文章编号:1004-0609(2013)S1-s490-04

热处理对Ti44Al6Nb0.6B合金组织及力学性能的影响

李建崇1,陈瑞润2,吕昕舆2,赵晓丽2,丁宏升2,郭景杰2,傅恒志2

(1. 中航工业北京航空材料研究院,北京 100095;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:通过改变热处理温度,研究热处理工艺对Ti44Al6Nb0.6B合金宏观组织、显微组织及力学性能的影响。结果表明:随着热处理温度的升高,Ti44Al6Nb0.6B合金的宏观组织晶粒尺寸不断增大,1 330 ℃时合金的组织为大量的粗大等轴晶;1 200 ℃和1 270 ℃热处理后,Ti44Al6Nb0.6B合金的显微组织均为全片层组织,1 330℃热处理后,合金具有明显的近全片层组织。显微硬度测试表明这3种热处理均降低了显微硬度值,但随着温度的升高,显微硬度有所提高,这可能是由于固溶强化引起的。

关键词:钛铝合金;热处理;细化;显微硬度;晶粒

中图分类号:TF 804.3 文献标志码:A

Influence of heat treatment on microstructure and mechanical properties of Ti44Al6Nb0.6B alloy

LI Jian-chong1, CHEN Rui-run2, Lü Xin-yu2, ZHAO Xiao-li2, DING Hong-sheng2, GUO Jing-jie2, FU Heng-zhi2

(1. AVIC Beijing Institute of Aeronautical Materials, Beijing 100095, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The influence of heat treatment on the macro/micro-structure and mechanical properties of Ti44Al6Nb0.6B alloy at different temperatures was studied. The results show that the grain size increases with the increase of the temperature. There are lots of coarse equiaxed grains in the sample when the heat treatment temperature is 1 330 ℃. The microstructure of Ti44Al6Nb0.6B alloy is changed into full lamella structure when it is heat treated at 1 200 ℃ and 1 270 ℃. However, the microstructure changes to near full lamella structure when the temperature is 1 330 ℃. Micro-hardness testing shows that all of the heat treatments decrease the hardness, but the hardness increases with the increase of temperature, which maybe resulted from solution strengthening.

Key words: TiAl alloy; heat treatment; refining; micro-hardness; grain

TiAl基合金因具有低密度、高比强度、良好的抗高温蠕变及抗氧化性等优越的性能,成为新型高温结构材料的有力竞争者[1]。向TiAl基合金中加入高熔点的Nb可以有效提高合金的高温强度、抗氧化性能和抗蠕变性等高温性能[2],是目前提高TiAl基合金使用温度的最有效途径,基于此,高铌TiAl基合金成为航空航天领域的最具竞争力的高温材料之一。然而高铌TiAl基合金并未改善TiAl 基合金的低温塑性。因此,如何获得具有良好塑性的TiAl基合金是当前材料领域较为关心的问题之一。大量研究[3-4]表明:细小均匀的组织可以有效提高TiAl基合金的塑性等力学性能。目前可采用以下2种方法细化铸态TiAl基合金的组织:一是对合金熔体进行处理,通过加入β相稳定合金元素,如B和Re等,可明显抑制α相晶粒的长大,达到细化晶粒的目的;二是对热加工后组织进行热处理[5-11],获得室温塑性和强度较高的双态组织及具有优异抗蠕变性能和断裂韧性的全片层组织[12]。直接热处理包括淬火-回火热处理、时效热处理和循环热处理等方法,是改善TiAl基合金铸态组织的有效途径。

基于上述内容,本文作者对Ti44Al6Nb0.6B合金进行直接热处理,通过改变热处理温度,研究热处理工艺对Ti44Al6Nb0.6B合金的宏观组织、显微组织及力学性能的影响规律及机理。

1 实验

1.1 实验设备及试剂

XY-1600A高温箱式气氛电炉;高倍数码相机;Olympus金相显微镜;维式硬度计;金相腐蚀剂(体积分数):5%HF+5%HNO3+90%H2O。

1.2 实验方法

实验用合金的名义成分为Ti44Al6Nb0.6B(摩尔数分数,%)。将合金铸锭放置在高温箱式气氛电炉中,分别在1 200、1 270和1 330 ℃保温2 h,升温速率控制为10 ℃/s,然后炉冷至300 ℃,之后空冷至室温。

使用高倍数码相机拍摄合金的宏观组织,再对热处理之后的试样进行线切割、研磨及抛光、腐蚀,进行金相观察分析。测试试样的显微硬度。表1给出了不同的热处理温度及试样编号。

表1 Ti44Al6Nb0.6B合金的试样编号及对应的热处理温度

Table 1 Temperature of heat treatment and number of Ti44Al6Nb0.6B alloy

2 结果与讨论

2.1 热处理对Ti44Al6Nb0.6B合金宏观组织影响

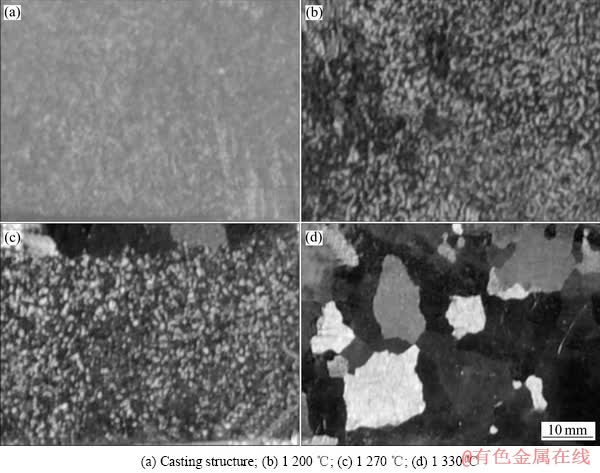

图1所示分别为Ti44Al6Nb0.6B合金的铸态组织和经1 200、1 270和1 330 ℃热处理后的宏观组织。观察4组试样的宏观组织发现,与原始铸态组织相比,1 200 ℃热处理后合金的晶粒尺寸增大,但晶粒粗化的效果并不明显;1 270 ℃热处理后,其晶粒尺寸变化很小;1 330 ℃热处理后,试样的组织转变为粗大的等轴晶。总的来说,随着热处理温度的升高,Ti44Al6Nb0.6B合金的晶粒粒径增大。1 200 ℃和1 270 ℃热处理后,晶粒长大幅度较小,而在1 330 ℃热处理之后,晶粒显著长大,并出现大量粗大的等轴晶。通常在α单相区进行保温的过程中,会出现晶粒的快速长大,因此可以预计1 330 ℃应该处于α单相区中,单步热处理工艺通常应尽量避开此温度区间。

图1 Ti44Al6Nb0.6B铸态以及经1 200、1 270和1 330 ℃热处理后的宏观组织

Fig. 1 Macrostructures of casting Ti44Al6Nb0.6B alloy and after heat treatment at 1 200, 1 270 and 1 330 ℃

图2所示为TiAlNb三元合金纵截面相图,由图2可知:热处理温度为1 200和1 270 ℃时,Ti44Al6Nb0.6B合金分别处于α+γ两相区、α单相区 内,而1 330 ℃,也在α单相区内且更接近α+β相区。从图2中可以观察到:在晶界处析出网络状的B化合物,有效阻止了晶粒的长大。这主要是由于B元素在TiAl基合金中的溶解度非常低,凝固过程中被排除到固液界面前沿,产生成分过冷,抑制晶粒生长,促进晶粒细化。

图2 TiAlNb三元合金纵截面相图

Fig. 2 Phase diagrams of TiAlNb ternary alloy

2.2 热处理对Ti44Al6Nb0.6B合金显微组织的影响

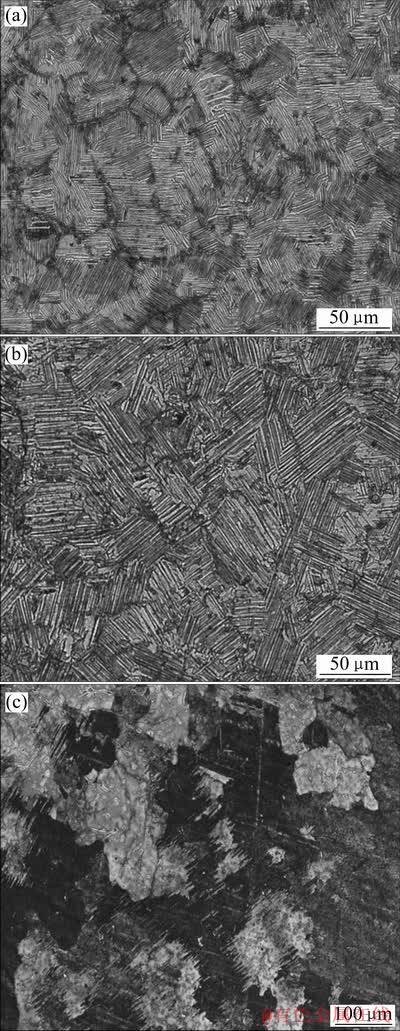

图3所示为Ti44Al6Nb0.6B合金经1 200、1 270和1 330 ℃热处理之后的金相显微组织照片。由图3可知:1号试样和2号试样为明显的全片层组织,2号试样的片层间距更细小,而3号试样的组织为典型的近全层片组织,且γ等轴晶粗大。

2.3 热处理对Ti44Al6Nb0.6B合金力学性能的影响

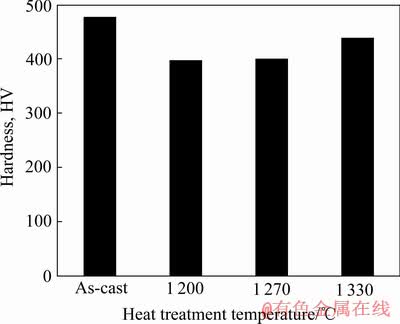

图4所示为Ti44Al6Nb0.6B合金经1 200、1 270和1 330 ℃热处理后的组织及铸态组织的显微硬度。由图4可知:经过热处理之后,Ti44Al6Nb0.6B合金的显微硬度降低,这是由于经过热处理后晶粒尺寸增大,导致显微硬度降低。随着热处理温度的升高,合金的显微硬度增大,但增大幅度不大。这可能是Nb 和B原子在基体中固溶强化的结果。当温度升高,合金元素的扩散更加均匀,固溶效果更加明显,合金元素进入规则排列的基体中,引起晶格畸变,故而有可能提高合金显微硬度。与此同时,当温度升高至α或α+γ相区进行保温,再冷却至室温,在这一过程中,可能导致室温下的α2+γ片层团中的α2片层粗化,故α2体积分数增加,相对于γ相,α2相硬度更高,因此,其显微硬度可能升高。

图3 Ti44Al6Nb0.6B合金在1 200、1 270和1 330 ℃时的显微组织

Fig. 3 Microstructures of Ti44Al6Nb0.6B alloy after heat treatment at 1 200 ℃(a), 1 270 ℃(b) and 1 330 ℃(c)

图4 不同热处理状态下Ti44Al6Nb0.6B合金的显微硬度

Fig. 4 Micro-hardness of Ti44Al6Nb0.6B alloy under different heat treatment conditions

3 结论

1) 随着热处理温度的升高,Ti44Al6Nb0.6B合金宏观组织的晶粒尺寸增大,当温度达到1 330 ℃时,晶粒显著长大,并出现大量粗大的等轴晶粒。

2) 经1 200 ℃和1 270 ℃热处理后,Ti44Al6Nb0.6B合金的显微组织均为全片层组织,1 330 ℃热处理后的合金显微组织具有明显的近全片层组织特点,且晶粒明显长大。

3) 与Ti44Al6Nb0.6B合金的铸态组织相比,经过热处理之后其显微硬度减小,随着热处理温度的升高,显微硬度增大,但增大幅度较小。

REFERENCES

[1] UENISHI K, KOBAYASHI K F. Processing of intermetallic compounds for structural applications at high temperature[J]. Intermetallics, 1996, 4: S95.

[2] CHEN G L, ZHANG W, WANG Y. Ti2Al2Nb intermetallic alloys based on the ternary intermetallic compound[C]// Structural Intermetallics. New York: TMS, 1993: 319.

[3] VEERARAGHAVAN D, VASUDEVAN V K. Phase transformations in two-phase TiAl/Ti3Al alloys during continuous heating and cooling, studied by electrical resistivity measurements[J]. Materials Science and Engineering A, 1995, 192/193: 950-956.

[4] 唐建成, 黄伯云, 贺跃辉. Ti-Al基合金中的Hall-Petch关系及影响因素分析[J]. 金属学报, 2002, 38(4): 365-368.

TANG Jian-cheng, HUANG Bo-yun, HE Yue-hui. Factors affecting the hal1-petch relationship in TiAl based alloys[J]. Acta Metallurgica Sinica, 2002, 36(4): 365-368.

[5] 刘 冬, 刘仁慈, 崔玉友, 杨 锐. 时效热处理对α挤压态TiAl合金显微组织的影响[J]. 中国有色金属学报, 2010, 20(S1): s242-s247.

LIU Dong, LIU Ren-ci, CUI Yu-you, YANG Rui. Effect of aged-heat treatment on microstructure of α extruded TiAl alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s242-s247.

[6] WANG W D, MA Y C, CHEN B. Effects of boron addition on grain refinement in TiAl-based alloys[J]. J Mater Sci Technol, 2010, 26(7): 639-647.

[7] GAISIN R, IMAYEV V, IMAYEV R, FECHT H J. A preliminary study on precipitation hardening of Ti38.5Al4Fe and Ti38.5Al4Fe5Nb0.2B intermetallic alloys via heat treatment[J]. Intermetallics, 2010, 18: 2238-2243.

[8] HUANG Jin-song, LIU Yong, HE Yue-hui, ZHANG Yong-hong, LIU Bin, ZHANG Wei, HE Xiao-yu, HUANG Bo-yun. Effects of tungsten and microstructures of Ti-Al-Nb-W-B alloy under different treatment processes[J]. Heat Treatment of Metals, 2006, 31(7): 13-17.

[9] QUA H P, LI P, ZHANG S Q, LI A, WANG H M. The effects of heat treatment on the microstructure and mechanical property of laser melting deposition γ-TiAl inter-metallic alloys[J]. Materials and Design, 2010, 31: 2201-2210.

[10] DINGX F, LIN J P, ZHANG L Q, WANG H L, HAO G J, CHEN G L. Microstructure development during directional solidification of Ti-45Al-8Nb alloy[J]. Journal of Alloys and Compounds, 2010, 506(1): 115-119

[11] 刘仁慈, 刘 冬, 崔玉友, 杨 锐. 热挤压γ-TiAl合金的组织演变[J]. 中国有色金属学报, 2010, 20(S1): s248-s252.

LIU Ren-ci, LIU Dong, CUI Yu-you, YANG Rui. Effect of aged-heat treatment on Microstructure evolution of hot extruded γ-TiAl alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s248-s252.

[12] 章德铭, 陈贵清, 韩杰才, 孟松鹤. γ-TiAl基高温结构材料研究评述[J]. 中国稀土学报, 2005, 23: 163-167.

ZHANG De-ming, CHEN Gui-qing, HAN Jie-cai, MENG Song-he. Review on studies of gamma TiAl based high- temperature structural materials[J]. Journal of the Chinese Rare Earth Society, 2005, 23: 163-167.

(编辑 何运斌)

基金项目:教育部新世纪优秀人才资助项目(NCET-12-0153);国家自然科学基金资助项目(51274076)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:陈瑞润,教授,博士;电话:0451-86413931;E-mail: ruirunchen@hit.edu.cn