Trans. Nonferrous Met. Soc. China 22(2012) s188-s192

Manufacturing, compressive behaviour and elastic modulus of Ti matrix syntactic foam fabricated by powder metallurgy

XUE Xiao-bing, WANG Li-qiang, WANG Min-min, Lü Wei-jie, ZHANG Di

State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China

Received 23 September 2011; accepted 5 January 2012

Abstract: Ti matrix syntactic foam has potential in the orthopaedic application because of its good biocompatibility, corrosion resistance and varied elastic modulus. Ti matrix syntactic foams embedded with thick-wall ceramic microspheres (CMs) were prepared using a powder metallurgy method. The structure, compressive behaviour and elastic modulus of Ti matrix syntactic foam embedded with thick-wall CMs were analyzed and compared with those embedded with thin-wall CMs. Results show that the compressive strength of Ti matrix syntactic foam increases with the increase of the volume fraction of CMs clearly. However, the strength increase would not increase the elastic moduli obviously which are still similar with those of human bone.

Key words: Ti matrix foam; compressive properties; elastic modulus; powder metallurgy

1 Introduction

Ti has been widely used in orthopaedic and dental applications because of its good biocompatibility and corrosion resistance. Despite the great advantages of Ti obtained, fixation of Ti implanting to the bone remains a problem. The implant loosening has the highest probability to cause the implant failure with the implant period increasing [1-6]. Researches indicated that this loosening was caused by the stress shielding effect, which was a result of the elastic modulus mismatch between implants and human bone. This effect can cause a removal of normal stress from the bone, and promote bone resorption around the implants, thus the bone becomes less dense and weaker [7,8]. Implant material with comparable elastic modulus with human bone can decrease the stress shielding effect [9-11]. Efforts were carried out to develop implant material with porous structure which can decrease the elastic modulus of material [1,12-14]. The controllable elastic modulus and excellent biocompatibility of porous Ti has a huge potential to be applied as implants.

The research of porous Ti had already achieved great success. Manufacturing processes, such as space-holder, replication, bubble generation, freeze casting, rapid prototyping and conversion of porous ceramic precursor to metallic Ti foam, were carried out to manufacture porous Ti [10]. Porous Ti has a comparable elastic modulus with human bone [15]. However, the compressive strength of porous Ti is not sufficient for the human cortical bone [16]. To expand the application of porous Ti, the strength of porous Ti needs to be improved.

A novel material, Ti matrix syntactic foam was manufactured, and the properties were reported in the previous studies [17-19]. Previous studies showed that the strength of ceramic microspheres (CMs) can affect the elastic modulus of Ti matrix syntactic foam obviously. Thin-wall CMs have a low compressive strength and thus part of the CMs was crushed during the compaction procedure. These crushed CMs can result in a undesirable elastic modulus of Ti matrix syntactic foam. In this work, the thick-wall CMs were selected to embed into the Ti matrix instead of the thin-wall CMs. The compressive behaviour was studied and the elastic modulus was examined. The influence of CM to the compressive behaviour of titanium was analyzed and the mechanism between the compressive strength and CM was established. The results were compared with Ti matrix syntactic foam fabricated with thin-wall CMs.

2 Experimental

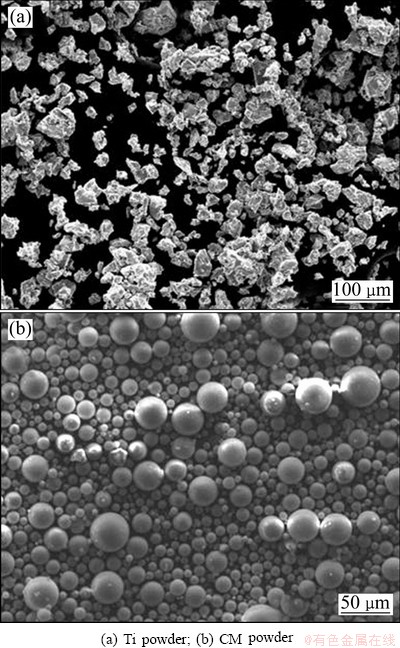

The raw materials used to manufacture Ti matrix syntactic foam samples were 99.4% (mass fraction) pure Ti powder and thick-wall CM powder supplied by 3M China Ltd. Figure 1 shows the morphologies of Ti powders and CM powders. The Ti powder particles have an irregular shape with a nominal average particle size of 30 μm. The CMs have sphere shape. Two particle size ranges of CMs, large one (>25 μm) and small one (<25 μm) were used, as shown in Fig. 1(b). The composition was detected as albite, Na(AlSi3O8), using XRD.

Fig. 1 Morphologies of raw materials

The manufacturing process had already been discussed in Ref. [19]. The Ti powder and CMs were first blended uniformly into a series of mixtures with volume ratio of Ti to CM of 6:4 (specimen S60) and 7:3 (specimen S70), respectively. 450 MPa compaction pressure was selected to achieve the green compact. The compacted preforms were sintered at 1200 °C for 2 h in a vacuum condition with a vacuum of 1×10-4 Pa and then furnace cooled to room temperature. The as-fabricated Ti matrix syntactic foam samples had a cylindrical shape with a diameter of 30 mm and a height of 25 mm.

The Ti matrix syntactic foam samples were first cut into cylinder specimens with a diameter of 8 mm and a height of 12 mm using a popular wire cut electrical discharge machine (WEDM). Static compression tests were conducted on a universal testing machine (Zwick/Roell Z020) with a cross-head speed of 0.5 mm/min. For each set of samples produced under the same conditions, five specimens were prepared and tested.

During each compression test, a series of unloading and reloading routines were carried out at the stresses of 30, 60, 90 and 120 MPa to determine the elastic modulus values. The gradients of the unloading curves of each sample were corrected using stiffness of testing machine. The results were averaged to give the elastic modulus of the sample.

3 Results and discussion

3.1 Structure and composition

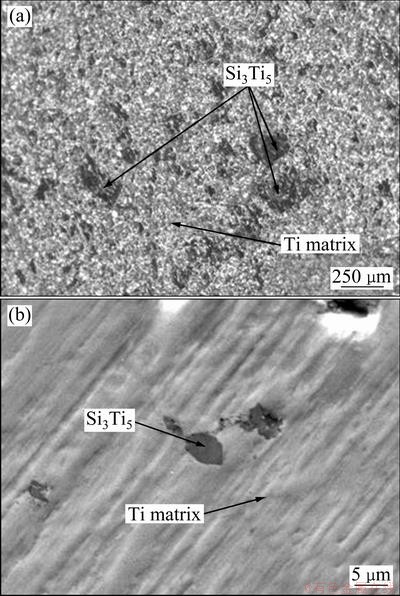

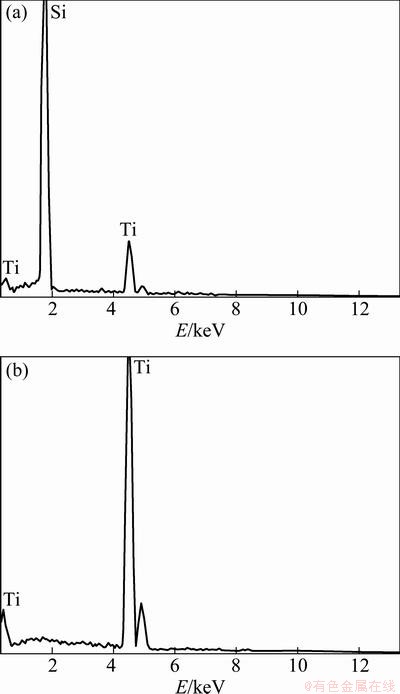

Figure 2 exhibits the optical and SEM micrographs of the surface of the Ti matrix syntactic foam samples. The surface has a homogeneous structure with a few amounts of black spot, as shown in Fig. 2(a). The dimensions of these spots vary from 2 μm to 200 μm. SEM analysis shows these black spots have a fine interface with the Ti matrix, as shown in Fig. 2(b). EDX results indicate that these black spots contain two elements: Si and Ti, as shown in Fig. 3. Figure 4 shows the XRD results of the Ti matrix syntactic foam sample. XRD results indicate that the samples manufactured by this process contain two phases: Ti and titanium silicide (Si3Ti5). It is reasonable to believe that the CMs has a reaction with Ti matrix during the sintering procedure. The reaction product is Si3Ti5. Because of this reaction, no obvious defect was observed on the interface between Ti and CMs. The dimension of Si3Ti5 is determined by the dimension of CMs.

Fig. 2 Optical (a) and SEM (b) micrographs of surface of Ti matrix syntactic foam

Fig. 3 EDX spectra of Si3Ti5 (a) and Ti matrix (b)

Fig. 4 Typical XRD spectrum of Ti matrix syntactic foam

3.2 Compressive behaviour

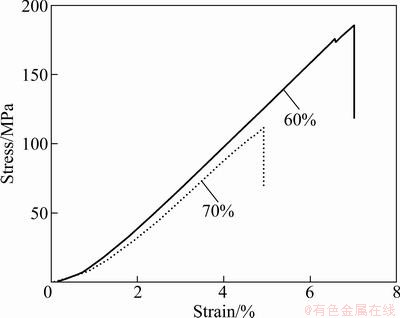

Figure 5 exhibits typical compressive behaviour of Ti matrix syntactic foam with Ti powder of 60% and 70% (volume fraction). Ti matrix syntactic foam exhibited obvious brittle performance during the compression test. This is because the embedded CMs result in the development of shear fracture during the compression. The embedded CMs have a high compressive strength and increase the compressive strength of Ti matrix syntactic foam. As a consequence, the increase of the volume fraction of embedded CMs can increase the compressive strength of Ti matrix syntactic foam significantly. Moreover, compared with the Ti matrix syntactic foam fabricated with thin-wall CMs, these Ti matrix syntactic foams fabricated with thick-wall CMs have a better ability of strength control.

Figure 6 shows the typical unloading and reloading stress—strain curves of Ti matrix syntactic foam with Ti of 60% (volume fraction) and 70%. Generally, the unloading and reloading curves develop following the initial loading curve approximately. The stress—strain curve of S60 has a lower plastic deformation than S70 when the unloading curve reach the zero stress point. This is because S60 has a higher CM volume fraction than S70, therefore, the elastic deformation occupied the main position of the S60 deformation during the compression. This phenomenon also indicates that the deformation of Ti matrix syntactic foam can be divided into two parts before the failure: pure elastic deformation of CMs and the elastic and plastic deformation of Ti matrix. The increase of the volume fraction of CM can increase the elastic deformation ability of Ti matrix syntactic foam.

Fig. 5 Compressive behaviour of Ti matrix syntactic foam with Ti powder volume fraction of 60% and 70%

Fig. 6 Unloading and reloading stress—strain curves of Ti matrix syntactic foam with Ti powder of 60% (a) and 70% (b) (volume fraction)

3.3 Compressive properties and elastic modulus

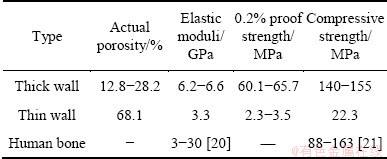

Table 1 lists the elastic modulus and compressive properties of Ti matrix syntactic foam. The results were corrected using the stiffness of Zwick testing machine. The properties of Ti matrix syntactic foam fabricated with thin-wall CMs are listed, too. Due to the higher compressive strength of thick-wall CMs, the green density of the compact is higher than the one fabricated with thin-wall CMs. As a consequence, the compressive strength of Ti matrix syntactic foam fabricated with thick-wall CMs is much higher than that fabricated with thin-wall CMs, and it is comparable to the human bone. Moreover, this increase didn’t cause a significant increase of the elastic modulus. The results show that the elastic modulus of the Ti matrix syntactic foam fabricated with thick-wall CMs (~6 GPa) is slightly higher than that fabricated with thin wall CMs (~3 GPa), but still close to the human bone.

Table 1 Porosity, elastic modulus and compressive properties of Ti matrix syntactic foam

4 Conclusions

1) Ti matrix syntactic foam embedded with CMs (thick wall and thin wall) was fabricated using a powder metallurgy process.

2) The actual porosity of the Ti matrix syntactic foam fabricated with thick wall was less than those fabricated with thin-wall CMs. Moreover, as a result of the high compressive strength of the thick wall CMs, the increase of the volume fraction of thick-wall CMs can increase the compressive strength of Ti matrix syntactic foam obviously.

3) There was an reaction of the interface between the Ti matrix and CMs during the sintering procedure. This reaction product, Ti silicide, which has strong compressive strength, can decrease the defects at the interface between Ti matrix and CMs, and increase the compressive strength of Ti matrix syntactic foam, too.

4) The elastic modulus of Ti matrix syntactic foam embedded with thick-wall CMs was slightly higher than that fabricated with thin-wall CMs, but still close to the human bone.

References

[1] PARK J, LAKES R S. Biomaterials: An introduction [M]. 3rd ed. New York: Springer, 2007: 204.

[2] THOMAS I. Mechanical properties of open-pore titanium foam [J]. Journal of Biomedical Materials Research, Part A, 2007, 81(4): 964-970.

[3] FILIP P. Titanium-nickel shape memory alloys in medical applications in titanium in medicine: material science, surface science, engineering, biological responses and medical applications [M]. Berlin: Springer, 2001: 54-90.

[4] CHEN H B, GAO W. An overview on biomedical porous titanium and its alloys [J]. Southern Metals, 2009, 169(4): 26-28.

[5] CUI Y P, HE G Q, LIU X S. Development of biomedical porous NiTi shape memory alloys [J]. Shanghai Metals, 2006, 28(6): 37-45.

[6] ZHANG Y, TANG H P, LI Z F, XIANG C S. Progress in titanium alloy foam [J]. Rare Metal Materials and Engineering, 2010, 39(1): 476-481.

[7] OH I H, NOMURA N, HANADA S. Microstructures and mechanical properties of porous titanium compacts prepared by powder sintering [J]. Materials Transactions, 2002, 43(3): 443-446.

[8] PERREN S M, POHLER O E M, SCHNEIDER E. Titanium as implant material for osteosynthesis applications, in titanium in medicine: material science, surface science, engineering, biological responses and medical applications [M]. Berlin: Springer, 2001: 783-825.

[9] WEN C E, MABUCHI M, YAMADA Y, SHIMOJIMA K, CHINO Y, ASAHINA T. Processing of biocompatible porous Ti and Mg [J]. Scripta Materialia, 2001, 45(10): 1147-1153.

[10] SINGH R, LEE PD, DASHWOOD R J, LINDLEY T C. Titanium foams for biomedical applications: A review [J]. Materials Technology: Advanced Performance Materials, 2010, 25(3-4): 127-136.

[11] RYAN G, PANDIT A, APATSIDIS D P. Fabrication methods of porous metals for use in orthopaedic applications [J]. Biomaterials, 2006, 27(13): 2651-2670.

[12] ESEN Z, BOR  Processing of titanium foams using magnesium spacer particles [J]. Scripta Materialia, 2007, 56(5): 341-344.

Processing of titanium foams using magnesium spacer particles [J]. Scripta Materialia, 2007, 56(5): 341-344.

[13] IMWINKELRIED T. Mechanical properties of open-pore titanium foam [J]. Journal of Biomedical Materials Research Part A, 2007, 81(4): 964-970.

[14] de VASCONCELLOS L M, LEITE D D, NASCIMENTO F O, de VASCONCELLOS L G, GRA A M L, CARVALHO Y R, CAIRO C A. Porous titanium for biomedical applications: an experimental study on rabbits [J]. CORD Conference Proceedings, 2010, 15(2): 407-412.

[15] OH I H, NOMURA N, MASAHASHI N, HANADA S. Mechanical properties of porous titanium compacts prepared by powder sintering [J]. Scripta Materialia, 2003, 49(12): 1197-1202.

[16] ZHAO Y Y. TAO X F, XUE X B. Manufacture and mechanical properties of metal matrix syntactic foams [C]//Materials Science and Technology (MS&T). Pittsburgh: MS&T'08, 2008: 2607-2615.

[17] XUE X B, ZHAO Y Y, KEARNS V, WILLIAMS R L, JONES D. Mechanical and biological properties of titanium syntactic foams [C]//2010 TMS Annual Meeting & Exhibition. Washington State Convention Center: TMS 2010 Annual Meeting & Exhibition, 2010: 129-135.

[18] XUE X B, ZHAO Y. Ti matrix syntactic foam fabricated by powder metallurgy: Particle breakage and elastic modulus [J]. Journal of the Minerals, Metals and Mateirals Society, 2011, 63(2): 43-47.

[19] YANG S, LEONG K F, DU Z, CHUA C K. The design of scaffolds for use in tissue engineering. part ii. rapid prototyping techniques [J]. Tissue Engineering, 2002, 8(1): 1-11.

[20] ASCENZI A, BONUCCI E. The compressive properties of single osteons [J]. The Anatomical Record, 1968, 161(3): 377-391.

粉末冶金工艺制备的钛基复合泡沫材料的压缩性能和弹性模量

薛晓冰,王立强,王敏敏,吕维洁,张 荻

上海交通大学 金属基复合材料国家重点实验室,上海 200240

摘 要:钛基复合泡沫材料由于其优异的生物相容性、抗腐蚀性以及可改的弹性模量,具有极大的生物医用潜力。采用粉末冶金工艺制备嵌入厚壁陶瓷微珠的钛基复合泡沫材料。分析和测试这种钛基复合泡沫材料的微观结构、压缩性能以及弹性模量。结果表明:厚壁陶瓷微珠能够显著提高材料的抗压强度;提高厚壁陶瓷微珠的体积分数,能够使材料的抗压强度获得极大的提高,同时,这种强度的提高并没有引起弹性模量的显著提高。该材料的弹性模量仍然与人体骨骼相近。

关键词:钛基复合泡沫;压缩性能;弹性模量;粉末冶金

(Edited by DENG Lü-xiang)

Foundation item: Project (AE0500006) supported by the Postdoctoral Research Fund of Shanghai Jiao Tong University, China; Project (2012CB619600) supported by the 973 Program of Ministry of Science and Technology of China; Project (12XD1402800) supported by the Academic Leader Program of Shanghai Science and Technology Committee, China; Project (10SG15) supported by the Dawn Program of Shanghai Education Commission, China

Corresponding author: Lü Wei-jie; Tel: +86-21-34202641; E-mail: luweijie@sjtu.edu.cn