DOI:10.19476/j.ysxb.1004.0609.2017.10.01

热处理工艺对Mg-6Zn-2Sm-0.4Zr镁合金显微组织和力学性能的影响

张 玉1,黄晓锋1, 2,马振铎1,李 雅1,马 颖1, 2,郝 远1, 2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要: 通过在Mg-6Zn合金中添加0.4%Zr和2%Sm(质量分数)制备出一种新型Mg-6Zn-2Sm-0.4Zr合金;利用光学显微镜(OM)、扫描电镜(SEM)及能谱仪(EDS)、X射线衍射仪(XRD)、显微硬度及力学性能测试研究铸造Mg-6Zn-2Sm-0.4Zr合金在铸态、固溶、时效处理下的显微组织和力学性能的变化。结果表明:合金铸态组织主要由基体α-Mg、晶界处呈连续或半连续分布的(α-Mg+Mg2Zn3+Mg41Sm5)共晶和晶内孤立的点状相组成。合金在440和450 ℃固溶12~36 h时间范围内,随着时间和温度的增加,固溶效果逐渐增强。当在450℃固溶28 h时获得了较好的显微组织,抗拉强度为230 MPa,伸长率为9.58%。随后经200 ℃时效6~48 h后,合金的力学性能明显提高,时效强化效应随时间的延长呈先增加后减小的趋势,其中时效12 h时同时出现了抗拉强度和伸长率的峰值258 MPa和14.43%,比铸态的分别提高44 MPa和90.80%。

关键词:Mg-6Zn-2Sm-0.4Zr镁合金;固溶处理;时效处理;显微组织;力学性能

文章编号:1004-0609(2017)-10-1961-09 中图分类号:TG146.2 文献标志码:A

镁合金作为工业应用中密度较低的金属结构材料,具有比强度和刚度高、良好的导热性及机械加工性能好等优点,作为结构材料能够显著达到减轻质量增效并已成功应用于航空航天、交通运输、轨道交通等领域;同时,也是一种节能环保、可持续发展的理想材料并逐渐进入人们的视野[1-3]。但是镁合金的室温、高温力学和耐蚀性能较差,很大程度上制约了镁合金在工业中的应用。所以,最近几年新型镁合金的研究成为热点。根据研究Mg-Zn二元合金由于晶粒粗大、热烈倾向和显微疏松严重、力学性能低下,通常采用合金化来改善其组织和力学性能[4]。有研究报道[5],镁合金可以通过合金元素的添加来实现晶粒的细化和组织的改善,进而提高力学性能。目前,镁合金的研究主要通过合金复合化强化和加工变形来提高其力学性能。比如添加 Gd、Y、Mn 和 Zn等合金元素来改善合金的力学性能,添加 Zn 可细化晶粒,有助于提高合金的塑性和强度[6]。此外,Zr通常作为一种晶粒细化剂添加到镁合金中来优化合金组织[7]。目前,一系列力学性能优良的合金如Mg-Zn-Ca、Mg-Zn-Zr、Mg-Zn-Cu、Mg-Zn-Al 和Mg-Zn-RE等系列合金先后被开发与应用。众所周知,稀土是表面活性元素,具有独特的电子层结构。有色合金中添加稀土元素后可以细化合金组织,净化合金熔体、生成的稀土化合物由于其良好的热稳定性可以强化晶界,提高其高温强度、抗蠕变性能和耐蚀性能,甚至在热处理后起到固溶强化、弥散强化的作用[8-11]。有研究报道,镁合金中添加稀土元素Y、La、Nd和Ce能够显著提高合金的室温和高温力学性能[12]。Sm是最廉价的稀土之一,具有独特的斜方结构,且在镁中的最大固溶度为5.7%(质量分数)[13-14]。ZHENG等[15]的研究表明,铸态Mg-3Sm-0.5Zn-0.4Zr 合金的屈服强度、抗拉强度及伸长率分别达到了94 MPa、189 MPa和11.7%。黄正华等[16]研究了Sm对AZ91D 合金显微组织与力学性能的影响,结果表明,铸态室温拉伸力学性能和冲击韧性整体均逐渐提高,且AZ91D-0.88Sm合金的抗拉强度和伸长率分别为 230 MPa和15.5%。目前,相对于其他RE和混合稀土,有关Mg-Zn-Sm系列的合金主要关注于低锌系,对高锌系Mg-Zn-Sm合金的显微组织和力学性能的报道较少。因此,本文作者以Mg-6Zn-2Sm-0.4Zr铸造镁合金的固溶和时效处理工艺优化为目标,研究其铸态组织和固溶、时效处理对合金组织和力学性能的影响规律,优选出较佳的固溶和时效处理工艺,同时探讨其合金的固溶和时效强化作用机理,为研究新型镁合金提供参考和扩大镁合金的使用范围提供实践指导。

1 实验

实验采用金属材料纯度约为99.99%Mg、Zn锭料和Mg-30%Sm和Mg-25%Zr的中间合金。所用实验合金在熔炼之前大致预热至200 ℃烘干。此外,为了保证材料的纯度,纯镁、锌锭和中间合金在预热之前用钢刷磨掉表面的油污和氧化层以减少熔炼杂质,然后在SG2-7.7kW井式电阻炉中熔炼。熔炼时,先将钢制坩埚预热至200 ℃,然后在里外刷上涂料并加入已预热的镁锭,用RJ-2熔剂和Ar气氛保护熔体,温度500 ℃时通入氩气进行保护,当Mg锭熔化后加入已预热好的Zn锭,合金熔体升至大约760 ℃时加入两种中间合金并保温30 min, 随后熔体温度降至740 ℃时,2%(质量分数)C2Cl6通过人工搅拌加入到熔体中以精炼除渣、除气(搅拌时不要破坏镁合金熔体表面)。精炼完后迅速撇净熔体表面的残渣并静止保温10~15 min,在730 ℃扒渣后,将其浇注于已预热至210 ℃左右的金属铸型中凝固成型。

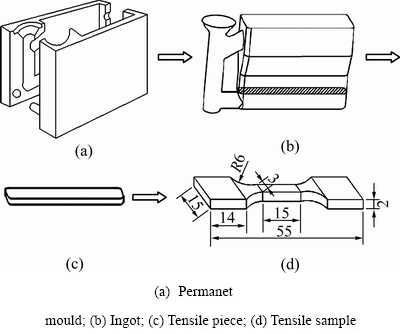

将获得的棒状和板状铸锭用线切割分别加工成直径15 mm×20 mm的圆柱状和拉伸试样,拉伸试样取样过程如图1所示。根据相关的研究[17],Sm在镁中的固溶度(质量分数)随温度的变化:5.7% (540 ℃)→ 4.3%(500 ℃)→1.8%(400 ℃)→0.8%(300 ℃)→ 0.4%(200 ℃),因此,制定固溶处理工艺为440 ℃和450 ℃下分别固溶12、20、28和36 h,然后取出试样迅速用冷水水淬。随后经固溶水淬后的试样在200 ℃时效6、12、24和48 h,保温结束后出炉空冷。固溶和时效处理均在箱式电阻炉(温度误差±2 ℃)中进行。为了避免试样被氧化,固溶处理时用硫粉对其进行覆盖保护,时效处理加热介质为甲基硅油。铸态和热处理后的试样经粗磨、精磨和抛光后分别用4%(体积分数)硝酸酒精和3 mL醋酸+2L ml乙醇+3 g苦味酸侵蚀。采用MeF-3型光学显微镜观察组织,利用扫描电镜(SEM)和配套的EDS进行微区形貌和成分分析。在X射线衍射仪(D/max-2400)进行合金的物相确定,Cu靶,扫描速度5 (°)/min,扫描角度10°~90°。在HvT- 1000A型显微硬度计上进行硬度测试,载荷0.98 N,保持时间15 s,每个试样在晶粒内测量10次取平均值。合金室温拉伸实验在WDW-100D型万能试验机上进行,拉伸速率为1 mm/s,每组3个试样,取其平均值作为实验结果。拉伸断口在SEM上进行观察分析。

图1 模具、坯锭和拉伸试样示意图

Fig. 1 Schematic diagrams for permanent mould, ingot and dimension of tensile test sample (unit: mm)

2 实验结果

2.1 铸态组织

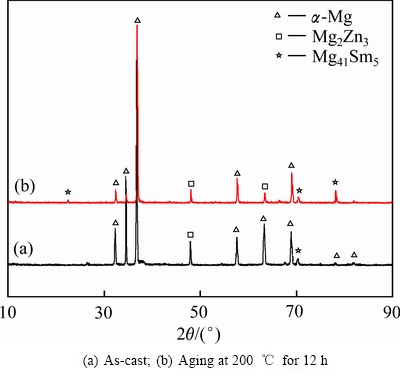

图2所示为Mg-6Zn-2Sm-0.4Zr合金在铸态和时效处理下的XRD谱。由图2可看出,无论是在铸态还是T6后,合金主要由基体α-Mg、二元合金相Mg2Zn3 和Mg41Sm5组成。根据已有的报道[18],Mg41Sm5属于体心四方晶体结构。此外,与铸态相比,经过T6处理后合金物相组成基本没有发生变化,但从物相衍射峰的强度和数量来看,各相数量出现明显的变化。由图2(b)看出,合金铸锭经T6(200 ℃,12 h)处理后,Mg2Zn3和Mg41Sm5衍射峰的数量明显多于铸态的。表明在T6处理过程中Mg2Zn3和Mg41Sm5析出相数量趋于增多。

图2 Mg-6Zn-2Sm-0.4Zr合金的XRD谱

Fig. 2 XRD patterns of Mg-6Zn-2Sm-0.4Zr

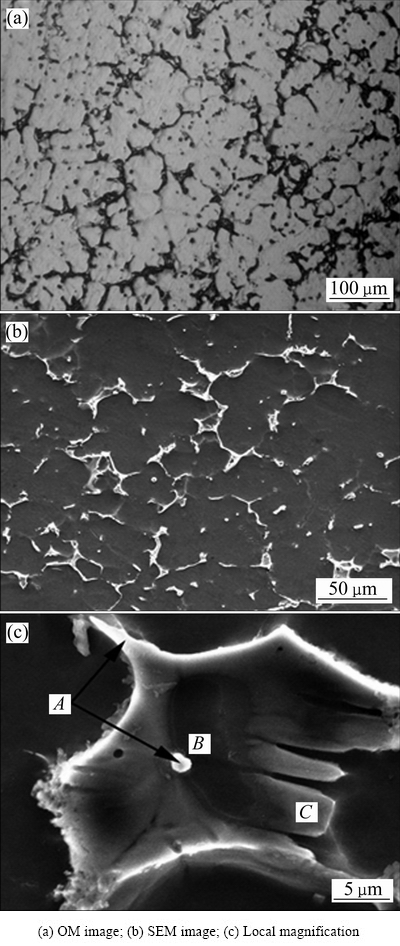

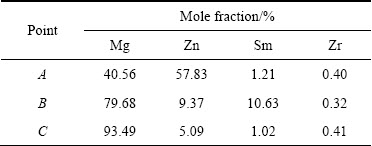

图3所示分别为Mg-6Zn-2Sm-0.4Zr合金铸态的OM和SEM像。由图3(a)可知,合金的铸态组织呈显了典型的枝晶组织形貌。在铸造凝固过程中,由于冷速较大,金属液凝固速度较快,固相扩散来不及进行,故其铸态组织主要由成分不均匀呈白色粗大的基体α(Mg)固溶体和呈黑色的共晶相构成,部分晶粒内部存在孤立的第二相颗粒。由图3(a)可知,基体α(Mg)近似呈蔷薇状的枝晶组织;由于溶质元素Zn和Sm原子的平衡分配系数 K<1[19],故凝固过程Zn和Sm原子被排挤到固液界面处,富集在已凝固的α-Mg周围,最后偏聚在晶界处。可以看到分布于枝晶间和晶界处以连续或半连续的共晶相,以离异共晶的形态存在(图3(b))。从图3(c)可看出,合金的共晶相由呈白色(A点)、灰色(C点)和浅黑色(B点)的共晶化合物组成,整个形态以块状存在。对图3(c)进行EDS分析,其结果如表1所示,呈白色的物相(A点)富集Zn,结合XRD结果(见图2(a)),确定为Mg2Zn3;呈浅黑色的化合物(B点)富集Sm(相比A和C点), 根据XRD结果,浅黑色化合物(B点)确定为Mg41Sm5相;呈灰色的化合物(C点)富集Mg和Zn,结合XRD结果,呈灰色的化合物(C点)确定为α-Mg和Mg2Zn3相。

图3 Mg-6Zn-2Sm-0.4Zr合金的铸态光学和扫描显微组织

Fig. 3 Micrographs of as-cast Mg-6Zn-2Sm-0.4Zr alloy

表1 Mg-6Zn-2Sm-0.4Zr合金EDS分析结果

Table 1 EDS results of Mg-6Zn-2Sm-0.4Zr alloy shown in Fig. 3(c)

2.2 热处理对合金显微组织的影响

2.2.1 固溶处理对合金显微组织的影响

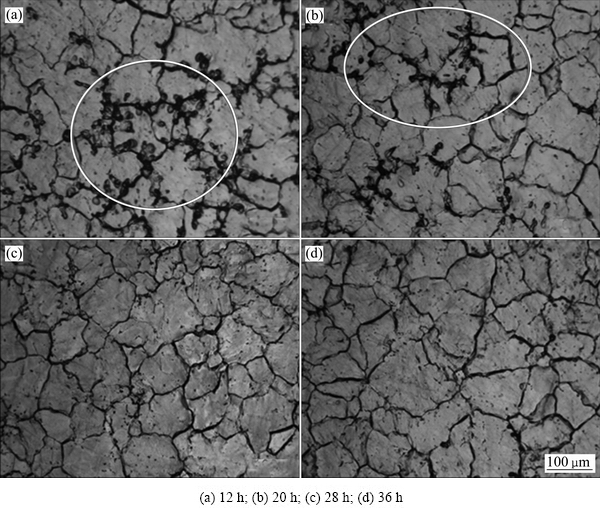

固溶处理主要是通过升高温度促进共晶化合物的溶解以提高基体的过饱和度,为合金时效时强化相的析出做准备。图4所示为在440 ℃不同固溶时间下Mg-6Zn-2Sm-0.4Zr合金显微组织的变化。由图4可知,相比铸态组织(见图3(a)),在同一温度下,随着固溶时间的延长,初生α-Mg晶粒的枝晶形貌逐渐消失并演变成了不规则的块状;晶界处共晶组织的形态和数量发生了明显的变化,共晶相逐渐溶解,合金组元分布趋于均匀,伴随着有明显的晶界析出。合金固溶12 h后(见图4(a)),相比图3(a)可以看出,枝晶组织形貌消失,枝晶偏析减小,晶界处大部分共晶化合物固溶到基体中,但部分晶界处仍有以连续或颗粒状残留的第二相粒子,这主要是由于非平衡凝固组织中偏聚的稀土化元素扩散速度较慢,需要较长的时间才能溶入基体。固溶20 h后(见图4(b)), 相比图4(a),晶界处残留的第二相进一步减少,析出晶界的区域增多。当固溶时间增加到28 h后,晶界处的共晶化合物基本上固溶到基体中,晶界更明显析出。说明合金中沿晶界分布的非平衡共晶化合物已发生了大量的溶解。图4(c)与4(b)和4(a)显微组织的形态和分布相比,发生了明显的变化,说明同一温度下适当延长保温时间能促进溶质原子的溶解和扩散。当固溶时间进一步增加到36 h时(见图4(d)),相比图4(c)和4(b),初生α-Mg晶粒有粗化的现象。晶粒粗化是由于合金在某一固定温度下固溶处理时,随着时间延长晶界处组元的浓度梯度趋于减小甚至与晶内的原子浓度达到平衡状态。若额外增加固溶时间,多余的输入热量成为晶粒长大的驱动力,促进初生晶粒或残余的共晶相颗粒长大和粗化,进而影响合金相关力学性能的提高。

图4 Mg-6Zn-2Sm-0.4Zr合金440 ℃固溶后的显微组织

Fig. 4 Microstructures of Mg-6Zn-2Sm-0.4Zr alloy solutionized at 440 ℃ for different time

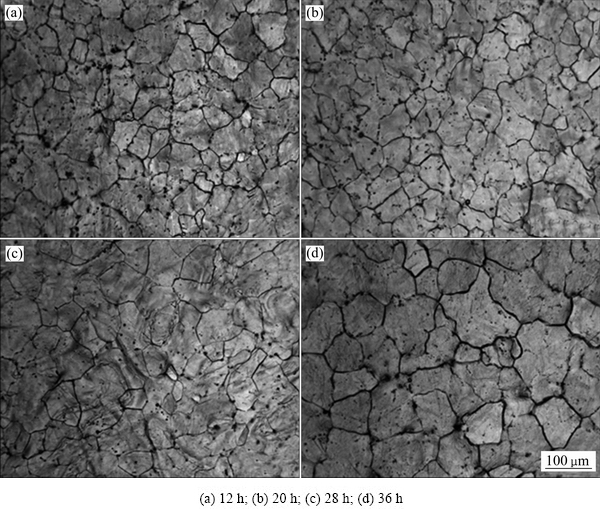

图5所示为在450 ℃不同固溶时间下Mg-6Zn- 2Sm-0.4Zr合金显微组织的变化。由图5可见,与440 ℃固溶工艺条件下相比,450 ℃条件下合金中初生α-Mg晶粒,晶界的形态和第二相的形态和数量都发生了显著变化。在相同固溶时间下,随着温度增加,枝晶和晶内偏析进一步消除,晶界处共晶化合物的溶解和溶溶质原子的扩散速度进一步加快,促进了固溶强化[20]。合金固溶12 h后(见图5(a)),相比图4(a),可看出,晶界处残留的第二相粒子和枝晶偏析进一步减少,晶界变得纤细且初生α-Mg晶粒趋于变小,晶界处仍有以颗粒状残留的第二相粒子。时间延长至20 h后(见图5(b)),晶界处残留的共晶化合物进一步减少且以更细小的颗粒分布于晶界处,析出的晶界更加明显。当固溶时间延长至28 h时(见图5(c)),相比图5(b)与5(a),晶界处孤立颗粒状的第二项粒子进一步减少,析出的晶界变得更纤细,枝晶偏析完全消除且合金组元分布趋于均匀,说明此工艺下合金中沿晶界和晶内的非平衡共晶化合物已发生了大量的溶解,此时,基体α(Mg)处于最大的过饱和状态。这是因为晶界上的原子排列不规则,点阵畸变较大,原子处于高能量的跳动状态,扩散速度较快,所以随着固溶时间的延长,晶界处粗大的共晶相会向α-Mg基体中固溶,使基体形成过饱和且均匀的固溶体,而剩余的细小的颗粒状的平衡共晶相分布在晶界和基体中[21]。此外,根据原子扩散距离与固溶时间成正比的理论,相界面出的浓度梯度激发Mg、Zn、Sm和Zr原子向基体内扩散[22]。通过这些原子的扩散达到晶粒内部化学成分均匀。当固溶时间继续增加到36 h后(见图5(d)),相比图5(c)和5(b),初生α-Mg晶粒和晶界处残余的第二相粒子有长大和粗化的现象。由以上实验分析可知,合金在440和450 ℃分别固溶12~36 h工艺下,同一温度下,固溶效果随时间延长而增加;在同一时间下,增加固溶温度能明显促进固溶强化效果,升高固溶温度对Mg-6Zn-2Sm-0.4Zr合金组织的影响比延长保温时间的影响要显著得多,因此,结合组织演变的结果,合金的固溶工艺在450 ℃、28 h时最佳。

图5 Mg-6Zn-2Sm-0.4Zr合金450 ℃固溶后的显微组织

Fig. 5 Microstructures of Mg-6Zn-2Sm-0.4Zr alloy solutionized at 450 ℃ for different time

2.2.2 时效处理后合金的显微组织

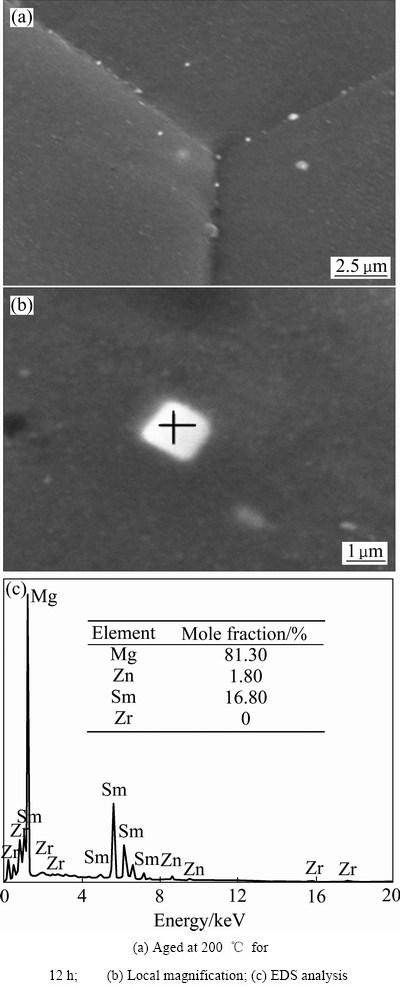

通过以上实验分析可知,合金经450 ℃固溶28 h时获得了较理想的效果。图6所示为合金经450 ℃固溶28 h后再经200 ℃时效12 h的SEM像及EDS分析。从图6(a)看出,有明显的晶界析出且在晶界处或晶粒内有呈白色的强化相析出。这些析出强化相都以孤立、颗粒状的形态存在。为了进一步确定合金在此工艺下处理后组织的精细特征和相组成成分,用SEM和对应的EDS分析了合金在大倍数下组织形态和微区成分。由图6(b)看出,有类似于方形的强化相析出,对此进行EDS分析显示(见图6(c)),除了Mg的含量,Sm的含量远高于Zn的,不含Zr,结合XRD分析结果(见图2(b)),该相确定为Mg41Sm5。

2.2.3 合金力学性能

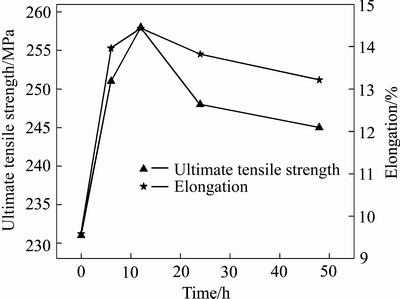

时效处理是一种很有效的改善合金性能的方法,可引起强度和硬度的大幅度提高[23]。在一定温度下时效处理,保温时间至关重要,如果保温时间较短,则会造成第二相析出不完全,合金出现“欠时效”;如果保温时间过长,则会造成第二相粒子粗化和发生晶粒长大,合金出现“过时效”。这两种条件下都会明显影响合金的力学性能。图7所示为合金450 ℃下固溶28 h后在200 ℃下时效不同时间对合金抗拉强度和伸长率的影响曲线图。由图7可知,时效时间对合金抗拉强度和伸长率的影响规律一致。在200 ℃下,随着保温时间延长,抗拉强度和伸长率都呈先增加后减小的趋势。合金在保温前期(6~12 h)抗拉强度和伸长率都呈上升的趋势且在保温12 h时同时达到了峰值258 MPa和14.43%,分别比铸态的提高44 MPa和90.80%;比最佳固溶工艺下的分别提高16 MPa和29.11%。这是由于固溶处理使得原来晶界处共晶相大量的回溶到基体中,合金组元分布趋于均匀、应力集中得以释放且割裂基体的作用减弱、粗大的α-Mg枝晶组织形貌完全消失,使基体处于过饱和的固溶体状态,在时效过程中,强化相析出的驱动力随时间延长而增大,从过饱和的固溶体中沿晶界析出Mg2Zn3和Mg41Sm5细小强化相颗粒,这些颗粒使基体产生严重的晶格畸变,有效阻碍了晶界和位错的运动[24],因而产生了良好的强化效果使合金的强度明显增加。由此说明,提高时效态镁合金的室温拉性能是要有足够的第二相粒子析出且与基体保持共格的关系,造成基体α-Mg晶格畸变。在保温后期(12~48 h),抗拉强度和伸长率都呈下降的趋势,这主要由于额外延长保温时间导致析出强化相与α(Mg)固溶体共格的关系遭到破坏、弹性畸变消失。此外,强化相发生粗化和晶粒的长大而失去强化效果。换句话说,合金从12 h后处于过时效阶段, 失去了进一步时效强化的效果,进而恶化合金的力学性能。从时效处理后获得的力学性能来看,适合工业应用的应选择450 ℃固溶28 h然后在200 ℃再时效12 h,此工艺下合金的抗拉强度和伸长率都得到了明显的提高且有利于缩短生产周期。

图6 Mg-6Zn-2Sm-0.4Zr合金时效处理后的SEM像

Fig. 6 SEM images of Mg-6Zn-2Sm-0.4Zr alloy after aging treatment((a), (b)) and EDS analysis(c)

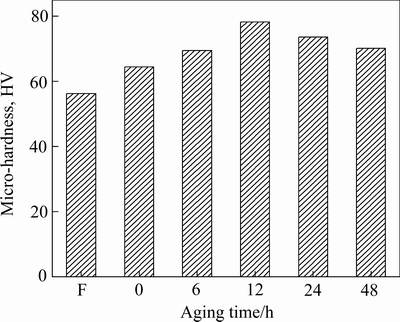

图8所示为Mg-6Zn-2Sm-0.4Zr合金在不同时效时间下、铸态和固溶态的显微硬度。由图8可见,热处理后合金的显微硬度均高于铸态的;时效后合金的显微硬度均高于固溶后的。当温度一定时,随时效时间的延长,合金的硬度呈先增加后降低的趋势,其中,时效12 h时可以看到明显的时效峰值,硬度达到78.3HV,相对于铸态和固溶态的分别增加22HV和13.8HV。这主要是在时效过程中沿着晶界析出的细小的强化相强化了晶界并对位错运动的阻碍更大,进而使合金的硬度增加。分析合金时效硬度曲线可知,随时效时间的增加,从过饱和固溶体中的脱溶量增加,第二相逐渐析出于晶界处,使合金的硬度迅速提高,硬度达到峰值后,合金中的第二相完全析出,脱溶产物不再增加,硬度达到最大值。随时效时间的继续延长第二相开始脱溶,与母相的共格关系开始破坏,由完全共格变为局部共格,此外,析出的强化相粒子出现粗化,故合金硬度开始降低。合金中位错和亚结构随时间延长而逐渐消失也是硬度降低的原因之一[25]。

图7 时效处理时间对 Mg-6Zn-2Sm-0.4Zr合金力学性能的影响

Fig. 7 Effects of aging treatment time on mechanical properties of Mg-6Zn-2Sm-0.4Zr alloy

图8 时效处理时间对 Mg-6Zn-2Sm-0.4Zr合金显微硬度的影响

Fig. 8 Effects of aging treatment time on micro-hardness of Mg-6Zn-2Sm-0.4Zr alloy

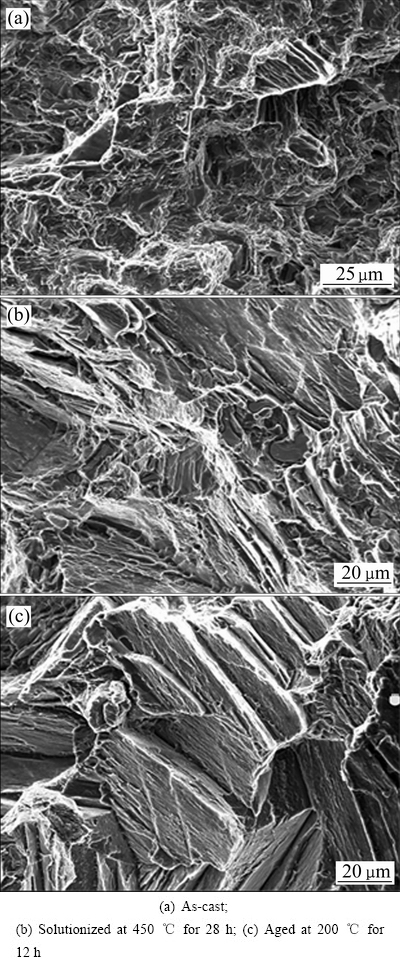

金属在不同温度下的塑性由其变形机制来决定, 变形中滑移系开动的多少及难易程度决定其断裂方式。由于镁是非对称的密排六方结构, 室温下的塑性变形限于基面{0001}〈1120〉滑移及锥面{1012}〈1011〉孪生, 塑性较差[26]。图9所示分别为合金铸态、450 ℃固溶28 h、450 ℃固溶28 h并在200 ℃时效12 h的室温拉伸断口形貌。由图9(a)可知,铸态合金的拉伸断口主要由不明显的解理面,少量的撕裂棱和微孔构成,结合相对低的力学性能,断口形貌呈沿晶界断裂的特征。这主要是由于金属液凝固时冷却速度较大,溶质原子扩散不充分,富集在晶界处,造成应力集中,形成晶间裂纹的几率增加,拉伸时裂纹优先在第二相与基体间的界面处产生[27]。合金经过固溶处理后,如图9(b)所示,相比图9(a), 拉伸断口形貌发生了明显的变化,由于原来枝晶间的共晶化合物大部分固溶到基体中,合金组元分布趋于均匀、铸造应力及缩松、缩孔消除,故断口主要由许多的撕裂棱,晶界和少量小的解理面构成,解理面上分布着高度不一的解理台阶,塑性断裂区增加,晶间断裂和沿晶界断裂减少,结合力学性能可知,其断裂方式以穿晶和沿晶断裂为主。相比图9(a)和9(b),合金经过T6后断口形貌又发生了极其明显的变化,如图9(c)所示,断口主要由许多不同方向大的解理刻面及其上面不太明显的小解理刻面、解理台阶和撕裂棱组成,部分解理刻面由撕裂棱连接起来。由于晶体的取向不同,造成解理台阶的扩展方向不同,进而形成不同方向的解理刻面。晶界处析出的强化相有效阻碍了裂纹的萌生与传播,因此合金的抗拉强度和伸长率有了明显的提高,断口形貌呈穿晶和韧性断裂的特征。

图9 Mg-6Zn-2Sm-0.4Zr合金拉伸断口形貌

Fig. 9 Micrographs of tensile fracture surface for Mg-6Zn- 2Sm-0.4Zr alloy before and after heat treatment

3 结论

1) 铸态Mg-6Zn-2Sm-0.4Zr合金的显微组织由α-Mg,Mg2Zn3和Mg41Sm5相组成,多数共晶化合物以连续或半连续的形态分布于晶界处,少量的分布在晶内。

2) 合金在440 ℃和450 ℃固溶不同时间下,随着时间和温度的增加,合金组元趋于均匀、枝晶偏析逐渐消除、晶界明显析出。当在450 ℃固溶28 h时,获得了较好的固溶效果,抗拉强度达230 MPa,伸长率达9.58%,比铸态的分别提高了16 MPa和29.11%。

3) 合金在450 ℃固溶28 h后,随后在200 ℃时效不同时间下,随着时间的延长,合金的力学性能和显微硬度都呈先增大后减小的趋势,其中在12 h时,抗拉强度和伸长率同时达到了峰值,分别为258 MPa和14.43%,比铸态的分别提高了44 MPa和90.80%;同时,显微硬度也达到了峰值78.3HV,相对于铸态和固溶态的分别增加了22HV和13.8HV。

4) 铸态时合金的室温断裂方式呈显沿晶断裂的特点,经固溶处理后,由于固溶强化的效果,合金的断口形貌以穿晶和沿晶断裂方式为主,T6后合金的断裂方式以穿晶和韧性断裂混合模型存在。

REFERENCES

[1] 王小娜, 韩立战, 顾剑锋. NZ30K镁合金时效析出动力学与强化模型的研究[J]. 金属学报, 2014, 50(3): 355-360.

WANG Xiao-na, HAN Li-zhan, GU Jian-feng. Precipitation kinetics and yield strength model for NZ30K-Mg alloy[J]. Acta Metallurgica Sinica, 2014, 50(3): 355-360.

[2] MORDIKE B L, EBERT T. Magnesium: Properties- applications-potential[J]. Materials Sciences and Engineering A, 2001, 302(1): 37-45.

[3] 汤伊金, 章桢彦, 靳 丽, 董 杰, 丁文江. Mg-Gd 系合金时效析出研究进展[J]. 中国有色金属学报, 2014, 14(1): 8-24.

TANG Yin-jin, ZHANG Zhen-yan, JIN Li, DONG Jie, DING Wen-jiang. Research progress on ageing precipitation of Mg-Gd alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 14(1): 8-24.

[4] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004.

[5] HU XY, FU P H, STJOHN D, PENG L M, SUN M, ZHANG M X. On grain coarsening and refining of the Mg-3Al alloy by Sm[J]. Journal of Alloys and Compounds, 2016, 663: 387-394.

[6] 周会会, 宋 鹏, 黄太红, 陆建生. 不同固溶状态Mg-10Gd-3Y-1.2Zn-0.5Zr合金的力学性能及断裂行为[J]. 稀有金属材料与工程, 2016, 45(3): 732-736.

ZHOU Hui-hui, SONG Peng, HUANG Tai-hong, LU Jian-sheng. Influence of different solution treatments on mechanical properties and fracture behavior of Mg-10Gd-3Y-1.2Zn-0.5Zr alloys[J]. Rare Metal Materials and Engineering, 2016, 45(3): 732-736.

[7] SUN M, WU G H, WANG W, DING W J. Effect of Zr on the microstructure, mechanical properties and corrosion resistance of Mg-10Gd-3Y magnesium alloy[J]. Materials Sciences and Engineering A, 2009, 523(1/2): 145-151.

[8] 王忠军, 张彩锫, 邵晓宏, 崔建忠, 乐启炽. 添加稀土Er于溶剂中对铸态AZ91镁合金组织与性能的影响[J]. 中国有色金属学报, 2007, 17(2): 181-187.

WANG Zhong-jun, ZHANG Cai-pei, SHAO Xiao-hong, CUI Jian-zhong, LE Qi-chi. Effects of Er addition in flux on microstructure and properties of casting AZ91 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 181-187.

[9] LIU W C, DONG J, SONG X, BELNOUE J P, HOFMANN F, DING W J, KORSUNSKY A M. Effect of microstructures and texture development on tensile properties of Mg-10Gd-3Y alloy[J]. Materials Science and Engineering A, 2011, 528(6): 2250-2258.

[10] HUANG Z H, QI W J, XU J, CAI C. Microstructures and mechanical properties of Mg-Al-Sm series heat-resistant magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 22-29.

[11] 徐广龙, 袁晓黎, 刘立斌. Mg-Al-Zn-Sm合金的组织、力学性能及其热力学分析[J]. 中国有色金属学报, 2012, 22(5): 1255-1261.

XU Guang-long, YUAN Xiao-li, LIU Li-bin. Microstructure and mechanical property of Mg-Al-Zn-Sm alloy and its thermodynamic analysis[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1255-1261.

[12] TONG G D, LIU H F, LIU Y H. Effect of rare earth additions on microstructure and mechanical properties of AZ91 magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S2): s336-s340.

[13] 李肖丰, 李全安, 陈 君, 张 清, 张兴渊. 衫对Mg-6Al-1.2Y-0.9Nd镁合金组织和耐蚀性能的影响[J]. 中国稀土学报, 2009, 27(1): 115-122.

LI Xiao-feng, LI Quan-an, CHEN Jun, ZHANG Qing, ZHANG Xing-yuan. Effect of samarium on microstructures and corrosion resistance of Mg-6Al-1.2Y-0.9Nd alloy[J]. Journal of the Chinese Society of Rare Earths, 2009, 27(1): 115-122.

[14] LI K J, LI Q A, JIANG X T, CHEN J, ZHANG X Y, ZHANG Q. Effects of Sm addition on microstructure and mechanical properties of Mg-6Al-0.4Zn alloy[J]. Scripta Materialia, 2009, 60(12): 1101-1104.

[15] ZHENG J, WANG Q D, JIN Z L, PENG T. Effect of Sm on the microstructure, mechanical properties and creep behavior of Mg-0.5Zn-0.4Zr based alloys[J]. Materials Science and Engineering A, 2010, 527(7/8): 1677-1685.

[16] 黄正华, 刘汪涵博, 戚文军, 徐 静. Sm对AZ91D 合金显微组织与力学性能的影响[J]. 中国有色金属学报, 2015, 25(10): 2649-2655.

HUANG Zheng-hua, LIUWANG Han-bo, QI Wen-jun, XU Jing. Effects of Sm on microstructure and mechanical property of AZ91D alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2649-2655.

[17] XIA X Y, SUN W H, LUO A A, STONT D S. Precipitation evolution and hardening in Mg-Sm-Zn-Zr alloys[J]. Acta Materialia, 2016, 111: 335-347.

[18] YUAN M, ZHENG Z Q. Effects of Zn on the microstructures and mechanical properties of Mg-3Sm-0.5Gd-xZn-0.5Zr(x=0, 0.3 and 6) alloy[J]. Journal of Alloys and Compounds, 2014, 590: 355-361.

[19] 赵永成, 颜世宏, 李宗安, 庞思明, 陈德宏, 成 维. 稀土元素Sm对Mg-Zn-Y合金组织结构和力学性能的影响[J]. 稀有金属, 2011, 35(5): 431-435.

ZHAO Yong-cheng, YAN Shi-hong, LI Zong-an, PANG Si-ming, CHEN De-hong, CHENG Wei. Influence of Sm on microstructure and mechanical properties of Mg-Zn-Y alloys[J]. Chinese Journal of Rare Metals, 2011, 35(5): 431-435.

[20] 黄太红, 宋 鹏, 周会会, 陆建生. 固溶温度对Mg-10Gd-3Y-1.2Zn-0.5Zr合金的组织演变规律和时效硬化行为的影响[J]. 稀有金属材料与工程, 2016, 45(2): 667-672.

HUANG Tai-hong, SONG Peng, ZHOU Hui-hui, LU Jian-sheng. Effects of solution temperature on microstructure evolution and aging hardness of Mg-10Gd-3Y-1.2Zn-0.5Zr alloy[J]. Rare Metal Materials and Engineering, 2016, 45(2): 667-672.

[21] 冯 凯, 黄晓锋, 张亚楠, 马 颖, 郝 远. 热处理工艺对ZC63镁合金组织及力学性能的影响[J]. 材料热处理学报, 2012, 33(6): 51-57.

FENG Kai, HUANG Xiao-feng, ZHANG Ya-nan, MA Ying, HAO Yuan. Effect of heat-treatment technology on microstructure and mechanical properties of ZC63 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2012, 33(6): 51-57.

[22] LI D J, ZENG X Q, DONG J, ZHAI C Q. Influence of heat treatment on microstructure and mechanical properties of Mg-10Gd-3Y-1.2Zn-0.4Zr alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(S1): s117-s123.

[23] 王晓亮, 李长荣, 郭翠萍, 杜振民. Mg-Zn合金时效过程中GP区析出的热力学分析[J]. 金属学报, 2010, 46(5): 575-580.

WANG Xiao-liang, Li Chang-rong, GUO Cui-ping, DU Zhen-min. Precipitation behavior of GP zones during aging process of Mg-Zn alloy[J]. Acta Metallcrgica Sinica, 2010, 46(5): 575-580.

[24] 崔忠圻, 覃耀春. 金属学与热处理[M]. 北京: 机械工业出版社, 2009.

CUI Zhong-qi, TAN Yao-chun. Metallography and heat treatment[M]. Beijing: China Machine Press, 2009.

[25] 徐 静, 徐 雷, 戚文军. 时效对Mg-6Zn-0.7Zr-0.5Cd-1.5Nd镁合金组织及性能的影响[J]. 热加工工艺, 2012,41(22): 213-215.

XU Jiang, XU Lei, QI Wen-jun. Effects of aging on the microstructure and mechanical properties of Mg-6Zn-0.7Zr- 0.5Cd-1.5Nd magnesium alloy[J]. Hot Working Technology, 2012,41(22): 213-215.

[26] 肖 阳, 张新明, 陈健美, 蒋 浩. Mg-15Gd-0. 6Zr合金的组织与力学性能[J]. 中国有色金属学报, 2006, 16(11): 1888-1894.

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei, JIANG Hao. Microstructures and mechanical properties of Mg-15Gd-0.6Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1888-1894.

[27] 张金山, 姬国强, 王 星, 张照光, 许春香, 王红霞, 陶卫建, 孙 勇. Sm对AM60合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2012, 41(4): 617-622.

Zhang Jin-shan, JI Guo-qiang, WANG Xing, ZHANG Zhao-guang, XU Xiang-xiang, WANG Hong-xia, TAO Wei-jian, SUN Yong. Effect of Sm on microstructure and mechanical properties of AM60 magnesium alloy[J]. Rare Metal Materials and Engineering, 2012, 41(4): 617-622.

Effects of heat-treatment technology on microstructure and mechanical properties of Mg-6Zn-2Sm-0.4Zr magnesium alloy

ZHANG Yu1, HUANG Xiao-feng1, 2, MA Zhen-duo1, LI Ya1, MA Ying1, 2, HAO Yuan1, 2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: A new type Mg-6Zn-2Sm-0.4Zr alloy was fabricated by adding 0.4%Zr and 2%Sm (mass fraction) in Mg-6Zn alloy, and the microstructure and mechanical properties of the cast alloy under the conditions of as-cast, solution and aging treatment were investigated by optical microscopy (OM), scanning electron microscopy (SEM) with equipped energy dispersive spectrometry (EDS), X-ray diffractometry (XRD), micro-hardness and mechanical tests. The results indicate that the as-cast alloy is mainly composed of matrix α-Mg, eutectic phases (α-Mg+Mg2Zn3+Mg41Sm5) with continuous or semi-continuous morphology distributed along grain boundaries and a few isolated particles inside grains. The alloy is solutionized at 440 ℃ and 450 ℃ for 12-36 h, with the increment of solution temperature and time, the solution effect gradually increases. When the alloy is treated at 450 ℃ for 28 h, the alloy exhibits relatively homogeneous microstructure and attains mechanical performance with ultimate tensile strength (UTS) of 230 MPa and elongation (EL) of 9.58%, respectively. After the alloy being aged at 200 ℃ for 6-48 h, the mechanical properties of alloy increase obviously, and the aging strengthening effect increases firstly and then decreases, the peak values of UTS (258 MPa) and EL (14.43%) of the alloy aged at 200 ℃ for 12 h are simultaneously obtained, which are increased by 44 MPa and 90.80% compared with those of the as-cast alloy, respectively.

Key words: Mg-6Zn-2Sm-0.4Zr magnesium alloy; solution treatment; aging treatment; microstructure; mechanical property

Foundation item: Project(51464032) supported by the National Natural Science Foundation of China; Project (2010CB635106) supported by the National Basic Research Development Program of China

Received date: 2016-09-27; Accepted date: 2017-03-08

Corresponding author: HUANG Xiao-feng; Tel: +86-931-2976688; E-mail: huangxf_lut@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51464032);国家重点基础研究计划资助项目(2010CB635106)

收稿日期:2016-09-27;修订日期:2017-03-08

通信作者:黄晓锋,副教授,博士;电话:0931-2976688;E-mail: huangxf_lut@163.com