文章编号:1004-0609(2009)03-0477-07

Sip/Al复合材料中的界面和硅相形貌的演变

王小锋1, 2,武高辉2,修子扬2,彭超群1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:采用金相显微镜、透射电子显微镜和高分辨电镜等手段,研究不同高温真空热处理工艺条件下,高体积分数Sip/Al复合材料(φ(Si)=65%)中硅铝界面特征与硅相形貌的演变过程。结果表明:热处理过程中硅相形貌演变为尖角钝化的颗粒状、球化的孤岛颗粒状和三维网络结构状。基于扩散理论将硅相形貌的演变分为3个阶段:不规则形状硅颗粒的尖角逐渐溶解到铝合金中,发生颗粒的钝化现象;较小硅颗粒周围逐渐溶解在铝合金中的硅在浓度梯度的作用下,通过扩散逐渐在较大硅颗粒周围析出并长大;长大的硅颗粒互相接触联结,形成网状结构。铸态Sip/Al复合材料中Si-Al界面平直,干净,无析出物,同时存在大量位错;高温热处理后的Si-Al界面变得圆滑,界面附近有细小的硅相析出物存在,几乎不存在位错。

关键词:Sip/Al复合材料;硅相;形貌演变;界面;析出相

中图分类号:TB 331 文献标识码:A

Evolution of silicon phase configuration and Si-Al interface of Sip/Al composites

WANG Xiao-feng1, 2, WU Gao-hui2, XIU Zi-yang2, PENG Chao-qun1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The evolution of silicon phase configuration and Si-Al interface in Sip/Al composites (φ(Si)=65%) fabricated by squeeze casting technology during high temperature heat-treatment were investigated. The microstructure was observed by optical microscopy, transmission electron microscopy and high resolution electron microscopy. The results show that the silicon phase configuration becomes round, annular and reticular. The configuration evolution is based on the diffusion of silicon atoms, and the process is comprised of three parts as follows: the irregular corners and edges of silicon particles are dissolved, the silicon atoms dissolved from smaller particles diffuse to larger particles, because of the concentration gradient exists between them, and the larger particles grow up, then the grown particles connect with each other, and form network configuration silicon. The Si-Al interface of composites is straight and free from interfacial reaction products, lots of dislocations are found. But after the heat treatment, the interface becomes smooth and dislocations disappear. Around the interfaces, fine silicon phases precipitate. ⊙

Key words: Sip/Al composites; silicon phase; configuration evolution; interface; precipitated phase

高体积分数Sip/Al复合材料作为一种新型的电子封装材料,是国内外当前电子封装材料领域的研究热点[1?4]。该材料具有许多优点,其制备条件简单,可采用多种方法制备;热物理性能优异且可调;机械加工性能较优;具有良好的封装工艺性能。此外,其原料成本低廉,来源广泛,其制品使用后还可以回收利用,是一种新型的环保材料[5?8]。针对该材料的微观组织结构研究表明,无论采用喷射沉积法[2, 5?6],粉末冶金法[9],还是浸渗法[7, 10?11]制备的材料中均存在局部细小球状硅相或大面积网络结构状硅相。硅相形貌对材料的热物理性能的影响很复杂,球状硅相能改善材料的导热性能,但增加了材料的热膨胀系数;网络结构状硅相使材料的热膨胀系数降低,但同时也使导热性能下降[3, 9, 12?13]。目前对高体积分数Sip/Al复合材料中硅相形貌转变的形成原因、形成过程和微观机制的研究很有限,仅少量研究初步认为是奥斯特瓦尔德(Ostward)熟化机制[11?13]。本文作者以采用挤压铸造法制备的高体积分数Sip/Al复合材料为研究对象,设计一系列不同条件下的高温真空热处理工艺,研究该复合材料中Si-Al界面和硅相形貌的演变过程。

1 材料与方法

实验材料为采用挤压铸造法制备的高体积分数Sip/Al复合材料[3],其中增强体Si颗粒的体积分数为65%,名义尺寸为10 μm,基体合金为4032Al,其名义化学成分如表1所列。

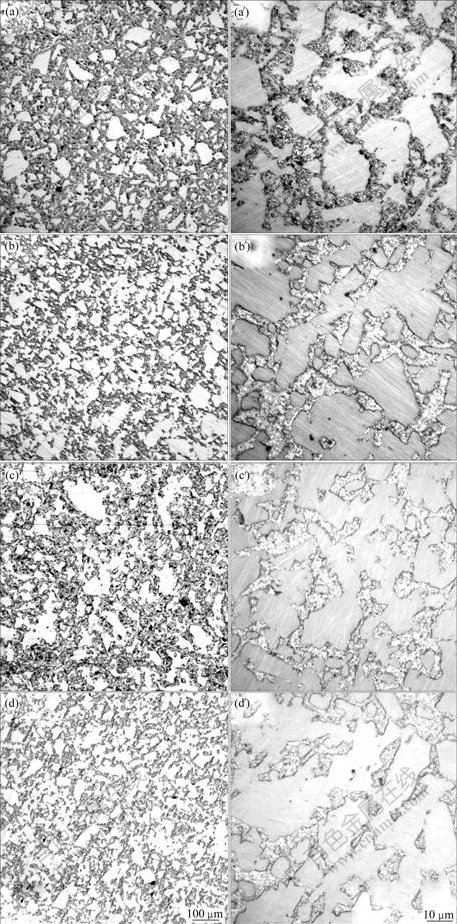

表1 4032Al合金的名义化学成分

Table 1 Nominal chemical composition of 4023Al alloy (mass fraction, %)

为防止基体铝合金的氧化,铸态Sip/Al复合材料在真空下进行高温热处理。热处理工艺如表2所列,升温速率均为30 ℃/min。

表2 铸态Sip/Al复合材料的热处理工艺

Table 2 Heat-treatment processes of as-cast Sip/Al composite

采用ZEISS-40MAX金相显微镜(OM)观察Sip/Al复合材料中硅相形貌的演变;利用PhilipsCM?12型透射电子显微镜(TEM)和JEM?2010F型高分辨透射电镜(HRTEM )观察Si/Al复合材料的界面和微观组织,电镜的加速电压为120和300 kV。TEM分析薄膜样品在Gattan?600离子减薄机上进行,减薄条件为:电压5 kV,电流1 mA。

2 结果与讨论

2.1 复合材料中硅相形貌的演变

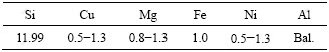

图1所示为分别经工艺1、2、3和4处理后材料的微观组织。

图1 不同热处理工艺后Sip/Al复合材料的显微组织(未腐蚀)

Fig.1 Microstructures of Sip/Al composites unpolished after different heat treatments: (a), (a′) Process 1; (b), (b′) Process 2; (c), (c′) Process 3; (d), (d′) Process 4

对比分析图1中硅相形貌的演变情况可知:图1(a)、(a′)中硅相基本保持不规则的颗粒状,仅有部分颗粒的尖角消失,出现“钝化”现象;图1(b)、(b′)中硅颗粒的边角几乎完全钝化,有部分颗粒开始相互联结;图1(c)、(c′)与图1(d)、(d′)中几乎所有的硅颗粒都已经相互联结,形成具有网络结构的硅相,并且后者形成的网络结构更完整。可见,在相同热处理温度(600 ℃)下,随着热处理时间的增加,材料中不规则颗粒状的硅相逐渐互相联结,最后形成具有网状结构的硅相。

二元Al-Si相图为典型的共晶相图[15],共晶温度为577 ℃,共晶点成分为12.2%Si。室温时Si在Al中几乎不固溶,随着温度的增加,Si在Al中的固溶度逐渐增加,在共晶温度下达到最高,为1.56%;在任何温度下,Al在Si中都几乎不固溶。因此,高温热处理时,Sip/Al复合材料中硅相形貌的演变过程必定是硅相逐步溶解到铝中,并通过扩散使不规则颗粒状的硅相互相联结,最后形成网络状的硅相。

根据Gibbs-Thomas定理[16],对于一个能够形成稀薄固溶体的两相系统,固溶相的尺寸越小,其中每个原子平均占有的界面能越多,因而其化学势越高,相应地,与它处于平衡态的母相中的溶质原子浓度就越高。由Al和Si组成的稀薄固溶体两相系统,在较小尺寸的硅相周围,Si在Al中的浓度较高;而在较大尺寸的硅相周围,Si在Al中的浓度则较低。因此,在浓度梯度的作用下,较小尺寸硅相周围的Si原子向较大尺寸硅相周围扩散并在其表面析出,使得较大硅相逐渐长大,最后较小尺寸硅相逐渐溶解,直至最终消失,而长大的硅相相互接触,联结,形成网状结构。在高温热处理时,高体积分数Sip/Al复合材料中硅相形貌的演变过程可分为3个阶段:第一阶段,不规则形状硅颗粒的尖角处逐渐溶解到铝合金中,发生颗粒的钝化现象;第二阶段,较小硅颗粒周围逐渐溶解在铝合金中的硅在浓度梯度的作用下,通过扩散逐渐在较大硅颗粒周围析出并长大;第三阶段,长大的硅颗粒之间互相接触,联结,形成网络结构。应当指出的是,由于复合材料中各个颗粒周围浓度场的叠加等因素的影响,实际情况要复杂得多。

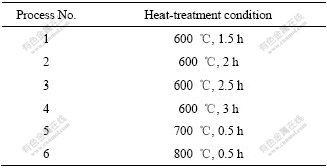

图2所示为复合材料经过表2中各个不同工艺热处理后的典型硅相演变形貌。图2(a)所示为热处理前复合材料中硅相为不规则的颗粒状;图2(b)所示为不规则形状的硅颗粒溶解到铝合金中,发生钝化现象,并且有部分颗粒相互联结;由图2(c)~(h)可以看出,较小颗粒逐渐溶解,较大颗粒逐渐联结,形成网状结构,其中图2(h)中较小颗粒已经完全消失,网状结构开始“粗化”。图2中A、B、C和D处为较小硅颗粒逐渐溶解于铝合金中,形成孤岛状的硅相;E、F、G、H和I处为两个或两个以上颗粒互相联结,形成环状的硅相。

图2 Sip/Al复合材料中Si相的形貌演变

Fig.2 Morphological evolution of Si phase in Sip/Al composites: A, B, C, D—Dissolving silicon particles; E, F, G, H, I—Connecting silicon phases

2.2 Si-Al复合材料中的界面与析出

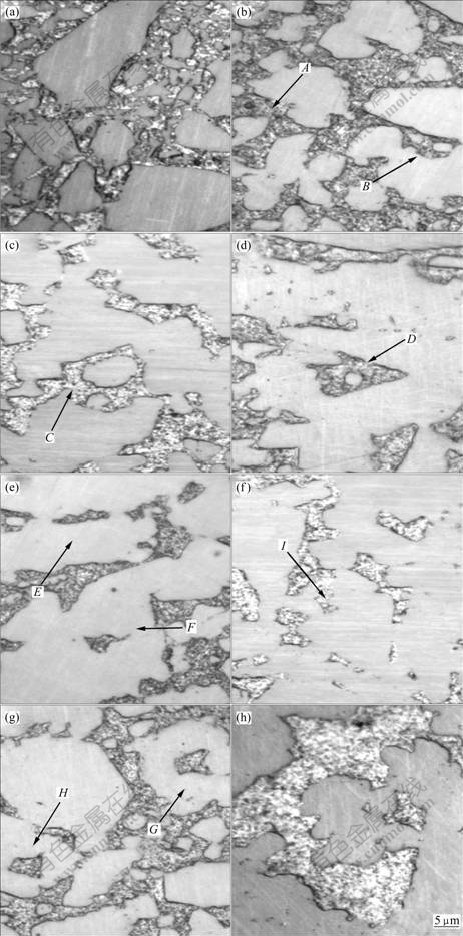

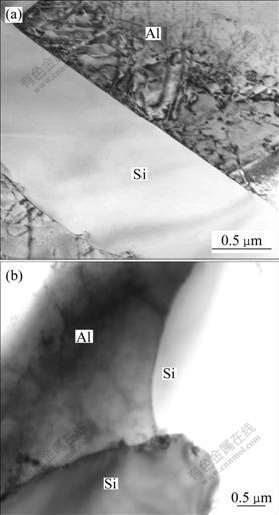

图3所示为Sip/Al复合材料高温热处理前后界面的透射电镜照片。由图3(a)可见,Si-Al界面平直、干净,没有反应物产生,也没有发生颗粒溶解现象;基体合金内部没有发现明显的析出物;界面区的位错密度较高,而且位错多产生于界面处,一端与界面相连,另一端为自由端。由图3(b)可见,Si-Al界面不再平直、干净,而是有一定曲率的平滑界面;界面区的位错非常少。此外,界面处还发现有一些析出物,基体合金内部也明显存在许多细小弥散的析出物。

图3 Sip/Al复合材料高温热处理前后界面的透射电镜照片

Fig.3 TEM micrographs of interfaces in Sip/Al composites before(a) and after(b) heat-treatment

对于采用挤压铸造法制备的Sip/Al复合材料而言,由于制备时间很短[3],增强体Si相来不及溶解,而且虽然基体合金含有少量的Si但不会发生Si原子的长程扩散现象,故界面平直干净。由于铸造过程中产生内应力,所以在界面处存在大量位错。对于进行高温热处理后的复合材料,由于硅颗粒的溶解,铝合金中Si的浓度提高,发生扩散。在热处理的最后阶段(铝合金凝固),增强体附近浓度较大的区域,Si析出产生大块的析出物,基体合金内部Si析出产生许多弥散的析出物。高温热处理后,复合材料中的应力消除,界面区的位错非常少。

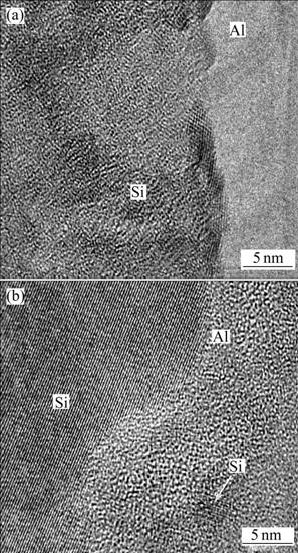

图4所示为Sip/Al复合材料高温热处理前后界面的高分辨电镜照片。由图4(a)可以看出,Si-Al界面呈不规则折线形,说明界面结合不太好,这可能是采用挤压铸造制备Sip/Al复合材料时,由于制备时间很短,Si-Al之间来不及结合造成的。由图4(b)可以看出,Si-Al界面圆润、光滑,Si-Al界面结合良好,这可能是在高温热处理时,Si在铝中能够充分扩散形成圆滑的界面,并与Al充分结合。此外,由图4(b)中还可以观察到硅相在基体铝合金中的存在。

图4 Sip/Al复合材料高温热处理前后界面处的高分辨电镜照片

Fig.4 HREM micrographs of interfaces in Sip/Al composites: (a) Before heat treatment; (b) After heat treatment

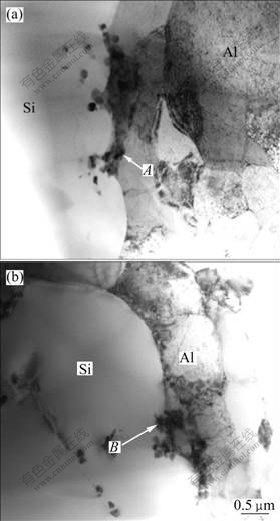

图5所示为Sip/Al复合材料高温热处理后界面处的析出情况。由图5可以看出,在Si-Al界面凹陷处存在硅相的析出(见图5中A和B处),这表明此处可能是尺寸较小的Si相溶解在Al中后,来不及扩散而在随后的冷却凝固过程中析出;也可能是扩散至此处的Si还没有在大尺寸Si相吸附长大,从而在此处析出。由图5(a)中的Si-Al界面可以发现,硅相边界呈现微小的波浪状,此种形貌与金属凝固时凝固前端界面的生长情况很相似,这说明此处硅相处在长大过程中。

图5 Sip/Al复合材料高温热处理后界面处析出物的TEM像

Fig.5 TEM micrographs of precipitation after heat-treatment in Sip/Al composites

3 结论

1) 高温热处理时,高体积分数Sip/Al复合材料中不规则形状的硅颗粒溶解在铝合金基体中,出现圆滑边角的硅相,即“钝化”现象;较小的硅颗粒逐渐溶解,出现“孤岛”状的硅相,最后消失;较大的硅颗粒逐渐长大,最后相互联结形成网状结构硅相。

2) 高体积分数Sip/Al复合材料中硅相形貌的演变过程由Si原子在Al中的扩散控制。较小尺寸的硅相逐渐溶解于铝合金中直至消失,较大硅相逐渐长大,最后互相联结形成网状结构。

3) 铸态Sip/Al复合材料中Si-Al界面平直、干净,没有反应物产生,铝合金内部没有明显的析出物,界面区的位错密度较高,而且位错多产生于界面处,一端与界面相连,另一端为自由端。高温热处理后,Si- Al界面不再平直、干净,而是有一定曲率的平滑界面;界面区的位错非常少。

4) Sip/Al复合材料高温热处理后界面处存在很明显的硅相析出,特别是在Si-Al界面凹陷处存在大量的硅相析出。

REFERENCES

[1] JACOBSON D M. Lightweight electronic packaging technology based on spray formed Si-Al[J]. Powder Metallurgy, 2000, 43(3): 200?206.

[2] HOGG S C, LAMBOURNE A, OGILVY A, GRANT P S. Microstructural characterisation of spray formed Si-30Al for thermal management applications[J]. Scripta Materialia, 2006, 55: 111?114.

[3] 王小锋. 三位网络结构Si-Al复合材料的制备工艺与性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2006.

WANG Xiao-feng. Study on fabrication and properties of three-dimensional network structure Si-Al composites[D]. Harbin: Harbin Institute of Technology, 2006.

[4] 杨伏良, 易丹青, 刘 泓, 张 伟. 高硅铝合金粉末的高温空气氧化预处理工艺[J]. 中国有色金属学报, 2007, 17(7): 1165?1171.

YANG Fu-liang, YI Dan-qing, LIU Hong, ZHANG Wei. Pretreatment technology of high-silicon aluminum alloy powder in high temperature atmosphere oxidation[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1165?1171.

[5] JACOBSON D M, OGILVY A J W. Spray-deposited Al-Si (Osprey CE) Alloys and their properties[J]. Mat.-wiss. u. Werkstofftech, 2003, 34: 381?384.

[6] de OLIVEIRA SANTOS H, SERNA M M, de LIMA N B, COSTA I, ROSSI J L. Crystallographic orientation-spray formed hypereutectic aluminium-silicon alloys[J]. Materials Research, 2005, 8(2): 181?186.

[7] XIU Zi-yang, WU Gao-hui, ZHANG Qiang, SONG Mei-hui. Thermo-physical properties of Sip/LD11 composites for electronic packaging[J]. Trans Nonferrous Met Soc China, 2005, 15(2): 227?230.

[8] ZWEBEN C. Advanced composites and other advanced materials for electronic packaging thermal management[C]// 2001 IMAPS International Symposium on Advanced Packaging Materials. Braselton, GA, USA: IEEE, 2001: 360?365.

[9] 冯 曦, 郑子樵, 李世晨, 杨培勇. 热压法制备Si-Al 电子封装材料及其性能[J]. 稀有金属, 2005, 29(1): 11?15.

FENG Xi, ZHENG Zi-qiao, LI Shi-chen, YANG Pei-yong. Properties of Si-Al electronic packaging materials fabricated by hot pressing[J]. Chinese Journal of Rare Metals, 2005, 29(1): 11?15.

[10] 胡 锐, 朱冠勇, 李金山, 耿兴国, 毕晓勤, 傅恒志. 无压浸渗法制备Al/70vol%Sip复合材料[J]. 材料科学与工艺, 2005, 34(9): 1381?1384.

HU Rui, ZHU Guan-yong, LI jin-shan, GENG Xing-Guo, BI Xiao-Qin, FU Heng-zhi. Preparation of Al/70vol%Sip composites by pressureless infiltration[J]. Materials Science and Technology, 2005, 34(9): 1381?1384.

[11] CHEN Y, CHUNG D D L. Silicon-aluminium network composites fabricated by liquid metal infiltration[J]. Journal of Materials Science, 1994, 29(23): 6069?6075.

[12] CHEN C W. Effects of Sip size and volume faction on properties of Al/Sip composites[J]. Materials Letters, 2002, 2: 334?341.

[13] 林均品, 张 勇, 陈国良. 骨架增强复合材料的微观结构和性能[J]. 材料工程, 2006, 6: 20?21.

LIN Jun-ping, ZHANG Yong, CHEN Guo-liang. Microstructures and properties of skeleton reinforced composite[J]. Materials Engineering, 2006, 6: 20?21.

[14] GUPTA M, LAVERNIA E J. Effect of processing on the microstructural variation and heat-treatment response of a hypereutectic Al-Si alloy[J]. J Mater Proc Technol, 1995, 54: 261?270.

[15] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: William Clowes & Sons Limited, 1976: 368?372.

[16] 冯 端. 金属物理学(第二卷)[M]. 北京: 科学出版社, 2000.

FENG Duan. Metal physics (Volume 2)[M]. Beijing: Science Press, 2000.

收稿日期:2008-05-15;修订日期:2008-09-11

通讯作者:王小锋,博士研究生;电话:0731-8836638;E-mail: 9wangxiaofeng@163.com

(编辑 李向群)