DOI:10.19476/j.ysxb.1004.0609.2018.06.02

热处理工艺对Mg-6Zn-3Al镁合金显微组织和力学性能的影响

张玉1,黄晓锋1, 2,郭峰1,李元东1, 2,毕广利1, 2,马颖1, 2,郝远1, 2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:通过金属型铸造制备新型Mg-6Zn-3Al(ZA63,质量分数,%)镁合金,并利用光镜(OM)、扫描电镜(SEM)、透射电镜(TEM)、X射线衍射仪(XRD)和力学性能测试研究ZA63合金在铸态、固溶和时效处理后显微组织和力学性能的变化规律。结果表明:合金铸态组织主要由基体α-Mg、晶界处呈连续或半连续分布的(α-Mg+Mg2Zn3+Mg7Zn3+Mg32(Al,Zn)49)共晶和晶内孤立的颗粒相组成。合金在350 ℃固溶12~36 h时,随着时间延长,固溶效果逐渐增强,且在28 h时获得了较好的组织和241 MPa的抗拉强度及11.12%的伸长率。随后在180 ℃时效 6~72 h后,合金的抗拉强度进一步提高,力学性能随保温时间延长呈先增加后减小的趋势,其中时效24 h时同时出现抗拉强度、伸长率和硬度的峰值298 MPa、9.78%和96.3 HV,比铸态的214 MPa、8.54%、62.2 HV分别提高39.25%、14.52%和54.82%。180 ℃时效24 h后,析出相的主要形态有板条状和短棒状。

关键词:Mg-6Zn-3Al镁合金;固溶处理;时效处理;显微组织;力学性能;析出相形态

文章编号:1004-0609(2018)-06-1092-09 中图分类号:TG146.2 文献标志码:A

镁合金是目前工业上可应用的最轻金属结构材料,且以具有资源丰富、密度低、比强度和比刚度高、良好的阻尼减震性及易切削加工等优点广泛应用于航天航空、交通运输、电子通讯工业等领域[1-5]。目前,最常用的镁合金系是以Mg-Al和Mg-Zn为基的Mg-Al-Zn和Mg-Zn-Zr三元系,如AM50A、AM60B、AZ91、ZK31和ZK60等合金[6-7]。然而这些合金塑性虽好,却室温和高温下强度较差[8],因此很大程度上制约了在工业生产中的广泛应用。此外,根据研究Mg-Zn二元合金由于晶粒粗大、结晶温度范围宽、热裂倾向和显微疏松严重、力学性能低下,通常采用合金化来改善其组织和力学性能[9]。有研究报道[10-11],可以通过合金元素的添加来实现镁合金晶粒细化和组织改善,进而提高力学性能。所以,最近几年新型镁合金的研究成为热点。铝(Al)是一种熔点低、价格低廉、有助于改善Mg-Zn合金的铸造性能的合金元素[12]。近年来已开发的新型Mg-Zn-Al系合金有ZA62和ZA102[13-14]等。这些新型的Mg-Zn-Al系合金与广泛商业化应用的AZ91和AM60合金相比,具有优良的铸造性能和耐热性能,且成本低廉,显示出了良好的发展潜力和应用前景[15]。镁合金除了通过添加合金强化外,镁合金的热处理强化及其机理也是镁合金研究的重要方向之一。通常镁合金的强化有固溶强化、沉淀析出强化、弥散强化、细晶强化等。而其中沉淀析出强化是镁合金强化的一个重要机制[16]。众所周知,一个部件的性能是由其显微组织决定,显微组织又由加工工艺和随后的热处理所决定[17]。根据一些新型Mg-Zn-Al合金的研究,如ZA75[18]和ZA84[19]是典型的可热处理强化型合金且通过热处理后,相比其铸态的性能有了明显提高。因此,基于上述关于新型Mg-Zn-Al合金的报道,本文作者在Mg-6Zn基上通过合理的合金化获得了一种新型Mg-6Zn-3Al(ZA63)镁合金,并以其合金的固溶和时效处理工艺优化为目标,研究其铸态组织和固溶、时效处理对其合金组织和力学性能的影响规律,优化出较佳的固溶和时效处理工艺,同时旨在开发一种力学性能较高的新型合金,为研究新型Mg-Zn-Al镁合金提供参考,同时为后期实验做准备。

1 实验

制备实验ZA63合金所用的原材料为纯镁锭 (>99.99%),纯锌锭(>99.999%)和纯铝锭(>99.99%)。所用合金在熔炼之前用钢刷磨掉表面的油污和氧化层以减少熔炼杂质并大致预热至200 ℃烘干待用,随后放入钢制坩埚中在SG2-7.7kW井式电阻炉中进行熔炼。熔炼时,先将钢制坩埚预热至200 ℃,然后在里外刷上涂料并加入镁锭,用RJ-2熔剂和Ar气氛保护熔体以防止熔体的氧化和燃烧。当Mg锭熔化后于680 ℃加入Zn和Al锭,随后熔体升至750 ℃并保温20 min使合金元素趋于均匀。当温度降至730 ℃时,2%(实验合金的质量分数)的C2Cl6通过人工搅拌加入到熔体中以精炼除渣、除气。精炼完后迅速撇净熔体表面的浮渣并静止保温20 min。当熔体温度降至710 ℃时经扒渣后,将其浇注于已预热至200 ℃左右的金属铸型中获得所需的铸锭,待其冷却凝固后取样研究组织和力学性能。

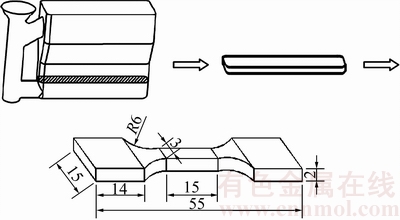

将获得的棒状和板状铸锭用线切割分别加工成 d 15 mm×20 mm的圆柱状和拉伸试样,拉伸试样取样过程如图1所示。根据文献[14, 20]和Mg-Zn二元相图,制定实验合金固溶工艺为:在350 ℃下分别保温12、20、28和36 h,然后用冷水水淬。随后经350 ℃固溶28 h后的试样在180 ℃时效6、12、24、48、60和72 h,保温结束后出炉空冷。固溶和时效处理均在箱式电阻炉(温度误差±2 ℃)中进行。为了避免试样被氧化,固溶时用硫粉对其进行覆盖保护,时效时加热介质为甲基硅油。铸态试样经磨光和抛光后用4%硝酸酒精侵蚀,而固溶和时效后的试样经磨光和抛光后用试剂(2.5 mL醋酸+45 mL乙醇+5 mL蒸馏水+2.75 g苦味酸)侵蚀。显微组织采用MeF-3光学显微镜(OM)和场发射扫描电镜(SEM)表征。在X射线衍射仪(D/max-2400)进行合金的物相确定,Cu靶、扫描速度5 (°)/min、扫描角度10°~90°。采用HvT-1000A型显微硬度计上进行硬度测试,载荷0.98 N,保持时间15 s,每个试样在晶粒内测量10次并取平均值。TEM试样先经手工磨至70~80 μm后,冲压为d 3 mm的圆片,最后利用离子减薄仪制得并在透射电镜上进行分析。合金室温拉伸测试在WDW-100D万能试验机上进行,拉伸速率为1 mm/s,每组3个试样重复进行,取其平均值作为实验结果。拉伸断口也在SEM上进行观察分析。

图1 坯锭和拉伸试样

Fig. 1 Schematic diagram for ingot and dimension of tensile test sample (unit: mm)

2 结果与讨论

2.1 铸态组织

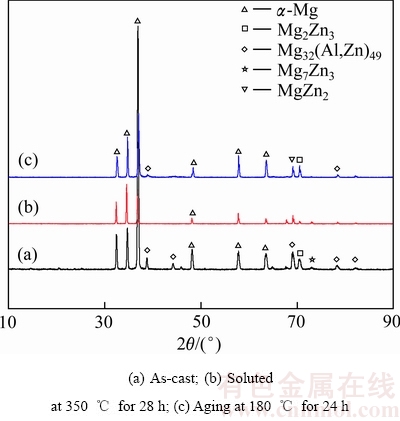

图2所示为ZA63合金在铸态,固溶和时效处理下的XRD谱。由图2(a)可看出,铸态合金主要由α-Mg、Mg2Zn3、Mg7Zn3和Mg32(Al,Zn)49相组成。根据存在的报道[21],Mg32(Al,Zn)49属于体心晶体结构(a=1.416 nm)。由图2(b)可知,合金经过350 ℃固溶28 h后,固溶体的衍射峰没有变化,第二相的衍射峰显著减弱,说明固溶处理后绝大部分非平衡共晶组织溶入基体中。合金经过180 ℃时效24 h后,与铸态和固溶态相比,有Mg32(Al,Zn)49和MgZn2相生成。根据文献[22],MgZn2属于底心单斜晶体结(a=2.596 nm, b=1.428 nm, c=0.524 nm, γ=102.5°),它是Mg-Zn基合金的主要强化相。此外,也有Mg2Zn3相生成,其强化作用较小。

图2 ZA63合金的XRD谱

Fig. 2 XRD patterns of ZA63 alloy

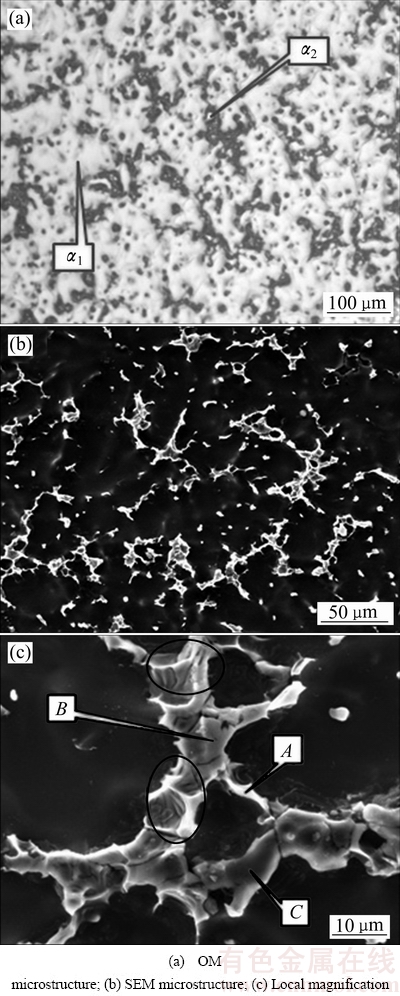

图3所示分别为ZA63合金铸态的OM和SEM显微组织。由图3(a)看出,合金铸态组织主要由白色的基体α-Mg和黑色的(α-Mg+Mg2Zn3+Mg7Zn3+ Mg32(Al,Zn)49)共晶相组成。基体整体呈典型的枝晶组织形貌,这是由于在凝固过程中,结晶的晶粒逐渐长大,并向枝晶组织发展,当枝晶长大到一定程度时,相邻枝晶的一次枝晶臂或二次枝晶臂相互搭接,最后形成互连的枝晶组织。同时看到,其中α-Mg有两种形态:一种为粗大的枝晶形态(α1-Mg),另外一种以小颗粒的形态存在(α2-Mg)。由图3(b)看出,大部分共晶化合物以连续粗大网状分布于晶界处,同时还有一定数量的以孤岛状和颗粒状的粒子分布于基体中。此外,整个组织分布存在明显的偏析现象。这主要归于在非平衡凝固过程中,由于溶质原子的再分配使初生α-Mg中的合金元素来不及扩散,致使合金元素在未凝固的液相中富集,表现为严重的枝晶偏析[23]。从图3(c)可看出,合金的共晶相由呈白色(A点)、灰色(B点)和浅黑色(C点)的共晶化合物组成,整个形态以富集的骨骼状存在。此外,在共晶化合物的局部区域有明显的层状结构产生(椭圆区域)。这主要是由于在非平衡凝固过程中形成了溶质富集和贫乏区域,溶质富集区的标准电极电位高于溶质贫乏区的标准电极电位,故溶质富集区形成了凸起[24]。

图3 ZA63合金的铸态光学和扫描显微组织

Fig. 3 Micrographs of as-cast ZA63 alloy

2.2 热处理对显微组织的影响

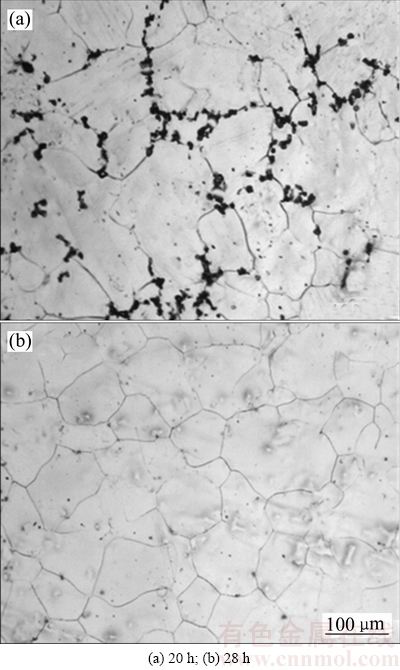

固溶处理是在合金共晶温度范围附近保温以促进共晶化合物的溶解、枝晶偏析的消除和提高基体的过饱和度,为合金时效时强化相的析出做准备。图4所示为ZA63合金在350 ℃保温不同时间后的显微组织。由图4看出,相比铸态组织(见图3(a)), 随着保温时间增加,α-Mg晶粒形貌、第二相的形态和数量都发生了显著变化。经12 h固溶后,晶界处仍有大量第二相粒子残留且偏析现象仍然比较严重。这主要是由于固溶时间较短,晶界处的合金元素没有完全回溶到基体中。当保温时间增加至20 h时(见图4(a)),相比保温12 h的,晶界处的共晶化合物和枝晶偏析程度进一步减少。当固溶时间达到28 h后,如图4(b)所示,共晶的形态由初始粗大网状完全演变为非连续细小孤立的颗粒状,同时分布于晶界处的非平衡凝固组织明显减少,且变得纤细。说明此工艺下合金中的第二相已发生了大量溶解。另外,枝晶间的偏析完全消除,合金组元分布更加均匀,枝晶组织形貌完全消除,说明同一温度下适当延长保温时间能有效促进溶质原子的溶解和扩散。当继续延长保温时间到36 h后,相比保温28 h的, 第二相的演变差别不大,然而有晶粒明显的长大倾向,这是由于随着固溶时间延长,对晶界有钉扎作用的析出相不断回溶,晶界不断迁移,晶粒相互吞并长大。综合图4可看出,当保温时间较短时,晶界和枝晶间隙处的非平衡凝固组织固溶不充分,需要更长的时间达到固溶效果;当额外增加保温时间后,晶粒有长大现象。因此,结合实验结果,ZA63合金的固溶效果在350 ℃固溶28 h时较佳。

图4 ZA63合金在350 ℃固溶不同时间后的显微组织

Fig. 4 Microstructures of ZA63 alloy after solution at 350 ℃ for different time

2.3 热处理对力学性能的影响

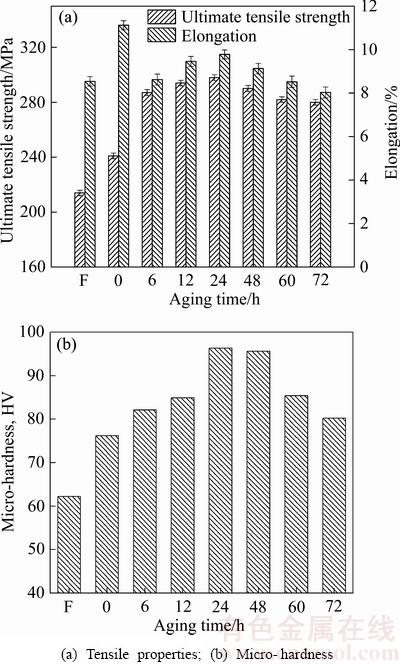

由合金的“成分-热处理-组织-性能”关系可知,显微组织在决定合金性能上扮演着重要角色。图5(a)和(b)所示分别是合金在180 ℃下时效时间对合金拉伸性能和显微硬度的影响曲线图。从图5(a)看出,合金经固溶后力学性能显著提高。这是由于Zn和Al元素固溶到基体α-Mg后,合金的位错密度增大,基体的晶格发生畸变,畸变产生的应力场与位错周围的弹性应力场交互作用,使溶质原子聚集到位错线附近,形成“气团”,导致位错运动阻力增大,从而使合金强化[25]。固溶体中各元素的固溶强化作用可用公式表达[26]:

(1)

(1)

式中:c为溶质浓度;F为位错摆脱溶质原子的钉扎所需要的临界力;b为溶质层厚度;G为溶质原子弹性模量。由上式可见,固溶强化效果会随着固溶体中溶质浓度的增加而提高。同时从图5(a)看到,相比铸态和固溶态的抗拉强度,时效后合金的抗拉强度进一步显著提高,并随时间延长呈先增加后减小的趋势。合金在保温前期(6~24 h),抗拉强度呈上升的趋势且在保温24 h时达到了峰值298 MPa,分别比铸态和最佳固溶态的增加了84 MPa和57 MPa。这是由于合金经固溶处理水淬时冷却速度很大,能够保存高温时的过饱和空位,在低温时效时,这些空位仍有迁移性且空位迁移的激活能和G.P.区形成的激活能相近,有利于G.P.区的形成[27]。从能量和晶粒间位向的角度考虑,G.P.区和过渡相与基体的界面为共格界面,界面能和形核功较低,有利于G.P.区和过渡相的孕育形核和生长,进而产生显著强化合金的作用。此外,合金固溶后基体处于过饱和状态,而晶界处于贫溶质状态且原子错配度较大,加之各种晶体缺陷远高于晶粒内部的,存在着成分起伏和溶质原子浓度梯度。在这些有利于强化相析出条件下,由于Al在Mg中的固溶度高于Zn,故合金时效时,Zn原子将率先从基体中析出,发生原子团簇,紧接着发生Al原子以及Zn和Al共同团簇形成G.P.区并逐渐转变成沿棱面析出并与基面垂直的棒状亚稳MgZn2相。该相对基面滑移有着较强的阻碍作用[28],在拉伸过程中阻碍了裂纹的萌生与传播,进而使合金的强度明显提高。在保温后期(24~72 h),抗拉强度呈下降的趋势,这主要由于随保温时间增加,脱溶相逐渐减少并发生粗化。如果定义初始基体过饱和相为α′,基体平衡相为α相,则在稳定相β相的周围就形成了一个从母相α′相分解生成平衡相α相和β相的反应界面。这将使 稳定相与基体的界面增加,进而整个体系中存在着大量的界面能。基于整个体系要处于热力学上的稳定状态要求,势必界面能要降低,界面能的降低就成为脱溶相粗化的驱动力[27]。微观上表现为析出平衡相发生粗化和晶粒长大,结果表现为失去沉淀弥散强化效果。此外,在后续时效过程中形成的稳定相由于与基体呈非共格关系,结合力较差,在拉伸变形过程中很容易与基体脱落[29],进而导致裂纹在该处萌生并沿晶界迅速扩展。同时看到,相比最佳固溶工艺(350 ℃,28 h)的伸长率11.12%,时效后的伸长率有所降低并随时间延长呈先增加后减小的趋势。在保温前期(6~24 h),伸长率呈上升的趋势且在保温24 h时达到了最大值9.78%,相比铸态的提高了14.52%。在保温后期(24~72 h),伸长率呈下降趋势。这主要是保温后期由于时间过长,析出相粒子长大,Orowan强化机制减弱[30],时效处理到了过时效阶段,随之强化效果也会降低。众所周知,Mg-Zn系合金具有明显的时效硬化特性[31]。由图5(b)可知,合金的显微硬度随时效时间的延长依次经历欠时效、峰时效和过时效3个阶段。在保温前期(0~12 h),硬度随时间的延长增加缓慢。这是由于脱溶相处于形核孕育期,时效硬化效应弱小。在保温中期(12~24 h),硬度迅速增加且在24 h时达到了峰值96.3 HV,随后随时间延长呈减小的规律,即合金进入过时效阶段。显微硬度的变化主要归于:随时效时间的增加,过饱和固溶体中溶质原子的脱溶量逐渐增加,并在基体晶界处孕育形核,析出细小的强化相引起共格变形,点阵严重畸变,对位错运动的阻碍更大,进而强化晶界使合金的硬度增加。硬度达到峰值后,在后续的时效过程中,由于原子团簇或G.P.区不断生成并逐渐长大,可作为过渡相的形核基底,进而不断的有过渡相生成,同时这些过渡相向稳定相转变。由于中间相和稳定相与基体分别呈半共格和非共格关系,位错在析出相质点周围形成位错环所需应力小于切割质点所需应力,位错与析出相之间的交互作用发生改变,Orowan绕过机制开始起作用,致使合金的硬化效应减弱[32]。此外,随时效时间延长,由于析出强化相的形核长大要依赖于晶内溶质原子的长程和短程扩散,使固溶体中的溶质浓度趋于贫化,这也是硬度降低的一个原因。

图5 时效时间对ZA63合金力学性能的影响

Fig. 5 Effects of aging time on mechanical properties of investigated ZA63 alloy

2.4 SEM和TEM分析

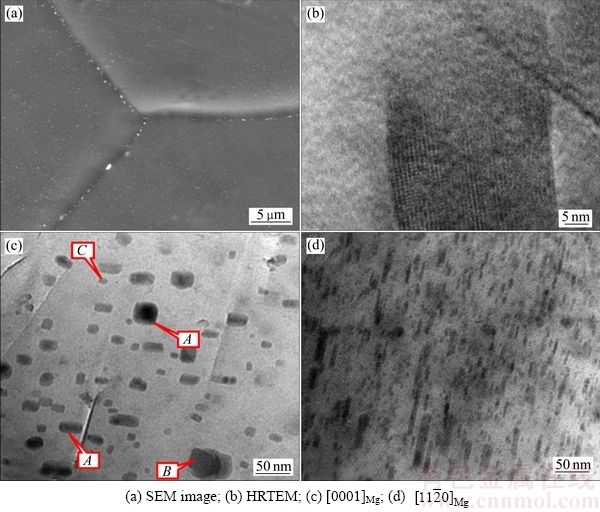

众所周知,在时效过程中,过饱和固溶体的脱溶是一个原子扩散复杂的过程,通常为G.P.区→过渡相→平衡相。在脱溶初期,合金中主要析出大量的原子团簇或者G.P.区,这些组织是有序的溶质原子富集集团,它们保持基体的结构,与基体完全共格,界面能较小,常产生较大的弹性应变。为了进一步确定合金在峰时效态的显微组织精细特征,用SEM和TEM进行了表征。图6所示分别为ZA63合金在峰时效态(180 ℃,24 h)的SEM和TEM像。由图6(a)看出,有明显的晶界析出并在晶界处有白色的颗粒沉淀相析出。这主要是由于合金固溶后处于不稳定状态,在时效过程中这种不稳定的状态成为析出沉淀相的驱动力,使第二相粒子在晶界处孕育形核并析出。从TEM高分辨图看到,沿晶界有长方形的沉淀相析出,这可能是中间相的横截面或者是大量原子团簇的G.P.区(见图6(b))。图6(c)和(d)所示为沉淀相的明场像,由图6(c)看出,合金中存在大量衬度明显、形态各异且尺寸不等的析出相,这些相的形态主要有3种:方型状(A点)、大颗粒状(B点)和小颗粒状(C点)。从图6(d)能够看到基体中有呈短棒状和板条状的相析出且几乎沿同一方向排布。

图6 ZA63合金在180 ℃时效24 h后的显微组织

Fig. 6 Microstructures of ZA63 alloy aged at 180 ℃ for 24 h

图7 ZA63合金拉伸断口形貌

Fig. 7 Micrographs of tensile fracture surface for investigated ZA63 alloy before and after heat treatment

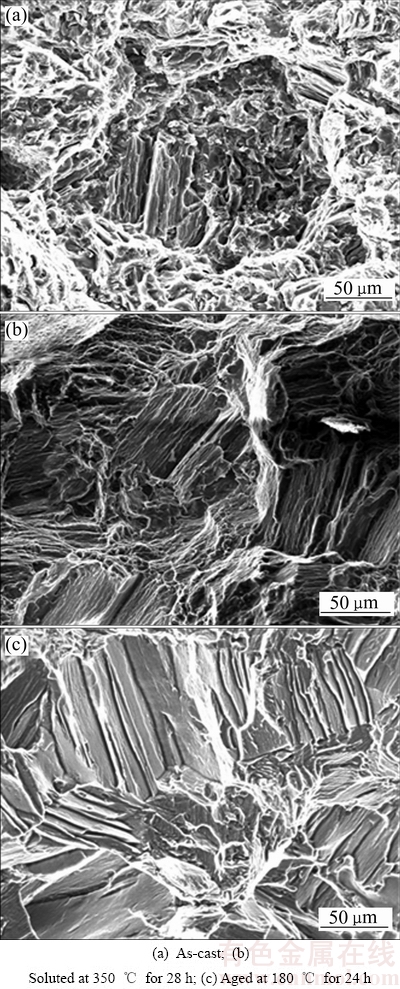

解理断裂、准解理断裂和沿晶断裂是镁合金的主要断裂方式[33]。图7所示分别为ZA63合金铸态、较佳固溶态和峰时效态的室温拉伸断口形貌。由图7(a)可知,铸态合金的断口形貌主要由不明显的解理面、少量的撕裂棱和微孔构成,断口形貌呈解理断裂的特征。微孔的形成主要是由于金属液凝固时冷却速度较大,溶质原子扩散不充分,形成了缩孔。合金经固溶处理后,如图7(b)所示,相比图7(a), 断口形貌发生了明显的变化。断口主要由许多且明显的撕裂棱、晶界和大量且较小的解理面构成,解理面上分布着高度不一的解理台阶;塑性断裂区显著增加,晶间断裂和沿晶界断裂减少,其断裂方式呈准解理断裂的特征。这是因为固溶处理使原来分布于枝晶间的大量共晶化合物回溶到基体中,枝晶偏析和铸造应力得以消除,合金组元分布趋于均匀、割裂基体的倾向减弱,进而使合金的塑性增加。相比图7(a)和7(b),合金经时效后断口形貌又发生了极其显著的变化,由图7(c)看出,断口主要由许多不同方向大的解理刻面、解理台阶和撕裂棱组成。结合力学性能可知,时效后的合金断口形貌呈解理和准解理混合断裂的特征。

3 结论

1) 合金铸态组织主要由α-Mg和(α-Mg+Mg2Zn3+ Mg7Zn3+Mg32(Al,Zn)49)共晶相组成,多数共晶化合物以连续或半连续的粗大网状分布于晶界处,少量的以孤立小颗粒的形态分布在晶内。

2) 合金在T4处理下,随着固溶时间增加,共晶相逐渐溶解、合金组元趋于均匀、枝晶偏析不断消除。当固溶28 h时,枝晶偏析完全消除,合金元素分布更加均匀,残余的共晶相以细小、弥散的形态分布于晶界处并有241 MPa的抗拉强度和11.12%的伸长率,比铸态的214 MPa和8.54%分别提高了12.62%和30.21%。

3) 合金经(350 ℃,28 h)处理后,随后在180 ℃时效不同时间下,随着时间延长,合金的力学性能呈先增大后减小的趋势;其中在24 h时,抗拉强度、伸长率和显微硬度同时达到了峰值,分别是298 MPa、9.78%和96.3 HV。

4) 合金经(350 ℃,28 h)固溶和(180 ℃,24 h)时效后,析出相的形态主要有板条状和短棒状。

5) 铸态时合金的室温断裂方式呈解理断裂的特征,经固溶处理后得到了固溶强化,合金的断口形貌以准解理断裂方式为主,时效后合金的断裂方式以解理和准解理断裂混合模型存在。

REFERENCES

[1] 陈 伟, 刘楚明, 苏再军, 舒 心. 铸态Mg-2Nd-0.2Zn- 0.4Zr-xY镁合金组织及力学性能[J]. 中南大学学报(自然科学版), 2012, 43(6): 2089-2095.

CHEN Wei, LIU Chu-ming, SU Zai-jun, SHU Xin. Microstructure and mechanical properties of as-cast Mg-2Nd- 0.2Zn-0.4Zr-xY alloy[J]. Journal of Central South University (Science and Technology), 2012, 43(6): 2089-2095.

[2] 许 轲, 蔡兴科, 吴利辉, 杨 柳, 邓运来. Mg-Gd-Y-Nd-Zr合金铸锭的均匀化[J]. 中南大学学报(自然科学版), 2009, 40(5): 1240-1244.

XU Ke, CAI Xing-ke, WU Li-hui, YANG Liu, DENG Yun-lai. Homogeneity of Mg-Gd-Y-Nd-Zr alloy as-cast[J]. Journal of Central South University (Science and Technology), 2009, 40(5): 1240-1244.

[3] 徐广龙, 袁晓黎, 刘立斌. Mg-Al-Zn-Sm合金的组织、力学性能及其热力学分析[J]. 中国有色金属学报, 2012, 22(5): 1255-1261.

XU Guang-long, YUAN Xiao-li, LIU Li-bin. Microstructure and mechanical property of Mg-Al-Zn-Sm alloy and its thermodynamic analysis[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1255-1261.

[4] 杨晓红, 彭丽梅, 杨晨辉, 贾 波, 安 建. 固溶时效Mg-4Y-3Nd合金析出相与基体的微观结构[J]. 材料热处理学报, 2015, 36(4): 39-43.

YANG Xiao-hong, PENG Li-Mei, YANG Chen-hui, JIA Bo, AN Jian. Microstructure of Mg-4Y-3Nd alloy after solution and aging treatment[J]. Transactions of Materials and Heat Treatment, 2015, 36(4): 39-43.

[5] CAI X L, YAN D Y. The effect of solution heat treatments on the microstructure and hardness of ZK60 magnesium alloys prepared under low-frequency alternating magnetic fields[J]. Materials Science & Engineering A, 2013, 559: 22-28.

[6] 朱蓓蓓, 孙扬善, 万晓峰, 薛 烽. Mg-Zn-Al系变形镁合金的显微组织和力学性能[J]. 东南大学学报(自然科学版), 2010, 40(3): 640-645.

ZHU Bei-Bei, SUN Yang-shan, WAN Xiao-feng, XUE Feng. Microstructures and mechanical properties of Mg-Zn-Al wrought magnesium alloys[J]. Journal of Southeast University (Natural Science Edition), 2010, 40(3): 640-645.

[7] HE S M, PENG L M, ZENG X Q, DING W J, ZHU Y P. Comparison of the microstructure and mechanical properties of a ZK60 alloy with and without 1.3wt% gadolinium addition[J]. Materials Science and Engineering A, 2006, 433(1/2): 175-181.

[8] 侯丹辉, 梁松茂, 陈荣石, 董 闯. 砂型铸造Mg-6Al-xZn合金凝固行为及晶粒尺寸[J]. 金属学报, 2014, 50(5): 601-609.

HOU Dan-hui, LIANG Song-mao, CHEN Rong-shi, DONG Chuang. Solidification behavior and grain size of sand casting Mg-6Al-xZn alloy[J]. Acta Metallurgica Sinica, 2014, 50(5): 601-609.

[9] 彭 建, 吕滨江, 潘复生, 张丁非. 高塑性Mg-Zn系系稀土镁合金的研究进展[J]. 热加工工艺, 2010, 39 (18): 15-19.

PENG J, Lü B J, PAN F S, ZHANG D F. Advances in high plasticity Mg-Zn-based rare-earth magnesium alloys[J]. Hot Working Technology, 2010, 39 (18): 15-19.

[10] WANG B G, WANG X, ZHOU J X, ZHANG G F, LIU F. Effects of solution heat treatment on microstructure and mechanical properties of Mg-3Al-1Si-0.3Mn-xSr alloy[J]. Materials Science and Engineering A, 2014, 618: 210-218.

[11] HU X Y, FU P H, STJOHN D, PENG L M, SUN M, ZHANG M X. On grain coarsening and refining of the Mg-3Al alloy by Sm[J]. Journal of Alloys and Compounds, 2016, 663: 387-394.

[12] ZHANG Y, HUANG X F, MA Z D, LI Y, GUO F, YANG J C, MA Y, HAO Y. The influences of Al content on the microstructure and mechanical properties of as-cast Mg-6Zn magnesium alloys[J]. Materials Science and Engineering A, 2017, 686: 93-101.

[13] 陈吉华, 陈振华, 严红革, 刘 强, 陈劲松. Mg-Zn-Al合金的组织稳定性与力学性能[J]. 湖南大学学报(自然科学版), 2007, 34(1): 47-51.

CHEN Ji-hua, CHEN Zhen-hua, YAN Hong-ge, LIU Qiang, CHEN Jing-song. Microstructural stability and mechanical properties of Mg-Zn-Al alloys[J]. Journal of Hunan University (Natural Science), 2007, 34(1): 47-51.

[14] 杨明波, 潘复生, 李忠盛, 沈 佳. Zn与Al质量比对Mg-Zn-Al三元镁合金铸态组织和凝固行为的影响[J]. 中国有色金属学报, 2008, 18(7): 1191-1198.

YANG Ming-bo, PAN Fu-sheng, LI Zhong-sheng, SHEN Jia. Effect of mass ratio of Zn to Al on as-cast microstructure and solidification behaviour of Mg-Zn-Al ternary magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1191-1198.

[15] 张 静, 潘复生. 金属型铸造ZA73镁合金凝固特征和组织研究[J]. 材料热处理学报, 2006, 27(3): 68-71.

ZHANG Jiang, PAN Fu-sheng. Solidification behavior and microstructure of permanent-mould cast ZA73 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(3): 68-71.

[16] 丁文江. 镁合金科学与技术[M]. 北京: 科学出版社, 2007.

DING Wen-jiang. Science and technology of magnesium alloys[M]. Beijing: Science Press, 2007.

[17] CHENG F L, CHEN T J, QI Y S, ZHANG S Q, YAO P. Effects of solution treatment on microstructure and mechanical properties of thixoformed Mg2Sip/AM60B composite[J]. Journal of Alloys and Compounds, 2015, 636: 48-60.

[18] XIAO W L, SHEN Y S, WANG L D, WU Y M, CAO Z Y, JIA S S, WANG L M. The influences of rare earth content on the microstructure and mechanical properties of Mg-7Zn-5Al alloy[J]. Materials and Design, 2010, 31(7): 3542-3549.

[19] BALASUBRAMANI N, PILLAI U T S, PAI B C. Optimization of heat treatment parameters in ZA84 magnesium alloy[J]. Journal of Alloys and Compounds, 2008, 457: 118-123.

[20] 冯 凯, 黄晓锋, 马 颖, 陈娟娟, 郝 远. 固溶时间对ZA72镁合金显微组织及力学性能的影响[J]. 中国有色金属学报, 2011, 21(9): 2035-2042.

FENG Kai, HUANG Xiao-feng, MA Ying, CHEN Juan-juan, HAO Yuan. Effects of different solution time on microstructure and mechanical properties of ZA72 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2035-2042.

[21] SHI Z Z, ZHANG W Z. Prediction of the morphology of Mg32(Al, Zn)49 precipitates in a Mg-Zn-Al alloy[J]. Intermetallics, 2013, 39: 34-37.

[22] ZHANG D F, SHI G L, ZHAO X B, QI F G. Microstructure evolution and mechanical properties of Mg-x%Zn-1%Mn(x=4, 5, 6, 7, 8, 9) wrought magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 15-25.

[23] 石 凯, 王日初, 解立川, 彭超群, 金和喜, 冯 艳. 固溶处理对Mg-6Al-5Pb-1Zn-0.3Mn阳极组织和性能的影响[J]. 中南大学学报(自然科学版), 2012, 43(10): 3785-3792.

SHI Kai, WANG Ri-chu, JIE Li-chuan, PENG Chao-qun, JIN He-xi, FENG Yan. Effect of solution treatment on microstructure and properties of Mg-6Al-5Pb-1Zn-0.3Mn anode[J]. Journal of Central South University (Science and Technology), 2012, 43(10): 3785-3792.

[24] 尹冬松, 张二林, 曾松岩. Mg-3Zn-Mn合金均匀化处理工艺研究[J]. 铸造技术, 2008, 29(12): 1647-1650.

YIN Dong-song, ZHANG Er-lin, ZENG Song-yan. Homogenization treatment process on as-cast Mg-3Zn-1Mn alloy[J]. Foundry Technology Research, 2008, 29(12): 1647-1650.

[25] 温 麒, 石巨岩, 张保平, 邓坤坤. 固溶处理对Mg-xZn-2Gd合金组织及性能的影响[J]. 热加工工艺, 2014, 43(22): 190-194.

WEN Qi, SHI Ju-yan, ZHANG Bao-ping, DENG Kun-kun. Effects of solution treatment on microstructure and mechanical properties of Mg-xZn-2Gd alloy[J]. Hot Working Technology, 2014, 43(22): 190-194.

[26] 张俊善. 材料强度学[M]. 哈尔滨: 哈尔滨工业大学出版社, 2004.

ZHANG Jun-shan. Materials strength science[M]. Harbin: Harbin Institute of University Press, 2004.

[27] 赵乃勤, 杨志刚, 冯运莉. 合金固态相变[M]. 北京: 中南大学出版社, 2008.

ZHAO Nai-qin, YANG Zhi-gang, FENG Yun-li. Solid phase transformations in alloys[M]. Beijing: Central South University Press, 2008.

[28] 邹宏辉, 曾小勤, 翟春全, 丁文江. 动态析出对Mg-5Zn-2Al(-2Y)合金蠕变行为的影响[J]. 金属学报, 2006, 42(1): 41-48.

ZOU Hong-hui, ZENG Xiao-qin, ZHAI Chun-quan, DING Wen-jiang. Effect of dynamic precipitation on creep behavior of Mg-5Zn-2Al(-2Y) alloy[J]. Acta Metallurgica Sinica, 2006, 42(1): 41-48.

[29] 唐 伟, 韩恩厚, 徐永波, 刘 路. 热处理对AZ80镁合金结构及性能的影响[J]. 金属学报, 2005, 41(11): 1199-1206.

TANG Wei, HAN En-hou, XU Yong-bo, LIU Lu. Effect of heat treatment on microstructure and properties of AZ80 magnesium alloy[J]. Acta Metallurgica Sinica, 2005, 41(11): 1199-1206.

[30] 陈敬区, 刘江文, 焦冬玲, 罗承萍. 铸造Mg-5Zn-0.6Zr-1RE-2Y镁合金的时效硬化和时效析出相[J]. 金属热处理, 2010, 35(6): 6-12.

CHEN Jing-qu, LIU Jiang-wen, JIAO Dong-ling, LUO Cheng-ping. Precipitates and harding of cast Mg-5Zn-0.6Zr-1RE-2Y magnesium alloy[J]. Heat Treatment of Metals, 2010, 35(6): 6-12.

[31] 李爱文, 刘江文, 伍翠兰, 罗承萍, 焦冬玲, 朱红梅. 铸造Mg-3Zn-1.5Cu-0.6Zr镁合金的时效硬化及析出相[J]. 中国有色金属学报, 2010, 20(6): 1053-1059.

LI Ai-wen, LIU Jiang-wen, WU Cui-lan, LUO Cheng-ping, JIAO Dong-ling, ZHU Hong-mei. Age-harding behavior and precipitates of as-cast Mg-3Zn-1.5Cu-0.6Zr Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1053-1059.

[32] 杨文超, 汪明朴, 盛晓菲, 张 茜. 轨道交通车辆用6005A合金板材时效析出及硬化行为研究[J]. 金属学报, 2010, 46(12): 1481-1487.

YANG Wen-chao, WANG Ming-pu, SHENG Xiao-fei, ZHANG Qian. Study of the aging precipitation and hardening behavior of 6005A alloy sheet for rail traffic vehicle[J]. Acta Metallurgica Sinica, 2010, 46(12): 1481-1487.

[33] ZHANG G H, CHEN J H, YAN H G, SU B, HE X, RAN M. Effects of artificial aging on microstructure and mechanical properties of the Mg-4.5Zn-4.5Sn-2Al alloy[J]. Journal of Alloys and Compounds, 2014, 592(8): 250-257.

Effects of heat treatment technology on microstructure and mechanical properties of Mg-6Zn-3Al magnesium alloy

ZHANG Yu1, HUANG Xiao-feng1, 2, GUO Feng1, LI Yuan-dong1, 2, BI Guang-li1, 2, MA Ying1, 2, HAO Yuan1, 2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: A new type Mg-6Zn-3Al (noted ZA63, mass fraction, %) magnesium alloy was prepared by permanent mould casting, and the microstructure and mechanical properties of the alloy under the conditions of as-cast, solution and aging treatment were systematically investigated by OM, SEM, TEM, XRD and mechanical tests, respectively. The results indicate that the as-cast alloy is mainly comprised of matrix α-Mg, eutectic phases (α-Mg+Mg2Zn3+Mg7Zn3+ Mg32(Al,Zn)49) with continuous or semi-continuous precipitated along grain boundaries and a few divorced granules within grains. When the alloy is treated at 350 ℃ for 12-36 h, the solution effects are gradually enhanced with increasing solution time. At 350 ℃ for 28 h, the alloy reveals relatively homogeneous microstructure, and the ultimate tensile strength (UTS) and elongation (EL) of 241 MPa and 11.12% are achieved, respectively. Subsequently, when the alloy is aged at 180 ℃ for 6-72 h, the mechanical test demonstrates that, the UTS further increases, the mechanical properties increase firstly and then decrease, the peak values of UTS, EL and micro-hardness of the alloy aged at 180 ℃ for 24 h are simultaneously obtained, which are 298 MPa, 9.78% and 96.3 HV and increase by 39.25%, 14.52% and 54.82% compared with those of the as-cast alloy (214 MPa, 8.54% and 62.2 HV), respectively. There are mainly two types of precipitates of the alloy after aging at 180 ℃ for 24 h, namely, the first precipitate is lath-like, the secondary one is a short-rod.

Key words: Mg-6Zn-3Al magnesium alloy; solution treatment; aging treatment; microstructure; mechanical property; precipitation morphology

Foundation item: Project(51464032) supported by the National Natural Science Foundation of China; (Project (2010CB635106) supported by the National Basic Research Development Program of China

Received date: 2017-03-20; Accepted date: 2018-01-24

Corresponding author: HUANG Xiao-feng; Tel: +86-13609312769; E-mail: huangxf_lut@163.com

(编辑 王超)

基金项目:国家自然科学基金资助项目(51464032);国家重点基础研究发展计划项目(2010CB635106)

收稿日期:2017-03-20;修订日期:2018-01-24

通信作者:黄晓锋,副教授,博士;电话:13609312769;E-mail: huangxf_lut@163.com