DOI:10.19476/j.ysxb.1004.0609.2019.08.10

铅合金搅拌摩擦焊接接头的组织与性能

曾祥浩1, 2,倪丁瑞1,薛 鹏1,肖伯律1,马宗义1,王莉莉3,张晋楠3

(1. 中国科学院 金属研究所,沈阳 110016;

2. 中国科学院大学,北京 100049;

3. 沈阳市新利兴有色合金有限公司,沈阳 110149)

摘 要:本研究采用搅拌摩擦焊接(FSW)技术成功实现了8 mm厚铅合金板材的高速焊接,得到了表面美观、无宏观焊接缺陷的FSW接头。结果表明:高转速可以促进前进侧与后退侧材料的充分混合,避免弱结合的产生;焊速加快,在高温下停留的时间短,接头软化程度得到抑制,因此在高转速和高焊速条件下能得到性能更好的铅合金FSW接头。在转速800 r/min、焊速800 mm/min工艺条件下,得到了抗拉强度为34 MPa的铅合金搅拌摩擦焊接接头,其强度达到母材的95%;其均匀伸长率为2.5%,断裂伸长率为7%,其均匀伸长率比母材的要大。

关键词:铅合金;搅拌摩擦焊;接头;微观组织;力学性能

文章编号:1004-0609(2019)-08-1654-06 中图分类号:TG456.9 文献标志码:A

有色金属电积工业普遍采用高浓度H2SO4电积体系[1],铅及铅合金性能稳定,在酸溶液中表面氧化物容易成型、且能自动修复,因此被广泛应用于不溶性阳极[2-3]。焊接是湿法冶金中的铅合金阳极板生产的重要工艺。以往的铅合金阳极板焊接多采用熔焊工艺,不仅存在工序多、效率低问题,还存在工艺可重复性差、焊缝缺陷多、接头性能低的突出问题。同时由于熔池表面极易生成一层氧化铅薄膜,导致焊缝中形成夹渣和边缘未焊透[4]。此外,由于铅的密度大、流动性高,横焊及仰焊时易导致熔池大量坠流,故所得的熔焊接头强度并不理想[5]。尤其是,由于铅沸点低,在传统熔焊过程中蒸发的铅易与空气中的氧化合,生成有毒的氧化物污染环境,会对人身体造成严重的伤害。因此,铅合金的优质、高效、绿色焊接是其广泛应用必须解决的问题。

搅拌摩擦焊接(Friction stir welding,FSW)是1991年由英国焊接研究所发明的固态连接技术。由于热输入低、无熔化、接头力学性能好、焊缝表观质量好、绿色环保等特点,广泛应用于铝合金、镁合金、铜合金等有色金属的焊接[6-7]。FSW可有效避免传统熔化焊产生的各种缺陷,可实现传统“难焊”的高强铝合金(如2000系和7000系铝合金)的高质量焊接,接头力学性能明显优于传统熔焊接头力学性能[8]。FSW在高强铝合金焊接上的成功也为铅合金的连接提供了新思路,然而关于铅合金FSW的研究论文还未见报道。

FSW接头的正常断裂往往会出现在接头的热影响区,其断裂机理通常有两种:一种是以6000系和7000系为代表的沉淀强化铝合金,由于焊接过程热的作用使得热影响区的沉淀相发生明显的溶解与长大,造成力学性能的降低,发生断裂[9];另一种是以5000系和纯铜为代表的加工硬化态材料,同样是由于焊接过程热的作用,使得热影响区发生动态回复,位错密度降低,力学性能下降,发生断裂[10]。由于铅合金FSW的研究性论文还未见报道,故对其接头的断裂机理目前也不清楚。

本研究对阳极板常用材料8 mm厚的轧制态Pb-Sn合金进行了FSW对接焊接,分析了焊接参数对焊接质量和力学性能的影响,重点探讨了接头的断裂行为与机理。

1 实验

本研究所用材料为8 mm厚的轧制态Pb-Sn合金,长200 mm,宽80 mm。Sn的含量为1.5%(质量分数)。

焊接设备为 FSW-5LM-020型数控搅拌摩擦焊机,实验中采用钢质焊接工具, 轴肩直径为22 mm;搅拌针为 M8的锥形螺纹针, 长度为 7.68 mm。优选2组参数对板材沿轧制方向进行对接焊接,分别为转速400 r/min,焊速 400 mm/min(样品命名为J400- 400);转速800 r/min,焊速800 mm/min(样品命名为J800-800)。

用Olympus Corporation HC-300Z/OL型光学显微镜和FEI Quanta 600型扫描电镜(SEM)分别对接头和断口进行微观组织分析。金相样品垂直于焊缝的横截面取样,样品经打磨、机械抛光、电解腐蚀后进行金相观察。采用Leco-LM-247AT型显微硬度试验机测试接头距表面4 mm处垂直于焊缝的显微硬度分布曲线,每隔1 mm打点,测试载荷0.5 N,保压15 s。采用SANS-CMT5205电子万能试验机以1×10-3 s-1应变速率进行室温拉伸试验。拉伸样品垂直于焊缝方向切取,长度140 mm,标距部分长40 mm,宽20 mm。母材拉伸样品尺寸与焊缝拉伸样品尺寸相同,每组拉伸样品取3个平行试样,拉伸结果取平均值。

2 结果与分析

2.1 焊缝的宏观形貌

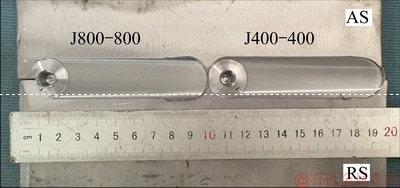

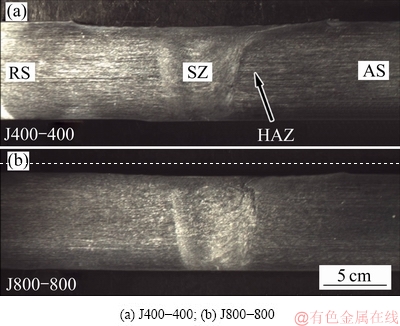

图1所示为两组焊接参数下焊缝表面照片。由图1可见,在两组焊接参数条件下均得到了平滑无缺陷的焊缝,成功实现了铅合金的搅拌摩擦焊接。图2所示为垂直于焊缝方向的宏观金相组织像,其中焊核右侧为前进侧,左侧为后退侧。由图2可见,在两组焊接参数条件下,焊核区均未观察到明显的宏观缺陷,得到了完整形状的焊核区。同时,焊核均为盆状形貌,但上部轴肩影响区域深度较浅,主要为搅拌针影响区。这一现象明显有别于铝合金,表明在铅合金的FSW过程中,轴肩对焊核上部材料的作用能力相对较小。这应该是由于铅的熔点较低,在摩擦热作用下,生温后软化明显,使材料不能紧跟轴肩,因此轴肩带动的材料塑变区域很小。

图1 Pb-Sn合金轧板FSW焊缝表面形貌

Fig. 1 Surficial morphologies of FSW joints of rolled Pb-Sn alloy plates (AS—Advancing side; RS—Retreating side)

图2 Pb-Sn合金轧板FSW接头横截面宏观形貌

Fig. 2 Cross-sectional macrostructures of FSW joints of rolled Pb-Sn alloy plates (SZ—Stir zone; HAZ—Heat affected zone)

2.2 工艺参数对焊缝性能的影响

由于铅合金的密度大,但强度往往却很低,在实际生产应用中容易变形导致短路,易造成安全事故,因此铅合金焊缝的力学性能是评判阳极板性能好坏的极其重要的参数之一[11]。

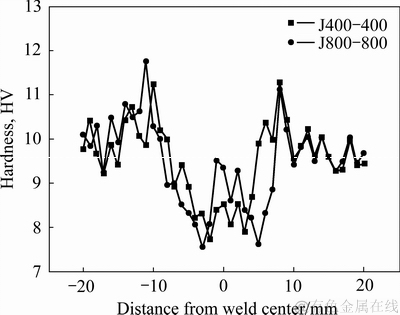

图3所示为在两组焊接参数条件下铅合金FSW接头的硬度曲线。从图3中可以看出以下三点发现:

1) 所有参数下,与母材(Parent metal,PM)相比接头均发生软化,硬度曲线呈现出“W”型,这与铝合金的FSW接头的硬度曲线规律类似[12-13]。具体来讲,从热影响区开始硬度逐渐降低,至热影响区和焊核区交界达到最低值,在两组参数条件下都约为7.5 HV。这与纯铜FSW接头最低硬度出现在热影响区原因一致[10],由于受热的作用,热影响区发生动态回复,硬度值降低。同时,热影响区越靠近焊核,受热作用越大,热影响区的回复程度也越大,硬度降低越显著;由于焊接工具的搅拌及热的作用,焊核处晶粒发生细化,故随后从热影响区往焊核方向硬度逐渐升高。

2) 在轴肩边缘位置的下方,材料的硬度值相对母材较高,这是由于轴肩向下的挤压作用使得轴肩下方的材料产生了加工硬化,强度相比母材有一定的提高。

3) 试样J800-800焊核区的硬度值比试样J400-400焊核区的要高,这是因为转速和焊速越大,FSW过程中的应变和应变速率也就越大,焊核区的晶粒更加细小[14],故在较高转速和焊速条件下,试样的焊核硬度值要高于在低转速和焊速条件下的高。

图3 Pb-Sn合金FSW接头的硬度曲线

Fig. 3 Microhardness profiles of different FSW joints of Pb-Sn alloy

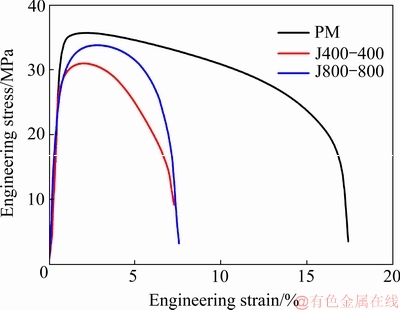

图4所示为母材和不同焊接参数下铅合金FSW接头的拉伸曲线。由图4可见,母材的抗拉强度最高为36.MPa,断裂伸长率为15%,但基本没有均匀伸长率,这是典型的变形态铅合金的拉伸特征[4]。试样J400-400和J800-800的抗拉强度比母材的稍低,分别为31 MPa和 34 MPa,焊接系数分别达到了86%和95%。其中试样J800-800接近等强焊接的水平,同时也不低于熔焊接头的抗拉强度[15]。试样J400-400的断裂伸长率和均匀伸长率分别为5%和1.5%。虽然试样J800-800的断裂伸长率只有7%,但其均匀伸长率却有2.5%,比母材相对较好,这是因为热影响区的材料发生了一定程度的动态回复,使得对位错的存贮能力有一定的提高,也间接证明前述分析的正确性。

图4 Pb-Sn合金母材和FSW接头的室温拉伸性能

Fig. 4 Engineering stress-strain curves of different FSW joints of Pb-Sn alloy at room temperature

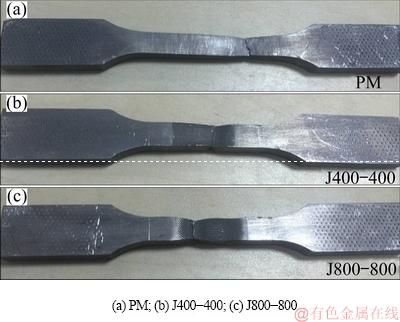

图5所示为母材和不同焊接参数下铅合金FSW接头的拉伸断裂位置。由图5可见,试样J800-800断裂在热影响区和焊核区的交接处,与其硬度曲线上的最低硬度点基本一致。而试样J400-400却断裂在焊核内,这与其硬度曲线上的最低硬度点并不一致。

图5 Pb-Sn合金母材和FSW接头拉伸断裂位置

Fig. 5 Failed tensile positions of different FSW joints and parent material of Pb-Sn alloy

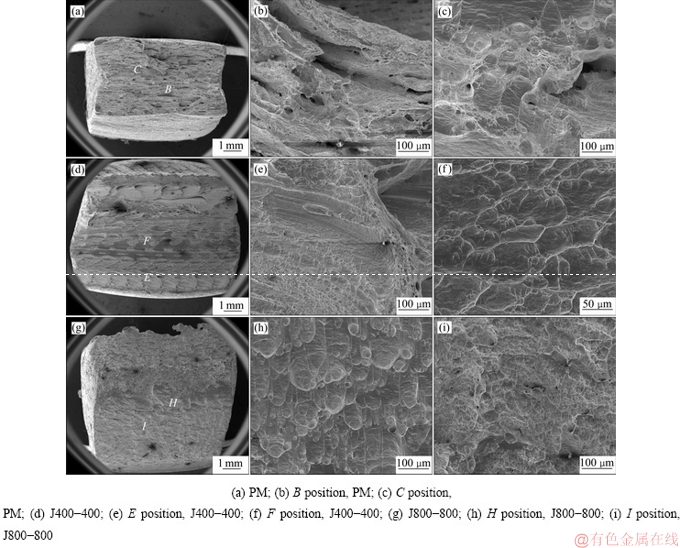

为了进一步分析铅合金断裂机理及试样J400- 400异常断裂的原因,本研究对PM和其FSW接头的断口进行了扫描电镜观察,如图6所示。图6(a)所示为母材拉伸断口的整体形貌,将其特征区域B、C放大如图6(b)、(c)所示。由图6(b)可见,铅合金母材在拉伸的过程中产生了许多细小的孔洞。而由图6(c)可见,在变形过程的滑移痕迹反映出铅合金母材具有较好的延展性,这与其拉伸曲线具有较高的断裂伸长率一致。图6(d)~(f)所示为试样J400-400拉伸断口的形貌,断口底部呈现FSW接头弱结合的典型形貌[16](见图6(e))。在较低的转速下,材料的流动并不充分,导致了前进侧和后退侧材料混合不充分[17-18],在焊核底部形成了弱的结合。而图6(f)中观察到了较浅的韧窝,这与其拉伸曲线具有一定的伸长率一致,反映出此试样具有一定的塑性。图6(g)所示为试样J800-800拉伸断口的整体形貌。由图6(g)可见,断口可以分为中间区域(区域H)和靠近表面区域(区域I)两部分,将其放大如图6(h)和(i)所示。由图6(h)可见,中间区域呈现出类似母材断口区域C的特征,表明此部分材料也具有良好的延展性。而由图6(i)可见,断口靠近表面区域存在明显的韧窝和撕裂棱,反映出其具有一定的塑性。试样J800-800拉伸断口的特征表明其具有较好的均匀伸长率和一定的断裂伸长率,这与其拉伸曲线的结果是一致的。

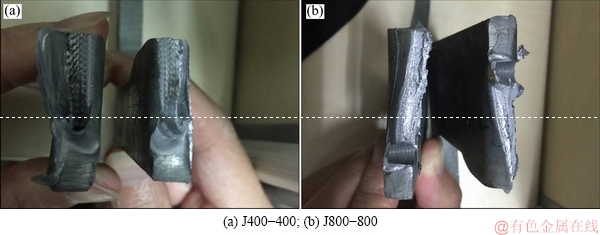

图7所示为不同焊接参数下铅合金FSW接头的弯曲断裂位置和断口宏观形貌。对于试样J400-400,弯曲断裂位置出现在焊核且断口呈现“拉链状”的特征。这与其拉伸断口的特征是一致的,为典型的FSW接头弱结合的典型形貌。而对于试样J800-800,弯曲断裂位置出现在热影响区,这与其拉伸断裂位置也是一致的。同时,虽然断裂位置未出现在焊核,但在焊核底部出现了裂缝,说明焊核底部也是铅合金FSW接头的薄弱区域之一,这一规律与铝合金FSW接头的性能特点也是类似的[17]。

图6 Pb-Sn合金母材和FSW接头断口的SEM像

Fig. 6 Fracture SEM images of different FSW joints and base material of Pb-Sn alloy

图7 Pb-Sn合金FSW接头的弯曲断裂位置

Fig. 7 Fractured bending positions of different FSW joints of Pb-Sn alloy

从上述试验结果来看,高转速可以促进前进侧与后退侧的材料充分混合,避免弱结合的产生,而高焊速下变形迅速,温度相对较低,接头的软化程度也相对较低。因此,高转速和高焊速参数下能够得到性能更好的铅合金FSW接头。更重要的是,高焊速也有利于提高焊接效率,更加适合于实际工业生产。虽然与传统熔焊铅合金接头相比,采用FSW接头的强度并没有太大的提高,但FSW这种固相焊接技术能够有效的避免在传统熔焊过程生成的有毒物质,能够实现铅合金的优质、高效、绿色焊接。

3 结论

1) 采用搅拌摩擦焊技术成功在两组焊接参数下实现了8 mm厚轧制态铅合金板的对接焊,得到了无宏观缺陷的焊接接头。

2) 高转速可以促进前进侧与后退侧的材料充分混合,避免弱结合的产生。高焊速下变形迅速,温度相对较低,接头的软化程度也相对较低。因此,高转速和高焊速下能够得到性能更好的铅合金FSW接头。

3) 在转速800 r/min、焊速800 mm/min工艺条件下,得到了抗拉强度为34 MPa的铅合金FSW接头,达到母材强度的95%。均匀伸长率为2.5%,断裂伸长率为7%,其中均匀伸长率高于母材的均匀伸长率。

REFERENCES

[1] 朱茂兰, 涂 弢, 朱根松, 张丽娜, 王瑞祥. Gd对有色金属电积用铅基阳极性能的影响[J]. 中国有色金属学报, 2014, 24(11): 2821-2826.

ZHU Mao lan, TU Tao, ZHU Gen song, ZHANG Li na, WANG Rui xiang. Influence of Gd on properties of Pb based anode for nonferrous electrowinning[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2821-2826.

[2] 洪 波, 蒋良兴, 吕晓军, 倪恒发, 赖延清, 李 劼, 刘业翔. Nd 对锌电积用 Pb Ag 合金阳极性能的影响[J]. 中国有色金属学报, 2012,22(4): 1126-1131.

HONG Bo, JIANG Liang xing, Lü Xiao jun, NI Heng fa, LAI Yan qing, LI Jie, LIU Ye xiang. Influence of Nd on Pb Ag alloy anode for zinc electrowinning[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1126-1131.

[3] LUPI C, PILONE D. New lead alloy anodes and organic depolarizer utilization in zinc electrowinning[J]. Hydrometallurgy, 1991, 52(3): 223-230.

[4] 黄伯云, 李成功, 石力开, 邱冠周,左铁镛. 中国材料工程大典, 第四卷[M]. 北京: 化学工业出版社, 2006: 464-480. HUANG Bai-yun, LI Cheng-gong, SHI Li-kai, QIU Guang-zhou, ZUO Tie-yong. China materials engineering canon, Volume 4[M]. Beijing: Beijing Chemical Industry Press, 2006: 464-480.

[5] 李松瑞. 铅及铅合金[M]. 长沙: 中南工业大学出版社, 1996: 1-21.

LI Song-rui. Plumbum and plumbum alloy[M]. Changsha: Central South University of Technology Press, 1996: 1-21.

[6] KHAN N Z, KHAN1 Z A, SIDDIQUEE A N, AL-AHMARI A M, ABIDI M H. Analysis of defects in clean fabrication process of friction stir welding[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1507-1516.

[7] PADHY G K, WU C S, GAO S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review[J]. Journal of Materials Science & Technology, 2018, 34(1): 1-38.

[8] 周鹏展, 贺地求, 邓 航. LF21 铝合金薄板搅拌摩擦焊组织与性能[J]. 中南大学学报(自然科学版), 2007, 38(5): 917-921.

ZHOU Peng-zhan, HE Di-qiu, DENG Hang. Microstructure and property of friction stir welded LF21 aluminum sheet[J]. Journal of Central South University(Science and Technology), 2007, 38(5): 917-921.

[9] SHANAVAS S, EDWIN RAJA DHAS J. Parametric optimization of friction stir welding parameters of marine grade aluminium alloy using response surface methodology[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(11): 2334-2344.

[10] XUE P, XIAO B L, ZHANG Q, MA Z Y. Achieving friction stir welded pure copper joints with nearly equal strength to the parent metal via additional rapid cooling[J]. Scripta Materialia, 2011, 64(11): 1051-1054.

[11] 戴炳蔚, 于 杰, 周晓龙, 刘克伟. LF21 Ce对锌电积用Pb-Sb合金阳极板性能的影响[J]. 热加工工艺, 2018, 47(4): 89-95.

DAI Bing-wei, YU Jie, ZHOU Xiao-long, LIU Ke-wei. Influence of Ce on properties of Pb-Sb alloy anode platefor zinc electrowinning[J]. Hot Working Technology, 2018, 47(4): 89-95.

[12] 谢永辉, 杨新岐, 崔 雷. 6061-T4铝合金单双道搅拌摩擦焊T型接头组织及性能[J]. 中国有色金属学报, 2015, 25(1): 72-79.

XIE Yong-hui, YANG Xin-qi, CUI Lei. Microstructure and property of 6061-T4 aluminum alloy T-joints by friction stir welding under single pass and double passes[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 72-79.

[13] ZHANG Z, XIAO B L, MA Z Y. Influence of water cooling on microstructure and mechanical properties of friction stir welded 2014Al-T6 joints[J]. Materials Science and Engineering A, 2014, 614: 6-15.

[14] ZENG X H, XUE P, WANG D, NI D R, XIAO B L, MA Z Y. Realizing equal strength welding to parent metal in precipitation-hardened Al-Mg-Si alloy via low heat input friction stir welding[J]. Science and Technology of Welding and Joining, 2018, 23(6): 478-486.

[15] SHEEN M T, CHANG C M, TENG H C, KUANG J H, HSIEH K C, CHENG W H. The influence of thermal aging on joint strength and fracture surface of Pb/Sn and Au/Sn solders in laser diode packages[J]. Journal of Electronic Materials, 2002, 31(8): 895-902.

[16] 王国庆, 赵衍华. 铝合金的搅拌摩擦焊接[M]. 北京: 中国宇航出版社, 2010: 198-239.

WANG Guo-qing, ZHAO Yan-hua. Friction stir welding of aluminum alloy[M]. Beijing: China Aerospace Press, 2010: 198-239.

[17] 陶 瑶. 两种典型第三代铝理合金搅拌摩擦焊接接头的组织与性能研究[D]. 沈阳: 中国科学院金属研究所, 2017: 67-91.

TAO Yao. Microstructure and mechanical properties of friction stir welded joints of two typical third generation aluminum-lithium alloys[D]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2017: 69-71.

[18] ZENG X H, XUE P, WANG D, NI D R, XIAO B L, MA Z Y. Effect of processing parameters on plastic flow and defect formation in friction-stir-welded aluminum alloy[J]. Metall Mater Trans A, 2018, 49(7): 2673-2683.

Microstructure and mechanical property of friction stir welded Pb alloy joints

ZENG Xiang-hao1, 2, NI Ding-rui1, XUE Peng1, XIAO Bo-lü1, MA Zong-yi1, WANG Li-li3, ZHANG Jin-nan3

(1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. University of Chinese Academy of Sciences, Beijing 100049, China;

3. Shenyang Xinlixing Non-ferrous Metal Alloy Co., Ltd., Shenyang 110149, China)

Abstract: In this study, Pb-Sn alloy sheets with thickness of 8 mm were subjected to friction stir welding (FSW) under various welding parameters. The results show that high rotation rates promote the mixture of material in the stirred zone, which is beneficial to avoid the formation of void defects. Meanwhile, a faster traverse speed reduces the duration of welding tool at high temperatures, which can restrain the soft of material during FSW. Thus, higher rotation rates and faster traverse speeds are beneficial to obtain FSW joints of Pb alloys with high strength. Under the rotation rate of 800 r/min and welding speed of 800 mm/min, a sound FSW joint is obtained with the ultimate tensile strength (UTS) of 34 MPa, reaching to 95% of that of the parent metal. The uniform elongation and elongation to failure of this joint are 2.5% and 7%, respectively.

Key words: Pb alloy; friction stir welding; joints; microstructure; mechanical property

Foundation item: Project(51331008) supported by the National Natural Science Foundation of China; Project (Z17-7-025) supported by the Shenyang Science and Technology Innovation Plan of Shenyang City, China

Received date: 2018-08-15; Accepted date: 2018-12-11

Corresponding author: NI Ding-rui; Tel: +86-24-23971749; E-mail: drni@imr.ac.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51331008);沈阳市科技创新“双百工程”项目(Z17-7-025)

收稿日期:2018-08-15;修订日期:2018-12-11

通信作者:倪丁瑞,研究员,博士;电话:024-23971749;E-mail:drni@imr.ac.cn