采用浸渍-还原法在炭纤维表面制备纳米镍催化剂颗粒

廖寄乔,王占锋,周建伟

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:为了在炭纤维表面原位生长纳米炭纤维/纳米碳管,研究它对炭/炭复合材料微观界面结构和导热性能的影响,以硝酸镍为催化剂前驱体,H2为还原气体,N2为载气,采用浸渍-还原技术在炭纤维表面制备纳米Ni催化剂颗粒。用扫描电镜观察Ni颗粒形貌和粒径,分析讨论还原温度和时间对纳米Ni颗粒的影响及纳米颗粒的形成原因。研究结果表明:随着还原温度升高,Ni颗粒逐渐变大;随着还原时间增加,催化剂前驱体涂层先分裂,再逐渐形成纳米Ni颗粒,而后又因烧结变大;H2和N2气在Ni颗粒形成过程中还起到刻蚀涂层、吸附弱化颗粒间粘结力的作用;合成纳米Ni颗粒的最佳工艺条件是:还原温度为400~450 ℃,还原时间为30~60 min。

关键词:纳米炭纤维/纳米碳管;浸渍-还原;纳米Ni催化剂颗粒;炭纤维

中图分类号:TQ342.742 文献标识码:A 文章编号:1672-7207(2007)06-1033-06

Synthesis of nano nickel particles on carbon fibers by impregnation-reduction method

LIAO Ji-qiao, WANG Zhan-feng, ZHOU Jian-wei

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract:In order to grow carbon nanofibers/carbon nanotubes on carbon fibers, and further investigate their effect on the interface microstructure and thermal conductivity of C/C composites, nano Ni catalyst particles were coated on the surfaces of carbon fibers by impregnation-reduction method using Ni(NO3)2 as catalyst precursor, H2 as reduction gas and N2 as carrier gas. The effects of reduction temperature and time on morphology and diameters of nano Ni particles were studied by scanning electron microscope (SEM), and the formation reasons of Ni particles were also discussed. The results show that the diameters of Ni particles increase with the increase of reduction temperature; Catalyst precursor coating is first broken up and then nano Ni particles are formed which then agglomerate bigger with the increase of reduction time. The formation of Ni particles is importantly due to H2 and N2 gas because they have etched catalyst coating to form small separated particle islands and adsorbed on Ni particles to prevent them associating. The optimized synthesis process of nano Ni particles is as follows: the reduction temperature is 400-450 ℃ and time is 30-60 min.

Key words:carbon nanofibers/carbon nanotubes; impregnation-reduction; nano Ni catalyst particles;carbon fibers

纳米炭纤维/纳米碳管具有独特的结构和优异性能[1-4],它在二次增强材料、复合材料、电子材料等方面有着广阔的应用前景[5-8]。炭/炭复合材料(carbon fibers/pyrocarbon composites, C/C composites)以其突出的力学性能、导热性能等很早已经广泛应用在航空航天等领域[9]。但在基体炭与炭纤维之间容易产生微裂纹,这对炭/炭复合材料的性能将产生不利影响。为了加强基体炭与炭纤维之间的连接,进一步在C/C复合材料性能上取得的新突破,纳米炭纤维/纳米碳管作为它们之间的二次增强材料应用于C/C复合材料。目前,已有关于用纳米炭纤维/纳米碳管直接掺杂来增强炭/炭复合材料的报道[10-11],但由于纳米炭纤维/纳米碳管分散不均和它与炭纤维结合不牢的问题,使复合材料的性能没有达到预期的要求。如果在炭纤维基体上原位生长纳米炭纤维/纳米碳管再做成复合材料,就可以避免上述问题。目前,虽然制备纳米炭纤维/纳米碳管的方法有石墨电弧法[12]、激光蒸发法[13]、催化裂解法(CVD)[14-16]等,但唯有CVD法适合在炭纤维基体上原位催化生长纳米炭纤维/纳米碳管再做成复合材料。CVD法催化炭纤维原位生长纳米炭纤维/纳米碳管的关键是纳米催化剂颗粒的制备。目前,在炭纤维表面制备纳米金属颗粒的方法有脉冲电镀法[17-18]、溅射 法[19]、气相沉积法[20]、直接浸渍法[21]等。采用前3种方法得到的纳米颗粒较均匀,但设备昂贵,过程复杂,不易控制;采用直接浸渍法过程简单,但涂层不均匀,且纳米金属颗粒制备与分散难易控制。在此,本文作者采用简单的浸渍-还原法在炭纤维表面涂上均匀的纳米Ni颗粒,并催化生长出纳米炭纤维/纳米碳管。用扫描电镜(SEM)观察产物的形貌,并标测了Ni颗粒粒径,分析还原温度和时间对Ni催化剂颗粒的影响,同时还探讨纳米Ni颗粒的形成原因。

1 实 验

1.1 炭纤维的预处理

将在2 300 ℃高温处理过的炭纤维基体放在浓硝酸浸泡30 min,除去表面的杂质。再用去离子水冲洗干净后放入60 ℃、浓度为10%的KOH水溶液中浸泡12 h,然后放入管式炉中,在N2气流、常压下于500 ℃煅烧2 h,提高炭纤维的活性和比表面积。

1.2 浸渍-还原实验

将预处理过的炭纤维基体放在硝酸镍的乙醇溶液中浸渍4 h,然后暴露在空气中让乙醇自然挥发。将浸渍后的炭纤维基体放入管式炉的恒温区,在N2(流量为120 mL/min)气流中加热到450 ℃,保温1.5 h使硝酸镍分解,然后调节温度到400~800 ℃,引入H2(流量为140 mL/min)还原10~90 min,反应结束后在N2气氛中冷却到室温。用扫描电镜对实验产物进行观察和分析。

2 结果与讨论 2.1 还原温度对纳米Ni催化剂颗粒的影响

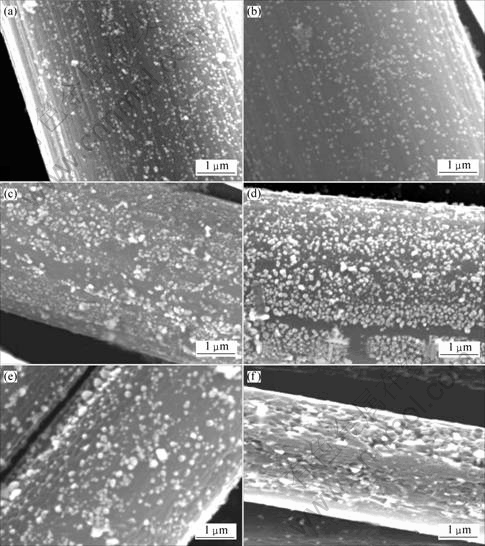

图1 所示为不同还原温度下Ni催化剂颗粒形貌的SEM照片。由图可见,在不同还原温度下得到Ni颗粒差异很大:在400 ℃和450 ℃时,Ni颗粒细小,分布均匀(见图1(a)和1(b));在500 ℃和600 ℃时,Ni颗粒稍微有所增大,分布较均匀,极少量的颗粒粘结到一起(见图1(c)和1(d));在700 ℃时,催化剂颗粒粒径明显增大,分布也不均匀(见图1(e));在800 ℃时,炭纤维表面被腐蚀,在凹陷处有少量较大的Ni颗粒存在(见图1(f))。由此可见,还原温度对金属Ni颗粒形貌和粒径有很大的影响。

分析图1可知:随着还原温度升高,Ni颗粒逐渐增大;在800 ℃时,炭纤维表面被氧化腐蚀,部分Ni可能溶到炭纤维里面,只有少量较大的Ni颗粒出现在凹陷处。由于随着温度升高出现轻微的烧结,导致部分Ni颗粒粘结到一起,影响Ni颗粒粒径和分布。从炭纤维变温氧化曲线可知:自700 ℃开始,炭纤维出现明显氧化失重现象[22]。因此,在800 ℃时炭纤维表面被还原出来的氧原子氧化腐蚀,表面出现严重的凹凸不平,导致Ni颗粒在凹陷处聚集长大,见图1(f)。

用SEM对大量Ni颗粒粒径进行测量,得到在不同还原温度下Ni催化剂颗粒的粒径分布情况,结果见表1。由于在一定范围内纳米炭纤维/纳米碳管的直径随着催化剂粒径的增加而增加,故控制催化剂颗粒粒径就是控制了纳米炭纤维/纳米碳管的直径[23-24]。因此,低温还原效果较好,最佳温度为400~450 ℃。

2.2 还原时间对纳米Ni催化剂颗粒的影响

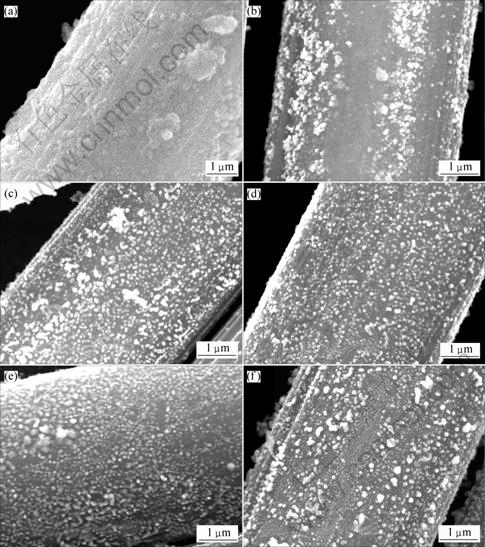

图2所示为不同还原时间下Ni催化剂颗粒形貌的SEM照片。由图可见,未经还原(0 min)时,炭纤维完全被硝酸镍涂层包覆(见图2(a));在10 min时,氧化镍涂层已经分裂,但只有少量较小Ni颗粒(见图2(b));在20 min时,炭纤维表面有大量的纳米Ni颗粒和少量岛状颗粒(见图2(c));在30 min时,纳米Ni颗粒完全均匀分散(见图2(d));在60 min时, Ni颗粒更细小,分布更均匀(见图2(e));在90 min时,部分纳米Ni颗粒又粘结成团,颗粒变大(见图2(f))。由此可见,还原时间对金属Ni颗粒粒径也有很大的影响,不同还原时间下得到的Ni颗粒形貌和粒径差异很大。

还原温度/℃:(a) 400;(b) 450;(c) 500;(d) 600;(e) 700;(f) 800

图1 不同还原温度下Ni催化剂颗粒形貌的SEM照片

Fig.1 SEM micrographs of catalyst particles reduced at different reduction temperatures

表1 不同还原温度下Ni催化剂颗粒粒径分布情况

Table 1 Particle size distribution of catalyst particles at different reduction temperatures

分析图2可知:未还原时,硝酸镍涂层完全包覆在炭纤维表面;还原时间较短时,只有少量涂层被刻蚀还原成Ni颗粒,且粒度较大;随着还原时间增加,涂层逐渐形成均匀的纳米Ni颗粒;还原时间较长时,还原出来的 Ni颗粒又粘结到一起,颗粒变大。因此,还原时间在30~60 min之间时,金属Ni颗粒细小,分布均匀,适合催化生长纳米炭纤维/纳米碳管。用SEM对大量Ni颗粒粒径进行测量,得到在不同还原温度下Ni催化剂颗粒的粒径分布情况,结果见表2。

还原时间/min:(a) 0;(b) 10;(c) 20;(d) 30;(e) 60;(f) 90

图2 不同还原时间下Ni催化剂颗粒形貌的SEM照片

Fig.2 SEM micrographs of catalyst particles reduced at different reduction times

表2 不同还原时间下Ni催化剂颗粒粒径分布情况

Table 2 Diameters distribution of catalyst particles at different reduction times

2.3 纳米Ni颗粒的形成

N2气和H2气在纳米Ni颗粒形成过程中起主要作用。从以上分析可知:还原之前催化剂前驱体呈涂层状,还原过程中先分裂成小块,而后逐渐形成均匀分散的纳米颗粒,这说明N2和H2具有刻蚀分裂涂层、阻止颗粒粘结的作用。具体来说,N2主要作为载气和稀释气体,控制还原速率和程度,同时N2的加入能加速混合气体对涂层的刻蚀速率,使Ni颗粒更细小[25]。而氢气除了作为还原气体将Ni的化合物还原成为金属单质之外,还具有下列作用:a. 和N2 混合起刻蚀作用,将催化剂前驱体涂层分裂成小块,并逐渐还原形成纳米Ni颗粒;b. 化学吸附在金属颗粒表面,弱化金属颗粒间的结合力,使Ni催化剂颗粒在纤维表面均匀分布,粒径趋向一致,适合于生长纳米炭纤维/纳米碳管;c. 能分解不具有催化活性的镍的碳化物,形成具有活性的Ni颗粒[26]。由于混合气体具有上述作用,才促使纳米Ni颗粒的形成,图3所示为催化剂涂层分裂形成纳米颗粒的示意图,它形象地描述了Ni颗粒的形成过程。

图3 催化剂涂层分裂形成纳米颗粒示意图

Fig.3 Schematic diagram of formation of nano Ni catalyst particles on carbon fibers

3 结 论

a. 采用浸渍-还原法过程简单,能在炭纤维表面均匀地涂上纳米Ni颗粒。

b. 用浸渍-还原法制备纳米Ni催化剂时,随着还原温度升高,Ni颗粒逐渐变大;随着还原时间的增加,催化剂前驱体涂层先分裂成块,并逐渐还原形成纳米Ni颗粒,而后又因烧结变大,最佳的还原工艺条件是:温度为400~450 ℃,时间为30~60 min。

c. 在纳米Ni颗粒形成过程中,N2主要作为载气,并加速涂层分裂的速率;而H2除了作为还原气体外,还和N2混合作为刻蚀气体,使催化剂涂层慢慢分裂,同时还吸附在Ni催化剂颗粒的表面,阻止Ni颗粒粘结到一起,使Ni颗粒分布均匀。

参考文献:

[1] Yu M F, Files B S, Arepalli S, et al. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties[J]. Phys Rev Lett, 2000, 84(24): 5552-5555.

[2] Hone J, Batlogg B, Benes Z, et al. Quantized phonon spectrum of single-wall carbon nanotubes[J]. Science, 2000, 289(5485): 1730-1733.

[3] 张丽芳, 胡慧芳, 汪小知, 等. 含有2个五边形2七边形缺陷对的单壁碳纳米管的电学性能[J]. 中南工业大学学报: 自然科学报, 2003, 34(5): 510-512.

ZHANG Li-fang, HU Hui-fang, WANG Xiao-zhi, et al. Electronic properties of single carbon nanotubes with two pentagon-heptagon pairs defects[J]. Journal of Central South University of Technology: Natural Science, 2003, 34(5): 510-512.

[4] 李燕峰, 徐 慧, 马松山, 等. 单壁碳管直径对电子结构的影响[J]. 中南大学学报: 自然科学版, 2005, 36(1): 44-48.

LI Yan-feng, XU Hui, MA Song-shan, et al. Effect of diameter on electronic structure of open-ended single wall carbon nanotubes[J]. Journal of Central South University: Science and Technology, 2005, 36(1): 44-48.

[5] 赵丽萍. 碳纳米管的分散及其复合材料制备研究[D]. 上海: 中国科学院上海硅酸盐研究所, 2004.

ZHAO Li-ping. A study on dispersant of carbon nanotubes and synthesis of their composites[D]. Shanghai: Shanghai Institute of Ceramics Chinese Academy of Sciences, 2004.

[6] 李 峰, 白 朔, 成会明. 纳米碳管[J]. 新型碳材料, 2000, 15(3): 79-80.

LI Feng, BAI Shuo, CHENG Hui-ming. Carbon nanotubes[J]. New Carbon Materials, 2000, 15(3): 79-80.

[7] 李莉香, 李 峰, 英 哲, 等. 纳米碳管/聚合物功能复合材料[J]. 新型碳材料, 2003, 18(1): 69-74.

LI Li-xiang, LI Feng, YING Zhe, et al. Carbon nanotube/polymer functional composite[J]. New Carbon Materials, 2003, 18(1): 69-74.

[8] Hammel E, Tang X, Trampert M, et al. Carbon nanofibers for composite applications[J]. Carbon, 2004, 42: 1153-1158.

[9] 于 澍, 李溪滨, 刘根山, 等. 热解炭结构对炭/炭复合材料摩擦磨损性能的影响[J]. 中南工业大学学报: 自然科学版, 2002, 33(6): 613-616.

YU Shu, LI Xi-bin, LIU Geng-shan, et al. Influence of microstructure of pyrolytic carbon on friction and wear properties of carbon/carbon composites[J]. Journal of Central South University of Technology: Natural Science, 2002, 33(6): 613-616.

[10] GONG Qian-ming, Li Zhi, BAI Xiao-dong, et al. Thermal properties of aligned carbon nanotube/carbon nanocomposites[J]. Mater Sci Eng A, 2004, 384: 209-214.

[11] GONG Qian-ming, Li Zhi, ZHANG Zheng-yi, et al. Tribological properties of carbon nanotube-doped carbon/carbon composites[J]. Tribology International, 2006, 39(9): 937-944.

[12] Sumio I J. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354(6348): 56-58.

[13] Thess A, Lee R, Nikolaev P, et al. Crystalline ropes of metallic carbon nanotubes[J]. Science, 1996, 273(5274): 483-487.

[14] Ci L J, Wei J Q, Wei B Q, et al. Carbon nanofibers and single-walled carbon nanotubes prepared by the floating catalyst method[J]. Carbon, 2001, 39: 329-335.

[15] 杨子芹, 沈曾民, 陈晓红, 等. Co催化热分解制备弯曲状碳纳米管的研究[J]. 新型碳材料, 2000, 15(2): 34-38.

YANG Zi-qin, SHEN Zeng-min, CHEN Xiao-hong, et al. Preparation of curved carbon nanotubes using Co-catalyst pyrolysis[J]. New Carbon Materials, 2000, 15(2): 34-38.

[16] 朱东波, 黄启忠, 李 晔. Fe催化PAN炭纤维原位生长纳米炭纤维[J]. 新型碳材料, 2002, 17(3): 66-69.

ZHU Dong-bo, HUANG Qi-zhong, LI Ye. Fe-catalyzed in situ growth of carbon nanofibers on PAN carbon fibers[J]. New Carbon Materials, 2002, 17(3): 66-69.

[17] 刘曰利, 潘春旭. 脉冲电镀镍纳米晶基板上碳纳米管和碳纳米纤维的火焰法合成[J]. 中国有色金属学报, 2004, 14(6): 979-984.

LIU Yue-li, PAN Chun-xu. Synthesis of carbon nanotubes and carbon nanofibers on pulse plated Ni nano-crystalline substrate in ethanol flame[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 979-984.

[18] de Riccardis M F, Carbone D, Makris T D, et al. Anchorage of carbon nanotubes grown on carbon fibers[J]. Carbon, 2006, 44: 671-674.

[19] Li W Z, Wang D Z, Yang S X, et al. Controlled growth of carbon nanotubes on graphite foil by chemical vapor deposition[J]. Chem Phys Lett, 2001, 335: 141-149.

[20] 王国菊, 王必本, 王 波, 等. 沉积条件对CVD碳纤维生长的影响[J]. 功能材料与器件学报, 2004, 10(3): 369-373.

WANG Guo-ju, WANG Bi-ben, WANG Bo, et al. Influence of deposition conditions on growth and structure of carbon fibers by CVD[J]. Journal of Functional Materials and Devices, 2004,10(3): 369-373.

[21] Lei N, Kuroda K, Zhou L P, et al. Kinetic study of carbon nanotube synthesis over Mo/Co/MgO catalysts[J]. Carbon, 2006, 44(11): 2265-2272.

[22] 廖寄乔. 热解炭微观结构对C/C复合材料性能影响的研究[D]. 长沙: 中南大学粉末冶金研究院, 2003.

LIAO Ji-qiao. A study of influence of microstructure of pyrocarbon on the properties of C/C composites[D]. Changsha: Institute of Powder Metallurgy Research, Central South University, 2003.

[23] Dai H, Rinzler A G, Nikolaev P, et al. Single-walled nanotubes produced by metal-catalysed disproportionation of carbon monoxide[J]. Chem Phys Lett, 1996, 260: 471-475.

[24] Wang X B, Liu Y Q, Zhu D B. Controlled growth of well-aligned carbon nanotubes with large diameters[J]. Chem Phys Lett, 2001, 340: 419-424.

[25] 王国菊, 王必本, 朱满康, 等. N2对碳纳米管生长和结构的影响[J]. 材料导报, 2003, 17: 18-20.

WANG Guo-ju, WANG Bi-ben, ZHU Man-kang, et al. Influence of N2 on growth and structure of carbon nanotubes[J]. Materials Review, 2003, 17: 18-20.

[26] 范月英, 成会明, 苏 革, 等. 气相生长纳米炭纤维的研究进展[J]. 新型碳材料, 1997, 14(2): 14-20.

FAN Yue-ying, CHENG Hui-ming, SU Ge, et al. Advances of research in vapor grown carbon nanofibers[J]. New Carbon Materials, 1999, 14(2): 14-20.

收稿日期:2007-02-19;修回日期:2007-04-19

基金项目:国家重点基础研究发展计划资助项目(2006CB600904);中国博士后基金资助项目(2005年)

作者简介:廖寄乔(1970-),男,湖南长沙人,教授,从事炭/炭复合材料和纳米碳管的研究

通信作者:廖寄乔,男,教授;电话:0731-8877418;E-mail: Liaojiqiao@126.com