DOI:10.19476/j.ysxb.1004.0609.2019.08.02

粉末压制Al-5Ti-1B合金的显微组织与晶粒细化性能

王顺成,康跃华,周 楠,宋东福,郑开宏

(广东省材料与加工研究所,广州 510650)

摘 要:采用气雾化工艺制备Al-5Ti-1B合金粉,然后压制成Al-5Ti-1B合金,研究了粉末压制Al-5Ti-1B合金的显微组织与晶粒细化性能,并与铸造Al-5Ti-1B合金进行了比较。结果表明:气雾化快速凝固可以抑制TiB2粒子的团聚和细化TiAl3相,使TiB2粒子和TiAl3相均匀分布在粉末压制Al-5Ti-1B合金的α(Al)基体上。在纯铝熔体中添加0.2%(质量分数)的粉末压制Al-5Ti-1B合金并保温2 min,可使纯铝的晶粒组织从粗大的柱状晶细化为平均直径为183 μm的等轴晶。保温时间延长至180 min,纯铝的晶粒平均直径仍保持在229 μm。与铸造Al-5Ti-1B合金相比,粉末压制Al-5Ti-1B合金具有更强的晶粒细化能力和抗细化衰退能力。

关键词:晶粒细化剂;Al-Ti-B合金;气体雾化;粉末压制;快速凝固

文章编号:1004-0609(2019)-08-1583-08 中图分类号:TG146.2 文献标志码:A

晶粒细化可以提高铝及铝合金铸锭的组织成分均匀性和塑性加工性能。Al-Ti-B合金是目前铝加工行业最常用的晶粒细化剂,大部分的铝及铝合金在铸造过程中都需要添加Al-Ti-B合金[1]。目前,Al-Ti-B合金主要采用氟盐铝热反应法生产,即先制备成Al-Ti-B合金液,然后再铸造成合金锭或连铸连轧成合金杆。由于TiB2粒子之间具有较强的亲和性以及合金液的非平衡凝固原因,导致Al-Ti-B合金中TiB2粒子团聚严重。TiB2粒子团聚首先会降低Al-Ti-B合金的晶粒细化性能,其次还会阻塞铝及铝合金液的过滤板或过滤管,甚至使铝材和箔材表面产生砂眼、针孔和撕裂等缺陷,无法满足高性能、高精密、高光亮等高端工业铝材的生产需要[2]。

为了提高Al-Ti-B合金的质量,研究人员先后研究了电磁搅拌[3-4]、超声振动[5-6]、甩带快冷[7]、剧塑性变形[8]、合金元素[9-12]等对Al-Ti-B合金显微组织与晶粒细化能力的影响。这些方法虽然可以提高Al-Ti-B合金的组织均匀性和晶粒细化能力,但都无法完全克服TiB2粒子的团聚问题。气雾化是一种快速凝固工艺,常用于制备金属及合金粉[13-14]。但迄今为止,未见有采用气雾化工艺制备Al-Ti-B合金的报道。因此,本文采用气雾化工艺制备Al-5Ti-1B合金粉,然后压制成Al-5Ti-1B合金,研究了粉末压制Al-5Ti-1B合金的显微组织与晶粒细化能力,并与铸造Al-5Ti-1B合金进行了比较。

1 实验

实验材料为纯铝(99.85%,质量分数,下同)、K2TiF6和KBF4粉。实验设备为中频感应电炉、气雾化制粉机和200 t四柱油压机。采用氟盐铝热反应法制备Al-5Ti-1B合金液,先将K2TiF6和KBF4粉按质量比为2.2:1的比例混合,再在中频感应电炉内加热熔化纯铝并过热至850 ℃,然后加入K2TiF6和KBF4的混合粉并搅拌反应30 min,经精炼、除渣后得到Al-5Ti-1B合金液。对Al-5Ti-1B合金液进行取样,经JY-ULTIMA2型等离子体发射光谱仪分析,Al-5Ti-1B合金液的化学成分(质量分数)为:Ti 5.02%,B 1.05%,Fe 0.08%,Si 0.09%,V 0.01%,其余为Al。

取部分Al-5Ti-1B合金液降温至750 ℃后浇注到钢模内,铸造成Al-5Ti-1B合金。将其余Al-5Ti-1B合金液转移到气雾化制粉机内,在氮气压力为3.5 MPa、雾化温度为750 ℃和氮气保护条件下雾化成Al-5Ti-1B合金粉,然后在温度为500 ℃、压强为90 MPa条件下将合金粉压制成Al-5Ti-1B合金。

晶粒细化实验对象为纯铝,实验设备为7.5 kW石墨坩埚电阻炉。将纯铝置于石墨坩埚电阻炉内加热熔化并过热至720 ℃,经精炼和扒渣后,分别加入质量分数为0.2%的粉末压制Al-5Ti-1B合金和铸造Al-5Ti-1B合金,搅拌并保温2、60、120、180 min后,分别取纯铝液浇注到置于耐火砖上外径75 mm、高25 mm、壁厚5 mm的环状钢模内,铸造成直径65 mm、高25 mm的纯铝锭试样。

采用NANOSEM430型高分辨率场发射扫描电子显微镜观察Al-5Ti-1B合金粉的形貌。在D/MAX-RC型X射线衍射仪对Al-5Ti-1B合金粉的物相组成进行分析。将Al-5Ti-1B合金粉镶嵌制样,在粉末压制和铸造Al-5Ti-1B合金上分别取样,试样经磨制和抛光后,在NANOSEM430型高分辨率场发射扫描电子显微镜上进行显微组织观察和能谱分析。将细化实验的纯铝锭试样沿高度的中间部位锯开,经车削、磨制、抛光并用混合酸溶液(70 mL HCl+25 mL HNO3+5 mL HF)腐蚀后,观察纯铝锭试样的晶粒组织,采用截线法测量纯铝锭的晶粒平均直径。

2 结果与分析

2.1 显微组织

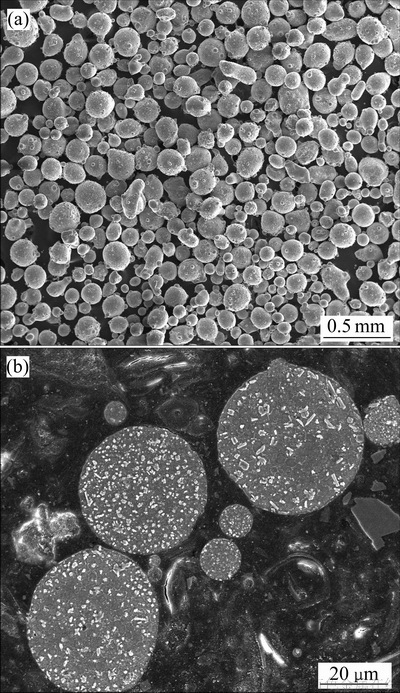

图1所示为Al-5Ti-1B合金粉的形貌和显微组织。气雾化制粉过程可分为液流的破碎和液滴的飞行冷却两个阶段[15]。Al-5Ti-1B合金液在高速气流的喷射冲击作用下首先破碎成液滴,液滴在飞行过程中由于表面张力的作用而发生球化,冷却凝固后得到球形Al-5Ti-1B合金粉。部分液滴在飞行过程中受到高速气流的喷射冲击作用而发生变形,冷却凝固后则得到椭球形的Al-5Ti-1B合金粉。从图1(a)可看到,大部分Al-5Ti-1B合金粉的形状呈球形,合金粉的粒径小于100 μm,少部分Al-5Ti-1B合金粉的形状呈椭球形。

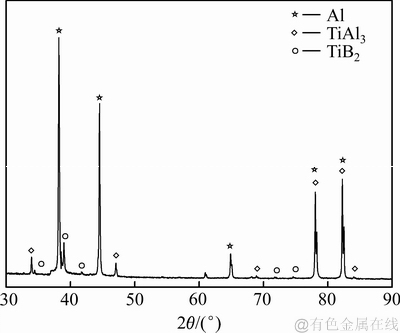

图2所示为Al-5Ti-1B合金粉的XRD谱。从图2可看到,Al-5Ti-1B合金粉由α(Al)、TiAl3和TiB2组成。采用气雾化工艺制备Al-5Ti-1B合金粉,在高速气流的喷射冲击作用下,Al-5Ti-1B合金液首先雾化成液滴,该过程会把合金液中的大量TiB2粒子和Ti原子分散到液滴内。液滴在飞行过程中的冷却速度可高达103~107 K/s[16-18],液滴的尺寸越小,冷却速度越快,快速凝固可抑制液滴内TiB2粒子发生聚集和TiAl3相的长大。从图1(b)可看到,TiB2粒子和TiAl3相均匀分布在粉内的α(Al)基体上,未见有TiB2粒子的偏析团聚现象和粗大的TiAl3相。由于液滴的尺寸越小,飞行过程中的冷却凝固速度越快,越有利于抑制液滴内TiB2粒子的团聚和TiAl3相的长大。因此,Al-5Ti-1B合金粉的粒径越小,粉内的TiAl3相尺寸越细小,TiB2粒子和TiAl3相分布也越均匀。

图1 Al-5Ti-1B合金粉的形貌和显微组织

Fig. 1 Morphology (a) and microstructure (b) of Al-5Ti-1B alloy powders

图2 Al-5Ti-1B合金粉的XRD谱

Fig. 2 XRD pattern of Al-5Ti-1B alloy powders

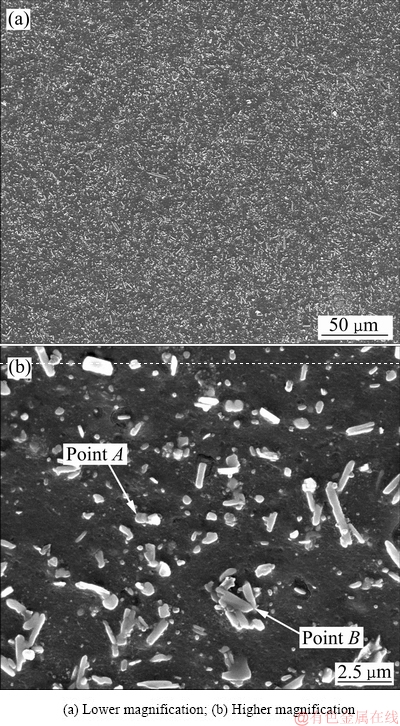

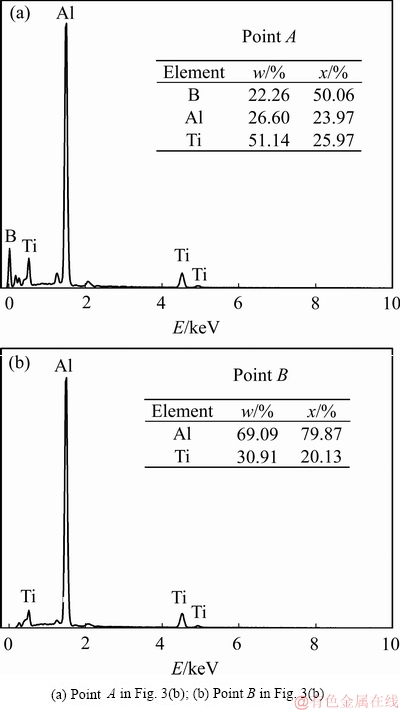

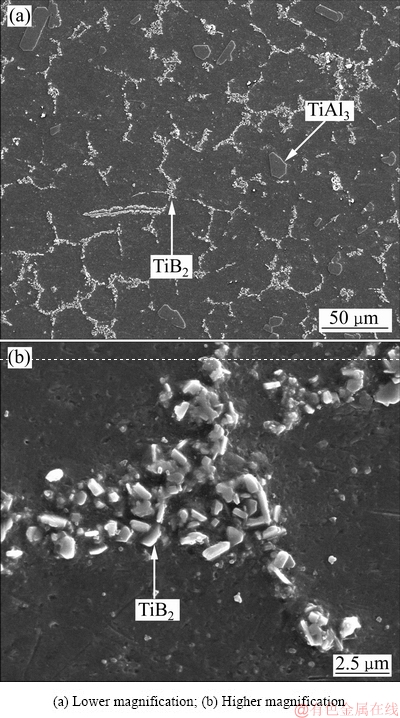

图3所示为粉末压制Al-5Ti-1B合金的显微组织,图4所示为TiB2粒子和TiAl3相的扫描电镜能谱。从图3可看到,TiB2粒子和TiAl3相均匀分布在粉末压制Al-5Ti-1B合金的α(Al)基体上,未见有TiB2粒子的团聚块和粗大的TiAl3相。结合扫描电镜能谱分析结果(见图4)可看到,图3(b)中的细小颗粒状物为TiB2粒子,板条状和方块状物为TiAl3相,其中,TiB2粒子的尺寸小于1 μm,TiAl3相的尺寸小于3 μm。上述结果表明,采用气雾化工艺将Al-5Ti-1B合金液雾化成粉,可以抑制TiB2粒子的团聚和细化TiAl3相,然后再将合金粉压制成Al-5Ti-1B合金,最终可使TiB2粒子和TiAl3相均匀分布在粉末压制Al-5Ti-1B合金的α(Al)基体上。

图5所示为铸造Al-5Ti-1B合金的显微组织。从图5可看到,由于Al-5Ti-1B合金液在铸造过程中的冷却凝固速度较慢,且合金液的冷却凝固属于非平衡凝固,最终导致大量的TiB2粒子偏析于α(Al)晶粒的晶界上,形成粗大的TiB2粒子团聚块,而TiAl3相则长大成粗大的板条状或方块状,TiAl3相的最大尺寸达到40 μm。

图3 粉末压制Al-5Ti-1B合金的显微组织

Fig. 3 Microstructures of powder compacted Al-5Ti-1B alloy

图4 TiB2粒子和TiAl3相的扫描电镜能谱

Fig. 4 EDS spectra of TiB2 particle and TiAl3 phase

图5 铸造Al-5Ti-1B合金的显微组织

Fig. 5 Microstructures of as-cast Al-5Ti-1B alloy

2.2 晶粒细化性能

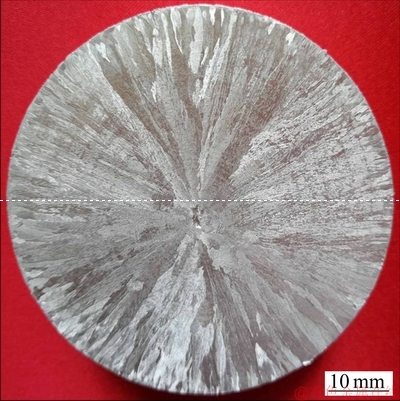

图6所示为未添加Al-5Ti-1B合金时纯铝的晶粒组织。从图6可看到,未添加Al-5Ti-1B合金时,纯铝的晶粒组织为发达的柱状晶,受钢模激冷作用,距离纯铝锭表层约5 mm宽的区域形成一层细小的柱状晶,纯铝锭中心区域为粗大的等轴晶,其余区域均为粗大的柱状晶,晶粒平均直径达到2500 μm。

图6 未添加Al-5Ti-1B合金时纯铝的晶粒组织

Fig. 6 Grain structure of pure aluminum without adding Al-5Ti-1B alloy

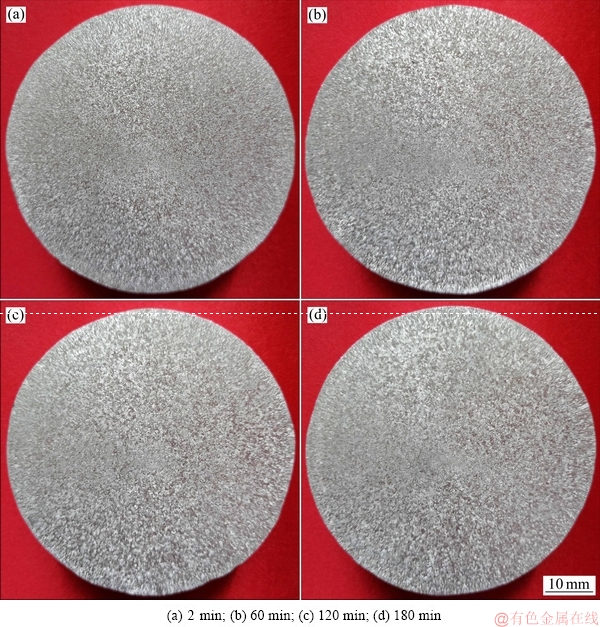

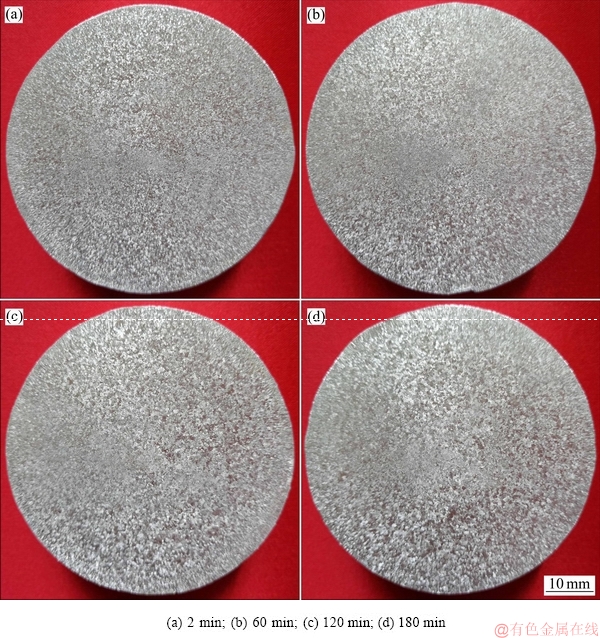

图7和8所示分别为添加0.2%的粉末压制Al-5Ti-1B合金和铸造Al-5Ti-1B合金后保温不同时间时纯铝的晶粒组织。从图7和8可看到,添加粉末压制Al-5Ti-1B合金和铸造Al-5Ti-1B合金后,纯铝的晶粒组织都被细化为细小均匀的等轴晶,晶粒尺寸显著减小。但添加0.2%的粉末压制Al-5Ti-1B合金并保温2 min时,纯铝锭被细化为平均直径183 μm的等轴晶,而添加0.2%的铸造Al-5Ti-1B合金并保温2 min时,纯铝锭被细化为平均直径218 μm的等轴晶。通过比较可看到,粉末压制Al-5Ti-1B合金比铸造Al-5Ti-1B合金具有更强的晶粒细化能力。

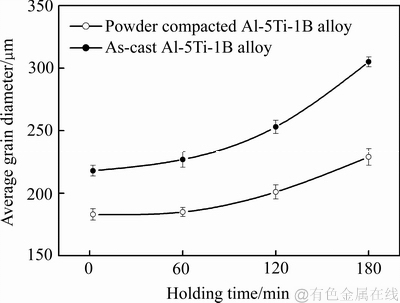

图9所示为纯铝的晶粒平均直径随保温时间的变化曲线。从图9可看到,添加粉末压制Al-5Ti-1B合金和铸造Al-5Ti-1B合金后,随着保温时间的延长,纯铝的晶粒尺寸都逐渐增大,表明晶粒细化效果都出现了衰退现象。但添加粉末压制Al-5Ti-1B合金,当保温时间延长至180 min时,纯铝的晶粒平均直径为229 μm;而添加铸造Al-5Ti-1B合金,当保温时间延长至180 min时,纯铝的晶粒平均直径增大到了305 μm。通过比较可看到,粉末压制Al-5Ti-1B合金比铸造Al-5Ti-1B合金具有更强的抗细化衰退能力。

图7 添加粉末压制Al-5Ti-1B合金后保温不同时间时纯铝的晶粒组织

Fig. 7 Grain structures of pure aluminum with adding powder compacted Al-5Ti-1B alloy and holding different time

图8 添加铸造Al-5Ti-1B合金后保温不同时间时纯铝的晶粒组织

Fig. 8 Grain structures of pure aluminum with adding as-cast Al-5Ti-1B alloy and holding different time

图9 纯铝的晶粒平均直径随保温时间的变化曲线

Fig. 9 Change curves of average grain diameter of pure aluminum with holding time

3 讨论

采用氟盐铝热反应法制备Al-5Ti-1B合金液,K2TiF6和KBF4与铝液的总反应式如下[19-20]:

3K2TiF6+2KBF4+12Al=TiB2+2TiAl3+5KAlF4+K3AlF6

Al-5Ti-1B合金液中含有大量TiB2粒子,由于TiB2粒子之间具有较强的亲和性而容易聚集成团[21]。Al-5Ti-1B合金液是Ti原子的过饱和熔体,并且TiAl3相的生长具有择优取向,在合金液的非平衡凝固过程中,TiAl3相容易长大成粗大的板块状。

气雾化制粉过程可分为液流的破碎和液滴的飞行冷却两个阶段,在高速气流的喷射冲击作用下,Al-5Ti-1B合金液首先被雾化成液滴,该过程把合金液中的大量TiB2粒子和Ti原子分散到液滴内,这为抑制TiB2粒子的团聚和TiAl3相的长大奠定了基础。液滴在随后的飞行过程中快速冷却凝固,从而可以抑制液滴内TiB2粒子发生团聚和TiAl3相的长大。当合金粉压制成Al-5Ti-1B合金后,最终使TiB2粒子和TiAl3相都均匀分布在粉末压制Al-5Ti-1B合金的α(Al)基体上。而在传统铸造过程中,由于Al-5Ti-1B合金液的冷却凝固速度较慢,导致TiB2粒子偏聚在α(Al)晶粒的晶界上,形成粗大的TiB2粒子团聚块,而TiAl3相则长大成粗大的板条状。

根据Al-5Ti-1B合金的双重形核细化机制[22-23],当Al-5Ti-1B合金加入到铝熔体后,Al-5Ti-1B合金发生熔解,TiB2粒子由于熔点高(2980 ℃)而直接保留在铝熔体中,TiAl3相则会逐渐熔解并释放出游离Ti原子。在铝熔体冷却凝固过程中,由于Ti原子与TiB2粒子之间存在活性梯度,Ti原子会逐渐向TiB2粒子的表面富集,并在TiB2粒子的表面上重新形成TiAl3相。当铝熔体温度降到包晶反应温度665 ℃时,TiB2粒子表面的TiAl3相与铝熔体发生包晶反应生成α(Al)晶核,最后长大成α(Al)晶粒,即TiB2粒子作为α(Al)晶粒异质形核的核心起到晶粒细化作用。

由于铸造Al-5Ti-1B合金中的TiB2粒子聚集成团,当铸造Al-5Ti-1B合金加入到铝熔体后,TiB2粒子难以均匀分散到到铝熔体中,使参与α(Al)晶粒异质形核的TiB2粒子数量减少,从而降低了铸造Al-5Ti-1B合金的晶粒细化能力。由于TiB2粒子的密度较大(4.52 g/cm3),在铝熔体静置保温过程中会发生自然沉降,使参与α(Al)晶粒异质形核的TiB2粒子数量逐渐减少,即Al-5Ti-1B合金的晶粒细化效果出现衰退[24]。而TiB2粒子聚集成团则会加速TiB2粒子在铝熔体中的沉降速度,使Al-5Ti-1B合金的晶粒细化效果的衰退速度加快。正是由于TiB2粒子聚集成团,使铸造Al-5Ti-1B合金的抗细化衰退能力较差。粉末压制Al-5Ti-1B合金的TiB2粒子和TiAl3相分布均匀,TiAl3相尺寸细小,当Al-5Ti-1B合金加入到铝熔体后,TiB2粒子会更容易分散到铝熔体中,使参与α(Al)晶粒异质形核的TiB2粒子更多,TiAl3相也更容易熔解释放出游离Ti原子,使粉末压制Al-5Ti-1B合金的具有更强的晶粒细化能力。TiB2粒子分布均匀又可以减缓TiB2粒子在铝熔体中的沉降速度,使粉末压制Al-5Ti-1B合金具有更强的抗细化衰退能力。

4 结论

1) 气雾化快速凝固可以抑制TiB2粒子偏析团聚并细化TiAl3相,使TiB2粒子和TiAl3相均匀分布在粉末压制Al-5Ti-1B合金。

2) 气雾化快速凝固Al-5Ti-1B合金粉的粒径越小,TiB2粒子和TiAl3相分布越均匀,TiAl3相尺寸越小。

3) 添加0.2%的粉末压制Al-5Ti-1B合金并保温2 min,可使纯铝晶粒组织细化为平均直径183 μm的等轴晶,保温180 min,纯铝的晶粒平均直径为229 μm。

4) 粉末压制Al-5Ti-1B合金比铸造Al-5Ti-1B合金具有更强的晶粒细化能力和抗细化衰退能力。

REFERENCES

[1] 马世光, 熊 慧, 王祝堂. 回顾与展望全球铝产品产量及对晶粒细化剂的需求[J]. 轻合金加工技术, 2011, 39(10): 1-9.

MA Shi-guang, XIONG Hui, WANG Zhu-tang. Review and outlook of output of aluminum product and grain refiner requirement in the world[J]. Light Alloy Fabrication Technology, 2011, 39(10): 1-9.

[2] 王顺成, 张彩锦, 戚文军, 郑开宏, 李建湘. 国外几种Al-Ti-B晶粒细化剂的质量评价[J]. 轻合金加工技术, 2011, 39(6): 11-15.

WANG Shun-cheng, ZHANG Cai-jin, QI Wen-jun, ZHENG Kai-hong, LI Jian-xiang. Quality evaluation of overseas Al-Ti-B grain refiners[J]. Light Alloy Fabrication Technology, 2011, 39(6): 11-15.

[3] 李润霞, 张文华, 张 鹏, 张博通, 陈建春, 于宝义. 电磁搅拌对Al-5Ti-B中间合金组织及细化效果的影响[J]. 铸造, 2016, 65(1): 1-5.

LI Run-xia, ZHANG Wen-hua, ZHANG Peng, ZHANG Bo-tong, CHEN Jian-chun, YU Bao-yi. Effect of electromagnetic stirring on the microstructure and refinement of Al-5Ti-B master alloy[J]. Foundry, 2016, 65(1): 1-5.

[4] 王顺成, 郑开宏, 戚文军, 石 路, 宁长维. 电磁搅拌对Al-5Ti-1B的显微组织与晶粒细化能力的影响[J]. 有色金属科学与工程, 2014, 5(1): 58-62.

WANG Shun-cheng, ZHENG Kai-hong, QI Wen-jun, SHI Lu, NING Chang-wei. Effect of electromagnetic stirring on microstructure and grain refining efficiency of Al-5Ti-1B grain refiner[J]. Nonferrous Metals Science and Engineering, 2014, 5(1): 58-62.

[5] HAN Yan-feng,LI Ke,WANG Jun,SHU Da, SUN Bao-de. Influence of high-intensity ultrasound on grain refining performance of Al-5Ti-1B master alloy on aluminum[J]. Materials Science and Engineering A, 2005, 405: 306-312.

[6] 缪 欢, 阎峰云, 江海霞, 杨 飞, 刘景山. 超声制备Al-5Ti-1B晶粒细化剂的组织和细化效果[J]. 特种铸造及有色合金, 2018, 38(1): 110-113.

MIAO Huan, YAN Feng-yun, JIANG Hai-xia, YANG Fei, LIU Jing-shan. Microstructure and grain refining performance of Al-5Ti-B grain refiner prepared under ultrasound treatment[J]. Special Casting & Nonferrous Alloys, 2018, 38(1): 110-113.

[7] 董天顺, 崔春翔, 刘双进, 刘福才. Al-Ti-B细化剂的快速凝固及其细化机理研究[J]. 稀有金属材料与工程, 2008, 37(1): 29-32.

DONG Tian-shun, CUI Chun-xiang, LIU Shuang-jin, LIU Fu-cai. Study on the rapid solidification and refining mechanism of Al-Ti-B refiner[J]. Rare Metal Materials and Engineering, 2008, 37(1): 29-32.

[8] GHADIMI H, NEDJHAD H S, EGHBALI B. Enhanced grain refinement of cast aluminum alloy by thermal and mechanical treatment of Al-5Ti-B master alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1563-1569.

[9] WANG Zheng-jun, SI Nai-chao. Synthesis and refinement performance of the novel Al-Ti-B-Re master alloy grain refiner[J]. Rare Metal Materials and Engineering, 2015, 44(12): 2970-2975.

[10] WANG Xue-jiao, XU Cong, MUHAMMAD A, HANADA S, YAMAGATA H, WANG Wen-hong, MA Chao-li. Effects of Al-Ti-B-RE grain refiner on microstructure and mechanical properties of Al-7.0Si-0.55Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2244-2250.

[11] 廖成伟, 陈 欢, 罗成志, 陈建春, 潘春旭. 新型Al-Ti-B-Sr复合中间合金线材的制备及其应用[J]. 中国有色金属学报, 2014, 24(8): 2026-2034.

LIAO Cheng-wei, CHEN Huan, LUO Cheng-zhi, CHEN Jian-chun, PAN Chun-xu. Preparation and application of novel Al-Ti-B-Sr composite master alloy wire[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2026-2034.

[12] MA Teng-fei, CHEN Zi-yong, NIE Zuo-ren, HUANG Hui. Microstructure of Al-Ti-B-Er refiner and its grain refining performance[J]. Journal of Rare Earths, 2013, 31(6): 622-627.

[13] CAI Zhi-yong, ZHANG Chun, WANG Ri-chu, PENG Chao-qun, QIU Ke, FENG Yan. Preparation of Al-Si alloys by a rapid solidification and powder metallurgy route[J]. Materials and Design, 2015, 87: 996-1002.

[14] DING Pei-pei, MAO Ai-qin, ZHANG Xiang, JIN Xia, WANG Biao, LIU Min, GU Xiao-long. Preparation, characterization and properties of multicomponent AlCoCrFeNi2.1 powder by gas atomization method[J]. Journal of Alloys and Compounds, 2017, 721: 609-614.

[15] 赵 雷, 江鸿翔, AHMAD Tauseef, 赵九洲. Cu-Co-Fe合金雾化合金液滴凝固过程研究[J]. 金属学报, 2015, 51(7): 883-888.

ZHAO Lei, JIANG Hong-xiang, AHMAD Tauseef, ZHAO Jiu-zhou. Study of solidification for gas-atomized droplet of Cu-Co-Fe alloy[J]. Acta Metallurgica Sinica, 2015, 51(7): 883-888.

[16] CAI Zhi-yong, ZHANG Chun, WANG Ri-chu, PENG Chao-qun, QIU Ke, WANG Nai-guang. Effect of solidification rate on the coarsening behavior of precipitate in rapidly solidified Al-Si alloy[J]. Progress in Natural Science: Materials International, 2016, 26(4): 391-397.

[17] HE Shi-wen, LIU Yong, GUO Sheng. Cooling rate calculation of non-equilibrium aluminum alloy powders prepared by gas atomization[J]. Rare Metal Materials and Engineering, 2009, 38(S1): 353-356.

[18] 解立川, 彭超群, 王日初, 蔡志勇, 刘文水, 马如龙. 冷却速度对气雾化非平衡Al-27%Si合金粉末组织形貌特征的影响[J]. 稀有金属材料与工程, 2015, 44(4): 1006-1011.

XIE Li-chuan, PENG Chao-qun, WANG Ri-chu, CAI Zhi-yong, LIU Wen-shui, MA Ru-long. Influences of cooling rate on microstructures and morphologies of non-equilibrium Al-27%Si alloy powders by gas atomization[J]. Rare Metal Materials and Engineering, 2015, 44(4): 1006-1011.

[19] YUCEL B. An improved practice to manufacture Al-Ti-B master alloys by reacting halide salts with molten aluminium[J]. Journal of Alloys and Compounds, 2006, 420: 71-76.

[20] LI Peng-ting, LI Yun-guo, NIE Jin-feng, LIU Xiang-fa. Influence of forming process on three-dimensional morphology of TiB2 particles in Al-Ti-B alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 564-570.

[21] 李喜珍, 边秀房, 李秀军, 刘相法. Al-Ti-B合金中TiB2和AlB2的从头算研究[J]. 金属学报, 2001, 37(3): 235-238.

LI Xi-zhen, BIAN Xiu-fang, LI Xiu-jun, LIU Xiang-fa. AB initio studies of TiB2 and AlB2 in the Al-Ti-B alloy[J]. Acta Metallurgica Sinica, 2001, 37(3): 235-238.

[22] FZN Z, WANG Y, ZHANG Y, QIN T, ZHOU X R, THOMPSON G E, PENNYCOOK T, HASHIMOTO T. Grain refining mechanism in the Al/Al-Ti-B system[J]. Acta Materialia, 2015, 84: 292-304.

[23] 戚文军, 王顺成, 陈学敏, 农 登, 周 志. Al-5Ti-1B合金的有效形核相与晶粒细化机制[J]. 稀有金属, 2013, 37(2): 179-185.

QI Wen-jun, WANG Shun-cheng, CHEN Xue-min, NONG Deng, ZHOU Zhi. Effective nucleation phase and grain refinement mechanism of Al-5Ti-1B master alloy[J]. Chinese Journal of Rare Metals, 2013, 37(2): 179-185.

[24] LIMMANE C, EIDHEB W. Fading mechanism of grain refinement of aluminum-silicon alloy with Al-Ti-B grain refiners[J]. Materials Science and Engineering A, 2003, 349: 197-206.

Microstructure and grain refining performance of Al-5Ti-1B alloy prepared by powder compaction

WANG Shun-cheng, KANG Yue-hua, ZHOU Nan, SONG Dong-fu, ZHENG Kai-hong

(Guangdong Institute of Materials and Processing, Guangzhou 510650, China)

Abstract: The Al-5Ti-1B alloy powder was prepared by gas-atomization process and then compacted into Al-5Ti-1B alloy. The microstructure and grain refining performance of powder compacted Al-5Ti-1B alloy were studied and compared with that of conventional cast Al-5Ti-1B alloy. The results show that the rapid solidification during the gas-atomization can inhibit the aggregation of TiB2 particles and refine the size of TiAl3 phase. The TiB2 particles and TiAl3 phases are uniformly distributed in the powder compacted Al-5Ti-1B alloy. With adding 0.2% (mass fraction) powder compacted Al-5Ti-1B alloy in the pure aluminum melt and holding for 2 min, the pure aluminum can be refined from coarse columnar grains to fine equiaxed grains with an average diameter of 183 μm. When the holding time is prolongated to 180 min, the average grain diameter of pure aluminum is still remained at 229 μm. Compared with the conventional cast Al-5Ti-1B alloy, the powder compacted Al-5Ti-1B alloy has a stronger grain refining ability and resistance to grain refinement fading.

Key words: grain refiner; Al-Ti-B alloy; gas atomization; powder compaction; rapid solidification

Foundation item: Project(2017GDASCX-0117) supported by the Innovation Capacity Building of Key Scientific Research Institutions of Guangdong Academy of Sciences, China; Project(2017A070702019) supported by the Special Fund for Public Welfare Research and Capacity Building of Guangdong Province, China

Received date: 2018-08-08; Accepted date: 2018-12-11

Corresponding author: WANG Shun-cheng; Tel: +86-20-61086333; E-mail: wangsunceng@163.com

(编辑 何学锋)

基金项目:广东省科学院院属骨干科研机构创新能力建设项目(2017GDASCX-0117);广东省科技厅公益研究与能力建设项目(2017A070702019)

收稿日期:2018-08-08;修订日期:2018-12-11

通信作者:王顺成,教授级高工,博士;电话:020-61086333;E-mail:wangsunceng@163.com