文章编号:1004-0609(2009)06-1038-06

Cf/SiC复合材料与Ti合金的Ag-Cu-Ti-TiC复合钎焊

熊进辉,黄继华,张 华,赵兴科,林国标

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:以Ag-Cu-Ti-TiC复合钎料为中间层,在适当的工艺参数下真空钎焊Cf/SiC复合材料与Ti合金。利用SEM、EDS和XRD分析接头的微观组织结构,利用剪切实验检测接头的力学性能。结果表明:钎焊时,借助液态钎料,复合钎料中的Ti与Cf/SiC复合材料反应,在Cf/SiC复合材料与连接层界面形成Ti-Si-C、Ti-Si和少量TiC化合物的混合反应层;复合钎料中的Cu与Ti合金中的Ti发生互扩散,在连接层与Ti合金界面形成不同成分的Cu-Ti化合物过渡层;钎焊后,形成TiC颗粒强化的致密复合连接层,TiC的加入降低了接头的残余热应力,Cf/SiC/Ag-Cu-Ti-TiC/TC4接头的剪切强度明显高于Cf/SiC/Ag-Cu-Ti/TC4接头的。

关键词:Cf/SiC复合材料;Ti合金;钎焊;Ag-Cu-Ti-TiC

中图分类号:TG407 文献标识码: A

Brazing of Cf/SiC composite to Ti alloy using Ag-Cu-Ti-TiC composite filler materials

XIONG Jin-hui, HUANG Ji-hua, ZHANG Hua, ZHAO Xing-ke, LIN Guo-biao

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Cf/SiC composite was joined with Ti alloy using Ag-Cu-Ti-TiC mixed powder as interlayer under condition of some suitable brazing parameters. The microstructures of the brazed joint were investigated by SEM, EDS and XRD. The mechanical properties of the brazed joints were measured by mechanical testing machine. The results show that Ti element in the interlayer can react with the brazed composite, a mixture of Ti-Si-C, Ti-Si and TiC composites finally form the reaction layer between the composite and interlayer. Ti alloy constantly dissolves and Cu diffuses into the Ti alloy, the diffusion reaction layers between the interlayer and Ti alloy forms. The performed joints have dense bonding layers reinforced by TiC. These composite brazing layers relax the thermal stress of the joint effectively. These characteristics are beneficial to the joint, of which the shear strength are remarkably higher than the optimal shear strength of the joint brazed with pure Ag-Cu-Ti.

Key words: Cf/SiC composite; Ti alloy; brazing; Ag-Cu-Ti-TiC filler materials

Cf/SiC复合材料具有优异的高温强度,良好的耐腐蚀抗氧化及耐磨性能,由于C纤维的植入,使其具有优良的综合力学性能,因此,Cf/SiC复合材料是应用于航空航天发动机、先进火箭燃烧室等高温场合的一种重要的结构材料[1?6]。TC4是一种典型的Ti合金材料,是目前应用最广泛的耐高温合金之一,具有良好的焊接、铸造、成型等加工性能。在一些Cf/SiC复合材料的高温应用场合,有必要将Cf/SiC复合材料与金属连接起来,特别是Ti合金,这样可以获得彼此互补的优势,有利于扩大Cf/SiC复合材料和Ti的应用。但是,目前关于Cf/SiC复合材料与金属连接技术还不成熟,相关的研究报道也比较少[7?11]。Cf/SiC复合材料与金属连接主要存在两方面困难:一方面是连接材料对母材,特别是Cf/SiC复合材料润湿比较困难;另一方面是异种材料之间热膨胀系数差而导致其接头附近具有较大的残余热应力。

用于复合材料与金属连接的主要方法有扩散焊和钎焊。扩散焊对母材的表面状态要求比较严格,且在连接过程中需要对母材施加较高的压力,这不适合对存在较多孔隙的Cf/SiC陶瓷基复合材料的连接。比较而言,钎焊对母材的表面状况要求较低,可在无压力或小压力条件下完成连接,更适合于Cf/SiC陶瓷基复合材料的连接。Ag-Cu-Ti活性钎料是一种性能优良的钎料,对大部分陶瓷和金属均有很好的润湿性和连接性,且熔点较低,可以在相对较低的温度下实现连接,减小高温对被连接材料的破坏。因此,从钎焊温度和钎焊性能来看,使用Ag-Cu-Ti活性钎料应是比较好的选择。但由于Ag-Cu-Ti活性钎料的熔点较低,其接头的高温性能较差。另外,使用Ag-Cu-Ti活性钎料时,不能解决由于异种材料间热膨胀系数差而导致其接头附近具有较大的残余热应力问题。近年来,逐渐获得关注的一种降低钎焊接头热应力的方法,是通过在连接层中引入低膨胀系数的增强相,降低连接层的热膨胀系数,如将Al2O3、SiC和TiN陶瓷颗粒、金属W颗粒以及C短纤维分别加入到钎料中连接陶瓷与金属,均获得一定的效果[12?17]。

为缓解接头的热应力和利用TiC颗粒的复合化来提高接头的高温性能,本文作者探讨在Ag-Cu-Ti活性钎料中加入热膨胀系数较低的TiC粉末连接Cf/SiC复合材料和TC4钛合金,以形成TiC颗粒强化的复合接头,分析研究接头的组织结构和力学性能。

1 实验

焊接母材为3D-Cf/SiC陶瓷基复合材料与TC4钛合金。Cf/SiC陶瓷基复合材料的密度为2.0~2.1 g/cm3,气孔率为10%~15%,纤维束为3 K,纤维体积占45%~50%,室温抗弯强度约400 MPa,切割成6 mm×5 mm×4 mm的方块。TC4钛合金的组分为Ti-6AI-4V (质量分数,%),钛合金为d15的棒状,切割成5 mm厚的圆柱体。钎焊使用的原料粉末为:合金钎料粉的成分67.6Ag-26.4Cu-6Ti (质量分数,%),粒度约为 50 mm;TiC粉粒度约为8 mm,纯度均大于99.9%。

焊接前,将钛合金焊接面以250 mm砂纸打磨,以除去表面氧化层;复合材料以45 mm砂纸将焊接面研磨。 研磨好的钛合金和复合材料均用酒精清洗干净。根据组成粉末的密度,在Ag-Cu-Ti合金粉末中,换算加入不同体积分数的TiC增强相。将配好的粉末加分散剂、连接剂,研磨、混合均匀成膏状,涂在复合材料与钛合金被连接表面之间,控制好焊料预置间隙200 mm以内。

钎焊设备为VQB?335型多功能真空钎焊炉。焊接工艺为:真空度高于6 MPa,连接温度为900~950 ℃,保温时间为5~30 min,升温速率10 ℃/min,降温速率3 ℃/min。

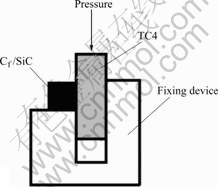

采用LEO?1450扫描电镜背散射像、能谱对连接层、反应界面进行了观察分析。将复合材料层完全除掉并适当研磨后,采用X射线衍射对连接层进行物相分析。接头剪切强度实验是在电子万能实验机上进行的,剪切试样示意图如图1所示,加载速率为0.5 mm/min,每个实验数据点测3个样品,取其平均值。

图1 接头力学性能测试示意图

Fig.1 Schematic diagram of mechanical properties of joined sample

2 结果与分析

2.1 组织结构分析

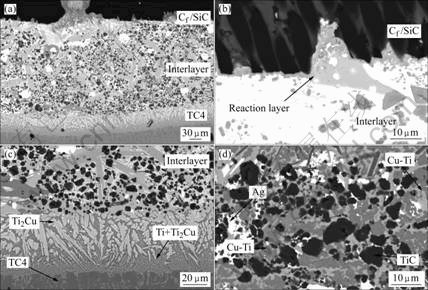

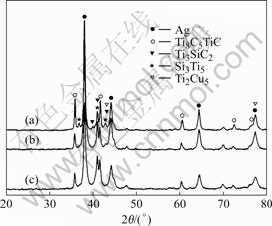

图2所示为使用Ag-Cu-Ti-30%TiC(体积分数)复合钎料在950 ℃保温15 min复合钎焊接头典型组织的背散射像。图3所示为使用Ag-Cu-Ti-30%TiC(体积分数)复合钎料在相同工艺参数下复合钎焊接头的XRD谱。

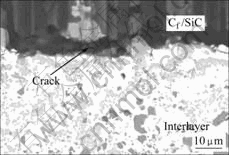

图2(a)中,上部为Cf/SiC陶瓷基复合材料,中间为连接层,下部为钛合金,连接层均匀致密,与复合材料和钛合金界面结合良好。图2(b)为连接层与复合材料结合界面背散射像,图中上部为Cf/SiC陶瓷基复合材料,下部为连接层。由图2(b)可以看到,界面处有少量碳纤维裸露,这是由于连接层中的Ti与复合材料SiC基体反应,使C纤维植入连接层中,同时连接层中部分液态钎料也能直接渗入复合材料孔隙和微裂纹中,形成连接层与复合材料犬牙交错的结合状态,增加了复合材料与连接层的结合面积,提高了结合强度,也说明钎料中Ti与复合材料中SiC的反应程度要大于与复合材料中C纤维的反应程度。界面处存在非常薄的反应层,EDS分析表明,反应层主要含Ti、Si和C,结合XRD分析结果可以得出,反应层及其附近区域中主要含有Ag、Si-Ti、Ti-Si-C和TiC等化合物。

图2 Ag-Cu-Ti-30%TiC在950 ℃保温15 min复合钎焊接头组织的背散射像

Fig.2 Backscattered electron micrographs of joint brazed by Ag-Cu-Ti-30%TiC at 950 ℃ for 15 min: (a) Joint; (b) Interface between composite and interlayer; (c) Interface between interlayer and Ti alloy; (d) High magnification image of interlayer

图3 Ag-Cu-Ti-30%TiC复合钎焊接头XRD谱(950 ℃保温15 min)

Fig.3 XRD patterns of joint brazed by Ag-Cu-Ti-30%TiC at 950 ℃ for 15 min: (a) Interface between composite and interlayer; (b) Interlayer; (c) Interface between TC4 and interlayer

上述化合物是在钎焊过程中连接层中活性元素Ti与SiC基体的一系列反应得到的[18]。钎焊时,当液态钎料与SiC基体接触时,液态钎料中的Ti首先与SiC基体发生如下反应(1),生成TiC和Si。

生成的TiC晶粒在SiC基体表面形核并向液相生长。随着钎焊的进行,反应(1)生成的TiC和Si继续和Ti发生反应(2),生成Ti3SiC2化合物。

最终,由TiC和Ti3SiC2化合物组成的混合反应层覆盖在SiC基体表面(见图2(b))。此外,反应(1)生成的Si原子在浓度梯度的趋势下从反应层扩散到Cu-Ti液相中,与Cu-Ti液相中的Ti发生反应(3),生成Ti5Si3,并随着钎焊后的冷却过程残留在Cu-Ti合金中。

图2(c)所示为连接层和钛合金界面区域的背散射像。由图2(c)可见,钛合金界面附近形成了扩散带,能谱分析表明,扩散带中主要为Ti和Cu。在连接过程中,Ti由钛合金扩散进入连接层,Cu则由连接层扩散进入钛合金。结合扩散规律和能谱分析,钛合金与连接层形成的界面扩散带由Ti和Ti2Cu相组成。扩散带可以大体分为两层,靠近钛合金侧扩散带颜色较钛合金基体的浅,经能谱分析由Ti和细小的Ti2Cu相组成,靠近连接层一侧扩散带中可见有粗大的浅灰色相生成,能谱分析为Ti2Cu相,因此,连接层和钛合金界面区域的扩散带由Ti、细小Ti2Cu和粗大Ti2Cu相组成。X射线衍射分析也证明连接层中有Ti2Cu相。

图2(d)所示为连接层局部放大的背散射像。结合EDS与XRD的分析结果可以知道,颜色深浅不一的基体相为含Ti量不同的Cu-Ti相,颜色深的含Ti量较大。白色相为Ag的固溶体,黑色相为TiC颗粒,弥散分布在Cu-Ti相中,其周围有一厚度很薄的深灰色覆盖层,EDS分析表明该层主要含Ti和C,但Ti含量比TiC颗粒内部的低,说明在钎焊过程中Ti颗粒中的Ti有向连接层液相扩散的倾向。Cu-Ti基底中弥散分布的TiC颗粒可以降低整个金属连接层的热膨胀系数,使其热膨胀系数介于复合材料和钛合金之间,缓解了接头的热应力。

2.2 力学性能分析

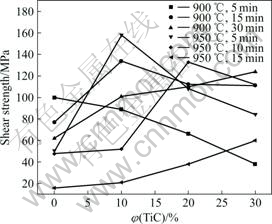

图4所示为不同的焊接工艺下Ag-Cu-Ti-TiC复合钎焊接头的室温剪切强度平均值与TiC的体积分数间的关系。

图4 不同焊接工艺下Ag-Cu-Ti-TiC复合钎焊接头剪切强度与TiC体积分数的关系

Fig.4 Relationship between shear strength of joints and volume fraction of TiC in Ag-Cu-Ti-TiC brazed under different conditions

由图4可见,当焊接温度较低、保温时间较短时,如900 ℃保温5 min时,接头的强度随着TiC体积分数的增加而减少;在900 ℃保温30 min和950 ℃保温15 min时,接头的强度随着TiC体积增加而增加;但强工艺条件下(如950 ℃保温15 min时)的强度普遍较低;焊接工艺为900 ℃保温15 min、950 ℃保温5 min和950 ℃保温10 min时的接头强度随着TiC体积分数的增加均出现相对最大值;其中焊接工艺为950 ℃保温5 min时,TiC含量为10%的接头强度最高(为157 MPa),远高于不加TiC时剪切强度的最高值(102 MPa),反映了TiC的强化和降低接头热应力的作用。

从图4可见,不同TiC添加量接头的最大强度对应的焊接工艺不一样。如添加10% TiC时,焊接工艺为950 ℃保温5 min;添加20% TiC时,焊接工艺为950 ℃保温10 min;添加30% TiC时,焊接工艺为 900 ℃,保温30 min。表明随着增强相含量的增加,工艺条件有需要加强的趋势。

在弱工艺(如在900 ℃保温5 min)条件下,随着TiC含量增加,钎焊时液相连接层的流动性降低,连接层与复合材料的界面反应程度降低,界面C纤维较少露出,连接层与复合材料基体之间甚至形成局部未连接裂纹,如图5所示。由图5可看出,增强相的引入,使得连接层液态钎料与固相的接触表面增加,与复合材料连接表面相作用的有效Ti含量将会降低,因此,降低了连接层与复合材料的界面反应程度,造成界面反应不足,同时由于流动性变差,对复合材料的渗透性也会变差。因此,在弱工艺条件下,随着TiC含量的增加,接头强度降低。

图5 弱工艺条件(900 ℃保温5 min)下连接层与复合材料界面裂纹的SEM像

Fig.5 SEM images showing crack generating between composite and interlayer of joint brazed by Ag-Cu-Ti-20% TiC at 900 ℃ for 5 min

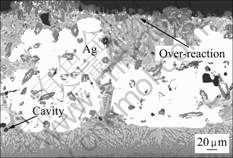

在强工艺条件(如950 ℃保温30 min)下,较低的TiC含量伴随着过度的界面反应,反应层中形成很多Ti3SiC2和Ti5Si3脆性化合物,Ag相聚集,钛合金的侵蚀现象严重,甚至在连接层中形成孔洞,如图6所示。

图6 强工艺条件(950 ℃保温5 min)下过度反应后连接界面的SEM像

Fig.6 SEM image of interlayer after over-reaction of joint brazed by Ag-Cu-Ti-10%TiC at 950 ℃ for 30 min

随着TiC含量增加,界面反应被抑制,产生的连接良好,如图2所示。以及由于低膨胀系数TiC含量的增加,接头热应力降低,使得接头的强度随着TiC含量的增加而相对增加。

在弱工艺条件和强工艺条件下,接头的强度、连接层的组织结构和界面反应层的改善随着TiC含量的增加呈相反规律的变化,在二者合适工艺条件下和适当TiC含量的情况下,复合材料具有适度界面反应和良好的组织结构,充分发挥TiC增强相对接头热应力的缓解作用,强化接头连接层。

3 结论

1) 复合钎料中的Ti借助液态钎料与Cf/SiC复合材料反应,在Cf/SiC复合材料与连接层界面形成Ti-Si-C、Ti-Si和少量TiC化合物的混合反应层。复合钎料中的Cu与Ti合金中的Ti发生互扩散,在连接层与Ti合金界面形成不同成分的Cu-Ti化合物过渡层,连接层中TiC颗粒均匀分布在Cu-Ti相。

2) 当工艺因素较弱(焊接温度较低、保温时间较短)时,接头强度随着增强相的增加而降低;当工艺因素较强(保温时间较长、焊接温度较高)时,接头强度随着增强相的增加而增加;工艺因素介于这两种情况之间,接头强度随着增强相的增加出现最大值后降低。

3) 由于低膨胀系数TiC颗粒的引入,降低整个金属中间连接层的热膨胀系数,使其热膨胀系数介于复合材料和钛合金间,缓解了接头的热应力。

4) 钎焊工艺参数为950 ℃保温5 min,TiC含量为10%时,接头剪切强度最高,达到157 MPa,高于采用Ag-Cu-Ti钎料时接头的最高剪切强度(102 MPa)。

REFERENCES

[1] Imuta M, Gotoh J. Development of High temperature materials including CMCs for space application[J]. Key Engineering Mater, 1999, 164/165: 439?444.

[2] ECKE A. Thermal shock fiber reinforced ceramic matrix, composites[J]. Ceramic Engineering and Science Process, 1991, 73(7/8): 1500?1508.

[3] XU Y D, CHENG L F, ZHANG L T. Carbon/silicon carbide composites prepared by chemical vapor infiltration combined with silicon melt infiltration[J]. Carbon, 1999, 37(8): 1179?1187.

[4] Bourrat X, Alrivie M, Michaux A. TEM thin foil preparation for ceramic composites with multilayered matrix[J]. Journal of the European Ceramic Society, 2005, 25(6): 809?815.

[5] Golczewski J A, Aldinger F. Phase separation in Si-(B)-C-N polymer-derived ceramics[J]. Materials Research and Advanced Techniques, 2006, 97(2): 114?118.

[6] Haug J, Lamparter P, Weinmann M, Aldinger F. Diffraction study on the atomic structure and phase separation of amorphous ceramics in the Si-(B)-C-N system. 2. Si-B-C-N ceramics[J]. Chemistry of Materials, 2004, 16(1): 83?92.

[7] Lin Guo-biao, Huang Ji-hua, Zhang Hua. Microstructure and mechanical performance of the brazed joints of Cf /SiC composite and Ti alloy using Ag-Cu-Ti-W[J]. Science and Technology of Welding and Joining, 2006, 11(4): 379?383.

[8] Lin Guo-biao, Huang Ji-hua. Brazed joints of Cf/SiC composite to Ti alloy using Ag-Cu-Ti-(Ti+C) mixed powder as interlayer[J]. Powder Metallurgy, 2006, 49(4): 345?348.

[9] Li Shu-jie, Zhang Jian-jun, Liang Xiao-bo. Joining of carbon fibre reinforced SiC (Cf/SiC) to Ni-based superalloy with multiple interlayers[J]. International Journal of Modern Physics B, 2003, 17(8): 1777?1781.

[10] Xiong Jiang-tao, Li Jing-long, Zhang Fu-sheng. Joining of 3D C/SiC composites to niobium alloy[J]. Scripta Materialia, 2006, 55: 151?154.

[11] Asthana R, Singh M. Joining of partially sintered alumina to alumina, titanium, hastealloy and C-SiC composite using Ag-Cu brazes[J]. Journal of the European Ceramic Society, 2008, 28: 617?631.

[12] Hanso W B. Joining of ceramics using a ceramic-modified braze alloy[J]. Materials Technology, 1999, 14(2): 53?56.

[13] 杨建国, 方洪渊, 万 鑫. Ag-Cu-Ti活性钎料加入Al2O3陶瓷颗粒对Al2O3陶瓷钎焊接头性能的影响[J]. 材料科学与工艺, 2001, 9(S1): 676?678.

YANG Jian-guo, FANG Hong-yuan, WANG Xin. Effects of Al2O3-particulate-contained Ag-Cu-Ti filler materials on the properties of Al2O3 joints[J]. Journal of Material Science and Technology, 2001, 9(S1): 676?678.

[14] YANG Jun, WU Ai-ping, ZOU Gui-sheng. Solid-liquid state bonding of Si3N4 ceramics with ceramic-modified brazing alloy[J]. Tsinghua Science and Technology, 2004, 9(5): 601?606.

[15] ZHU Min-guang, CHUNG D D L. Improving the strength of brazed joints to alumina by adding carbon fibers[J]. Journal of Materials Science, 1997, 32: 5321?5333.

[16] 林国标, 黄继华, 张建纲. SiC陶瓷与Ti合金的(Ag-Cu-Ti)-W复合钎焊接头组织结构研究[J]. 材料工程, 2005(10): 17?22.

Lin Guo-biao, Huang Ji-hua, Zhang Jian-gang. Research of microstructure of composite-brazing joints of SiC ceramics and Ti alloy by using (Ag-Cu-Ti)-W as bonding material[J]. Journal of Materials Engineering, 2005(10): 17?22.

[17] Lin Guo-biao, Huang Ji-hua, Zhang Hua. Joints of carbon fiber-reinforced SiC composites and Ti-alloy brazed by Ag-Cu-Ti-short carbon fibres[J]. Journal of Materials Processing Technology, 2007, 189: 256?261.

[18] NAKA M, FENG J C, SCHUSTER J C. Phase reaction and diffusion path of the SiC/Ti system[J]. Metallurgical and Materials Transactions A, 1997, 28(6): 1385?1390.

基金项目:国家高技术研究发展计划资助项目(2006AA03A221)

收稿日期:2008-06-30;修订日期:2008-12-17

通讯作者:黄继华,教授,博士;电话:010-62334859;E-mail: jihuahuang47@sina.com

(编辑 李艳红)