文章编号: 1004-0609(2006)06-0937-08

热处理对镍基单晶高温合金微观组织和

高温持久性能的影响

马文有, 李树索, 乔 敏, 宫声凯, 郑运荣, 韩雅芳

(北京航空航天大学 材科学与工程学院, 北京 100083)

摘 要: 采用螺旋选晶法, 制备了一种镍基单晶高温合金。 在非真空箱式电阻炉中进行分级均匀化热处理, 研究了热处理制度对合金显微组织及持久性能的影响。 结果表明: 合金的铸态组织由γ-Ni固溶体相、 初生和次生的γ′-Ni3Al相、 以及γ/γ′共晶相组成; 1305~1310℃、 16h固溶处理后, 次生γ′全部固溶, 少量γ/γ′共晶没有完全固溶; 1315℃、 16h固溶处理后, γ/γ′共晶全部固溶; 1320℃、 2h固溶处理后, 出现少量初熔; 两次时效处理明显改变了γ′的尺寸、 形貌及分布; 合金经1180℃、 2h+1290℃、 2h+1315℃、 16h AC+1140℃、 4h AC+870℃、 24h AC完全热处理后, 在1100℃, 137MPa条件下持久寿命达到100h。 持久裂纹主要沿与拉应力垂直的枝晶间横向段萌生扩展, 与γ/γ′共晶完全固溶状态相比, 未固溶的γ/γ′共晶更容易成为主要裂纹源。

关键词: 镍基单晶高温合金; 固溶处理; 热处理; 持久性能; 显微组织 中图分类号: TG113.12; TG132.3

文献标识码: A

Effect of heat treatment on microstructure and stress rupture life of Ni-base single crystal superalloy

MA Wen-you, LI Shu-suo, QIAO Min, GONG Sheng-kai,

ZHENG Yun-rong, HAN Ya-fang

(School of Material Science and Engineering,

Beijing University of Aeronautics and Astronautics, Beijing 100083, China)

Abstract: A Ni-base single crystal superalloy was prepared by screw selecting method. The homogenizing heat treatment carried out in an antivacuum chamber oven, and the effect of heat treatment on the microstructure and stress rupture life at 1100℃ was studied. The results show that the as-cast structure of the alloy is composed of γ-Ni solid solution phase, primary and secondary γ′-Ni3Al phase, and γ /γ′ phases. After solid solution treatment under the condition of 1305-1310℃ for 16h, secondary γ′ is solved completely but a small amount of γ/γ′ eutectic remains. While after the solid solution treatment at 1315℃ for 16h, γ/γ′ eutectic is solved completely. A small amount of primary melting appears after the solid solution treatment at 1320℃ for 2h. It is found that the sizes, morphologies and distributions of γ′ phase change greatly by double aging treatment. After full heat treatment of 1180℃, 2h+1290℃, 2h+1315℃, 16h AC+1140℃, 4h AC+870℃, 24h AC, the stress rupture life of alloy is 100h under the condition of 1100℃ and 137MPa.The study of the microstructure for cracked specimens shows that the cracks propagate mainly along the interdentritic area perpendicular to the tensile stress. It is also found that the remained γ/γ′ eutectic is the weak and crack initiation points during the creep tests of the alloy.

Key words: Ni-base single crystal superalloy; solid solution treatment; heat treatment; stress rupture properties; microstructure

自普惠公司[1]研制开发第一代单晶高温合金PWA1480以来, 单晶高温合金已成为先进航空发动机涡轮叶片首选材料之一。 正在研制的推重比10发动机F119(美)、 F120(美)、 GE90(美)、 EJ2000(英、 德、 意、 西)、 M88-2(法)、 P2000(俄)以及其它新型发动机都采用单晶高温合金制作涡轮叶片[2]。 目前, 镍基单晶高温合金已由20世纪80年代初的第一代发展到现在的第四代, 无Re、 3%Re、 6%Re和4%Re+4%Ru(质量分数)基本上是第一代、 第二代、 第三代和第四代合金化学成分的主要特征[3]。

从单晶高温合合金发展进程来看, 总的发展趋势是: 1难熔元素(Ta、 Re、 W、 Mo)的加入量不断增加[4, 5], 以改善合金的高温性能。 以CMSX系列单晶合金为例[6], 第一代难熔元素加入量14.6%, 第二代为16.4%, 第三代高达20.7%。

2) C、 B、 Zr、 Hf等晶界强化元素从限用转为限量使用[2]。 单晶合金没有晶界, 加入C、 B、 Zr、 Hf等晶界强化元素易降低合金的初熔点, 但近年来研究表明, 微量的晶界元素能改善合金的某些性能[7]。 LIU等[8]在研究一种单晶合金时发现微量的C可减少合金中的孔洞, 对合金抗蠕变性能有益; PWA1487和ReneN5合金中加入了微量的Y[9], 使合金的抗氧化性能得以大幅度提高。

3) Ru在单晶合金中的应用。 研究表明, Re是强TCP形成元素[10], 它强烈偏析于枝晶干区又难于扩散, 在高温固溶处理时均匀化困难, 合金在长时使用中析出TCP相, 损伤合金的高温持久性能。 Ru的主要作用是稳定组织, 抑制TCP相的形成[11-13]。

本文设计的单晶合金成分为: 难熔元素(Ta、 Re、 W、 Mo、 Nb)的加入量达到17.5%, 并加入质量分数为0.1%Y、 0.1%Hf和0.015%C。 在高温度梯度定向凝固炉中, 采用螺旋选晶法制成单晶合金持久性能试棒。 研究具有〈001>取向的单晶合金样品在铸态及热处理后组织中相的种类、 形态、 分布以及热处理对合金高温持久性能的影响。

1 实验

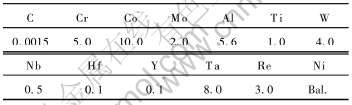

试验合金的成分设计如表1所示。 母合金采用真空感应熔炼, 然后在高温度梯度定向凝固炉中, 采用螺旋选晶法将母合金制成〈001>取向d15mm×150mm的单晶试棒。 定向凝固时抽拉速度为4~6mm/min。 采用背散射劳埃法确定单晶取向, 试棒主应力轴与[001]方向的偏离度小于10℃。 从单晶试棒上切取试样在1180~1320℃之间做固溶处理试验, 确定γ′相的溶解温度。 将试棒在1180℃、 2h+1290℃、 2h +(1305℃、 1310℃、 1315℃)、 16h AC+1140℃、 4h AC+870℃、 24h AC条件下进行热处理, 加工成尺寸为d5mm×65mm的台阶圆柱形高温持久试样, 在1100℃、 137MPa条件下进行高温持久实验。 利用光学金相显微镜、 扫描电镜(SEM)、 X射线能谱(EDS)等分析技术对铸态、 热处理态和持久断裂后的试样进行组织分析。

表1 合金的化学成分

Table 1 Chemical composition of alloys (mass fraction, %)

2 结果与讨论

2.1 合金的铸态组织

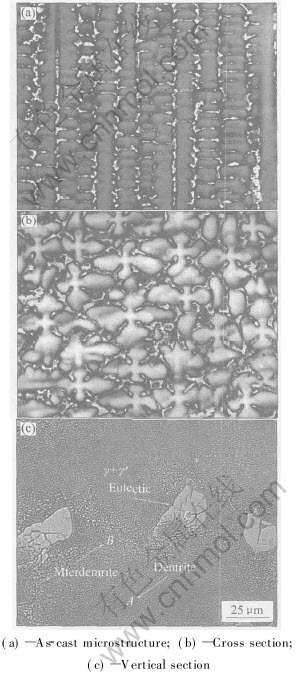

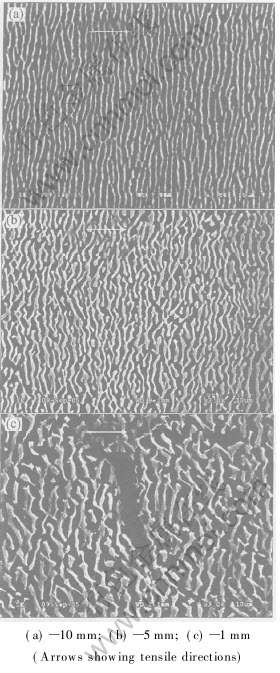

图1 单晶合金的铸态枝晶形貌

Fig.1 Dendrite morphologies of as-cast single crystal superalloy

铸态单晶合金显微组织如图1所示。 图1(a)和(b)所示分别为纵向和横向铸态树枝晶组织。 由图可以看出, 树枝晶形貌清晰可见, 排列规则整齐。 纵截面呈现树干状的为一次枝晶生长形貌; 横截面上呈现“+”形状的为二次枝晶形貌。 背散射劳埃法测得一次枝晶生长方向为〈001〉, 呈现“+”形状的二次枝晶生长方向分别为〈010〉和〈100〉。 经测试一次枝晶间距平均为300μm, 二次枝晶间距平均为80μm, 在枝晶间分布着大量的γ/γ′共晶。 图1(c)为在更高放大倍率下观察到的合金中γ、 γ′的分布情况。 由图可以, 看出在枝晶干区(A区)次生γ′较细, 枝晶间区(B区)次生γ′较粗, 同时在枝晶间(C区)还分布着类似花瓣状的大块初生γ/γ′共晶。 在定向凝固过程中, 初生和次生γ′凝固顺序是不同的, 初生γ′是从液相中析出, 次生γ′是从γ固溶体中脱溶出来的, 初生γ′比次生γ′形成温度高一些。 由于在凝固过程中存在成分偏析, 铸态合金的枝晶间富集了大量Al、 Ti和Ta等γ′相形成元素, 从而形成了大量的γ/γ共晶和粗大的γ′相。

2.2 合金的热处理态组织

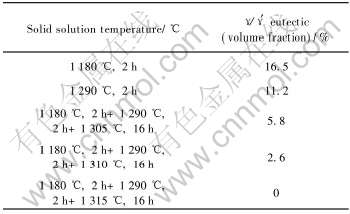

γ′相是单晶合金的主要强化相, 它的大小、 形态以及分布直接影响合金的高温性能。 在铸态单晶合金中, 粗大的γ′相不利于合金高温性能, 须进行高温固溶和时效处理, 以便重新析出形状、 尺寸、 含量和分布均佳的γ′, 从而提高γ′相强化效果。 DSC测试结果表明, 合金固液两相区温度在1300~1380℃之间, 为此选择表2的固溶处理工艺。 其中1180℃、 2h, 1290℃、 2h为2级均匀化处理, 目的是消除合金中元素偏析。 表2所列结果表明: 随着固溶温度的升高γ/γ′相含量逐渐降低, 合金经1315℃、 16h固溶处理, γ/γ′共晶已完全固溶。

图2所示为合金在均匀化处理前后枝晶及γ′相的组织形貌。 比较图2(a)~(c)可以看出, 铸态组织(图2(a))中枝晶花样非常明显, 元素偏析比较严重。 经1180℃、 2h(图2(b))、 1290℃、 2h(图2(c))均匀化处理后, 枝晶偏析得到很大程度的改善, γ/γ′共晶形貌变化不大, 仍呈形状不规则的“板条状”或“葵花状”, 尺寸变小, 数量降到11.2%(体积分数, 下同)。

表2 不同固溶温度条件下γ/γ′共晶固溶情况

Table 2 Amount of γ/γ′ eutectic islands after solution at different temperatures

图2 合金在均匀化处理前后γ′相的变化

Fig.2 Change of γ′ phase before and after different uniform heat treatment of alloy

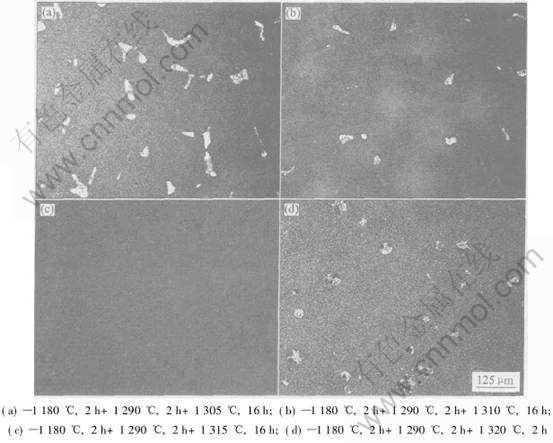

图3所示为合金在不同温度固溶处理后γ′相的组织形貌。 在1180℃、 2h+1290/2h+1305℃、 16h固溶处理时, 枝晶间细小γ′首先固溶, 次生γ′经充分溶解后也全部固溶, 合金中有5.8%左右的γ/γ′共晶没有完全固溶(图3(a))。 在1180℃、 2h +1290℃、 2h+1310℃、 16h固溶处理时, 随着固溶温度的升高, γ/γ′共晶数量逐渐减少, 但仍残留2.6%左右没有完全固溶(图3(b))。 在1180、 2h+1290、 2h+1315℃、 16h固溶处理时, 合金中元素经过长时间高温扩散, γ/γ′共晶已全部固溶, 枝晶偏析基本消失(图3(c))。 在1180℃、 2h+1290℃、 2h+1320℃、 2h固溶处理时, 出现少量初熔, 初熔量在3%左右(图3(d)), 初熔相结构正在进一步研究。

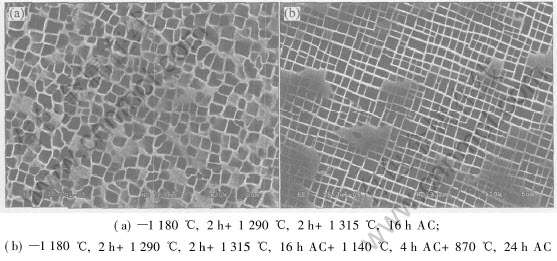

图4所示为固溶和两次时效处理后的γ′组织形貌。 经1180℃、 2h+1290℃、 2h+1315℃、 16h AC固溶处理后, 合金在随后空冷过程中重新析出细小的γ′, 尺寸范围在200~300nm, 形状近似立方状, 分布趋于均匀(图4(a))。 固溶处理后的合金再经1140℃、 4h AC+870℃、 24h AC两次时效处理后, γ′明显长大, 尺寸范围在400~500nm, 平均约为450nm, 立方化程度明显增加, 含量约为65%左右, 均匀分布在厚度约为50~80nm左右的γ基体中(图4(b))。

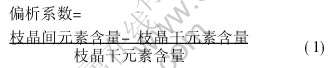

用能谱分析了几种状态样品的枝晶干和枝晶间化学成分, 结果如表3所列。 其中偏析系数可表示为

表3所列数据表明: 难熔元素W和Re是负偏析元素, 在枝晶干区浓度较高; Al、 Ti、 Ta是正偏析元素, 在枝晶间区浓度较高。 经过多级热处理后, 负偏析元素W的偏析系数由铸态的-19.4%下降到-8.0%, Re偏析系数由铸态的-15.8%下降到-4.2%; 正偏析元素Al的偏析系数由铸态的14.1%下降到3.5%, Ti的偏析系数由铸态的34.1%下降到7.3%, 同时, Mo、 Co、 Cr、 Ta等元素的偏析状况也得到一定程度的改善。

图3 合金在不同固溶处理后 γ′相的变化

Fig.3 Change of γ′ phase after different solid solution treatments for alloy

图4 固溶和时效热处理后γ′形貌变化

Fig.4 γ′ morphologies after solid solution and aging heat treatment

表3 合金元素在枝晶干和枝晶间的成分偏析

Table 3 Compositional segregation analysis of alloy elements

between dentrite and interdentrite (mass fraction, %)

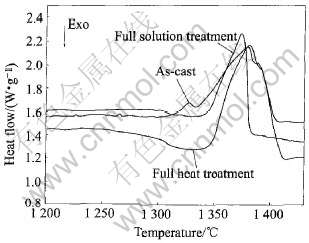

2.3 DSC测试固液两相温度

图5所示3条曲线分别为合金在铸态、 1180℃、 2h+1290℃、 2h+1315℃、 16h AC完全固溶处理和1180℃、 2h+1290℃、 2h+1315℃、 16h AC+1140℃、 4hAC+ 870℃、 24h AC完全热处理后的DSC测试曲线。

铸态曲线在1320~1330℃之间出现一个吸热峰(箭头所示), 表明在此温度范围内合金存在初熔, 这与固溶处理时合金在1320℃出现少量初溶是一致的。 完全固溶曲线和完全热处理曲线表明合金经过长时间高温处理后, 合金中元素得到充分扩散, 元素偏析状况明显改善, 初熔相已完全消失。

2.4 持久断裂后试样的显微组织

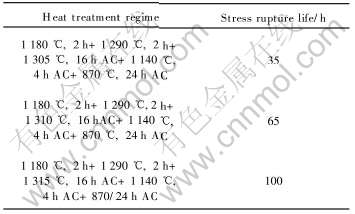

表4所列为在1100℃、 137MPa条件下, 固溶温度对合金持久寿命的影响, 高温持久试样的寿命均取自2~3根试样平均值。 由表中数据可以看出, 固溶处理对合金高温持久性能影响很大, 合金经1180℃、 2h+1290℃、 2h+1315℃、 16h AC+1140℃、 4h AC +870℃、 24h AC完全固溶处理后, 持久寿命明显提高。

图5 合金的DSC测试曲线

Fig.5 DSC testing curves of alloy

表4 不同热处理制度下的合金在1100℃、 137MPa条件下的持久寿命

Table 4 Stress rupture life at 1100℃, 137MPa after different heat treatments

图6 合金在1180℃、 2h+1290℃、 2h+1315℃、 16h AC+1140℃、 4h AC+870℃/24h AC热处理条件下经1100℃、 137MPa持久断裂后距断口表面不同位置处纵截面的γ′相形貌

Fig.6 γ′ morphologies on longitudinal section at different positions from fracture surface of alloy under conditions of 1180℃, 2h+1290℃, 2h+1315℃, 16h AC+1140℃, 4h AC+870℃, 24h AC after stress rupture test at 1100℃, 137MPa

图6所示为合金在1180℃、 2h +1290℃、 2h+ 1315℃、 16h AC+1140℃、 4hAC+ 870℃、 24h热处理条件下, 经1100℃和137MPa持久断裂后距断口表面不同位置处纵剖面的γ′相形貌。 由图可以看出, 试样的显微组织发生了明显的变化, 主要是γ′相粗化成“筏排”状, 形成了由黑色的γ′相和白色的γ相组成的板层状组织通常称“筏排”组织。 比较图6(a)~(c)可知, 距断口表面不同位置处γ′粗化程度有很大差别。 距断口较远处γ′粗化缓慢, 筏排组织形貌比较规则, γ基体通道较窄, 呈近似连续分布状态, 筏排组织与应力轴方向基本垂直(图6(a))。 距断口较近处γ′粗化显著增加, γ基体通道变宽, “筏排”组织形貌变得不规则, 与应力轴方向呈一定角度(图6(b))。 在断口附近, “筏排”组织已完全粗化, γ基体通道显著宽化, 呈不连续分布状态, “筏排”组织与应力轴之间夹角变小, 而且离断口越近夹角越小(图6(c))。 这是因为在拉伸蠕变过程中, 由于夹头被固定, 拉伸轴线不能偏转, 使得晶格发生了转动。 此外, 在颈缩区内, 由于试棒横截面逐渐缩小, 应力状态由单向应力转变成三向应力, 进一步加剧了颈缩区的晶格转动, 晶格转动必将带动γ′“筏排”组织转动, 从而导致断口附近“筏排”组织与应力轴方向呈现一定角度。 此外, 在颈缩区内, 试棒处于三向应力状态, 使得颈缩区内γ′“筏排”组织的宽度有所增加, γ′“筏排”组织形貌变得不规则[14]。

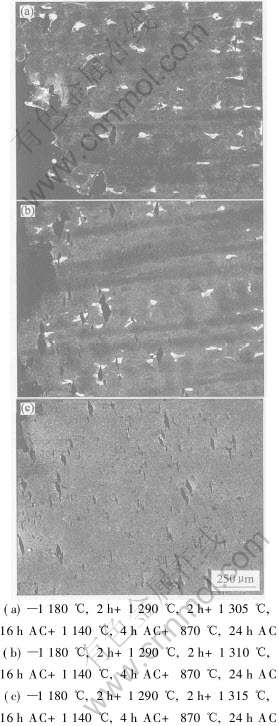

图7 合金在不同热处理条件下,经1100℃、 137MPa持久断裂后断口附近的裂纹分布

Fig.7 Distributions of cracks near fracture surface of alloys under different conditions of heat treatment after stress rupture test at 1100℃, 137MPa

图7所示为合金在不同热处理条件下, 经1100℃、 137MPa持久断裂后断口附近的裂纹分布。 由图可以看出, 在1180℃、 2h+1290℃、 2h+1305℃、 16h AC+1140℃、 4h AC+870℃、 24h AC热处理后, 持久断口附近裂纹较宽, 密度较小, 裂纹主要集中在枝晶间未固溶完全的γ/γ′共晶处, 并随着试棒颈缩区内蠕变应变量的增大萌生扩展(图7(a))。 在1180℃、 2h+1290℃、 2h+1310℃、 16h AC+1140℃、 4h AC+870℃、 24h AC热处理后, 由于未固溶完全的γ/γ′共晶量减少, 断口附近裂纹密度明显增加, 除在枝晶间未固溶的γ/γ′共晶处出现较大裂纹外, 还在枝晶干处出现细小的裂纹(图7(b))。 在1180℃、 2h+1290℃、 2h+1315℃、 16h AC+1140℃、 4h AC+870℃、 24h AC热处理后, γ/γ′共晶已完全固溶, 断口附近裂纹密度显著增加, 在枝晶干和枝晶间都出现细小的裂纹(图7(c))。 在单晶高温合金中, 当γ/γ′共晶未完全固溶时, 在高温条件下枝晶间γ/γ′共晶往往是主要裂纹源, 而在没有未固溶的共晶相和初熔情况下, 合金中的微孔洞易成为主要裂纹源[15]。

3 结论

1) 本实验设计的单晶合金的铸态组织主要由γ和γ′相组成。 在1315℃、 16h固溶处理时, γ/γ′共晶全部固溶。

2) 合金经1180℃、 2h+1290℃、 2h+1315℃、 16h AC+1140℃、 4h AC+870℃、 24h AC完全热处理后, 均匀化效果显著, 树枝晶偏析明显改善, 合金中γ′尺寸约为450nm, 呈立方形均匀分布在γ基体通道中。

3) 在1100℃、 137MPa条件下进行持久实验时, 合金中出现了明显的“筏排”组织, 距断口越近 “筏排”组织粗化越严重, 形状越不规则。

4) 未固溶的γ/γ′共晶不利于合金的高温性能, 持久裂纹主要在枝晶间未固溶的γ/γ′共晶处萌生扩展。

REFERENCES

[1]Gell M, Duhl D L, Giamei A F. The Development of single crystal super alloy turbine blades[J]. Super-alloys, 1980, 09: 205.

[2]陈荣章. 单晶高温合金发展现状[J]. 材料工程, 1995(8): 4-6.

CHEN Rong-zhang. Development status of single crystal superalloys [J]. Materials Engineering, 1995(8): 4-6.

[3]郑运荣, 韩雅芳. 燃气涡轮用单晶高温合金的成本因素[J]. 金属学报, 2002, 38(11): 1203-1209.

ZHENG Yun-rong, HAN Ya-fang. Cost considerations of single crystal superalloys for gas turbine[J]. Acta Metallurgica Sinica, 2002, 38(11): 1203-1209.

[4]郑运荣. 铸造镍基高温合金中的初生μ相[J]. 金属学报, 1999, 35(12): 1242-1245.

ZHENG Yun-rong. Primary μ pahse in cast nickel base superalloys[J]. Acta Metallurgica Sinica, 1999, 35(12): 1242-1245.

[5]郑亮, 谷臣清, 张国庆. Ta对低Cr高W铸造镍基高温合金显微组织的影响[J]. 稀有金属材料与工程, 2005, 34(2): 194-198.

ZHENG Liang, GU Chen-qing, ZHANG Guo-qing. Effect of Ta addition microstructure of cast nickel base superalloys containing low level of Cr and high level of W[J]. Rare Metal Materials and Engineering, 2005, 34(2): 194-198.

[6]G E Fuchs. Solution heat treatment response of a third generation single crystal Ni-base superalloy[J]. Mater Sci Eng A, 2001, A300: 52-60.

[7]谢世殊, 王志兴, 杨洪才. 一种变形高强度高温合金的成分设计[J]. 中国有色金属学报, 1998, 8(1): 167-170.

XIE Shi-shu, WANG Zhi-xing, YANG Hong-cai. A component design of high strength wrought superalloy [J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 167-170.

[8]LIU Li-rong, JIN Tao, ZHAO Nai-ren, et al. Effect of carbon addition on the creep properties in a Ni-based single crystal superalloy [J]. Mater Sci Eng A, 2004, A385: 108-111.

[9]李成功, 傅恒志, 于翘. 航空航天材料[M]. 北京: 国防工业出版社, 2002. 97.

LI Cheng-gong, FU Heng-zhi, YU Chi. Aerospace Materials[M]. Beijing: National Defence Industry Press, 2002. 97.

[10]Feng Q, Nandy T K, Tin S, et al. Solidification of high-refractory ruthenium-containing superalloys[J]. Acta Materialia, 2003, 51: 269-284.

[11]Yeh A C, Tin S. Effect of Ru and Re additions on the high temperature flow stresses of Ni-base single crystal superalloys[J]. Scripta Materialia, 2005, 52: 519-524.

[12]Walston S, Cetel A, MacKay R. Joint development of a fourth deneration single crystal superalloy[A]. Proceedings of Superalloy 2004[C]. USA: TMS, 2004. 15-24.

[13]郑亮, 谷臣清, 郑运荣. Ru对铸造镍基高温合金凝固行为的影响[J]. 中国有色金属学报, 2002, 12(6): 1199-1204.

ZHENG Liang, GU Chen-qing, ZHENG Yun-rong. Effect of Ru addition on solidification behavior of cast nickel base superalloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1199-1204.

[14]郭喜平, 傅恒志, 孙家华. 单晶高温合金中γ′筏形组织的形成及转动[J]. 金属学报, 1994, 30(7): A 321-325.

GUO Xi-ping, FU Heng-zhi, SUN Jia-hua. Formation and rotation of γ′ rafts in Ni-base single crystal superalloy NASA IR 100[J]. Acta Metallurgica Sinica, 1994, 30(7): A 321-325.

[15]刘丽荣, 金涛, 赵乃仁, 等. 一种Ni基单晶高温合金[001]方向的持久性能与断裂行为[J]. 金属学报, 2004, 40(8): 858-862.

LIU Li-rong, JIN Tao, ZHAO Nai-ren, et al. Stress rupture properties and fracture behavior of a Ni base single crystal superalloy along [001] direction[J]. Acta Metallurgica Sinica, 2004, 40(8): 858-862.

基金项目: 国家自然科学基金资助项目(50371004)

收稿日期: 2005-10-10; 修订日期: 2006-02-05

通讯作者: 李树索, 博士, 副教授; 电话: 010-82314488; E-mail: lishs@buaa.edu.cn

(编辑何学锋)