DOI:10.19476/j.ysxb.1004.0609.2018.06.23

变渣皮厚度条件下铜冷却壁变形

李峰光1, 2,张建良2

(1. 湖北汽车工业学院 材料科学与工程学院,十堰 442002;

2. 北京科技大学 冶金与生态工程学院,北京 100083)

摘 要:根据热弹性力学理论,建立渣皮厚度可变的铜冷却壁热-力耦合应力场分布计算模型,从铜冷却壁在不同渣皮厚度条件下的变形情况这一角度分析煤气温度、冷却制度、镶砖材质和炉渣性质等多种因素对铜冷却壁寿命的影响规律。计算结果表明:冷却壁本体变形随煤气温度的升高而线性增加;随着渣皮厚度的增大,冷却壁本体的变形量先减小后增大,渣皮厚度约为20 mm时冷却壁本体变形最小;冷却水流速的增大对降低冷却壁变形量有显著作用,而冷却水温度的升高会使冷却壁本体的变形量显著增大;提升镶砖热导率可明显减小冷却壁本体变形,而增大镶砖热膨胀系数会明显增加壁体变形量;炉渣热膨胀系数越小,铜冷却壁本体变形越小。

关键词:铜冷却壁;渣皮;热-力耦合;热变形;ANSYS

文章编号:1004-0609(2018)-06-1268-08 中图分类号:TF321.4 文献标志码:A

铜冷却壁表面渣皮的存在可有效降低铜冷却壁表面耐材或其本体温度,并保护铜冷却壁免受炉料和煤气流的冲刷磨损作用,对延长铜冷却壁寿命具有重要意义。目前国内外对于铜冷却壁表面渣皮的研究主要集中在渣皮对铜冷却壁传热的影响[1-6]及挂渣稳定性方面[7-9]。然而,铜冷却壁表面渣皮的存在及其厚度的变化将对铜冷却壁传热体系造成较大影响,进而影响铜冷却壁本体的温度分布和应力分布,因而也不可避免的影响到铜冷却壁本体在不同工况下的热变形情况。石琳等[10]通过热态试验结合数值模拟方法研究铸造铜冷却壁热变形后认为,冷却壁固定方式和边缘接触压力将对铜冷却壁的变形方向和变形量产生重大影响。而刘奇等 [11]的研究则表明,铜冷却壁在受热情况下将变形成为弧形,而采用铜钢复合结构则可有效减小冷却壁的热变形。郭光胜等[12]对湘钢铜冷却壁大量损坏问题进行调研和分析后认为,在湘钢破损的冷却壁中,有27块表现为热变形损坏,而铜冷却壁破损的主要原因是铜冷却壁热面挂渣不稳定而导致其长期经受较大的热应力和热变形。此外,许多高炉操作者也根据实际生产情况对铜冷却壁变形情况进行了分析,并提出一系列应对措施[13-14]。上述相关研究在一定程度上揭示了铜冷却壁在不同工况下的变形规律,为生产实际提供了较大的指导作用,但均忽略或较少关注生产中渣皮厚度将经常性变化这一实际情况。实际上,渣皮厚度的波动将对铜冷却壁在各工况下的传热情况和变形规律均产生较大的改变。因此,本文作者采用热力耦合分析的方法对挂有炉渣的铜冷却壁进行变形情况计算,分析了煤气温度、冷却制度、渣皮厚度、炉渣导热系数、镶砖材质等多种因素对铜冷却壁变形情况的影响,进而探讨变渣皮厚度条件下各因素对铜冷却壁寿命的影响规律。

1 计算模型

1.1 热-力耦合分析模型

采用ANSYS软件进行铜冷却壁传热体系的热-力耦合分析和铜冷却壁变形分析。考虑到所计算问题中渣皮厚度较小但温度、应力梯度很大,网格精细度要求较高且计算量较大的实际情况,采用间接热-力耦合分析方法进行分析,相关模型和边界条件已在本文作者前期的研究工作中详细描述(详见文献[8])。求解所需遵守的热弹性力学方程和所涉及材料的力学参数分别见文献[15]和表1[16-17]。

其中,渣皮和镶砖的物性参数随高炉冶炼条件也选用种类不同而发生变化,均为所考虑的因素,因此这二者的物性参数由实际的计算工况决定。

1.2 计算工况及条件

主要考察在不同渣皮厚度条件下煤气温度、冷却制度等诸多因素发生改变时铜冷却壁本体变形情况,因此所考虑的变化因素包括煤气温度、冷却制度(含冷却水流速及却水温度)、镶砖材质(含镶砖热导率和镶砖热膨胀系数)和炉渣性质(炉渣热膨胀系数)。对于上述每种因素,在其变化范围内等距取5个值进行计算,针对每个因素的每个取值,均计算渣皮厚度在5~85 mm变化条件下的应力分布情况。在对某一影响因素进行分析计算时,其他各因素取其特征值。其中,各影响因素的取值范围和特征值如表2所列。计算过程中认为铜冷却壁镶砖已经完全消失,燕尾槽位置被炉渣填充。

2 计算结果与分析

2.1 典型冷却壁变形

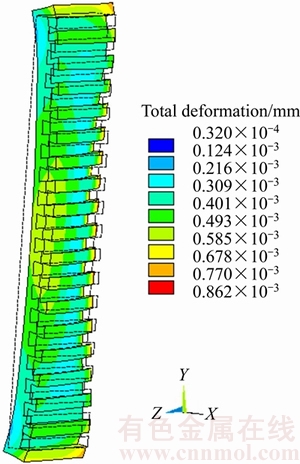

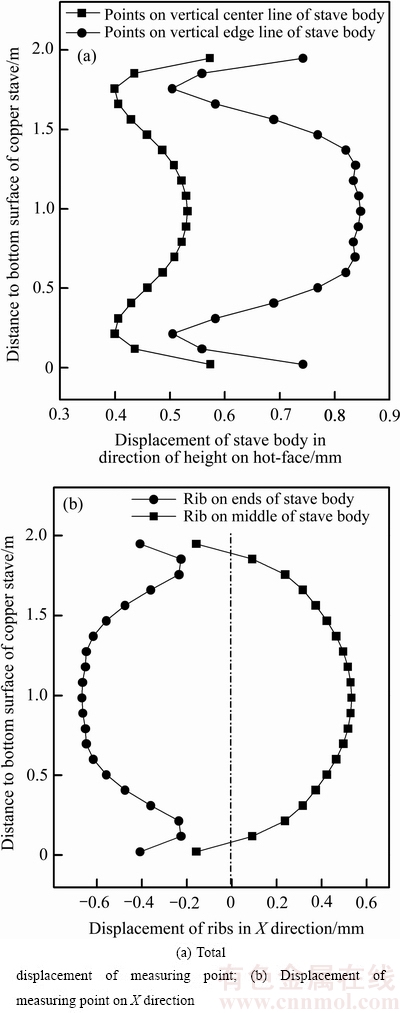

铜冷却壁在高炉内工作时,由于受到螺栓固定作用、重力、热应力等多种约束作用而会产生变形,过大的冷却壁变形除了会对壁体本身寿命造成影响外,还会导致壁体与填料层之间产生空气气隙,影响传热效果。因此,铜冷却壁在高炉内工作时,应尽量降低其变形。图1显示了典型的冷却壁变形情况(煤气温度1300 ℃,冷却水流速2.0 m/s,冷却水温度35 ℃)。在图1中,虚线表示冷却壁变形前轮廓。由图1可以看出,铜冷却壁在高炉内工作时,在螺栓的约束和热应力共同作用下,在高度方向上,冷却壁中部向热面凸出,而冷却壁两端向冷面凸出,整体形成弓形;在冷却壁宽度方向上,亦表现为冷却壁中部向热面凸出,而冷却壁两端向冷面凸出。

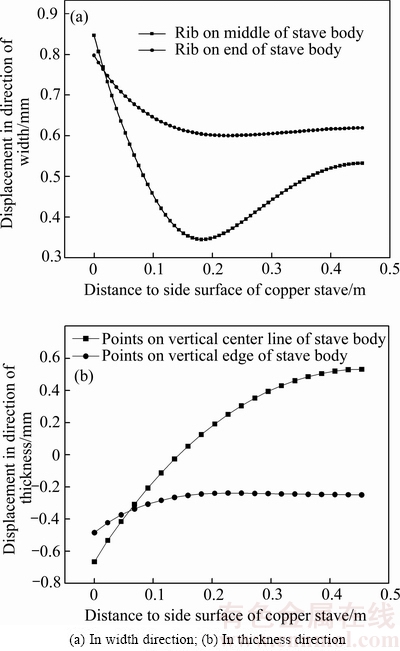

图2和图3更清楚地反映了冷却壁宽度方向上和高度方向上的变形规律。图中测量点总位移仅表示某点位置离开其原始位置的距离,不含有方向性,而x方向位移即表示冷却壁在厚度方向上的位移,正值表示该点向热面移动,负值表示该点向冷面移动。由图2和3可知,在宽度方向上,靠近固定螺栓位置,由于螺栓的约束作用,壁体变形量最小,而由螺栓位置向冷却壁两个侧面,变形量迅速增大,冷却壁两端筋肋的变形量要远大于冷却壁中部筋肋的;在高度方向上,亦表现为螺栓约束位置变形量较小,而冷却壁两端和冷却壁中部变形较大,其中冷却壁两个侧面处变形量远大于冷却壁中部相应位置的变形量。同时,由图2和图3可以看出,无论在高度方向上还是在宽度方向上,均表现为冷却壁中部向热面鼓出变形,而冷却壁两侧和上下底面向冷面弯曲变形,且越靠近冷却壁中部,变形量越大。这与国内某厂损坏铜冷却壁拆下后形状一致,如图4所示。

由于在冷却壁固定方式一定的情况下,不同工况下冷却壁变形情况基本一致,区别在于各位置处变形量数值的变化,而铜冷却壁热面中心位置变形量较大,因此,在下述分析各工况条件对冷却壁变形问题的影响时,取冷却壁热面几何中心点为参考点,以该点的变形量指代冷却壁变形量。

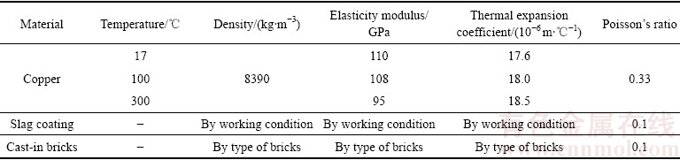

表1 各材料弹性力学参数

Table 1 Elasticity mechanics parameters of materials

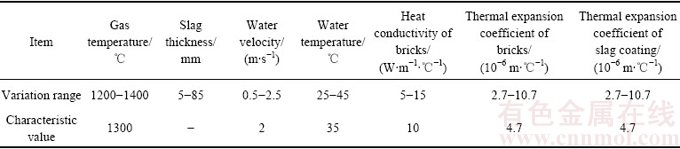

表2 不同煤气温度计算工况下参数选择

Table 2 Parameters under different conditions of gas temperature

图1 铜冷却壁典型变形图

Fig. 1 Typical deformation of copper staves

图2 冷却壁宽度及厚度方向上位移变化规律

Fig. 2 Change law of stave body’s displacement

图3 铜冷却壁高度方向上位移变化

Fig. 3 Vertical displacement changes of stave body

图4 国内某钢厂损坏铜冷却壁变形情况

Fig. 4 Damage and deformation condition of copper cooling stave in a Chinese steel plant

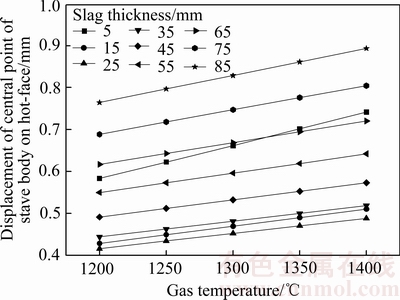

2.2 煤气温度变化对冷却壁变形的影响

如图5所示,在各渣皮厚度条件下,煤气温度的变化均会线性地增大壁体变形量,在不同的渣皮厚度条件下,冷却壁变形量随煤气温度上升的趋势大小有所区别。以渣皮厚度5 mm为例,当煤气温度由1200 ℃上升至1400 ℃,冷却壁位移由0.583 mm增加至0.741 mm,增大了27.1%。这说明即便在有渣皮保护的条件下,煤气温度的升高也会在较大范围内增大冷却壁变形,对冷却壁的安全工作构成威胁。

图5 煤气温度变化对壁体变形量的影响

Fig. 5 Influence of gas temperature on deformation of stave body

2.3 渣皮厚度变化对冷却壁变形的影响

图6所示为渣皮厚度变化对冷却壁变形的影响。由图6可看出,随着渣皮厚度的增大,冷却壁本体变形呈现先减小后增大的趋势。在渣皮厚度小于20 mm时,随着渣皮厚度增大,冷却壁变形逐渐减小,这是由于渣皮的存在降低了冷却壁本体温度,减小了冷却壁热膨胀,因此冷却壁位移减小。而当渣皮超过20 mm后,随着渣皮厚度的增大,冷却壁本体变形量又逐渐增大。此时,虽然冷却壁热膨胀量继续减小,但是由于渣层与铜冷却壁膨胀量不一致,逐渐增厚的渣层使得冷却壁与渣层之间的相互约束作用增强,冷却壁本体变形量逐渐增大。以煤气温度1300 ℃曲线为例,当渣皮厚度由5 mm增加至15 mm,渣皮冷却壁变形量由0.662 mm减小至0.469 mm,即渣皮厚度每增大1 mm,冷却壁变量减小0.02 mm;在渣皮厚度为15~35 mm范围内,渣皮厚度的变化对冷却壁变形量的影响相对较小,冷却壁变形量仅在0.452mm至0.481mm之间波动,渣皮厚度每变化1 mm,冷却壁变形量仅变化0.003 mm;而渣皮厚度由35 mm增加至85 mm,冷却壁变形量由0.481 mm增加至0.829 mm,平均渣皮厚度每增加1 mm,冷却壁变形量增大0.04 mm。

以上分析说明只有适宜的渣皮厚度方可减小冷却壁变形量,在各煤气温度条件下,适宜的渣皮厚度均为15~35 mm。

图6 渣皮厚度变化对壁体变形量的影响

Fig. 6 Influence of slag coating thickness on deformation of stave body

2.4 冷却制度对壁体变形的影响

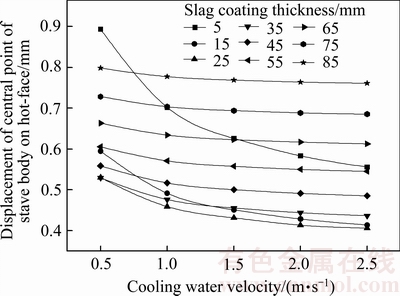

2.4.1 冷却水流速变化对壁体变形的影响

图7所示为冷却水流速变化对壁体变形的影响,由图7可以看出,无论何种渣皮厚度条件下,冷却水流速的增大均能减小冷却壁变形量,且在渣皮厚度较小时表现得更加明显。下面分别以渣皮厚度5 mm和85 mm两种工况进行说明。在渣皮厚度5 mm条件下,冷却水流速由0.5 m/s增加至2.5 m/s,冷却壁变形量由0.893 mm降低至0.556 mm,共降低了37.7%;而相应在渣皮厚度85 mm条件下,冷却壁变形量由0.799 mm降低至0.761 mm,共降低5.0%。这说明渣皮越薄,冷却水流速对冷却壁变形的影响越明显。同时,壁体变形量与冷却水流速之间呈现指数关系,冷却水速较小时,增大水速可显著减小冷却壁变形量;而当冷却水速增加至一定程度时,继续增大水速对减小冷却壁变形量的作用变的较不明显。以渣皮厚度5 mm工况为例,在冷却水流速0.5 m/s增加至1.5 m/s,壁体变形量减小了30.0%;而冷却水流速继续由1.5 m/s增加至2.5 m/s,冷却壁变形量减小了11.2%。

以上分析说明在一定的水速范围内冷却水流速的增大对降低冷却壁变形量有显著作用,且在渣皮厚度较小和冷却水速较低时其作用更加明显。根据计算结果,冷却水流速应维持在1.5 ~ 2.5 m/s之间以降低冷却壁变形量。

图7 冷却水流速变化对壁体变形量的影响

Fig. 7 Influence of cooling water velocity on deformation of stave body

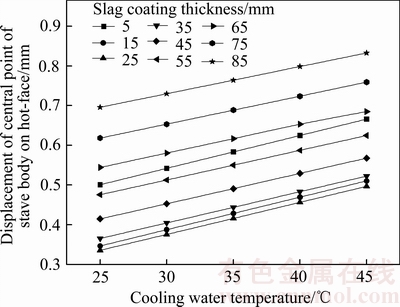

2.4.2 冷却水温度变化对壁体变形的影响

由图8可知,冷却壁变形量与冷却水温度呈线性关系,随着冷却水温度的提升,冷却壁本体的变形量显著增大。以渣皮厚度45 mm工况为例,冷却水温度由25 ℃上升至45 ℃,冷却壁变形量相应由0.415 mm上升至0.568 mm,增加了36.9%。因此,为降低冷却壁变形量,需尽量降低并维持稳定的冷却水温度。

2.5 镶砖材质变化对壁体变形的影响

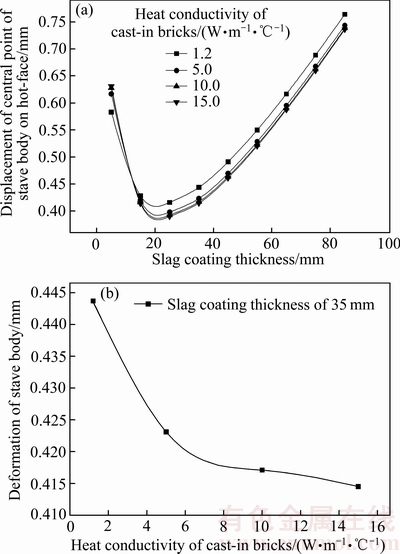

2.5.1 镶砖热导率变化对壁体变形的影响

由图9可知,在渣皮厚度大于15 mm时,镶砖热导率的提升可降低壁体变形量。相较于冷却壁燕尾槽内镶砖完全被炉渣取代的工况,当燕尾槽内保留有15 W/(m·℃)的镶砖时,冷却壁本体变形量下降约6.7%。在热导率小于7 W/(m·℃)时,镶砖热导率的提升对壁体变形量的降低效果极为明显;当镶砖热导率高于7 W/(m·℃)时,镶砖热导率的提升对壁体变形量的影响较小。因此,从控制壁体变形量的角度出发,在铜冷却壁燕尾槽内应采用导热率大于7 W/(m·℃)的镶砖。

图8 冷却水温度变化对铜冷却壁变形量的影响

Fig. 8 Influence of cooling water temperature on deformation of stave body

图9 镶砖热导率对壁体变形量的影响和壁体变形量随镶砖热导率变化趋势

Fig. 9 Influence of cast-in brick’s heat conductivity on deformation of stave body(a) and variation tendency of deformation(b)

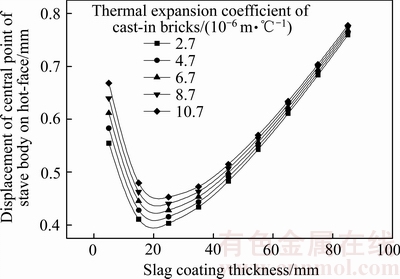

2.5.2 镶砖热膨胀系数变化对壁体变形的影响

镶砖热膨胀系数的增大会明显增加壁体变形量,且在渣皮厚度较小时表现得更加明显,如图10所示。当渣皮厚度为5 mm时,镶砖热膨胀系数由2.7×10-6 m/℃变为10.7×10-6 m/℃,壁体变形量由0.554 mm上升至0.668 mm,上升约20.5%。

图10 镶砖热膨胀系数对壁体变形量的影响

Fig. 10 Influence of insert brick’s thermal expansion on deformation of stave body

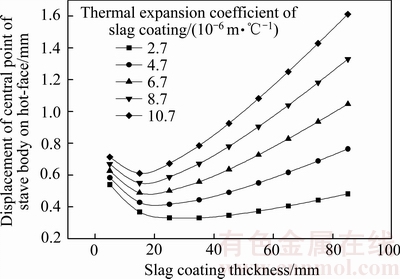

2.6 炉渣热膨胀性对冷却壁变形的影响

在相同的渣皮厚度条件下,炉渣热膨胀系数的减小可明显降低铜冷却壁变形量如图11所示。而当渣皮厚度增大时,铜冷却壁本体变形量随之先减小后增大,即铜冷却壁变形量在某个渣皮厚度时达到谷值。炉渣热膨胀系数越大,壁体变形量谷值所对应的渣皮厚度值越小,且经过谷值后,壁体变形量的增大趋势更加明显。当炉渣热膨胀系数为10.7×10-6 m/℃时,铜冷却壁最大变形量达到1.612 mm(对应渣皮厚度85 mm);而炉渣热膨胀系数为2.7×10-6 m/℃时,冷却壁最大变形量仅为0.539 mm(对应渣皮厚度5 mm),约为前者的1/3。这意味着炉渣热膨胀系数越小,壁体变形将越小,且随着渣皮厚度变化而产生的变形量波动也越小,这将有利于降低铜冷却壁应力疲劳,延长铜冷却壁寿命。

图11 炉渣热膨胀系数变化对壁体变形量的影响

Fig. 11 Influence of slag coating’s thermal expansion on deformation of stave body

3 结论

1) 冷却壁本体变形随煤气温度的升高而线性增加;随着渣皮厚度的增大,冷却壁本体的变形量先增大后减小,渣皮厚度约为20 mm时冷却壁本体变形最小。

2) 冷却水流速的增大对降低冷却壁变形量有显著作用,且在渣皮厚度较小和冷却水速较低时其作用更加明显,冷却水流速应维持在1.5~2.5 m/s之间;冷却壁变形量与冷却水温度呈线性关系,随着冷却水温度的升高,冷却壁本体的变形量显著增大。

3) 镶砖热导率的提升可明显减小冷却壁本体变形,而镶砖热膨胀系数的增大会明显增加壁体变形量,且在渣皮厚度较小时表现的更加明显。

4) 炉渣热膨胀系数越小,铜冷却壁本体变形越小,且铜冷却壁本体变形量随渣皮厚度变化而产生的波动也越小。

REFERENCES

[1] GANGULY A, REDDY A S, KUMAR A. Process visualization and diagnostic models using real time data of blast furnaces at Tata steel[J]. ISIJ International, 2010, 50(7): 1010-1015.

[2] YEH C P, HO C K, YANG R J. Conjugate heat transfer analysis of copper staves and sensor bars in a blast furnace for various refractory lining thickness[J]. International Communications in Heat and Mass Transfer, 2012, 39(1): 58-65.

[3] 朱仁良, 居勤章. 铜冷却壁高炉操作现象及思考[J]. 炼铁, 2012, 31(3): 10-15.

ZHU Ren-liang, JU Qin-zhang. Operation conditions of copper cooling stave for blast furnace and suggestion[J]. Ironmaking, 2012, 31(3): 10-15.

[4] 王宝海, 张洪宇, 车玉满. 鞍钢铜冷却壁高炉的热负荷管理[J]. 炼铁, 2008, 27(2): 37-39.

WANG Bao-hai, ZHANG Hong-yu, CHE Yu-man. Heat load management of copper cooling stave for BF in Anshan Iron and Steel Co. LTD[J]. Ironmaking, 2008, 27(2): 37-39.

[5] ZHANG He-shun, MA Hong-bin, CHEN Jun, ZHOU Ji-lie. The practice of copper cooling stave application for Shougang No.2 BF[C]// Proceedings of the 5th International Congress on the Science and Technology of Ironmaking. Shanghai, 2009: 883-887.

[6] 左海滨, 洪 军, 张建良, 李峰光, 沈 猛, 铁金艳. 不同工况下各种材质高炉冷却壁温度场数值模拟[J]. 武汉科技大学学报, 2014, 37(2): 102-105.

ZUO Hai-bin, HONG Jun, ZHANG Jian-liang, LI Feng-guang, SHEN Meng, TIE Jin-yan. Numerical simulation of temperature field of BF cooling staves of different materials under different conditions[J]. Journal of Wuhan University of Science and Technology, 2014, 37(2): 102-105.

[7] ZUO Hai-bin, ZHANG Jian-liang, LI Feng-guang. Damage reason analysis of copper cooing stave[C]// The American Ceramic Society. Materials Science and Technology Conference and Exhibition 2013. Montreal: Research Gate, 2013: 574-581.

[8] 李峰光, 张建良. 基于ANSYS“生死单元”技术的铜冷却壁挂渣能力计算模型[J]. 工程科学学报, 2016, 38(4): 546-554.

LI Feng-guang, ZHANG Jian-liang. Calculation model of the adherent dross capacity of copper staves based on ANSYS birth-death element technology[J]. Chinese Journal of Engineering, 2016, 38(4): 546-554.

[9] 计秀兰, 刘增勋, 吕 庆, 张振峰. 冶炼钒钛磁铁矿高炉的铜冷却壁挂渣分析[J]. 钢铁钒钛, 2012, 33(1): 55-59.

JI Xiu-lan, LIU Zeng-xun, Lü Qing, ZHANG Zhen-feng. Analysis on slag skull on BF copper cooling stave for vanadium-bearing titaniferous magnetite smelting[J]. Iron and Steel Vanadium Titanium, 2012, 33(1): 55-59.

[10] 石 琳, 李志玲. 埋纯铜管铸铜冷却壁热态试验和热应力热变形研究[J]. 内蒙古科技大学学报, 2009, 40(6): 699-707.

SHI Lin, LI Zhi-ling. A study on hot test and thermal stress and distortion of cast copper staves with buried copper pipes[J]. Journal of Inner Mongolia University of Science and Technology, 2009, 40(6): 699-707.

[11] 刘奇, 程树森, 牛建平, 刘东东. 铜钢复合冷却壁传热及热应力分析[J]. 中国有色金属学报, 2015, 25(2): 523-533.

LIU Qi, CHEN Shu-seng, NIU Jian-ping, LIU Dong-dong. Heat transfer and thermal stress analysis of copper steel composite stave [J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 523-533.

[12] 郭光胜, 张建良, 刘彦祥, 蒋友源, 周云花, 但家云. 湘钢1号高炉铜冷却壁破损机理研究[J]. 炼铁, 2016, 36(3): 19-23.

GUO Guang-sheng, ZHANG Jian-liang, LIU Yan-xiang, JIANG You-yuan, ZHOU Yun-hua, DAN Jia-yun. Study on copper cooling stave damage mechanism of Xiangtan Steel’s No.1 BF[J]. Ironmaking , 2016, 36(3): 19-23.

[13] 王宝海. 鞍钢高炉铜冷却壁破损原因调查分析[C]// 2014年全国炼铁生产技术会暨炼铁学术年会. 郑州, 2014: 825-830.

WANG Bao-hai. Investigation on broken copper cooling staves at the No.3 BF of An-Steel[C]// 2014 Annual National Ironmaking Technology and Academic Conference. Zhenzhou, 2014: 825-830.

[14] 卢正东, 陈令坤, 邹祖桥, 左红星, 张正东. 武钢6号高炉中修破损调查[J]. 武钢技术, 2016, 54(4): 16-20.

LU Zheng-dong, CHEN Ling-kun, ZOU Zu-qiao, ZUO Hong-xing, ZHANG Zheng-dong. Intermediate repair investigation on damage of No.6 blast furnace in WISCO[J]. WISCO Technology, 2016, 54(4): 16-20.

[15] 陈明祥. 弹塑性力学[M]. 1版. 北京: 科学出版社, 2007: 105-108.

CHEN Ming-xiang. Elasticity and Plasticity[M]. 1st ed. Beijing: Science Press, 2007: 105-108.

[16] 石 琳, 程素森, 张利君. 高炉铜冷却壁的热变形[J]. 中国有色金属学报, 2005, 15(12): 2040-2046.

SHI Lin, CHEN Su-seng, ZHANG Li-jun. Thermal distortion of blast furnace copper staves[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 2040-2046.

[17] 刘增勋. 高炉冷却壁热力耦合分析[D]. 沈阳: 东北大学, 2009: 27-33.

LIU Zeng-xun. Coupled thermo-mechanical analysis about blast furnace staves[D]. Shenyang: Northeastern University, 2009: 27-33.

Deformation of copper cooling stave under conditions of variable slag coating thickness

LI Feng-guang1, 2, ZHANG Jian-liang2

(1. School of Materials Science and Engineering, Hubei University of Automotive Technology, Shiyan 442002, China;

2. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: A thermal-mechanical coupling model of copper cooling stave with variable slag coating was founded based on the thermal elastic mechanics, and the influences of the gas temperature, the cooling system, the materials of insert bricks, and the properties of the slag on the stave life were analyzed from the view point of the deformation of stave body. The results show that the deformation of stave body increases linearly with the increase of gas temperature; the deformation of stave body decreases at first and then increases when the slag coating thickness increases, and the deformation of the stave body has the minimum when the slag coating thickness is 20 mm; the increase of water velocity has a significant influence on reducing deformation of stave body, while increase of cooling water temperature incurs conspicuous growth of deformation; the increase of the heat conductivity of cast-in bricks and the decrease of the thermal expansion coefficient of slag significantly reduce the deformation of stave body while the increase of the thermal expansion coefficient of cast-in bricks obviously enlarges the deformation of stave body.

Key words: copper cooling stave; slag coating; thermal-mechanical coupling; thermal deformation; ANSYS

Foundation item: Project(51604103) supported by the National Natural Science Foundation of China; Project (2016CFB293) supported by the Natural Science Foundation of Hubei Province, China; Project(BK201607) supported by Doctoral Research Start-up Foundation of Hubei University of Automotive Technology, China

Received date: 2017-03-31; Accepted date: 2017-05-23

Corresponding author: LI Feng-guang; Tel: +86-15901154466; E-mail: lemon2006@126.com

(编辑 王超)

基金项目:国家自然科学基金资助项目(51604103);湖北省自然科学基金资助项目(2016CFB293);湖北汽车工业学院博士科研启动基金资助项目(BK201607)

收稿日期:2017-03-31;修订日期:2017-05-23

通信作者:李峰光,讲师,博士;电话:15901154466;E-mail: lemon2006@126.com