文章编号:1004-0609(2012)06-1725-06

Ni-Al基涂层制备工艺及其抗氧化性能

欧桃平,操光辉

(上海大学 材料科学与工程学院,上海 200072)

摘 要:通过调整固体粉末渗铝法工艺在镍基高温合金DZ417G基体上制备了Ni-Al二元成分区间内组织可控的γ′-Ni3Al、γ′-Ni3Al+β-NiAl、β-NiAl、β-NiAl+δ-Ni2Al3和δ-Ni2Al3涂层,采用光学显微镜、X射线衍射仪和扫描电镜对涂层的结构、断面形貌以及高温氧化后的表面形貌进行观察和分析。900 ℃和1 100 ℃空气恒温氧化实验结果表明:涂层能显著提高材料的抗氧化性能,在涂层厚度相同的情况下,NiAl涂层抗氧化性能最好。

关键词:高温合金;包埋渗;涂层;抗氧化性能

中图分类号:TG174.445 文献标志码:A

Preparation processes of Ni-Al-based coatings and their oxidation resistance

OU Tao-ping, CAO Guang-hui

(School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China)

Abstract: The γ′-Ni3Al, γ′-Ni3Al+β-NiAl, β-NiAl, β-NiAl+δ-Ni2Al3 and δ-Ni2Al3 coatings with structures controllable in the Ni-Al binary components range on Ni-based superalloy DZ417G were prepared by using appropriate pack cementation processes. The structures, cross sections and surface morphologies after high temperature oxidation of the coatings were observed and analyzed by optical microscopy, X-ray diffractometry and scanning electron microscopy. The experimental results of isothermal air oxidation at 900 ℃ and 1 100 ℃ indicate that these coatings can significantly improve the oxidation resistance of the substrate materials, and the oxidation resistance of NiAl coatings is the best at the same thickness of coatings.

Key words: superalloy; pack cementation; coatings; oxidation resistance

现代航空燃气涡轮发动机大推力、高效率、低油耗和长寿命的发展趋势使涡轮发动机叶片工作温度不断提高,为满足其要求,在过去几十年里已经发展了五代高温合金[1]。然而由于受其熔点的限制,进一步提高高温合金工作温度的潜力已十分有限。致力于进一步发展新型合金和冷却技术的同时,发展热障涂层(Thermal barrier coatings, TBCs)技术,可以有效提高发动机工作温度、延长其使用寿命[2-3]。热障涂层是指由金属粘结层和陶瓷表面涂层组成的涂层系统。金属粘结层减少了界面应力,避免陶瓷层的过早剥落,在整个涂层系统起着至关重要的作用。

目前,广泛应用的热障涂层粘结层材料MCrAlY (M=Ni or Co, or Ni+Co)通常采用等离子喷涂的方法制备。然而等离子喷涂法在喷涂过程中易造成涂层的氧化,且生产成本相对较高。采用固体粉末渗铝法制备金属粘结层,由于基体材料被渗剂包围,漏渗少,容易获得均匀与致密的涂层;该方法设备简单,易于操作,是制备热障涂层金属粘结层的理想选择[4]。无论是β-(Ni, Pt)Al涂层还是GLEESON等[3]报道的性能优异的Pt改性的γ-Ni+γ′-Ni3Al涂层均采用固体粉末渗铝法制备。目前,国内已经有很多用固体粉末渗铝法制备渗铝涂层的研究报道[5-8],但使用该方法在高温合金基体上制备涂层的相形成机制和规律还不够深入,因此,进一步研究该规律对涂层的研究工作具有十分重要的指导意义。固体粉末渗铝法获得的涂层组织和性能不仅与基体材料的化学成份有关,而且还与渗剂的成份、渗铝温度以及保温时间有关[9]。本文作者采用固体粉末渗铝法,通过调整渗剂的成分、渗铝温度和保温时间在Ni-Al二元相图成分区间内制备了组织可控的Ni-Al基涂层;在900 ℃和1 100 ℃进行空气恒温氧化实验,对涂层的抗氧化性能进行了研究。

1 实验

涂层基体材料为铸造镍基高温合金DZ-417G,化学成分见表1。实验所用试样加工成15 mm×15 mm×3 mm的片状。试样经水磨砂纸120#~800#逐级打磨后,在丙酮中超声波清洗,然后用冷风吹干备用。

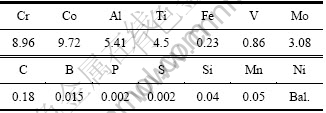

表1 DZ-417G合金化学成分

Table 1 Chemical compositions of DZ-417G alloy (mass fraction, %)

渗剂由Al粉(Cr-Al粉,铝含量为15%(质量分数))、NH4Cl粉和Al2O3粉组成,Al2O3粉使用前经1 200 ℃锻烧2 h,以除去低熔点物质。将以上粉末按一定比例混合均匀,然后和试样一起放入刚玉坩埚中,用耐火泥密封。将密封好的坩埚放入120 ℃干燥箱中干燥3~4 h,再放入电阻炉中,将炉温缓慢升至800~1 050 ℃保温2~4 h (详见表2),炉冷后取出。采用X射线衍射仪(D/MAX-3C XRD,λ=0.154 1 nm)分析测定涂层的相组成,用光学显微镜(Leica DM 6000M)观察涂层的截面形貌。涂层试样分别在电阻炉中进行900 ℃和1 100 ℃空气恒温氧化实验,利用不连续称取质量法测定氧化动力学曲线,并采用扫描电子显微镜(JSM-6700F)观察试样氧化表面形貌。

2 结果与讨论

2.1 涂层断面形貌和相组成

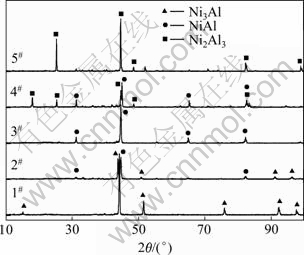

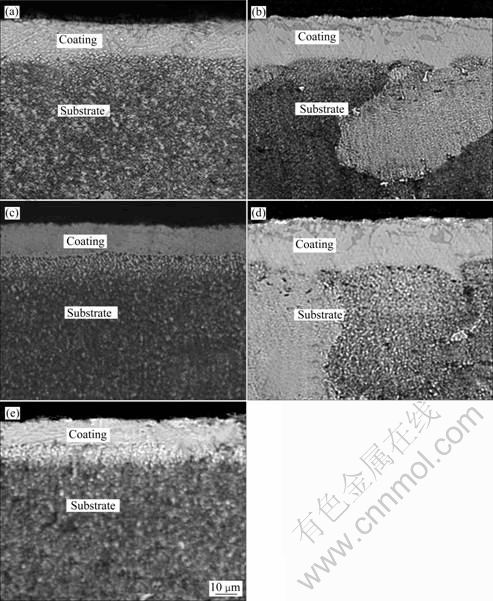

图1所示为不同工艺制备的涂层XRD谱。从图1中可以看到,经1#、3#和5#工艺制备的涂层分别为单相γ′-Ni3Al、β-NiAl和δ-Ni2Al3涂层,涂层的断面形貌分别如图2(a)、(c)和(e)所示,涂层的厚度整体均匀,均为20 μm左右;涂层和基体之间有明显过渡层。2#和4#工艺可分别制得γ′-Ni3Al+β-NiAl和β-NiAl+ δ-Ni2Al3双相涂层,由于延长了渗铝时间,γ′-Ni3Al+β-NiAl和β-NiAl+δ-Ni2Al3涂层厚度比γ′-Ni3Al、β- NiAl和δ-Ni2Al3单相涂层稍厚,为25 μm左右(见图2(b)和(d))。2#工艺制备的γ′-Ni3Al+β-NiAl涂层中,γ′-Ni3Al相为主相,β-NiAl相分布在涂层的表层,呈不连续的带状分布。而对于4#工艺制备的β-NiAl+ δ-Ni2Al3涂层,β-NiAl相为主相,δ-Ni2Al3相呈块状分布于涂层的表层。

图1 不同工艺制备的涂层X射线衍射分析

Fig. 1 XRD patterns of coatings made by different preparation processes: 1#—γ′-Ni3Al; 2#—γ′-Ni3Al+β-NiAl; 3#—β-NiAl; 4#—β-NiAl+δ-Ni2Al3; 5#—δ-Ni2Al3 coating

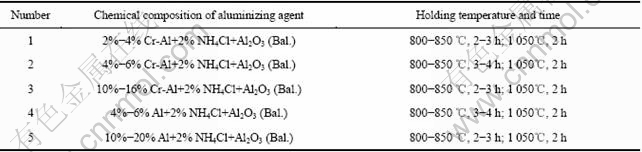

表2 涂层制备工艺

Table 2 Preparation processes of coatings

图2 涂层横截面光学显微形貌

Fig. 2 Optical cross-sectional images: (a) 1#—γ′-Ni3Al; (b) 2#—γ′-Ni3Al+ β-NiAl; (c) 3#—β-NiAl; (d) 4#—β-NiAl+ δ-Ni2Al3; (e) 5#—δ-Ni2Al3 coatings

2.2 涂层形成过程分析

在涂层制备的升温过程中,当温度超过340 ℃时,渗剂中的NH4Cl开始分解,生成气态HCl和NH3,其中气态HCl中的氯与渗剂中的Al反应形成气态AlCl、AlCl2和AlCl3化合物(见表3的反应1~4),低价的氯化铝(AlCl和AlCl2)扩散到试样表面时,与基体材料发生表面反应,释放出活性Al原子[10],并形成高价铝化物AlCl3(见表3的反应5~6);AlCl3又与渗剂中的Al反应生成新的低价铝化物(见表3的反应7),这些低价氯化铝又与基体材料发生表面反应,释放出活性铝原子。如此循环反复,不断向试样表面传递活性铝原子,这样在试样表面就存在扩散元素Al的浓度梯度。Al原子向基体方向扩散的瞬间,将会把与其邻近的Ni原子推至高能不稳定状态,由于Al原子在γ-Ni中既能以置换固溶体存在,又能以金属间化合物的形式存在[11],这有利于Al原子和高能态的Ni原子交换位置,当Al超过其在γ-Ni的溶解度时,就形成Al和Ni的化合物[12]。根据Ni-Al二元相图,在本研究工艺温度下,Al和Ni可形成Ni3Al、NiAl和Ni2Al3等化合物[13],由于形成Ni2Al3的吉布斯自由能最小(见表3反应8~10),故Ni2Al3比Ni3Al和NiAl较易生成。所以为了得到铝含量相对较低的Ni3Al相和NiAl相,必须减少活性铝原子的浓度。采用铝含量相对较低的Cr-Al或者Fe-Al合金粉,可以有效降低铝的活性[14],从而得到Ni3Al或NiAl涂层以及二者的混合相涂层。Cr-Al粉中的Cr在渗剂中不参与化学反应,不会进入涂层当中,因而对涂层的结构和性能不会产生影响。

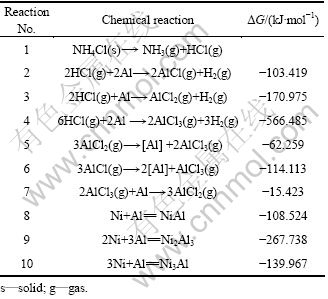

表3 800 ℃渗铝时可能发生的反应及其吉布斯自由能[11, 15]

Table 3 Possible reactions and their Gibbs energies during aluminizing at 800 ℃[11, 15]

2.3 涂层的抗氧化性能

2.3.1 等温氧化动力学

图3所示为Ni3Al涂层、NiAl涂层、Ni2Al3涂层试样和无涂层的基体材料在900 ℃和1 100 ℃等温氧化动力学曲线。由图3(a)可以看出,在氧化实验的前10 h,各试样的质量随时间的增加而快速增加,氧化10 h以后,各试样的氧化质量增加开始变缓。在整个氧化过程中,NiAl涂层试样氧化质量增加最慢,Ni3Al涂层试样氧化质量增加稍大于Ni2Al3涂层试样;没有涂层的基体材料的氧化质量增加始终是最快的。由图3(b)可以看出,在1 100 ℃的氧化温度下,各试样等温氧化质量增加比900 ℃快很多。在整个氧化过程中无涂层基体试样氧化质量增加最快,经过10 h氧化后,氧化质量增加呈指数增加。Ni3Al涂层、NiAl涂层和Ni2Al3涂层试样氧化质量增加近似呈直线增大。

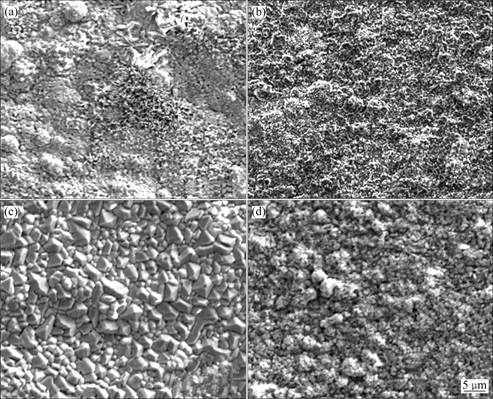

2.3.2 涂层表面氧化形貌

经900 ℃等温氧化25 h后,试样表面形貌如图4所示。无涂层试样(图4(a))氧化表面大多呈珊瑚网状,并且散布着较少但尺寸较大的球形颗粒;图4(b)显示Ni3Al涂层氧化表面为众多成团簇拥在一起的小长方体氧化颗粒,在这些小长方体氧化颗粒之间分布着更细小的氧化物颗粒;NiAl涂层氧化表面(见图4(c))晶粒呈规则的细小多边形,排列紧密;Ni2Al3涂层的表面(见图4(d))分布着众多的小球形颗粒。

图3 涂层等温氧化动力学曲线

Fig. 3 Isothermal oxidation kinetics of coatings at 900 ℃(a) and 1 100 ℃(b)

经过1 100 ℃等温氧化10 h后,没有涂层的基体试样表面开始被破坏并产生剥落;等温氧化20 h后基体试样已经完全被破坏,形成大量剥落的氧化皮。Ni3Al涂层试样氧化15 h开始有剥落现象,氧化结束后表面已经有大量因剥落形成的坑;而NiAl和Ni2Al3涂层只有少量细小的剥落物,整个样品完整,表面仅有很少的氧化斑点。Ni2Al3为脆性相,具有高的缺陷浓度[16],这样就加速铝在氧化过程中的扩散,导致铝浓度迅速降低,使Ni2Al3向NiAl转变;在氧化过程中形成的氧化膜不如NiAl涂层致密,所以其抗氧化性能比NiAl涂层的差。Ni3Al涂层的铝浓度相对较低,表面氧化后形成大量柱状的TiO2,破坏了涂层的致密性,抗氧化性能比NiAl涂层的差。

图4 900 ℃等温氧化试样表面的SEM像

Fig. 4 SEM images of surfaces of samples after isothermal oxidation at 900 ℃ for 25 h: (a) Substrate; (b) Ni3Al coating; (c) NiAl coating; (d) Ni2Al3 coating

3 结论

1) 采用固体粉末渗铝法在镍基高温合金DZ417G基体上成功制备出了γ′-Ni3Al、γ′-Ni3Al+β-NiAl、β-NiAl、β-NiAl+δ-Ni2Al3和δ-Ni2Al3涂层,涂层组织致密;通过控制渗剂成分和保温时间,可以在Ni-Al二元相图成分区间内任意控制涂层相组成。

2) 900 ℃和1 100 ℃空气等温氧化实验显示,涂层能显著提高基体材料的抗氧化性能,NiAl涂层抗氧化性能优于Ni2Al3涂层的,Ni2Al3涂层的抗氧化性能又优于Ni3Al涂层的。

REFERENCES

[1] 胡壮麒, 刘丽荣, 金 涛, 孙晓峰. 镍基单晶高温合金的发展[J]. 航空发动机, 2005, 31(3): 1-7.

HU Zhuang-qi, LIU Li-rong, JIN Tao, SUN Xiao-feng. Development of the Ni-base single crystal superalloys[J]. Aeroengine, 2005, 31(3): 1-7.

[2] CLARKE D R, LEVI C G. Materials design for the next generation thermal barrier coatings[J]. Annual Review of Materials Research, 2003, 33: 383-417.

[3] GLEESON B. Thermal barrier coatings for aeroengine applications[J]. Journal of Propulsion and Power, 2006, 22(2): 375-383.

[4] KEMPSTER A. Recent developments in aluminum diffusion[J]. Anti-Corrosion Methods and Materials, 1998, 45(2): 81-83.

[5] 黄志荣, 李培宁, 徐 宏. 可控固体粉末渗铝新工艺[J]. 新技术新工艺, 2004(10): 59-61.

HUANG Zhi-rong, LI Pei-ning, XU Hong. A controlled new process of pack aluminization[J]. New Technology & New Process, 2004(10): 59-61.

[6] 李 克, 张正义, 苏怡兴, 张 莉. 航空高温合金用新型气相渗铝工艺研究[J]. 热处理, 2009, 24(5): 24-29.

LI Ke, ZHANG Zheng-yi, SU Yi-xing, ZHANG Li. New type gas aluminizing for high-temperature alloy in aeronautic industry[J]. Heat Treatment, 2009, 24(5): 24-29.

[7] 张光业, 张 华, 张厚安, 尹何迟, 郭建亭. 高温合金低压气相沉积渗铝工艺研究[J]. 材料保护, 2006, 39(7): 35-37.

ZHANG Guang-ye, ZHANG Hua, ZHANG Hou-an, YIN He-chi, GUO Jian-ting. Low-pressure gas deposition aluminizing process for K17 superalloy[J]. Materials Protection, 2006, 39(7): 35-37.

[8] 杨世伟, 刘海涛, 朱玲斌, 娄 瑾. K4104合金渗Al-Si涂层抗高温氧化性能研究[J]. 中国腐蚀与防护学报, 2006, 26(6): 371-375.

YANG Shi-wei, LIU Hai-tao, ZHU Ling-bin, LOU Jin. Study on high temperature oxidation properties of Al-Si coatings on K4104 superalloy[J]. Journal of Chinese Society for Corrosion and Protection, 2006, 26(6): 371-375.

[9] BAHADUR A, SHARMA T L, PARIDA N. Structure-property correlation in Al-diffusion coated steels[J]. Journal of Materials Science, 1993, 28(19): 5375-5381.

[10] 郑伯伟, 黄志荣. HK40钢固体粉末渗铝的动力学研究[J]. 江苏石油化工学院学报, 2002, 14(3): 33-36.

ZHANG Bo-wei, HUANG Zhi-rong. Study on the kinetics of pack aluminization of HK40 steel[J]. Journal of Jiangsu Institute of Petrochemical Technology, 2002, 14(3): 33-36.

[11] 王红星, 盛晓波, 储成林, 林萍华, 董寅生. Cu基体电镀Ni层表面渗Al组织及其形成机理[J]. 中国有色金属学报, 2007, 17(10): 1616-1621.

WANG Hong-xing, SHENG Xiao-bo, CHU Cheng-lin, LIN Ping-hua, DONG Yin-sheng. Aluminizing microstructure and its formation mechanism on electro-deposited nickel layer on copper matrix[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1616-1621.

[12] 胡赓祥, 钱苗根. 金属学[M]. 上海: 上海科技出版社, 1980: 122.

HU Geng-xiang, QIAN Miao-gen. Physical metallurgy[M]. Shanghai: Shanghai Science Technology Press, 1980: 122.

[13] VOUDOURIS N, CHRISTOJLOU C, ANGELOPOLOS G N. Formation of aluminide coating on nickel by a fluidized bed CVD process[J]. Surface and Coatings Technology, 2001, 141(2/3): 275-282.

[14] ZHANG Y, STACY J P, PINT B A, HAYNES J A, HAZEL B T, NAGARAJ B A. Interdiffusion behavior of Pt-diffused γ+γ′ coatings on Ni-based superalloys[J]. Surface and Coatings Technology, 2008, 203(5/7): 417-421.

[15] 叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 2版. 北京: 冶金工业出版社, 2002: 57-625.

YE Da-lun, HU Jian-hua. Practical handbook of the thermodynamic data for inorganic substances[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2002: 57-625.

[16] JANSSEN M M P, RIECK G D. Reaction diffusion and Kirkendall effect in the nickel-aluminum system[J]. Transactions of the Metallurgical Society of AIME, 1967, 239: 1372-1385.

(编辑 李艳红)

基金项目:上海市科学技术委员会资助项目(08PJ1405200,10JC1405100)

收稿日期:2010-11-23;修订日期:2011-06-25

通信作者:操光辉,教授,博士;电话:021-56337244;E-mail: ghcao@shu.edu.cn