文章编号:1004-0609(2016)-11-2303-06

焊前热处理对铍青铜微电阻点焊接头性能的影响

黄永德1,毛锦荣 1,付 强1,张成聪 2,何 鹏3

(1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. 上海航天设备制造总厂,上海 200245;

3. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001)

摘 要:采用微电阻点焊方法成功实现0.1 mm厚铍青铜薄片的连接,研究铍青铜焊前固溶处理(固溶态)和固溶再时效处理(时效态)对搭接接头力学性能和显微组织的影响。结果表明:铍青铜经不同热处理后,时效态接头的抗拉剪力明显高于固溶态的。固溶态铍青铜接头的最大平均抗拉剪力为60.54 N时,熔核由较小的胞状晶、较大的等轴枝晶和柱状枝晶组成;时效态接头最大平均抗拉剪力为137.28 N时,熔核由较大的胞状晶和均匀细小的等轴晶组成。在相同工艺参数下,时效态接头获得的热输入量约为固溶态接头的1.73倍。

关键词:铍青铜;焊前热处理;微电阻点焊;力学性能;显微组织

中图分类号:TG457.13 文献标志码:A

铍青铜是一种耐蚀、耐疲劳、无磁性、导电导热性能优异的有色金属,经固溶处理和固溶再时效处理后都具有较高的强度、硬度以及弹性极限[1]。目前,铍青铜合金被广泛应用于弹簧、继电器、豆荚杆以及卫星天线的构件中[2]。在铍青铜小尺寸合金元件的制造与应用过程中,材料的有效连接尤为重要,由于铍青铜热处理后的高弹性、高硬度以及元件的超薄尺寸等特点,使用传统的焊接方法易出现变形、表面气化和烧穿等现象[3];钎焊焊接需要整体加热,会导致铍青铜弹性严重下降;激光焊虽热影响区小,能量密度集中,适合微小型构件的连接,但铍铜合金激光吸收率极低,焊接效率低下;而微电阻点焊是通过工件内部产生电阻热,作用面积小,不会产生表面气化、烧穿等现象。另外,它独有的电极夹持作用能使弹性薄片构件紧密贴合,是焊接铍青铜薄片的理想方法[4-6]。

微电阻点焊方法电极压力较小,其接头质量易受材料表面状态的影响,而材料表面状态又因表面粗糙度、表面硬度的变化而改变,许多学者开展了表面粗糙度相关研究。例如,徐春容等[7]研究不同表面粗糙度条件下的铍青铜薄片微电阻点焊,发现表面粗糙度较小时能获得更优质接头,当粗糙度增加到一定值后,接头性能不再受表面状态影响。在表面硬度方面,程方杰等[8]通过建立弹塑性力学模型对低碳钢和铝合金两种材料在电阻点焊中各接触表面上的接触特征进行了分析,发现接触材料的表面硬度和材料的弹性模量及屈服强度均制约着接触率。TAN等[9]研究镍薄板的微电阻点焊中动态电阻的变化,研究表明在塑性变形的情况下,接触面间的电阻与表面硬度呈函数关系。ELY等[10]对可伐金属、冷轧钢以及镍片的微电阻点焊进行了研究,发现镍的微电阻点焊过程中需要更大的焊接电流。

综上所述,材料表面硬度对微电阻点焊接头质量的影响已有部分研究,但表面硬度对接头质量的具体影响机制鲜见报道。在铍青铜微电阻点焊过程中,焊前热处理会改变其表面硬度,可知表面硬度是制约接触电阻的重要因素[11]。本文作者通过比较固溶态和时效态青铜的点焊接头力学性能和微观组织结构,分析焊前热处理对其接头性能的影响规律以及具体影响机制,从而为铍青铜薄片的工程应用进行了探索研究。

1 实验

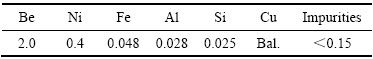

试验材料选用厚度为0.1 mm的QBe2薄片,化学成分如表1所列。

表1 铍青铜母材化学成分

Table 1 Chemical composition of QBe2 base metal (mass fraction, %)

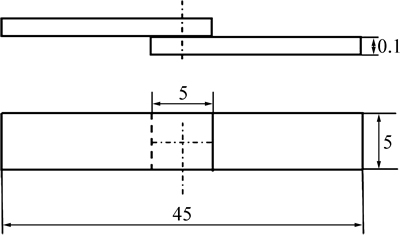

焊接试样加工尺寸为25 mm×5 mm×0.1 mm,焊接中搭接量为5 mm,如图1所示。

图1 形状尺寸示意图

Fig. 1 Schematic diagram of shape and size (Unit: mm)

焊前分别对试验材料进行固溶(780 ℃保温10 min)、固溶+人工时效(320 ℃保温2 h)处理[12]。采用盐酸酸洗表面去除氧化皮,并用丙酮清洗去除杂质以保证焊接面光整清洁。焊机型号为MDA-4000B逆变直流焊机,电极选用端面直径为3.2 mm的W80钨铜合金。试验中,焊接电流选用3.0~5.0 kA,焊接时间固定5 ms,电极压力选用40~220 N,为减少试验误差,每个参数焊接3个试样,接头抗拉剪力取平均值。焊后沿焊点中心截取制备金相试样,采用5 g Fecl3+25 mL HCL+100 mL C2H5OH腐蚀焊点,在MR5000型倒置金相显微镜上进行观察。试验选用INSTRON5540型电子精密拉伸机进行静态拉伸测试,拉伸速度为1 mm/min。用WT-401MVD型显微硬度计测量焊点横截面显微硬度,加载时间为10 s,加载质量为200 g。

2 结果与分析

2.1 熔核组织结构分析

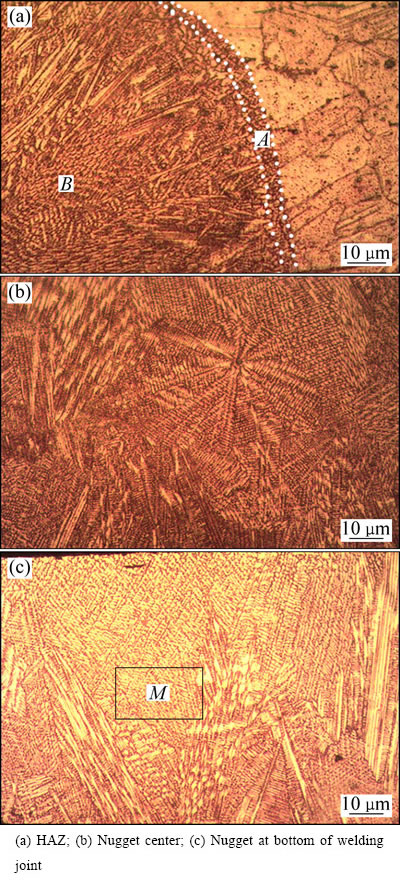

图2所示为焊接电流为4.0 kA、焊接时间为5 ms、电极压力为128 N时固溶态铍青铜接头各区域的显微组织。图2(a)为固溶态接头热影响区显微组织,图中由右至左分别为母材组织、较细小的胞状晶(A区域)和等轴枝晶(B区域)组成;熔核中心则由等轴枝晶和柱状枝晶混合组成,如图2(b)所示。图2(c)为熔核底部区域显微组织,其显微组织由等轴树枝晶联生组成,其中晶粒大小各异,靠近电极的M区域,由于过冷度很大,晶粒更为细小。

图2 固溶态铍青铜接头各区的显微组织

Fig. 2 Microstructures of joint of QBe2 at solid solution state

图3所示为焊接电流为4.5 kA、焊接时间为5 ms、电极压力为180 N时时效态铍青铜接头热影响区、熔核中心区以及熔核底部的显微组织。图3(a)为时效态接头热影响区的显微组织。从图3(a)中可看出,接头组织由左至右分别为母材组织、胞状晶(A区域)、联生结晶区、等轴晶(B区域)。图3(b)所示为熔核中心区域的显微组织。熔核中心由均匀细小的等轴晶组成;图3(c)所示为接头熔核底部区的显微组织。时效态熔核底部晶体以等轴枝晶组成,其形态垂直于焊核边缘生长。

图3 时效态铍青铜接头各区的显微组织

Fig. 3 Microstructures of joint of QBe2 at aging state

对比图2和3可知,时效态接头热影响区(胞状晶区)的宽度大于固溶态接头的,且胞状晶粒较固溶态接头更为粗大,说明时效态接头高温停留时间较长,胞状晶区晶粒有充足的时间长大。时效态接头熔核中心具有更高的温度,且中心区冷却速度相近,故晶粒细小均匀;固溶态接头熔核中心温度较低,中心不同区域冷却速度变化较大,成分过冷度各异,故各区域等轴枝晶生长方向各异。两种接头底部区域晶粒存在不同的联生生长方向,这是由于金属凝固过程中,各区域溶质浓度大小不同,出现成分过冷,导致不同区域最优生长方向各不相同。

综上所述,时效态接头热影响区的过渡区域(胞晶区)更趋于稳定,熔核中心区域和底部区域的晶粒比固溶态细小。分析可知,时效态接头在此工艺参数下可以获得更多的热输入,即高温停留时间要长,晶粒得到细化,接头晶粒大小直接可以影响其力学性能。

2.2 接头拉剪性能分析

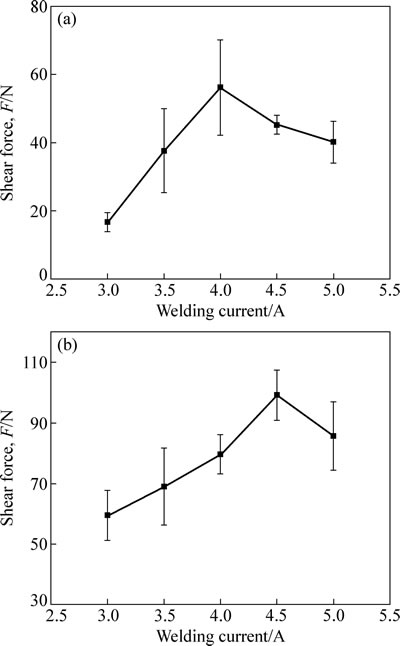

图4所示为焊接时间为5 ms、电极压力为40 N热处理状态下的点焊接头抗拉剪剪力与焊接电流关系曲线。观察固溶态接头抗拉剪力与焊接电流的关系以及时效态接头抗拉剪力与焊接电流的关系可知,在相同工艺参数下,当焊接电流由3.0 kA增大为5.0 kA时,固溶态铍青铜接头的抗拉剪力先增大后减小;当焊接电流为4.0 kA时,接头平均抗拉剪力为56.12 N,时效态铍青铜接头抗拉剪力同样随焊接电流先增大后减小;当焊接电流为4.5 kA时,平均抗拉剪力为99.19 N。由图4可知,在相同工艺参数下,时效态接头的力学性能整体高于固溶态。

图4 固溶态和时效态铍青铜接头抗拉剪力和焊接电流的关系

Fig. 4 Relationship between tensile shear force and welding current of joint of Qbe2 at solid solution sate (a) and aging state (b)

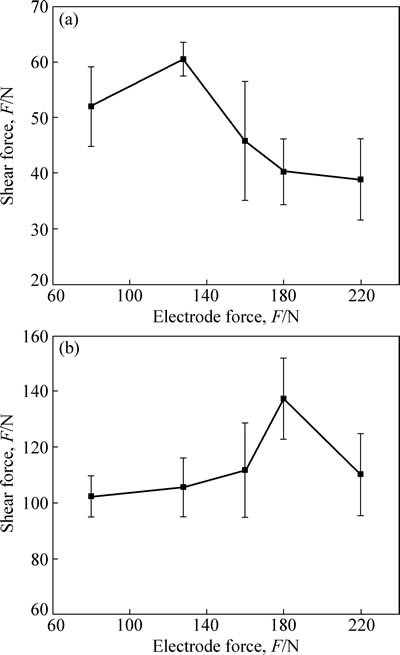

图5所示为铍青铜保持焊接电流和焊接时间不变时固溶态和时效态接头的抗拉剪力与电极压力关系曲线。其中图5(a)所示为焊接电流为4.0 kA、焊接时间为5 ms时固溶态接头抗拉剪力与电极压力的关系。观察曲线可知,当电极压力从80 N增加到128 N时,抗拉剪力呈上升趋势;继续增大压力时,抗拉剪力逐渐下降;当电极压力为128 N时,固溶态铍青铜点焊接头平均抗拉剪力最大值为60.54 N。图5(b)所示为焊接电流为4.5 kA、焊接时间5 ms时时效态接头抗拉剪力与电极压力的关系曲线。可以看出,当电极压力从80 N增大到180 N时,抗拉剪力逐渐上升;继续增加电极压力时,抗拉剪力逐渐下降;当电极压力为180 N时,时效态铍青铜接头平均抗拉剪力的最大值为137.28 N。综上所述可知,在改变电极压力条件下,当焊接电流在一定范围内时,可提高铍青铜点焊接头抗拉剪力,且时效态铍青铜接头力学性能显著高于固溶态的。

图5 固溶态和时效态铍青铜接头抗拉剪力与电极压力的关系

Fig. 5 Relationship between tensile shear force and electrode force of joint of QBe2 at solid solution state (a) and aging state (b)

2.3 表面硬度对接头性能的影响

众所周知,焊接接头质量的好坏与焊接热输入有关[13]。从时效态和固溶态铍青铜接头力学性能和焊缝组织性能分析可知,时效态接头力学性能优越,熔核中心组织晶粒均匀细小,可知固溶态和时效态铍青铜接头在相同工艺参数以及最大抗拉剪力下所获得的焊接热输入不同。焊接热输入可以直接影响焊接质量,而焊接热输入又与电阻产热有关[14]。

在微电阻点焊中,电阻是产热的主要因素,其中包括接触电阻、膜电阻和体电阻。与常规电阻电焊不同,微电阻点焊的电极压力小,接触电阻在产热过程中起主要作用。另外,同种材料焊前清理方法相同,认为其膜电阻是相同的,同种材料体电阻一样[15]。接触电阻与材料接触表面硬度有关,当材料在电极压力作用下发生塑性变形时,接触电阻(Rc)可以表示为以下公式[16]:

(1)

(1)

式中:F为压力;ρ为电阻率;ζ为压力因子;H为接触或压入硬度;n为接触点数目。

对于不同热处理状态下的铍青铜薄片,由式(1)可知,其电阻率相同,在相同工艺参数下,其压力F、压力因子ζ及接触点n均相同,而接头的压入硬度H不同,此时,试样结合界面的接触电阻也不同。

对两种热处理状态的母材进行显微硬度测试,测试位置为母材宽度垂直平分线上,测试间隔为0.5 mm,显微硬度分布结果如图6所示。由图6可看出,时效态铍青铜母材的显微硬度明显高于固溶态的,时效态母材的平均显微硬度为370HV,固溶态的平均显微硬度为125HV。

图6 固溶态和时效态铍青铜母材表面显微硬度的分布

Fig. 6 Surface microhardness distribution of base metal of QBe2 at solid solution state and aging state

经分析计算,时效态接头母材平均硬度为370HV,固溶态接头母材平均硬度(HVs)为125HV,时效态母材(HVs)表面硬度约为固溶态铍青铜表面硬度的3倍,即

HVa≈HVs (2)

由此可知,时效态接头接触电阻 ,当电流通过金属板时,此时产生的热量Q=I2Rt(其中I为电流,R为由接触电阻等组成的动态电阻,t为通电时间)。因此,在结合面局部初步熔化前,相同工艺下,时效态铍青铜接头所获得的电阻热约为固溶态的1.73倍,即

,当电流通过金属板时,此时产生的热量Q=I2Rt(其中I为电流,R为由接触电阻等组成的动态电阻,t为通电时间)。因此,在结合面局部初步熔化前,相同工艺下,时效态铍青铜接头所获得的电阻热约为固溶态的1.73倍,即

Qa≈1.73Qs (3)

由此可推断,铍青铜热处理状态不同,使材料的表面硬度发生改变,表面硬度的变化影响了接触电阻,从而使得焊接热输入不同,直接影响了焊接质量。在相同工艺下,由于时效态铍青铜接触面的硬度高于固溶态的,因此,获得的热输入更多,电阻点焊所形成的熔核尺寸更大,接头的抗拉剪力更高。

平均最大抗拉剪力下,时效态铍青铜的焊接电流为4.5 kA,电极压力为180 N;固溶态的焊接电流为4.0 kA,电极压力为128 N。已知接触电阻Ra>Rs,焊接电流Ia>Is,亦可计算出时效态铍青铜接头所获得的电阻热大于固溶态,即Qa>Qs。

3 结论

1) 铍青铜焊前固溶处理和固溶再时效处理的点焊接头力学性能差异明显。当焊接电流为4.0 kA、焊接时间为5 ms、电极压力为128 N时,固溶态接头平均最大抗拉剪力为60.54 N;当焊接电流为4.5 kA、焊接时间为5 ms、电极压力为180 N时,时效态接头平均最大抗拉剪力为137.28 N。

2) 时效态熔核中心和底部区域组织为均匀细小的等轴晶,固溶态铍青铜熔核中心和底部区域组织为等轴枝晶和柱状枝晶,两种热处理状态下的接头热影响区为胞状晶,且时效态热影响区的宽度大于固溶态的。

3) 表面硬度是影响铍青铜接头性能的主要因素。表面硬度越高接触电阻越大,在相同工艺参数下,接头获得的热输入越高,且时效态接头获得热输入量大约是固溶态的1.73倍。

REFERENCES

[1] 刘兴军, 王翠萍, 甘世溪, 大沼郁雄, 贝沼亮介, 石田清仁. 高性能铜合金热力学数据库的开发及其在材料设计中的应用[J]. 中国有色金属学报, 2011, 21(10): 2512-2522.

LIU Xing-jun, WANG Cui-ping, GAN Shi-xi, OHNUMA I, KAINUMA R, ISHIAD K. Development of thermodynamic database for copper base alloy systems and its application in material design[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2512-2522.

[2] 范 瑛, 谭 云, 淘 萍, 丰 杰. 铍青铜的性能研究综述[J]. 材料导报, 2014, 28(23): 100-103.

FAN Ying, TAN Yun, TAO Ping, FENG Jie. Summary of studies on the machanical properties of beryllium bonze[J]. Materials Riew, 2014, 28(23): 100-103.

[3] 许德美, 秦高梧, 李 峰, 王战宏, 钟景明, 何季麟, 何力军. 国内外铍及含铍材料的研究进展[J]. 中国有色金属学报, 2014, 24(5): 1213-1219.

XU De-mei, QIN Gao-wu, LI Feng, WANG Zhan-hong, ZHONG Jing-ming, HE Ji-lin, HE Li-jun. Advance in beryllium and beryllium-containing materials[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1213-1219.

[4] 陆巍巍, 陈玉华, 谢吉林, 王善林, 封小松. NiTiNb箔片激光焊接工艺及其接头的组织与性能[J]. 中国有色金属学报, 2014, 24(10): 2940-2945.

LU Wei-wei, CHEN Yu-hua, XIE Ji-lin, WANG Shan-lin, FENG Xiao-song. Laser welding process of NiTiNb foil and microstructure and properties of welding joint[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2940-2945.

[5] 张柯柯, 涂益民. 特种先进连接方法[M]. 哈尔滨: 哈尔滨工业大学出版社, 2007: 10-14.

ZHANG Ke-ke, TU Yi-min. Special advanced connection method[M]. Harbin: Harbin Institute of Technology Press, 2007: 10-14.

[6] 付 强, 张成聪, 陈玉华, 黄永德. 铍青铜薄片微电阻点焊工艺及接头组织性能研究[J]. 热加工工艺, 2015, 44(15): 45-48.

FU Qiang, ZHANG Cheng-cong, CHEN Yu-hua, HUANG Yong-de. Study on process and micro structure and properties of joints in micro-resistance spot welding of beryllium bronze sheets[J]. Hot Working Technology, 2015, 44(15): 45-48.

[7] 徐春容, 黄永德. 表面粗糙度对铍青铜微电阻点焊接头性能的影响[J]. 南昌航空大学学报, 2007, 21(2): 63-66.

XU Chun-rong, HUANG Yong-de. Effects of surface roughness on joints properties in small scale resistance spot welding of beryllium copper[J]. Journal of Nanchang Hangkong University, 2007, 21(2): 63-66.

[8] 程方杰, 廉金瑞, 单 平, 胡绳荪. 典型材料点焊时表面接触规律的研究[J]. 天津大学学报(自然科学与工程技术版), 2002, 35(1): 10-14.

CHENG Fang-jie, LIAN Jin-rei, SHAN Ping, HU Sheng-sun. Study on the surface contact rules of representative materials in spot welding[J]. Journal of Tan Jin University (Science and Technology), 2002, 35(1):10-14.

[9] TAN W, LAWSON S, ZHOU Y. Effects of Au plating on dynamic resistance during small-scale resistance spot welding of thin Ni sheets[J]. Metallurgical and Materials Transactions A, 2005, 36: 1901-1910.

[10] ELY K J, ZHOU Y. Micro-resistance spot welding of kovar, steel and nickel[J]. Science and Technology of Welding and Joining, 2001, 6(2): 63-72.

[11] 陈玉华, 谢吉林, 倪 泉, 黄永德. 铜/镀镍钢微电阻点焊接头形成机理[J]. 焊接学报, 2015, 36(9): 35-38.

CHEN Yu-hua, XIE Ji-lin, NI Quan, HUANG Yong-de. Formation mechanism of copper/nickel coated steel dissimilar metals joint by micro spot resistance welding[J]. Transactions of the China Welding Institution, 2015, 36(9): 35-38.

[12] 谢建新, 王 宇, 黄海友. 连续柱状晶组织铜及铜合金的超延展变形行为与塑性提高机制[J]. 中国有色金属学报, 2011, 21(10): 2325-2335.

XIE Jian-xin, WANG Yu, HUANG Hai-you. Extreme plastic extensibility and ductility improvement mechanisms of continuous columnar-grained copper and copper alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2325-2335.

[13] 刘楚明, 刘 娜, 曾祥亮, 陈志永, 李慧中, 徐 雷. 形变时效工艺对低铍Cu-Ni-Be合金力学性能和电导率的影响[J]. 中南大学学报(自然科学版), 2010, 41(2): 509-512.

LIU Chu-ming, LIU Na, ZENG Xiang-liang, LI Hui-zhong, XU Lei. Effects of deformation aging on mechanical properties and electricity conductivity of Cu-Ni-Be alloy[J]. Journal of Central South University (Science and Technology), 2010, 41(2): 509-512.

[14] FUKUMOTO S, ZHOU Y. Mechanism of resistance microwelding of crossed fine nickel wires[J]. Metall Meter Trans A, 2004, 35(10): 3165-3176.

[15] 彭昌永, 高福全, 范如源. 铝合金薄壁件的点焊及表面处理工艺研究[J]. 现代制造工程, 2003(1): 47-49.

PENG Chang-yong, GAO Fu-quan, FAN Ru-yuan. The technical study of the spot welding and surface treating on thin-slab structure of aluminum alloy[J]. Machinery Manufacturing Engineer, 2003(1): 47-49.

[16] TAN W, ZHOU Y, KERR H W, LAWSON S. A study of dynamic resistance during small scale resistance spot welding of thin Ni sheets[J]. Applied Physics, 2004, 37: 1998-2008.

Effect of heat treatment before welding on properties of micro-resistance spot welded joints of QBe2

HUANG Yong-de1, MAO Jin-rong1, FU-qiang1, ZHANG Cheng-cong2, HE Peng3

(1. School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. Shanghai Spaceflight Manufacture (Group) Co., Ltd., Shanghai 200245, China;

3. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The beryllium bronze sheets with thickness of 0.1 mm at solid solution state and aging state were welded successfully by the micro-resistance spot method. The effects of heat treatment before welding on the microstructure, mechanical properties of the lap joints were researched. The results show that after heat treatment, the mechanical performances of the joints produced at aging state are obviously superior to those at solid solution state. The average tensile shear force of the joints made by beryllium bronze at solid solution state is 60.54 N. And the nugget zone is characterized by fine cellular crystals, equiaxial dendrite and dendritic columnar crystals. However, the average value of the joints produced with aging state reaches to 137.28 N. The nugget consists of cellular crystal and the fine equiaxed grains. At the same process parameters, the heat input of beryllium bronze joints with aging state is about 1.73 times higher than that at solid solution state.

Key words: beryllium bronze; heat treatment before welding; micro-resistance spot welding; mechanical property; microstructure

Foundation item: Project(SAST201209) supported by Shanghai Aerospace Science and Technology Innovation Fund, China; Project(15YF1405400) supported by Soil Plan of Shanghai Youth Science and Technology Talents

Received date: 2015-10-23; Accepted date: 2016-03-20

Corresponding author: HUANG Yong-de; Tel: +86-791-83863023; E-mail: huangydhm@nchu.edu.cn

(编辑 李艳红)

基金项目:上海航天科技创新基金资助项目(SAST201209);上海市青年科技英才扬帆计划项目(15YF1405400)

收稿日期:2015-10-23;修订日期:2016-03-20

通信作者:黄永德,副教授,博士;电话:0791-83863023;E-mail:huangydhm@nchu.edu.cn