文章编号:1004-0609(2016)-11-2279-08

激光热处理对7475铝合金阳极氧化膜表面-界面性能的影响

王进春1,孔德军1, 2

(1. 常州大学 机械工程学院,常州 213164;

2. 常州大学 江苏省材料表面科学与技术重点实验室,常州 213164)

摘 要:利用阳极氧化法在7475铝合金表面制备一层氧化膜,通过激光热处理(LHT)对氧化膜进行改性处理,采用扫描电子显微镜(SEM)、能谱分析仪(EDS)、X射线衍射仪(XRD)分析氧化膜表面-界面形貌、化学元素分布和物相,并对其表面和结合界面化学元素进行面扫描和线扫描分析,研究激光热处理对氧化膜组织和性能的影响。结果表明:激光热处理后,7475铝合金氧化膜表面孔洞增多,界面形成致密热影响区;氧化膜主要由Al2O3和SiO2组成,而热影响区主要由Al2O3组成;Al、O、Si原子在结合界面发生富集现象,其界面为化合物型+扩散型形式。

关键词:7475铝合金;氧化膜;激光热处理;性能

中图分类号:O532,TQ153.6 文献标志码:A

7475合金是Al-Zn-Mg-Cu系热处理强化新型铝合金,具有优异的综合性能,已经广泛应用于航空领域[1-4]。由于7475合金的硬度较低,耐磨损性能差[5],影响了其使用性能,一般需要进行表面改性处理,主要包括阳极氧化、溶胶-凝胶法、稀土转化膜、电镀、化学镀等[6-11]。其中阳极氧化是在适当的电解液中,在外加电流作用下,在金属表面生成致密氧化膜的方法[12],具有较高硬度和结合力,从而达到改善耐磨性能的目的[13]。然而,阳极氧化法在铝合金表面生成的氧化膜具有多孔状结构,对膜层的耐蚀性和耐磨性产生不利影响[14]。激光热处理(LHT)是一种新型的表面强化技术,具有加热迅速、效率高和易控制等优点[15],可以改善氧化膜表面组织和结构,提供其使用性能。目前,国内外对激光热处理陶瓷类材料开展了相关研究。彭国良等[16]利用激光辐照效应来改善金属氧化膜对激光与材料的能量耦合系数;PODRABINNIK等[17]对冷喷涂铝/铝镍复合涂层激光热处理后性能进行了研究;OLAKANMI等[18]利用激光烧结/熔融来改善铝合金的显微组织和性能;AHUIR-TORRES等[19]利用脉冲激光处理来改善TiO2表面纳米孔分布和性能;然而这些研究对阳极氧化膜的激光热处理工艺效果和作用机理分析甚少。本文作者通过激光热处理对7475铝合金阳极氧化膜进行处理,采用SEM、EDS和XRD等手段分析激光热处理后氧化膜表面-界面形貌、化学元素和物相组成,为激光热处理+阳极氧化在铝合金领域的应用提供试验依据。

1 实验

试验材料为7475铝合金其组成如下(质量分数,%):Si≤0.10,Fe≤0.12,Cu 1.2~1.9,Mn≤0.06,Mg 1.9~2.6,Cr 0.18~0.25,Ti≤0.06,Zn 5.2~6.2,余量为Al。阳极氧化工艺如下:去油→去除自然氧化膜→化学抛光→水洗→高压阳极氧化→热封闭。制备工艺如下:Na2SiO3 15 g/L,KOH 2 g/L,(NaPO3)6 2~5 g/L,防烧灼剂为C4H4O6Na2;冷却方式采用蛇型冷却管,温度为30~40 ℃,阴极为钛板,阳极为7475铝合金;具体过程如下:实验时一般控制阳极化电压在30 s内由0升至150 V,同时,电流密度升至6 A/dm2、60 s时电流密度达到峰值10 A/dm2,之后电流密度迅速下降,当电流密度下降至2 A/dm2时,氧化反应结束,即得所需要阳极氧化膜。激光热处理前对膜层表面进行黑化处理,以提高激光吸收率。激光热处理在GLS-IB型激光加工系统上进行,其工艺参数如下:功率为600 W,扫描速度为15 mm/s,光斑直径为5 mm,保护气为氩气,气体流量为20 L/min。激光热处理后试样采用JSUPRA55型场发射扫描电镜及其配制的能谱仪分析其表面-界面形貌、表面面能谱、界面线能谱和面能谱,并用D/max2500 PC型X射线衍射仪对物相进行分析。利用X-350A型X射线应力仪对激光热处理前后膜层表面进行残余应力测试,测试方法采用侧倾固定ψ法,定峰方法采用交相关法,辐射靶材为Cr Kα,X光管电压为27.0 kV,X光管电流为7.0 mA,衍射晶面为(311),衍射晶面方位角ψ分别设为0°、24°、35°和45°,扫描起始角及终止角分别为161°和151°,扫描步距为0.20°,计数时间为0.50 s,采用配置的残余应力分析软件自动处理与分析有关实验数据。

2 分析与讨论

2.1 表面-界面形貌

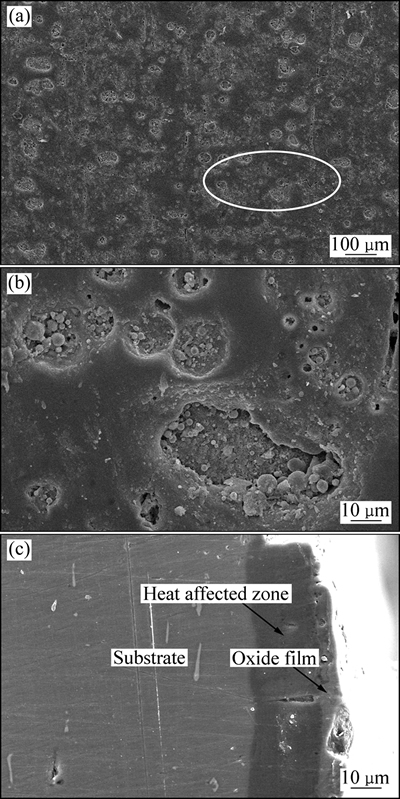

图1 激光热处理后阳极氧化膜表面及界面形貌

Fig. 1 Surface ((a), (b)) and interface (c) morphologies of anodic oxidation film after LHT

激光热处理后氧化膜表面形貌如图1(a)所示,其局部放大电镜图如图1(b)所示,可见表面存在较多气孔,气孔形状不规则,尺寸在30~80 μm之间。由于氧化膜本身孔隙等缺陷存在,激光能量不能均匀作用在膜层表面,激光透过孔隙使得基材汽化膨胀,对孔隙后壁产生巨大冲击,使得后壁局部向熔池内部凹陷。熔池液体金属在重力和表面张力作用下塌陷,并将金属蒸气、保护气及少量空气等卷入熔池形成气泡[20]。由于铝合金流动性较好,少数气泡随液体金属流动迁移而逸出熔池。多数气泡由于激光热处理速度较快被迅速冷却凝固的金属包围,于是在膜层表面形成众多气孔。图1(c)所示为激光热处理后界面形貌,可见试样分为氧化层、热影响区强化层和基体3个部分。氧化膜厚度不均匀,尺寸在3~10 μm之间,界面存在气孔。热影响区厚度大约为20μm,为激光热处理后在氧化膜和基体之间形成的强化层,界面致密。激光热处理后,基体、热影响区、和氧化膜的显微硬度分别为150、380和440.8HV0.3。

2.2 XRD分析

图2 激光热处理前后氧化膜表面XRD谱

Fig. 2 XRD patterns of anodic oxidation film before (a) and after (b) LHT

图2所示为激光热处理前后氧化膜表面XRD谱。由图2(a)可知,阳极氧化膜在衍射角38.38°和78.1°处出现2个尖锐峰,分别对应于为α-Al2O3的(104)、(201);在衍射角为44.62°和64.98°处出现2个尖锐峰,与JCPDS(10-465)标准卡片对照,分别对应于γ-Al2O3的(400)、(440)等2个晶面的衍射峰,说明氧化膜中含有γ-Al2O3结构。由于γ-Al2O3为亚稳相,存在着γ-Al2O3向稳定相α-Al2O3的转变,因此,阳极氧化形成的氧化膜是以α-Al2O3为主。激光热处理后氧化膜XRD分析结果如图2(b)所示,膜层主要由α-Al2O3、γ-Al2O3和Al相组成,同时存在SiO2和Si—Al—O相,由席勒公式计算可知,Si—Al—O相为非晶态结构。SiO2和Si-Al-O相由下列反应产生:

SiO32--2e→SiO2+O2 (1)

SiO2+nAl2O3→SiO2·nAl2O3 (2)

XRD分析结果显示,激光热处理后膜层中α-Al2O3含量远高于γ-Al2O3,激光热处理发出大量热量,产生的局部高温起到重复烧结作用,促使亚稳相γ-Al2O3向高温稳定相α-Al2O3转变[21]。高强度Al相存在与膜层表面气孔形成有关,由于膜层表面孔隙等缺陷,激光透过孔隙使基材剧烈汽化膨胀,液体金属在重力、表面张力以及侵入气体的协同作用下形成气泡,最终在膜层表面形成气孔,X射线透过膜层表面气孔检测到基体中的主要组成物相所致。

2.3 残余应力分析

图3所示为激光热处理前后氧化膜表面残余应力分析结果。由图3(a)可知,氧化膜表面残余应力为-50 MPa,为压应力。激光热处理后氧化膜表面残余应力为5 MPa,为拉应力(见图3(b))。Pilling-Bedworth认为氧化膜与基体的摩尔体积的差别造成内应力[22-23]。其摩尔体积比:

α=Vox/VMe (3)

式中:Vox为1 mol金属原子氧化膜对应的体积;VMe为1 mol金属原子基体对应的体积。

当α>1时,氧化膜产生压应力,否则产生拉应力。对于铝的氧化膜,α>1,表现为压应力。实验结果符合上述理论,残余应力分布和大小具有离散型,激光热处理前后氧化膜表面残余应力变化不大,在一个有限范围内。

2.4 表面面能谱分析

图3 激光热处理前后氧化膜表面残余应力分析结果

Fig. 3 Analysis results of residual stresses on anodic oxidation film before (a) and after (b) LHT

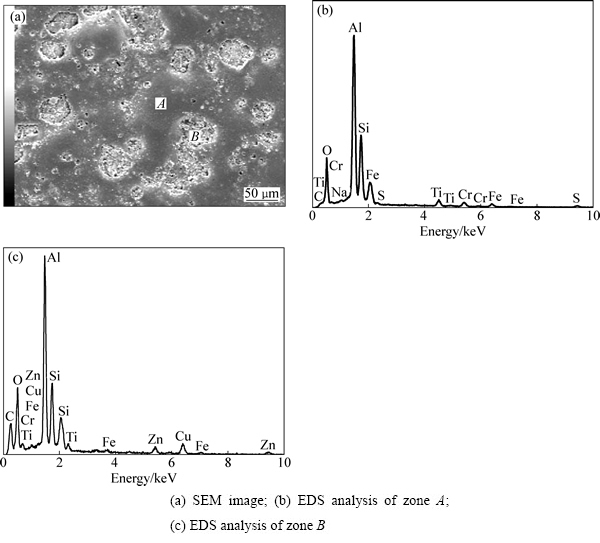

对图4(a)所示完整膜层A处进行能谱分析,其结果如图4(b)所示,由EDS分析结果可知,激光热处理后氧化膜仍以Al和O为主要组成成分,由于高含量的高温稳定相α-Al2O3存在,激光热处理不改变其主要组成成分;较强Si原子峰线存在是由于高温氧化过程中生成SiO2和Si-Al-O相,和图2中结论一致。其化学组成(质量分数,%)如下:Al 35.54,O 24.05,Si 20.99,Ti 5.42,Cr 5.98,Fe 6.89,Na 0.42,S 0.70。其中,Al、O和Si质量分数之和高达80.58%,进一步说明其是氧化膜的主要组成成分,Ti、Cr和Fe是来自基体元素,Na和S原子保持较低含量,为杂质元素。对图4(a)所示孔洞位置B处进行局部能谱分析,其结果如图4(c)所示,其化学元素组成(质量分数,%)如下:Al 21.82,O 16.01,Si 7.71,Ti 4.15,Cr 9.33,Fe 17.65,C 12.99,Cu 6.76,Zn 3.43。孔洞部位的Al、O和Si质量分数之和为45.54%,相对于图4(b)中Al、O和Si质量分数之和,下降近35%,氧化膜层均匀性受到破坏,不利于其耐蚀性能;同时,EDS还显示合金中的Cu、Cr、Fe和Zn的存在。

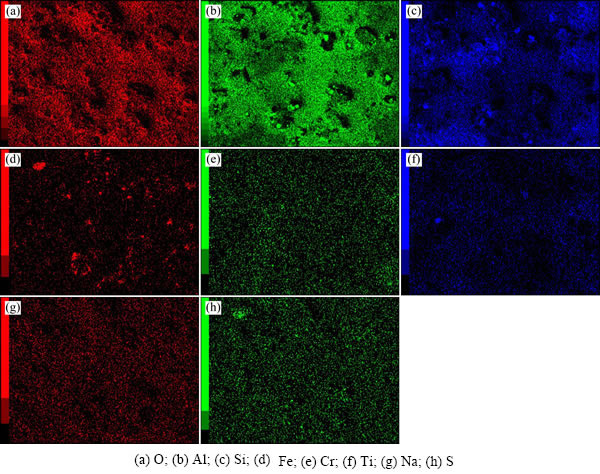

对图4(a)表面进行面能谱分析,其结果如图5所示。O、Al和Si原子在膜层表面分布不均匀,出现富集现象,其结果如图5(a)~(c)所示,这与图1(a)中所述激光热处理在膜层表面形成气孔的结论一致。Fe原子在膜层表面分布不均匀,主要富集分布在膜层表面气孔所在位置,如图5(d)所示。Cr、Ti、Na和S原子在膜层表面分布均匀,呈弥散分布,如图5(e)~(h)所示。

图4 激光热处理后氧化膜表面的表面形貌及EDS分析结果

Fig. 4 SEM image and EDS analysis results of anodic oxidation film surface after LHT

图5 激光热处理后氧化膜面能谱分析

Fig. 5 Plane scan analysis of elements on anodic oxidation film surface after LHT (corresponding Fig. 4(a))

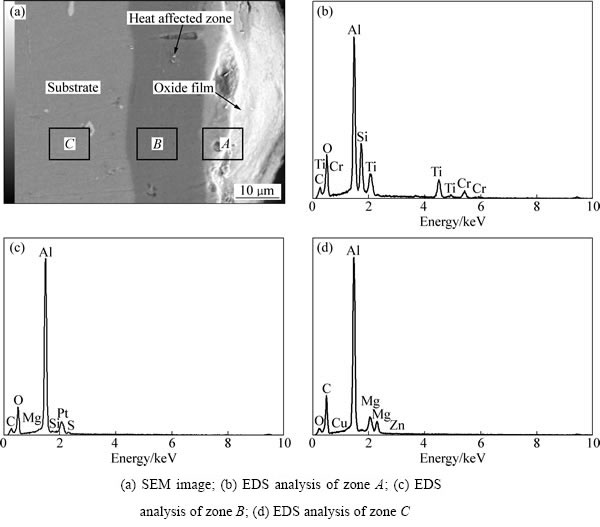

2.5 界面面能谱与线能谱分析

对图6(a)界面3个部分所示位置进行能谱分析,A处能谱分析结果如图6(b)所示,其化学元素组成(质量分数,%)如下:Al 31.30、O 23.71、Si 13.19、Ti 14.28、Cr 7.63、C 9.90。Al、O和Si的质量分数之和为68.20%,结合图2中XRD分析结果可知,氧化膜中Al和O以六方最密堆积Al2O3的形式存在,同时,Si还与Al、O以SiO2、Si—Al—O相的形式存在,使得膜层硬度得到提高。Ti的存在和氧化过程中以钛板作为阴极有关,Cr是来自基体元素,C为杂质元素。B处能谱分析结果如图6(c)所示,其化学元素组成(质量分数,%)如下:Al 60.30,O 23.47,Si 0.88,Mg 0.21,S 1.56,C 13.57。Al的质量分数为60.30%,相对于图6(b)中氧化膜Al原子含量提高近2倍,Si原子含量下降到很低水平;热影响区强化层中Al和O摩尔比接近3:2,仅以Al2O3的形式存在。Mg是来自基体元素,S和C为杂质元素。C处能谱分析结果如图6(d)所示,其化学元素组成(质量分数,%)如下:Al 88.98、O 0.81、Mg 0.80、Cu 3.65、Zn 5.43。Al的质量分数高达88.98%,O的质量分数仅0.81%,不含Si原子,含有少量Cu和Zn,可见基体以Al作为主要组成成分,仅有较少铝的氧化物存在。

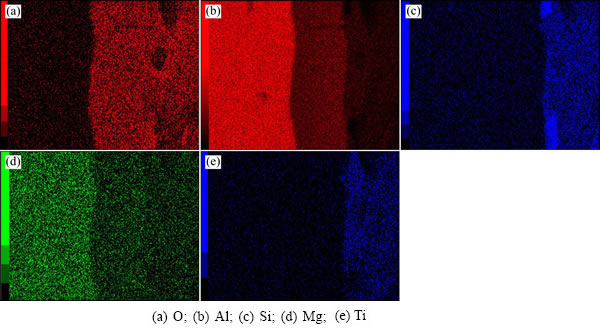

对图6(a)中结合界面进行面能谱分析,其结果如图7所示。O、Al、Si在界面产生明显分层富集现象,如图7(a)~(c)所示,以Al2O3和SiO2形式存在,有利于提高膜层的阶梯硬度。图7(d)和(e)所示分别为Mg、Ti原子在界面上分布情况,氧化膜和强化层中出现的Mg原子是由于基体中Mg原子的扩散结果;Ti原子在界面也发生了扩散现象,但扩散程度相对较小。由于S和Cr原子为微含量,面能谱分析未显示结果。

图6 激光热处理后氧化膜层界面的SEM像及EDS分析结果

Fig. 6 EDS analysis results of anodic oxidation film interface after LHT

图7 激光热处理后界面元素能谱分析

Fig. 7 Plane scan analysis of elements at interface after LHT (corresponding to Fig. 6(a))

图8 激光热处理后界面元素线扫描分析结果

Fig. 8 Line scan analysis of elements at interface after LHT

对图6(a)中结合界面进行线能谱分析。Al原子沿基体向氧化膜方向呈二阶梯下降趋势,如图8(a)所示,这和图6中EDS分析结果一致。O原子沿膜层向基体方向呈单阶梯下降趋势,如图8(b)所示,O原子向基体发生扩散现象。在氧化膜-强化层结合界面处形成Al2O3和SiO2化合物,此时界面为化合物型。同时,氧化膜中Si向强化层和基体扩散,如图8(c)所示,形成扩散界面。在强化层-基体结合界面处Al2O3溶解基体中Al原子形成扩散界面,这表明氧化膜-强化层-基体的结合界面是化合物型+扩散型形式,由Al—O和Si—O化学键提供结合力。Mg原子由基体向氧化膜和强化层发生扩散现象,如图8(d)所示。S原子在强化层出现尖峰,如图8(e)所示。Ti原子由氧化膜向强化层和基体发生扩散现象,如图8(f)所示。Cr晶体是体心立方点阵,不易与其他元素形成置换固溶体,扩散程度较小,如图8(g)所示。

3 结论

1) 激光热处理后,氧化膜表面出现众多气孔,气孔形状不规则,尺寸在30~80 μm之间;界面上在氧化膜和基体之间形成致密强化层,有利于提高其耐蚀性能。

2) 激光热处理后氧化膜主要由氧化物Al2O3和SiO2组成,强化层主要由六方最密堆积的Al2O3组成,基体以Al作为主要组成成分,仅有较少铝的氧化物存在。

3) Al、O、Si原子在氧化膜-强化层-基体的结合界面发生富集现象,其界面为化合物型+扩散型形式。

REFERENCES

[1] 刘 冰, 彭超群, 王日初, 王小峰, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-quen, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminum alloys[J]. Materials and Design, 2014, 56: 862-871.

[3] 孔德军, 王进春, 刘 浩. 7475铝合金阳极氧化膜表面-界面组织与特征[J]. 中国有色金属学报, 2014, 24(7): 1744-1751.

KONG De-jun, WANG Jin-chun, LIU Hao. Surface-interface structures and characteristics of anodic oxidation film on 7475 aluminium alloy [J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1744-1751.

[4] 陈 军, 段雨露, 彭小燕, 肖 丹, 徐国富, 尹志民. 7475-T7351 铝合金厚板的疲劳性能[J]. 中国有色金属学报, 2015, 25(4): 890-899.

CHEN Jun, DUAN Yu-lu, PENG Xiao-yan, XIAO Dan, XU Guo-fu, YIN Zhi-min. Fatigue performance of 7475-T7351 aluminum alloy plate [J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 890-899.

[5] JANNICA H, STAFFAN J. The influence from shape and size of tool surface defects on the occurrence of galling in cold forming of aluminium[J]. Wear, 2011, 27: 2517-2524.

[6] LEE Gyu-Sun, BAE Sung-Hoone, LEE Young-Ze. The influence of formation of transfer layer on the characteristics of friction and wear mechanism between several coatings and anodized aluminum alloy [J]. Surface & Coatings Technology, 2010, 205(S1): s152-s157.

[7] 张学军, 高春香, 王 蕾, 李 琪, 王淑菊, 张 英. 溶胶-凝胶法制备Al2O3/ZrO2涂层及对γ-TiAl合金高温氧化行为的影响[J]. 稀有金属材料与工程, 2010, 39(2): 367-371.

ZHANG Xue-jun, GAO Chun-xiang, WANG Lei, LI Qi, WANG Shu-ju, ZHANG Ying. Preparation of Al2O3/ZrO2 coating by sol-gel method and its effect on high-temperature oxidation behavior of γ-TiAl based alloys[J]. Rare metal materials and engineering, 2010, 39(2): 367-371.

[8] 马运柱, 黄倩芳, 刘文胜. 溶胶-凝胶法CeO2涂覆钨纤维工艺[J]. 中国有色金属学报, 2012, 22(11): 3107-3112.

MA Yun-zhu, HUANG Qian-fang, LIU Wen-sheng. Process of CeO2 coating on tungsten fibers by sol-gel method[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3107-3112.

[9] ZHAO Dan, SUN Jie, ZHANG Li-li, TANG Yong, LI Ji. Corrosion behavior of rare earth cerium based conversion coating on aluminum alloy[J]. Journal of Rare Earths, 2010, 28(S1): s371-s374.

[10] 宋贵宏, 张 硕, 李 锋, 陈立佳. 铝合金上电弧离子镀(Ti, A1)N膜的腐蚀特性[J]. 稀有金属材料与工程, 2010, 39(z1): s259-s262.

SONG Gui-hong, ZHANG Shuo, LI Feng, CHEN Li-jia. Corrosive property of the (Ti, AI)N coatings on Al alloy by are ion plating[J]. Rare Metal Materials and Engineering, 2010, 39 (z1): s259-s262.

[11] 孔德军, 王进春, 刘 浩. 化学镀非晶态Ni-P镀层的摩擦与磨损性能[J]. 中国有色金属学报, 2014, 24(10): 2519-2524.

KONG De-jun, WANG Jin-chun, LIU Hao. Friction and wear properties of amorphous Ni-P coating prepared by electroless plating[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2519-2524.

[12] 罗列超, 赵荣根, 孟 佳, 陈杰锋. 航天器用铝光亮阳极氧化涂层特性研究[J]. 无机材料学报, 2002, 17(6): 1269-1275.

LUO Lie-chao, ZHAO Rong-gen, MENG Jia, CHEN Jie-feng. White aodic coating on aluminium surface for spacecraft[J]. Journal of Inorganic Materials, 2002, 17(6): 1269-1275.

[13] 陈岁元, 杨永泽, 梁 京, 刘常升. 铝合金表面高耐磨自润滑硬质阳极氧化膜的制备[J]. 东北大学学报(自然科学版), 2010, 31(12): 1721-1724.

CHEN Sui-yuan, YANG Yong-ze, LIANG Jing, LIU Chang-sheng. Aluminum alloy on the surface of high wear-resistant self-lubricating hard anode oxidation membrane preparation[J]. Journal of Northeastern University (Natural Science Edition), 2010, 31(12): 1721-1724.

[14] 郭彦飞, 张 鲲, 刘 莉, 胡 琪, 赵君文, 董立新, 郑学斌. 溶胶-凝胶封孔处理对铝合金阳极氧化膜耐蚀及耐磨性能的影响[J]. 材料热处理学报, 2014, 35(9): 182-187.

GUO Yan-fei, ZHANG Kun, LIU Li, HU Qi, ZHAO Jun-wen, DONG Li-xin, ZHENG Xue-bin. Effects of sealing process by sol-gel technology on corrosion and wear resistance of aluminum anodic oxide film[J]. Transactions of Materials and Heat Treatment, 2014, 35(9): 182-187.

[15] 叶存冬, 孔德军. 激光热处理对X80管线钢焊接接头疲劳性能的影响[J]. 材料热处理学报, 2014, 35(10): 64-69.

YE Cun-dong, KONG De-jun. Effect of laser heat treatment on fatigue resistance of X80 pipeline steel welded joints[J]. Transactions of Materials and Heat Treatment, 2014, 35(10): 64-69.

[16] 彭国良, 闫 辉, 刘 峰, 王玉恒, 郑艳丽, 束庆邦. 金属氧化膜对激光辐照效应的影响[J]. 红外与激光工程, 2013, 42(5): 1253-1257.

PENG Guo-liang, YAN Hui, LIU Feng, WANG Yu-heng, ZHENG Yan-li, SHU Qing-bang. Oxidation effect for laser irradiating the metal[J]. Infrared and Laser Engineering, 2013, 42(5): 1253-1257.

[17] PODRABINNIK P, GRIGORIEV S, SHISHKOVSKY I. Laser post annealing of cold-sprayed Al/alumina-Ni composite coatings[J]. Surface and Coatings Technology, 2015, 271: 265-268.

[18] OLAKANMI E O, COCHRANE R F, DALGARNO K W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties[J]. Progress in Materials Science, 2015, 74: 401-477.

[19] AHUIR-TORRES J I,  , ARENAS M A, CONDE A, de DAMBORENEA J. Synthesis of TiO2 nanopore arrays by pulsed laser treatment and anodic oxidation[J]. Surface & Coatings Technology, 2014, 259: 408-414.

, ARENAS M A, CONDE A, de DAMBORENEA J. Synthesis of TiO2 nanopore arrays by pulsed laser treatment and anodic oxidation[J]. Surface & Coatings Technology, 2014, 259: 408-414.

[20] 巩水利, 姚 伟, Steve SHI. 铝合金激光深熔焊气孔形成机理与控制技术[J]. 焊接学报, 2009, 30(1): 60-63.

GONG Shui-li, YAO Wei, SHI S. Porosity formation mechanisms and controlling technique for laser penetration welding of aluminum alloy[J]. Transactions of the China Welding Institution, 2009, 30(1): 60-63.

[21] 文 磊, 王亚明, 周 玉, 王长利, 郭立新, 欧阳家虎. LY12 铝合金微弧氧化涂层组织结构对基体疲劳性能的影响[J]. 稀有金属材料与工程, 2009, 38(s2): s747-s750.

WEN Lei, WANG Ya-ming, ZHOU Yu, WANG Chang-li, GUO Li-xin, OUYANG Jia-hu. Influence of coating microstructure on fatigue performance of microarc oxidation coated LY12 alloy specimen[J]. Journal of Rare Earths, 2009, 38(s2): s747-s750.

[22] 刘伟华, 左 禹, 郭 超, 赵旭辉. 氧化工艺对ZL201铝合金阳极氧化膜受热开裂行为的影响[J]. 中国有色金属学报, 2008, 18(2): 323-329.

LIU Wei-hua, ZUO Yu, GUO Chao, ZHAO Xu-hui. Effects of anodizing parameters on cracking behavior of anodic film on ZL201 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 323-329.

[23] NELSON J C, ORIANI R A. Stress generation during anodic oxidation of titanium and aluminum[J]. Corrosion Science, 1993, 34(2): 307-326.

Effects of laser heat treatment on surface-interface properties of anodic oxidation film on 7475 aluminium alloy

WANG Jin-chun1, KONG De-jun1, 2

(1. College of Mechanical Engineering, Changzhou University, Changzhou 213164, China;

2. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164, China)

Abstract: A layer of oxide film was prepared on the surface of 7475 aluminum alloy by anodic oxidation, which was strengthened with laser heat treatment (LHT), the surface-interface morphologies, chemical element compositions and phase were analyzed by scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), X-ray diffractometry (XRD), respectively, and the chemical elements of the surface and bonding interface were analyzed with plane scan and line scan, respectively. The results show that the number of pores increases on the 7475 aluminum alloy oxide layer surface, and the dense heat affected zone forms at the interface after LHT. The oxide layer is mainly composed of Al2O3 and SiO2, the heat affected zone is mainly composed of Al2O3. The hierarchical enrichment phenomenon of Al, O and Si atoms at the binding interface is produced after LHT, the bonding of compound type + diffusion type forms at the interface.

Key words: 7475 aluminum alloy; anodic oxide film; laser heat treatment; property

Foundation item: Project(2013-216) supported by the Chief Expert (Engineer) of Jiangsu Province Science and Technology Association, China; Project(BE2016052) supported by Key Research and Development Project of Jiangsu Province, China

Received date: 2015-07-09; Accepted date: 2016-03-14

Corresponding author: KONG De-jun; Tel: +86-15961203760; E-mail: kong-dejun@163.com

(编辑 龙怀中)

基金项目:江苏省科协首席专家(工程师)项目(2013-216);江苏省重点研发计划资助项目(BE2016052)

收稿日期:2015-07-09;修订日期:2016-03-14

通信作者:孔德军,教授,博士;电话:15961203760;E-mail:kong-dejun@163.com