朱知寿, 王新南, 童 路, 商国强. 航空用损伤容限型钛合金研究与应用[J]. 中国材料进展, 2010, 29(5): 14-17.

ZHU Zhi-shou, WANG Xin-nan, TONG Lu, SHANG Guo-qiang. Research and application of damage tolerance titanium alloys for aeronautical use [J]. Materials China, 2010, 29(5): 14-17.

[5] 王志辉, 夏长清, 彭小敏, 陈志宏, 李学雄. 热处理工艺对Ti62421s 高温钛合金组织与力学性能的影响[J]. 中国有色金属学报, 2010, 20(12): 2298-2306.

WANG Zhi-hui, XIA Chang-qing, PENG Xiao-min, CHEN Zhi-hong, LI Xue-xiong. Effect of heat treatment on microstructure and mechanical properties of Ti62421s high temperature titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(12): 2298-2306.

[6] 史小云, 付宝全, 王文盛, 唐晓东, 陈小苗. 锻造温度对TC4-DT 钛合金棒材力学性能及显微组织的影响[J]. 中国有色金属学报, 2010, 20(S1): 79-82.

SHI Xiao-yun, FU Bao-quan, WANG Wen-sheng, TANG Xiao-dong, CHEN Xiao-miao. Effect of forging temperature on mechanical property and microstructure of TC4-DT titanium [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 79-82.

[7] 张文毓. 高性能低成本钛合金研究进展[J]. 航空制造技术, 2011(5): 74-76.

ZHANG Wen-Liu. Research progress of high-performance and low cost titanium alloy [J]. Aeronautical Manufacturing Technology, 2011(5): 74-76.

[8] BHATTACHARJEE A, GHOSAL P, GOGIA A K, BHARGAVA S, KAMATA S V. Room temperature plastic flow behaviour of Ti-6.8Mo-4.5Fe-1.5Al and Ti-10V-4.5Fe-1.5Al: Effect of grain size and strain rate [J]. Materials Science and Engineering A, 2007, 452/453: 219-227.

[9] KHALED M, IBRAHIM, MHAEDE M, WAGNEI L. Microstructure evolution and mechanical properties of heated treated LCB titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2609-2615.

[10] 张 津, 刘贞阳, 郭海明. Ti8LC钛合金热处理工艺对硬度和组织的影响[J]. 稀有金属, 2011, 35(1): 17-21.

ZHANG Jin, LIU Zhen-yang, GUO Hai-ming. Effect of heat treatment on hardness and microstructure of Ti8LC alloy [J]. Chinese Journal of Rare Metals, 2011, 35(1): 17-21.

[11] 贾蔚菊, 曾卫东, 段风川, 王 焱, 周义刚. Ti8LC低成本钛合金疲劳裂纹扩展行为研究[J]. 稀有金属材料与工程, 2009, 38(12): 2171-2174.

JIA Wei-ju, ZENG Wei-dong, DUAN Feng-chuan, WANG Yan, ZHOU Yi-gang. Study on fatigue crack propagation behavior of low cost titanium alloy Ti8LC [J]. Rare Metal Materials and Engineering, 2009, 38(12): 2171-2174.

[12] 朱知寿, 商国强, 王新南, 费 跃, 李 军. 低成本高性能钛合金研究进展[J]. 钛工业进展, 2012, 29(6): 1-5.

ZHU Zhi-shou, SHANG Guo-qiang, WANG Xin-nan, FEI Yue, LI Jun. Research and development of low cost and high performance titanium alloys [J]. Titanium Industry Progress, 2012, 29(6): 1-5.

[13] 王新南, 费 跃, 刘 洲, 商国强, 李 军, 祝力伟, 朱知寿. 航空用新型低成本钛合金显微组织与损伤容限性能关系研究[J]. 钛工业进展, 2013, 30(2): 7-10.

WANG Xin-nan, FEI Yue, LIU Zhou, SHANG Guo-Qiang, LI Jun, ZHU Li-wei, ZHU Zhi-shou. Research of the relationship between microstructure and damage-tolerance property of new low cost titanium alloy in aviation applications [J]. Titanium Industry Progress, 2013, 30(2): 7-10.

[14] 费 跃, 朱知寿, 王新南, 李 军, 商国强, 祝力伟. 锻造工艺对新型低成本钛合金组织和性能影响[J]. 稀有金属, 2013, 37(2): 186-191.

FEI Yue, ZHU Zhi-shou. WANG Xin-nan, LI Jun, SHANG Guo-Qiang, ZHU Li-wei. Influence of forging processing on microstructure and mechanical properties of a new low-cost titanium alloy [J]. Chinese Journal of Rare Metals, 2013, 37(2): 186-191.

[15] 王金友, 马济民, 蔡建明, 李兴无. 各国钛合金[M]. 北京: 北京航空材料研究院, 2005: 119.

WANG Jin-you, MA Ji-min, CAI Jian-ming, LI Xing-wu. Titanium alloy [M]. Beijing: Beijing Institute of Aeronautical Materials, 2005: 119.

(编辑 方京华)

基金项目:中航工业创新基金资助项目(2012E62120R)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:朱知寿,研究员,博士;电话:010-62496635;E-mail: zhuzzs@126.com