DOI:10.19476/j.ysxb.1004.0609.2018.03.14

SPS制备含钼WC-6Co硬质合金的工艺性能

郭圣达1, 2,鲍 瑞1,易健宏1,羊建高2,刘 亮1,杨 平1

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 江西理工大学 工程研究院,赣州 341000)

摘 要:以Mo粉、Co粉和自主研发的WC-6Co复合粉为原料,通过球磨、SPS制备Mo添加量为1%(质量分数)的细晶WC-6Co硬质合金。利用XRD、SEM、XPS、维氏硬度计和电化学工作站等研究SPS烧结温度、保温时间对合金组织和性能的影响。结果表明:随着SPS烧结温度的升高和保温时间的延长,WC-6Co-1Mo合金相对密度和断裂韧性持续增加,维氏硬度先增大然后略有下降。当烧结温度为1250 ℃、保温时间为5 min时,制备的合金综合性能最佳。与相同工艺制备的WC-6Co和WC-6Co-4Mo合金进行对比,发现添加适量Mo能够有效抑制WC晶粒的长大,提高合金的硬度和韧性,但相对密度减小;同时,也能够增强合金在HCl溶液的耐腐蚀性能。

关键词:WC-6Co硬质合金;Mo;烧结参数;显微组织;耐腐蚀性能

文章编号:1004-0609(2018)-03-0556-09 中图分类号:TF124 文献标志码:A

WC-Co硬质合金因兼具有高硬度、高耐磨性、高强度和良好的断裂韧性而被广泛应用于涉及到国民经济的众多领域,已成为现代社会不可缺少的重要材料[1-3]。研究表明[4-5],硬质合金的力学性能主要受到微观组织和成分配比的影响,如WC晶粒度大小、WC晶粒度的分布、WC与Co的分布状态、WC与Co的成分比例等。因此,为了制备出具有优异性能的超细合金,须对合金显微组织及成分进行合理调整与严格控制。

由于Co对WC具有良好的润湿性和粘附作用,是硬质合金粘结相的首选材料[6],但是Co的耐腐蚀性能和抗氧化性较差,在腐蚀性环境中应用时会加速合金的失效,从而限制WC-Co硬质合金的应用,如海底钻探、流体喷嘴等。前期研究表明[7-9],在WC-Co硬质合金中掺入添加剂是增强粘结相、提高合金综合性能的有效途径之一。有研究学者通过往合金中添加VC、TiC等难熔金属碳化物来增强Co粘结相并优化晶粒,效果较好[3, 10-12]。LIN等[10]研究TiC对WC-Co硬质合金在碱性溶液中的腐蚀行为,结果表明,TiC使开路电位正向移动,合金自腐蚀电位升高,腐蚀电流密度减小,说明TiC能够增加合金在碱性溶液的耐腐蚀性能。LI等[11]认为添加VC能够抑制WC在粘结相中的溶解与析出过程,从而获得细化WC晶粒的效果。MACHIO等[12]研究VC对WC-Co硬质合金在酸性溶液中的腐蚀行为,结果表明,VC能增强合金的钝化行为,高VC含量能有效降低腐蚀电流密度,但碳化物成本较高,且对合金力学性能存在不利影响,如TiC能增强合金硬度、耐磨性和在碱性溶液中的耐腐蚀性能,但合金的强度降低[13]。POTGIETER等[14]研究了Ru对WC-Co硬质合金在硫酸中的腐蚀行为,发现Ru影响了阴极塔菲尔斜率,说明其能影响腐蚀反应中的阴极反应。同时,还发现Ru对合金耐腐蚀性能的增强效果优于VC的。

Mo在 (W,Ti)C基合金中作为添加剂的作用已经获得了大量研究[15-17],结果表明:Mo能增加Ni等粘结相对WC、TiC的润湿性,从而提升合金性能;ZHANG等[18]研究含Mo的无粘结相硬质合金,发现W原子与Mo原子均向向对方迁移,形成含Mo的WC固溶体和含W的Mo2C固溶体,但未导致合金晶粒的显著长大。通过文献[7]发现,关于Mo元素对WC-Co硬质合金性能影响的研究较少。因此,针对上述研究现状,本文作者利用放电等离子烧结技术(SPS)的快速升温烧结等特点,烧结制备含1% Mo(质量分数,下同)的WC-6Co硬质合金,研究Mo对合金显微组织、力学性能和在HCl溶液耐腐蚀性能的影响。同时,研究SPS关键工艺参数(烧结温度、保温时间)对合金组织与性能的影响。以期为获得综合性能更加优异的WC-Co硬质合金的制备提供可靠的理论依据。

1 实验

1.1 原料与设备

实验使用的原料为自主研发的WC-6Co复合粉(WC 94%、Co 6%(质量分数)),复合粉颗粒粒径约为30 μm,WC晶粒约为0.26 μm[19];Mo粉和Co粉购自赣州精科科技有限公司,平均粒度2 μm,纯度>99.9%。实验设备主要有三辊球混机、真空干燥箱和SPS烧结炉。

1.2 实验方法

将WC-6Co复合粉、Mo粉按比例称量,置于不锈钢球磨罐中。为消除粘结相含量变化对合金组织、性能的影响,在添加了1% Mo的配料中,再添加0.064%(质量分数)的Co,使Co的总含量保持6%(质量分数)不变,详细配比如表1所列(表1中合金1~7分别表示不同成分配比及采用不同烧结工艺制备的硬质合金)。往球磨罐中加入无水乙醇为球磨介质,球料比为5:1,球磨球为直径6 mm的硬质合金球。设置球磨转速为100 r/min,球磨时间48 h。将球磨好的料浆置于真空干燥箱中在70 ℃下加热真空干燥4 h。

称量上述制备的粉末20 g,置于直径为20 mm的石墨模具中,再将装有粉末的模具放入SPS炉内,通电直接加压加热一步烧结制备出添加了1% Mo的细晶WC-6Co硬质合金。固定烧结压力为50 MPa,采用如表1所列的实验工艺分别研究烧结温度、保温时间两个关键工艺参数对WC-6Co-1Mo硬质合金显微组织、力学性能的影响,获得最佳烧结工艺。最后将最佳烧结工艺制备的WC-6Co-1Mo硬质合金与WC-6Co和WC-6Co-4Mo硬质合金进行性能对比。

表1 成分配比及试验方案

Table 1 Nominal composition of alloys and test scheme

采用TM3030台式扫描电镜和JSM-7001E型场发射扫描电镜对复合粉形貌和细晶硬质合金显微组织进行观察;采用荷兰帕纳科锐影X射线衍射仪测定合金的物相;采用阿基米德原理测定硬质合金的密度;依据线性截矩法原理,采用Nano Measure软件测定计算WC的平均晶粒度;用PHI5000 Versaprobe-II型XPS检测合金全谱;采用维氏硬度计测定维氏硬度;利用Palmqvist公式计算合金断裂韧性,计算公式如下所示:

(1)

(1)

式中:li为压痕至裂纹尖端的长度,mm。列出的相对密度、硬度和断裂韧性值均为同一样品测量5次,再计算的平均值。

用上海辰华生产的CHI 660型电化学工作站测量合金在0.1 mol/L的HCl溶液中的极化曲线,进而根据自腐蚀电位值和腐蚀电流密度判断合金的耐腐蚀性能。测量采用三电极体系:饱和甘汞电极为参比电极、铂片为对电极、硬质合金为工作电极,工作面积固定为3.14 cm2。合金在检测前置于0.1 mol/L的HCl溶液中浸泡 1 h,扫描速率为5 mV/s,扫描范围为-800~1000 mV。

2 结果与讨论

2.1 烧结温度的影响

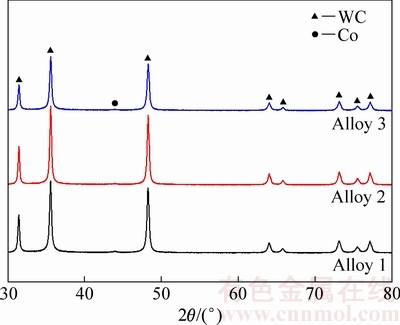

图1所示为试样1、2和3的XRD谱。从图1中可以看出,XRD显示出了WC的强峰和非常微弱的Co峰,而可能出现的Mo2C则未显示出来。分析认为是由于Mo的含量太低,而WC峰太强导致的[20]。7个试样的XRD谱均无明显变化且未出现脱碳相。

图1 烧结硬质合金的XRD谱

Fig. 1 XRD patterns of sintered cemented carbides

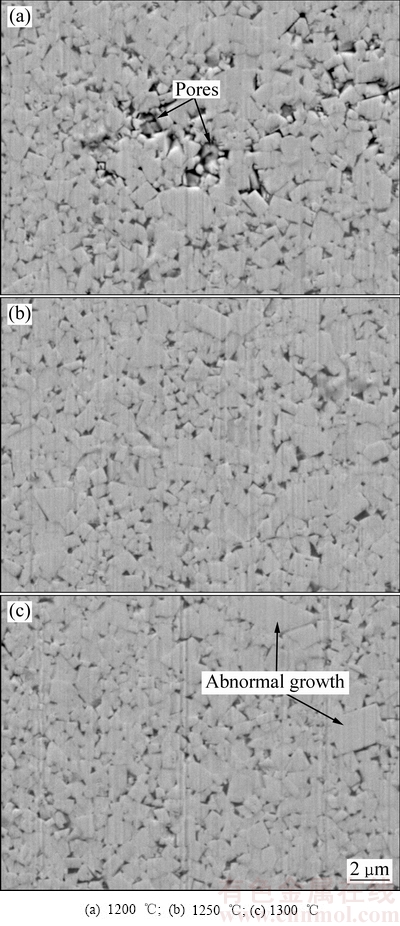

图2 不同烧结温度制备的WC-6Co-1Mo硬质合金的SEM像

Fig. 2 SEM images of WC-6Co-1Mo cemented carbides sintered at different sintering temperatures

图2所示分别为试样1、2和3在COMPO模式下的SEM像。利用Nano Measure软件计算出3个不同烧结温度(1200、1250和1300 ℃)制备的硬质合金WC晶粒度分别为0.89、0.91和0.98 μm,说明在相同烧结压力和保温时间作用下,烧结温度越高,合金WC晶粒度越大。当SPS烧结温度为1200 ℃时,WC晶粒度最细,但合金有少量孔隙存在,如图2(a)所示;当温度为1300 ℃时,WC晶粒度最大且合金存在异常长大的WC晶粒,如图2(c)所示;当烧结温度为1250 ℃时,合金未观察到孔隙和异常长大的WC晶粒(见图2(b))。分析认为,WC-Co硬质合金由WC颗粒与韧性较好的Co粉混合烧结制成,在传统的真空或压力烧结过程中为了能尽量消除孔隙,温度应保持在1320 ℃的共晶温度以上,使Co熔化为液相,填充孔隙完成致密化过程[21]。在本研究中,当温度为1200℃时,未达到共晶温度点,此时可将烧结体看作固相烧结,致密化行为主要受联结、扩散控制,致密化进展缓慢,因此,制备的合金存在较多孔隙;另有研究表明:SPS烧结时测量温度一般比样品实际温度低50~150 ℃[22],当烧结温度在1250 ℃时,样品实际已达到共晶温度,产生液相填充孔隙,增强合金的致密化程度;当烧结温度为1300 ℃时,样品实际温度远高于共晶温度,此时样品内产生大量液体,除了填充孔隙外,还会溶解大量细小的WC颗粒并析出于大颗粒上,产生Ostwald熟化现象,使WC晶粒发生异常长大[23]。因此,当烧结压力和保温时间为固定值时,设置1250 ℃的烧结温度,可获得微观组织最为理想的合金。

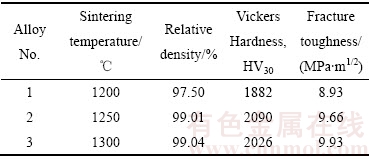

表2所列为合金相对密度、维氏硬度和断裂韧性随不同温度的变化结果。由表2可以看出,合金的相对密度随着烧结温度的升高而上升,当烧结温度为1200 ℃时,合金内部仍然有大量孔隙存在,如图2(a)所示,导致合金密度大幅降低;随着烧结温度的上升,孔隙被填充,使密度升高。随着烧结温度的继续升高,维氏硬度先升高而后略有下降,硬度主要受密度与WC晶粒、粘结相含量的影响,在实验中粘结相含量固定不变,因此硬度随着密度的上升而升高[7]。由Hall-Petch关系可知,合金硬度还随着WC晶粒度的减小而增加,当烧结温度为1300 ℃时,WC晶粒发生异常长大,使硬度略有减小[24]。断裂韧性随着烧结温度的增加而升高。合金的断裂韧性是指合金抵抗裂纹扩展的能力,当合金内部存有孔隙时,裂纹扩展阻力小,断裂韧性低;随着密度上升,韧性也增加,当烧结温度为1300 ℃时,合金致密度最大,并且存在长大的WC晶粒,Co平均自由程增大,此时合金断裂韧性达到最大值[25]。从表2还可看出,合金2和3的相对密度、硬度和断裂韧性值较为接近,说明当烧结温度大于1250 ℃,升高温度对合金密度、硬度和断裂韧性的影响不大,但对比图2(b)和(c)发现。1300 ℃时,WC晶粒存在异常长大,由此分析认为,1250 ℃为最佳烧结温度。

表2 不同烧结温度制备的合金性能

Table 2 Mechanical properties of cemented carbides sintered at different temperatures

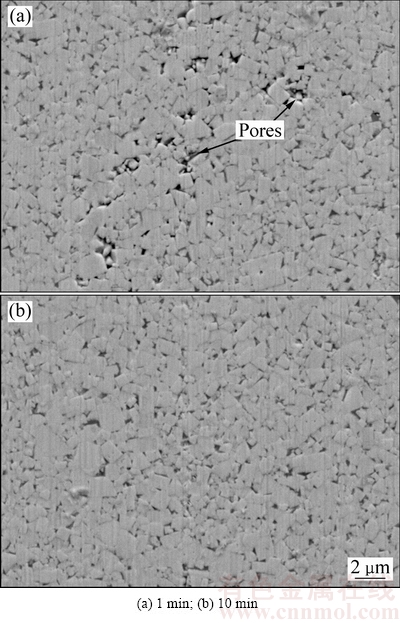

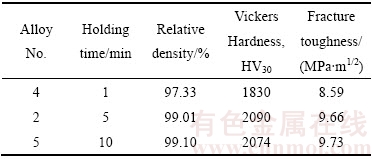

2.2 保温时间的影响

图3所示为固定烧结温度为1250 ℃时合金4(保温时间为1 min)和合金5(保温时间为10 min)在COMPO模式下的SEM像。联系合金2的SEM像(见图2(b)),可以看出不同保温时间对合金微观组织的影响。当保温时间为1 min时,合金存有少量孔隙,烧结不完全,保温时间为5 min和10 min的合金区别不大,说明保温5 min后,继续延长保温时间对合金显微组织的影响较小,同时考虑到节能因素,认为保温时间设置为5 min时,对制备合金最有利。烧结温度为1250 ℃,烧结体内有部分液体存在,能够通过流动迁移填充孔隙,使合金密度上升;但是保温时间太短,粘结相流动填充不完全,导致烧结后合金内部存有孔隙,随着保温时间的延长,粘结相进一步填充孔隙,致密度提高。

图3 不同保温时间制备的WC-6Co-1Mo合金的SEM像

Fig. 3 SEM images of WC-6Co-1Mo cemented carbides sintered for different holding times

表3所列为不同保温时间制备的合金的相对密度、维氏硬度和断裂韧性的检测结果。由表3可以看出,合金相对密度随着保温时间的延长而增加,在保温5 min后变化较小;硬度先上升然后略有下降,但变化幅度很小;断裂韧性持续升高。保温时间大于5 min时,由于烧结体内部有液相存在,使WC发生溶解-析出现象,WC晶粒长大,根据Hall-Petch关系可知合金硬度会略有下降,但是WC长大使粘结相平均自由程增加,使韧性增加。同时从表3看出,合金2和5的相对密度、硬度和断裂韧性相差较小,说明保温时间大于5 min时,该变量对合金性能影响较小,结合图3的分析认为选取5 min的保温时间最佳。

表3 不同保温时间制备的合金性能

Table 3 Mechanical properties of cemented carbides sintered for different holding times

综合上述实验结果与分析认为,添加1% Mo的WC-6Co硬质合金的最佳烧结温度为1250 ℃、保温时间为5 min。

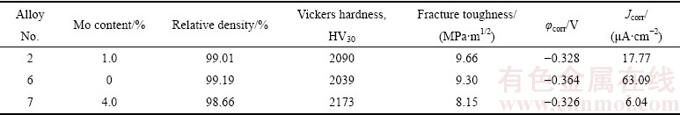

2.3 最佳烧结工艺硬质合金性能分析

固定SPS的烧结工艺参数,分别设置烧结温度为1250 ℃,保温时间为5 min,烧结压力保持在50 MPa,烧结制备WC-6Co硬质合金(合金6)和WC-6Co-4Mo硬质合金(合金7),并与合金2(WC-6Co-1Mo)进行微观组织与性能对比。图4所示为3组合金的SEM像(BSED模式),右上角分图分别为对应合金WC晶粒统计分布图。利用截矩法计算出未添加Mo(合金6)、添加1% Mo的合金(合金2)和添加4% Mo的合金(合金7)中WC平均晶粒度分别约为0.99、0.90和0.85 μm,说明硬质合金WC晶粒度随着Mo含量的增加而减小。此外,合金6中的WC晶粒存在有少量异常长大现象,如图6(a)箭头所示。从图4右上角分图看出,合金6的WC晶粒度分布较宽,且晶粒度大于0.9 μm的WC约占48%,合金2和7的晶粒度大于0.9 μm的WC含量分别为42%和37%,说明合金2和7的WC晶粒分布比合金6的更加均匀,且未发现异常长大现象;但是合金7中存在少量孔隙,如图6(c) 箭头所示。分析认为在烧结过程中,当温度在900℃左右时,Mo与C发生反应生成Mo2C[26],在后续的高温烧结阶段,Mo2C优先溶解于液相中阻止Ostwald效应进行,抑制WC在液相中的溶解-析出过程,使WC晶粒度更细更均匀[27];当Mo添加为4%时,过量的Mo溶于粘结相使其黏度增大、流动动力下降,难以填充合金孔洞,使合金相对密度明显减小。同时,Mo分布于WC/Co界面处并形成团聚,阻碍粘结相流动,使孔隙得以保留,合金密度下降。

图4 不同Mo含量WC-6Co硬质合金的SEM像和统计分布

Fig. 4 SEM images ((a), (b), (c)) and statistics distribution ((a′), (b′), (c′)) of WC-6Co cemented carbides with different Mo contents

图5所示为合金2表面的XPS谱,其中图5(a)为全谱图、图5(b)为Mo3d窄谱及拟合分峰图。从全谱图可以看出,C1s和W4f峰较高,说明合金主要为C与W组成的化合物,同时O1s峰较高,分析认为是在磨抛过程中合金产生较多氧化物导致的。从图5(b)中可以看出,Mo3d有4个峰,其中Mo3d5 228.6 eV和Mo3d3 231.5 eV两个峰对应于Mo2C;另外两个峰对应于MoO3[8]。由图5分析可知,合金在烧结后形成了Mo2C,但由于含量较低,在XRD结果中未显示出相应的物相。

表4为两组合金的密度、维氏硬度和断裂韧性的对比。可以看出,合金6的相对密度为99.19%,高于合金2的(99.01%),合金7的相对密度最低,为98.66%。结果显示:合金相对密度随着Mo含量的增加而减小。硬质合金致密化过程主要有WC颗粒重排、扩散和粘性流动。在烧结过程中,Mo与C反应生成的Mo2C相溶于液相中,使液相流动能力减弱,孔隙填充能力下降导致相对密度减小[28]。

合金6的维氏硬度为2039,低于合金2的,合金7的维氏硬度最大(2173),说明合金硬度随着Mo含量的增加而增大。这是由于Mo能有效抑制WC晶粒的长大,合金显微组织细小均匀,由Hall-Petch关系可知:合金硬度增大;而硬度又随着合金密度增加而增大。在本文实验中发现,添加Mo使合金WC晶粒减小、相对密度也变小,但合金硬度增加,说明在一定范围内,WC晶粒度大小对硬度变化的贡献大于相对密度的贡献。从表4看出,合金6的断裂韧性小于合金2的,但大于合金7的(8.15 MPa·m1/2),说明合金断裂韧性随着Mo含量的增大先增加,后呈下降趋势。当Mo含量较少时,Mo溶于Co粘结相中并对粘结相起到固溶强化作用,使其能承受更大的应力,当合金受到外力载荷时,Co相较低的流动应力能够使脆性WC骨架受到的载荷快速被转移出去,从而提升合金断裂韧性值[15];当Mo含量增加到一定量以后,导致合金内部留有大量孔隙,使WC与Co结合程度下降,韧性大幅降低。

图5 合金2表面的XPS谱

Fig. 5 XPS spectra of surface of alloy 2

表4 不同Mo含量的WC-6Co硬质合金性能

Table 4 Properties of cemented carbides with different Mo contents

图6所示为3组合金的极化曲线图。从图6中可以看出,添加了1% Mo合金2的自腐蚀电位为-0.328 V,比合金6(-0.364 V)的更大,而合金7的自腐蚀电位为-0.326 V,几乎与合金2的一样。结果表明:添加Mo元素能够增强合金的耐腐蚀性能,在本次实验范围内Mo含量对合金自腐蚀电位影响极小。另外,合金2的腐蚀电流密度为17.77 μA/cm2,低于合金6的(63.09 μA /cm2),说明添加1% Mo能够有效降低腐蚀电流,增强合金的耐腐蚀性能。同时发现,合金7的腐蚀电流密度仅为6.04 μA/cm2。结果表明:Mo含量越大,阻止电子迁移的能力越强,宏观表现为腐蚀电流密度越小。研究表明[9]:WC-Co在酸性条件下的腐蚀过程,实质上是Co相被氧化生成氧化钴溶解于溶液中、WC失去Co的粘结作用而脱落瓦解的过程。在实验的烧结过程中生成的Mo2C溶于Co粘结相并对粘结相起到固溶强化作用,使Co粘结相标准氧化电位得到提高,使合金自腐蚀电位升高。Mo含量越高,溶于粘结相中的Mo被氧化后生成MoO3的量越多,其分布于合金外表面形成一层保护膜,减小合金与腐蚀溶液直接接触的面积、降低电子迁移速率,宏观表现为降低腐蚀电流密度,从而提高合金的耐腐蚀性能。

图6 不同Mo含量硬质合金在0.1 mol/L HCl溶液中的极化曲线图

Fig. 6 Potentiodynamic polarization curves of WC-6Co cemented carbides with different Mo contents in 0.1 mol/L HCl solution

3 结论

1) 随着SPS烧结温度的升高和保温时间的延长,WC-6Co-1Mo合金的相对密度增大,维氏硬度先增大然后略有下降,断裂韧性持续增加。最佳的烧结工艺参数为烧结温度1250 ℃、保温时间5 min。

2) 对比在相同烧结条件下制备的传统WC-6Co、WC-6Co-1Mo和WC-6Co-4Mo硬质合金发现,添加Mo元素能够有效抑制WC晶粒长大,提高合金硬度和韧性,但相对密度下降;同时,添加Mo能够有效提升合金在HCl溶液中的耐腐蚀性能,抑制电子迁移速率。

REFERENCES

[1] BAO R, YI J H, PENG Y D, ZHANG H Z. Effects of microwave sintering temperature and soaking time on microstructure of WC-8Co[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 372-376.

[2] LI X F, LIU Y, WEI W, DU M, LI K Y, ZHOU J H, FU K. Influence of NbC and VC on micro-structures and mechanical properties of WC-Co functionally graded cemented carbides[J]. Materials and Design, 2016, 90: 562-567.

[3] SU W, SUN Y X, YANG H L, ZHANG X Q, RUAN J M. Effects of TaC on microstructure and mechanical properties of coarse grained WC-9Co cemented carbides[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1194-1199.

[4] KANERVA U, KARHU M, LAGERBOM J,  A, HONKANENC M, TURUNEN E, LAITINEN T. Chemical synthesis of WC-Co from water-soluble precursors: The effect of carbon and cobalt additions to WC synthesis[J]. International Journal of Refractory Metals and Hard Materials, 2016, 56: 69-75.

A, HONKANENC M, TURUNEN E, LAITINEN T. Chemical synthesis of WC-Co from water-soluble precursors: The effect of carbon and cobalt additions to WC synthesis[J]. International Journal of Refractory Metals and Hard Materials, 2016, 56: 69-75.

[5] 张 立, 程 鑫, 陈 述, 马 鋆, 吴厚平, 熊湘君. Cr、V、RE添加剂对特粗晶与超粗晶硬质合金微观组织与性能的影响[J]. 中国有色金属学报, 2012, 22(9): 2620-2625.

ZHANG Li, CHENG Xin, MA Yun, WU Hou-ping, XIONG Xiang-jun. Effects of Cr, V and RE additives on microstructures and properties of super extra coarse and extra coarse cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2620-2625.

[6] ZHAO Z Y, LIU J W, TANG H G, MA X F, ZHAO W. Effect of Mo addition on the microstructure and properties of WC-Ni-Fe hard alloys[J]. Journal of Alloys and Compounds, 2015, 646:155-160.

[7] LIN N, WU C H, HE Y H, ZHANG D F. Effect of Mo and Co additions on the microstructure and properties of WC-TiC-Ni cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2012, 30: 107-113.

[8] ZHANG Q K, LIN N, HE Y H. Effects of Mo additions on the corrosion behavior of WC-TiC-Ni hardmetals in acidic solutions[J]. International Journal of Refractory Metals and Hard Materials, 2013, 38: 15-25.

[9] QU X Q, XIAO D H, SHEN T T, SONG M, HE Y H. Characterization and preparation of ultra-fine grained WC-Co alloys with minor La-additions[J]. International Journal of Refractory Metals and Hard Materials, 2012, 31: 266-273.

[10] LIN N, HE Y H, WU C H, LIU S F, XIAO X H, JIANG Y. Influence of TiC additions on the corrosion behaviour of WC-Co hardmetals in alkaline solution[J]. International Journal of Refractory Metals and Hard Materials, 2014, 46: 52-57.

[11] LI X F, LIU Y, WEI W, DU M, LI K Y, ZHOU J H, FU K. Influence of NbC and VC on microstructures and mechanical properties of WC-Co functionally graded cemented carbides[J]. Materials and Design, 2016, 90: 562-567.

[12] KONADU D S, van der MERWE J, POTGIETER J H, POTGIETER-VERMAAK S, MACHIO C N. The corrosion behaviour of WC-VC-Co hardmetals in acidic media[J]. Corrosion Science, 2010, 52: 3118-3125.

[13] van der MERWE R, SACKS N. Effect of TaC and TiC on the friction and dry sliding wear of WC-6 wt.% Co cemented carbides against steel counterfaces[J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 94-102.

[14] POTGIETER J H, THANJEKWAYO N, OLUBAMBI P, MALEDI N, POTGIETER-VERMAAK S. Influence of Ru additions on the corrosion behaviour of WC-Co cemented carbide alloys in sulphuric acid[J]. International Journal of Refractory Metals and Hard Materials, 2011, 29: 478-487.

[15] GENGA R M, CORNISH L A, AKDOGAN G. Effect of Mo2C additions on the properties of SPS manufactured WC-TiC-Ni cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 12-21.

[16] 陈 健, 弓满峰, 伍尚华, 蒋强国. 掺杂对硬质合金微观结构和晶粒生长的影响[J]. 材料导报, 2014, 28(10): 25-30.

CHEN Jian, GONG Man-feng, WU Shang-hua, JIANG Qiang-guo. Effect of doping elements on microstructure and grain growth of cemented carbides[J]. Materials Review, 2014, 28(10): 25-30.

[17] 张盘龙, 倪 锋, 赵晶晶, 魏世忠. 钼基掺杂合金的研究现状[J]. 硬质合金, 2013, 30(2): 107-112.

ZHANG Pan-long, NI Feng, ZHAO Jing-jing, WEI Shi-zhong. Research status of doped molybdenum-based alloys[J]. Cemented Carbide, 2013, 30(2): 107-112.

[18] ZHANG L, CHEN S, SHAN C, HUANG F J, CHENG X, MA Y. Hot pressing densification of WC-MoxC binderless carbide[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 2027-2031.

[19] 郭圣达, 羊建高, 朱二涛, 陈 颢, 吕 健. WC-Co复合粉形貌遗传特性及粒度分布研究[J]. 稀有金属材料与工程, 2016, 45(5): 1330-1334.

GUO Sheng-da, YANG Jian-gao, ZHU Er-tao, CHEN Hao, Lü Jian. Genetic characteristics of morphology and particle size distribution of WC-Co composite powder[J]. Rare Metal Materials and Engineering, 2016, 45(5): 1330-1334.

[20] WANG C X, JIANG C H, CAI F, ZHAO Y T, ZHU K Y, CHAI Z. Effect of shot peening on the residual stresses and microstructure of tungsten cemented carbide[J]. Materials and Design, 2016, 95: 159-164.

[21] 郭圣达, 易健宏, 鲍 瑞. 放电等离子烧结制备钨钴硬质合金的研究现状[J]. 中国钨业, 2015, 30(6): 35-41.

GUO Sheng-da, YI Jian-hong, BAO Rui. Research status of WC-Co cemented carbide prepared by spark plasma sintering[J]. China Tungsten Industry, 2015, 30(6): 35-41.

[22] 刘雪梅, 宋晓艳, 张久兴, 赵世贤, 魏 君. 放电等离子烧结制备WC-Co硬质合金温度分布的数值模拟[J]. 中国有色金属学报, 2008, 18(2): 221-225.

LIU Xue-mei, SONG Xiao-yan, ZHANG Jiu-xing, ZHAO Shi-xian, WEI Jun. Simulation of temperature distribution during spark plasma sintering to synthesize WC-Co cermets[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 221-225.

[23] SIVAPRAHASAM D, CHANDRASEKAR S B, SUNDARESAN R. Microstructure and mechanical properties of nanocrystalline WC-12Co consolidated by spark plasma sintering[J]. International Journal of Refractory Metals and Hard Materials, 2007, 25: 144-152.

[24] EMANI S V, WANG C L, SHAWA L L, CHEN Z. On the hardness of submicrometer-sized WC-Co materials[J]. Materials Science and Engineering A, 2015, 628: 98-103.

[25] 朱 斌, 柏振海, 高 阳, 罗兵辉. WC晶粒对WC-15Fe-5Ni硬质合金组织与性能的影响[J]. 中国有色金属学报, 2016, 26(5): 1065-1074.

ZHU Bin, BAI Zhen-hai, GAO Yang, LUO Bing-hui. Effects of WC particle size on microstructure and properties of WC-15Fe-5Ni cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 1065-1074.

[26] LIU N, XU Y D, LI Z H, CHEN M H, LI G H, ZHANG L D. Influence of molybdenum addition on the microstructure and mechanical properties of TiC-based cermets with nano-TiN modification[J]. Ceramics International, 2003, 29: 919-925.

[27] SUN Y X, SU W, YANG Hai-lin, RUAN Jian-ming. Effects of WC particle size on sintering behavior and mechanical properties of coarse grained WC-8Co cemented carbides fabricated by unmilled composite powders[J]. Ceramics International, 2015, 41: 14482-14491.

[28] SUN L, YANG T E, JIA C C, XIANG J. VC, Cr3C2 doped ultrafine WC-Co cemented carbides prepared by spark plasma sintering[J]. International Journal of Refractory Metals and Hard Materials, 2011, 29: 147-152.

Effects of SPS sintering parameters on microstructure and properties of WC-6Co cemented carbides with Mo addition

GUO Sheng-da1, 2, RUI Bao1, YI Jian-hong1, YANG Jian-gao2, LIU Liang1, YANG Ping1

(1. School of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Project Research Institute, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: Using Mo powders, Co powders and WC-6Co composite powders as raw materials, the fine-grained WC-6Co cemented carbides with 1% Mo (mass fraction) addition were fabricated by ball-milling and spark plasma sintering technology. The effects of sintering temperature and holding time on the microstructure and properties of cemented carbides were investigated by XRD, SEM, XPS, Vickers hardness tester, electrochemical workstation, and so on. The results show that the relative density and fracture toughness of cemented carbides with 1% (mass fraction) Mo addition increase as the sintering temperature and holding time increasing. The Vickers hardness increases until the maximun value, and then follows a decreasing trend with the increase of sintering temperature and holding time. The best comprehensive properties achieve at temperature of 1250 ℃ ant holding time of 5 min comparing with WC-6Co and WC-6Co-4Mo cemented carbides prepared by the same processes. The results show that the appropriate content of Mo is beneficial for refining the WC grains, increasing the hardness and fracture toughness significantly. However, the relative density decreases with the addition of Mo slightly. Moreover, the corrosion resistance of WC-6Co cemented carbides in HCl solution increases with Mo addition.

Key words: WC-6Co cemented carbide; Mo; sintering parameter; microstructure; corrosion resistance

Foundation item: Project(51464013) supported by the National Natural Science Foundation of China; Project (2015FB127) supported by the Natural Science Foundation of Yunnan Province, China; Project (20151BBE50002) supported by the Natural Science Foundation of Jiangxi Province, China; Project(GJJ150648) supported by the Education Department of Jiangxi Province, China

Received date: 2016-12-21; Accepted date: 2017-07-12

Corresponding author: YI Jian-hong; Tel: +86-871-65916977; E-mail: yijianhong2007@sohu.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51464013);云南省科技厅面上项目(2015FB127);江西省科技厅科技支撑项目(20151BBE50002);江西省教育厅青年项目(GJJ150648)

收稿日期:2016-12-21;修订日期:2017-07-12

通信作者:易健宏,教授,博士;电话:0871-65916977;E-mail:yijianhong2007@sohu.com