DOI:10.19476/j.ysxb.1004.0609.2018.03.04

γ-TiAl单晶塑性变形中晶粒转动的CPFEM模拟

赵文娟1, 2,张 露1, 2,李晓滨3,彭远祎1, 2,黄明丽4,林启权1, 2

(1. 湘潭大学 机械工程学院,湘潭 411105;

2. 湘潭大学 焊接机器人及应用技术湖南省重点实验室,湘潭 411105;

3. 中冶建筑研究总院有限公司,北京 100088;

4. 东北大学 秦皇岛分校,秦皇岛 066004)

摘 要:基于晶体塑性理论和有限元方法建立适合面心正方结构(L10)金属力学行为的细观数值本构关系模型,并利用该晶体塑性有限元(CPFEM)模型对γ-TiAl单晶室温下的单向拉伸试验进行模拟。模拟中拉伸方向分别选取[1 0](普通滑移),[

0](普通滑移),[ 01](超滑移)、[11

01](超滑移)、[11 ](孪生)及任意取向[

](孪生)及任意取向[ 01]。结果表明:拉伸变形中γ-TiAl单晶晶粒以中心为转轴发生转动,且取向对其晶粒转动有显著的影响。[1

01]。结果表明:拉伸变形中γ-TiAl单晶晶粒以中心为转轴发生转动,且取向对其晶粒转动有显著的影响。[1 0](普通滑移)取向的晶粒转动较小,其余取向的晶粒转动角度相对较大;[1

0](普通滑移)取向的晶粒转动较小,其余取向的晶粒转动角度相对较大;[1 0]取向的晶粒,其拉伸阻力较小,进而普通位错容易启动,且拉伸中以普通滑移系的激活为主;其他取向拉伸时,滑移系激活的阻力较大,必须以扭转来调整取向因子从而协调变形,因而表现出显著的晶粒转动。

0]取向的晶粒,其拉伸阻力较小,进而普通位错容易启动,且拉伸中以普通滑移系的激活为主;其他取向拉伸时,滑移系激活的阻力较大,必须以扭转来调整取向因子从而协调变形,因而表现出显著的晶粒转动。

关键词:γ-TiAl合金;晶体塑性;取向;晶粒转动;塑性变形;有限元

文章编号:1004-0609(2018)-03-0465-09 中图分类号:TG146.2 文献标志码:A

在航天、航空、船舶及汽车等领域有广阔应用前景的轻质金属结构材料中,TiAl基合金以其低密度、高比强度、高比模量、良好的阻燃能力、抗氧化性及抗蠕变性能等倍受青睐[1-4]。目前,通过实验、计算模拟等手段对TiAl基金属间化合物的力学性能研究方兴未艾,晶体塑性有限元方法(Crystal plasticity finite element method,CPFEM)是其中的一种有效研究手段,持续吸引着研究者们的目光。

近年来,TiAl合金力学行为的相关数值计算已取得一定的研究进展。KAD等[5]首次利用晶体塑性理论模拟二维全片层γ-TiAl组织,认为片层的变形方式仅有软剪切和硬剪切两种模式,这样的过度简化使得其模拟结果与试验结果之间存在较大的偏差。ZAMBALDL等[6]通过建立简单的三维几何模型,研究层片状γ-TiAl基合金的塑性各向异性行为,发现晶粒取向影响着γ-TiAl基合金的塑性变形性能;且不同取向晶粒的屈服强度存在较大差异,与实验结果基本吻合。FALLAHI等[7]运用晶体塑性有限元方法,模拟了γ-TiAl双晶、三晶拉伸过程中不同晶粒取向对应力集中的影响,发现在应力集中的横截面上形成较大的应力梯度,有颈缩转动的趋势。另一方面,陈守东等[8]在铜极薄带轧制中滑移与变形的晶体塑性有限元模拟中,发现晶粒间及晶粒内的转动均会引起材料内部变形的不均匀。邓运来等[9]在对高纯铝柱状晶的冷轧试验研究中发现,形变晶粒各部分具有不同的转动趋势,靠近晶界部分的转动角度较小。AKHTAR[10]在单晶纯钛的拉伸试验中,发现随着剪切应变的增大,晶格转动使柱面滑移系得以启动。由此,在TiAl基合金的塑性变形中,明晰晶粒转动现象的成因,探索取向对晶粒转动及合金塑性变形行为的影响作用将对深入理解其微观塑性机制有着重要的意义。

γ-TiAl基合金主要由γ-TiAl和Ti3Al相组成,其中Ti3Al相变形困难,变形主要发生在γ-TiAl相内。由于γ-TiAl合金片层组织中L10结构的γ相的<110]和<011]取向在晶体学上不等价,导致这种复杂的晶体取向关系对γ-TiAl合金塑性变形中滑移系的启动和滑移有着重要的影响。γ-TiAl相中主要存在的滑移系有: 4个普通滑移系<110]{111},8个超滑移系<011]{111}和4个孪生系<112]{111}[11-14]。本研究基于以上的γ-TiAl主要滑移系选取晶粒的初始取向,建立综合考虑普通位错、超位错和孪生的晶体塑性有限元本构关系模型。模拟不同取向条件下γ-TiAl单晶的拉伸变形,观察变形中剪切应变的变化,研究拉伸中晶粒转动与晶粒初始取向之间的相互作用关系。

1 晶体塑性理论

1.1 晶体剪切滑移理论

采用晶体塑性理论描述塑性变形滑移中的应力应变关系。根据ASARO等[15]提出的率相关模型,基于施密特定律,晶体α滑移系的滑移率 由其相应的分解剪切应力

由其相应的分解剪切应力 来确定:

来确定:

(1)

(1)

式中: 表示参考剪切应变率;

表示参考剪切应变率; 表示该滑移系的分解剪切应力。m表示应变率敏感因子,反映应变率的影响;

表示该滑移系的分解剪切应力。m表示应变率敏感因子,反映应变率的影响; 表示滑移系的当前强度,反映材料的硬化规律。

表示滑移系的当前强度,反映材料的硬化规律。

任一滑移系的剪切应变率 发生变化都会对当前强度产生影响,其影响可用下述公式表示:

发生变化都会对当前强度产生影响,其影响可用下述公式表示:

(2)

(2)

式中:当 时,

时, 表示潜在硬化系数,

表示潜在硬化系数, (1≤q≤1.5)。当

(1≤q≤1.5)。当 时,

时, 表示自硬化系数,采用ASARO等[15]提出的硬化公式:

表示自硬化系数,采用ASARO等[15]提出的硬化公式:

(3)

(3)

式中:h0表示初始硬化模量; 表示单晶体第一阶段饱和流动应力;

表示单晶体第一阶段饱和流动应力; 表示滑移系临界剪切应力;

表示滑移系临界剪切应力; 表示所有滑移系的剪切应变总和,即:

表示所有滑移系的剪切应变总和,即:

(4)

(4)

1.2 晶粒转动的表征方法

晶体变形除了滑移和孪生外,晶粒的转动对晶体的变形有着不可忽视的作用。本研究在拉伸模拟过程中,着重关注垂直于拉伸轴的平面(XY平面)上的晶粒转动情况,通过晶粒的剪切应变来定量判断晶粒转动角度的大小。

物体变形前后其线元将发生转动,转动角度的大小可用线元来表示[16]。假设变形前两个任意线元的单位矢量分别为v和t,方向余弦分别为vi和ti,则夹角余弦为:

(5)

(5)

利用格林应变张量,式(5)可转化为:

(6)

(6)

由式(6)可以求得线元变形前后的夹角变化。又知变形前两线元相互垂直,则v·t=0,于是上式可以化 简为

(7)

(7)

在小变形情况下,忽略二阶小量,并令θ为变形后线元间直角的减小量,则由式(7)可得:

(8)

(8)

从式(8)可以看出,晶粒转动角度的大小是应变分量大小的2倍。

2 模拟过程

2.1 模型建立

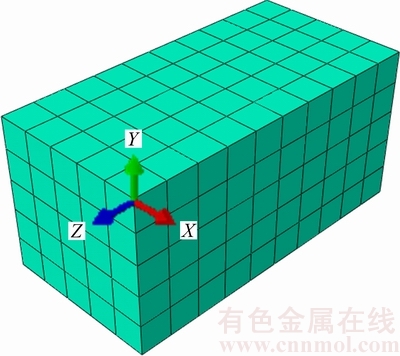

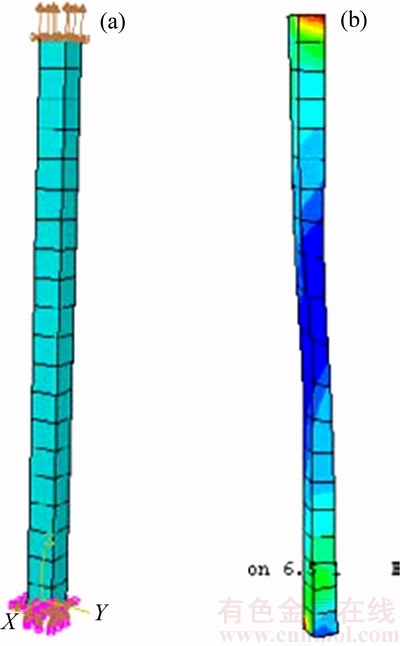

本研究基于ABAQUS平台,利用黄永刚[17]的UMAT编写适合γ-TiAl合金的晶体塑性本构子程序,建立γ-TiAl单晶的晶体塑性有限元模型。模拟晶胞尺寸为0.5 mm×0.5 mm×1 mm,包含250个单元,单元类型为C3D8,如图1所示。拉伸中,将模型中的一个XY端面固定,另一端面施加沿Z轴的拉伸载荷,变形速率为0.01 mm/s,拉伸至工程应变为0.1。

图1 单晶体模型示意图

Fig. 1 Schematic diagram of single crystal model

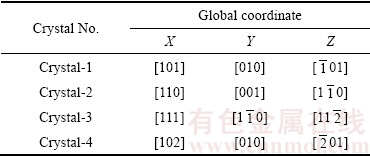

拉伸中4个晶粒的初始取向分别为其超滑移方向[ 01]、普通滑移方向[1

01]、普通滑移方向[1 0]、孪生方向[11

0]、孪生方向[11 ]以及与滑移系不相关的任意取向[

]以及与滑移系不相关的任意取向[ 01],分别记为晶粒1~4。各晶粒的初始取向与整体坐标系(尤其是拉伸方向Z)的对应关系如表1所示。其中,晶粒1的[

01],分别记为晶粒1~4。各晶粒的初始取向与整体坐标系(尤其是拉伸方向Z)的对应关系如表1所示。其中,晶粒1的[ 01]晶向对应整体坐标系的Z轴,其余类似。

01]晶向对应整体坐标系的Z轴,其余类似。

表1 局部坐标与整体坐标系的关系

Table 1 Relationship between local coordinates and global coordinates

2.2 参数设定

室温下γ-TiAl的单晶体弹性模量参数[11-13]如表2所示。参考AKHTAR等[10-12]的实验研究,选取适合γ-TiAl单晶材料本身的参数。γ-TiAl的主要滑移系可分为普通滑移系O、超滑移系S和孪生系T,如表3所示。普通滑移系的临界剪切应力取130 MPa,孪生系的临界剪切应力值与之相同,超滑移系的临界剪切应力取200 MPa。单晶第一阶段饱和流动应力τs取初始临界剪切应力的1.3倍。普通滑移系、超滑移系和孪生系的初始硬化模量分别取400、500和400 MPa。

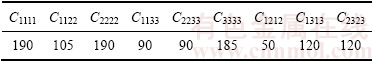

表2 γ-TiAl单晶体的弹性模量[11-13]

Table 2 Elastic modulus of γ-TiAl single crystal (Unit: GPa)

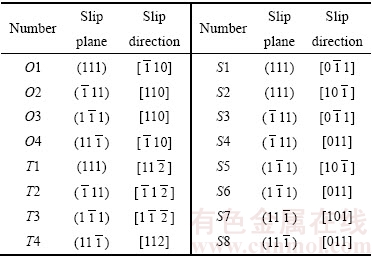

表3 γ-TiAl的滑移系

Table 3 Slip systems of γ-TiAl

3 结果与讨论

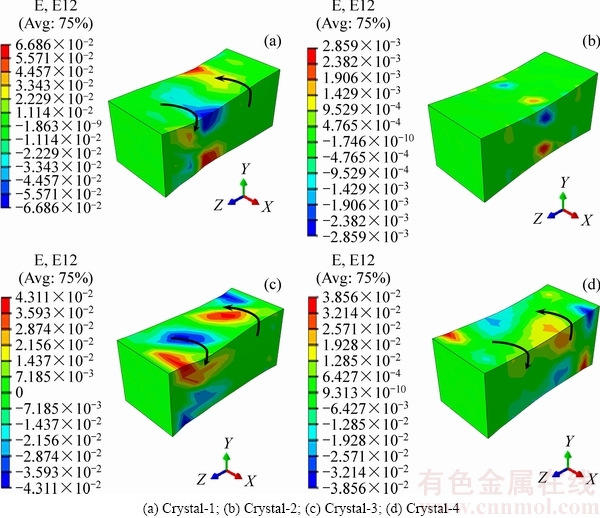

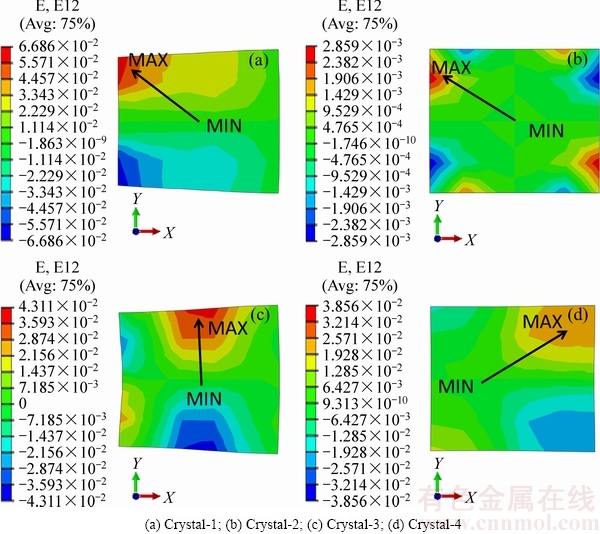

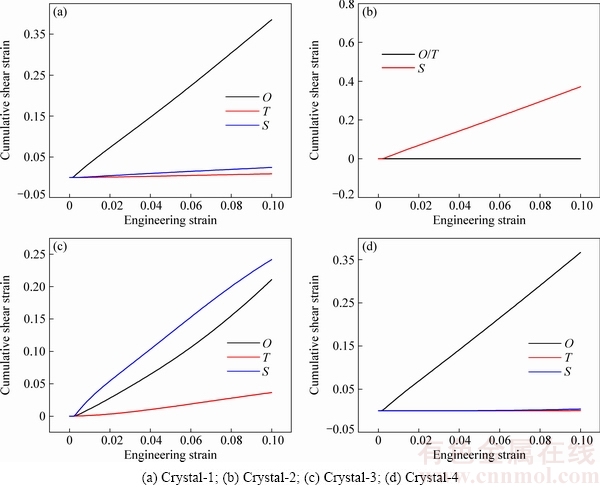

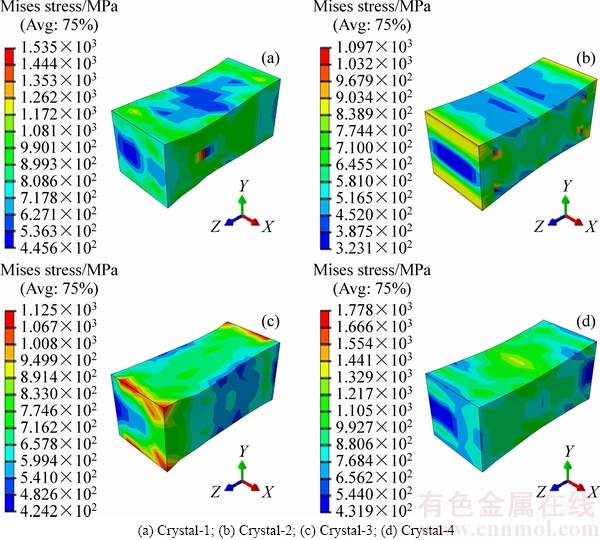

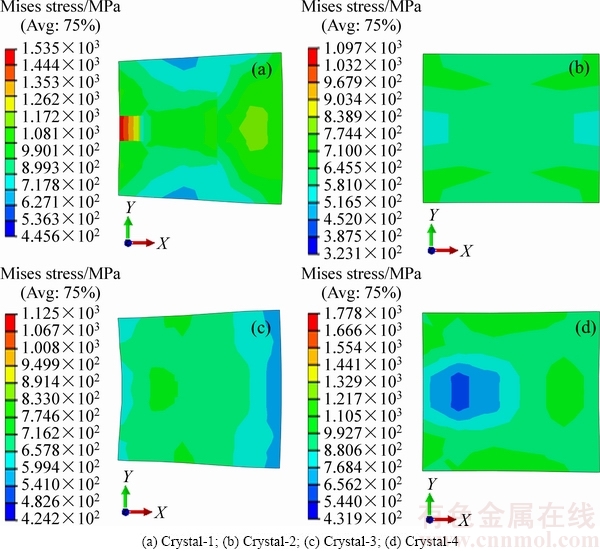

晶粒1~4拉伸变形终了时τXY剪切应变的三维分布图如图2(a)~(d)所示。图3(a)~(d)分别显示了晶粒1~4拉伸变形终了时垂直于拉伸方向(z轴)的XY截面上最大剪切应变的分布情况。拉伸变形的剪切应变观察结果表明,晶粒1~4的剪切应变是由中心部位到边缘逐渐增大的。晶粒中的剪切应变主要集中在晶粒的边缘位置,并且在晶界处有最大值;而在晶粒的中心部位几乎没有剪切应变。图2(a)所示为晶粒1拉伸变形终了时的剪切应变示意图,沿Z轴方向上的应变分布出现正负交替的现象。同时,由图3(a)可见晶粒1的XY截面上剪切应变呈对称分布,其XY平面绕Z轴发生旋转,两者的共同作用导致晶粒发生扭转。与晶粒1类似,其他晶粒也发生了不同程度的晶粒转动。晶体在塑性变形过程中发生扭转,已在一些实验观察中得到证实。AKHTAR[10]对纯钛的拉伸试验中,发现滑移是发生塑性变形的主要原因,同时滑移引起晶格转动。黄文等[18]通过模拟计算的方法,建立与Akhtar实验类似的纯钛拉伸模型,其结果与实验结果基本一致。图4中显示了模拟中变形前后的有限元网格模型,从图4(b)可以看出晶粒发生明显的扭转。该研究认为在不同剪切应变时,不同滑移系的启动和作用,导致晶格的转动。本研究中,图5所示为晶粒1~4在拉伸中滑移系发生的累计剪切应变,O、T、S分别代表普通滑移系、孪生滑移系和超滑移系(如表3所示)的累计应变。从图5(a)中可以看出,晶粒1变形中主要依靠普通滑移发生剪切变形,其他两种变形方式基本无贡献,晶粒4与之类似。晶粒2中以超滑移系的变形为主,而晶粒3中的3种变形方式对变形都表现出一定的贡献,唯有孪生系贡献较小。由此,晶体沿不同的取向拉伸,其滑移系的启动情况不尽相同。其中,普通滑移系容易启动,进而发生剪切变形;而孪生系与超滑移系对变形的贡献较小。晶体变形的本质是滑移系发生剪切应变,本研究的模拟结果表明,在拉伸应力的作用下,γ-TiAl单晶晶粒发生了不同程度的扭转,这与相关实验现象、模拟计算结果基本一致。

图2 拉伸变形终了时不同取向晶粒的剪切应变分布

Fig. 2 Shear strain distribution of single crystals with different orientations at final step of tensile deformation

图3 垂直于拉伸轴XY截面剪切应变分布示意图

Fig. 3 Schematic diagram of shear strain distribution on XY section perpendicular to tensile axis

图4 变形前和变形后钛单晶有限元模型[17]

Fig. 4 FEM model before (a) and after (b) deformation for single crystal Ti

拉伸变形终了时的三维应力分布如图6所示,可以看出应力分布的不均匀,由于晶粒的畸变导致形成较大的应力梯度。结合图2可以发现,应力梯度较大的区域对应的应变也相应较大。同时,如图7所示,从垂直于拉伸轴的XY截面应力分布中也可以看出,应力的分布基本是边缘区域的应力集中显著,而中心区域应力梯度比较小,即在晶粒边界变形程度较大,中心区域无明显变形。结合剪切应变的分布规律可知,在拉伸变形过程中,晶粒的转动是垂直拉伸轴(Z轴)的截面(XY截面)发生明显的扭转,且转动的幅度由中心到边界逐渐增大。

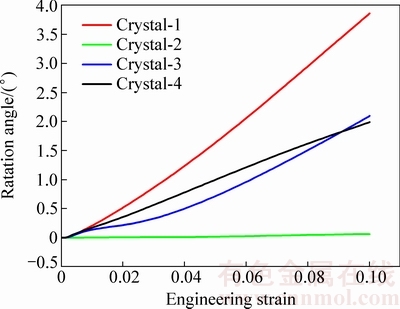

进一步观察模拟晶胞变形前后的线元转动变化,并定量计算了晶粒转动角度的大小(如1.2小节所述),其结果如图8所示。比较晶粒1~4转动角度的大小可以发现,拉伸应力作用下,各晶粒均发生不同程度的转动。当超滑移方向[ 01](晶粒1)与拉伸方向一致时,晶粒的转动角度最大(接近4°),其次是任意取向[

01](晶粒1)与拉伸方向一致时,晶粒的转动角度最大(接近4°),其次是任意取向[ 01](晶粒4),接着是孪生取向[11

01](晶粒4),接着是孪生取向[11 ](晶粒3),最后,普通取向[1

](晶粒3),最后,普通取向[1 0](晶粒2)的转动角度最小,基本为零。该结果表明,晶粒转动角度的大小与其初始取向有密切的关系。当拉伸方向与普通滑移方向[1

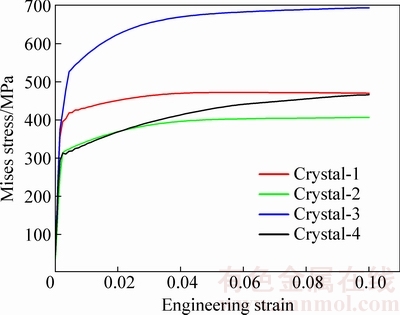

0](晶粒2)的转动角度最小,基本为零。该结果表明,晶粒转动角度的大小与其初始取向有密切的关系。当拉伸方向与普通滑移方向[1 0]一致时,晶粒的旋转角度偏小,基本可视为尚未发生转动。反之,拉伸方向与其他滑移方向一致时,晶粒出现明显的转动,并且随着变形的进行,转动的角度随之增大。同时,图9显示了晶粒1~4的等效应力与应变的关系,从中可以看出晶粒2的拉伸峰值应力最小(400 MPa左右),峰值应力最大的是晶粒3,其应力值高达694 MPa;表明拉伸时晶粒转动导致的晶粒取向改变对材料的强度有一定的影响。

0]一致时,晶粒的旋转角度偏小,基本可视为尚未发生转动。反之,拉伸方向与其他滑移方向一致时,晶粒出现明显的转动,并且随着变形的进行,转动的角度随之增大。同时,图9显示了晶粒1~4的等效应力与应变的关系,从中可以看出晶粒2的拉伸峰值应力最小(400 MPa左右),峰值应力最大的是晶粒3,其应力值高达694 MPa;表明拉伸时晶粒转动导致的晶粒取向改变对材料的强度有一定的影响。

图5 不同拉伸取向下滑移系的剪切应变

Fig. 5 Shear strain of slip system at different tensile directions

图6 拉伸变形终了时不同取向晶粒的应力分布

Fig. 6 Stress distribution of single crystals with different orientations at final step of tensile deformation

图7 垂直于拉伸轴XY截面的应力分布示意图

Fig. 7 Stress distribution on XY section perpendicular to tensile axis

拉伸过程中,当[1 0]普通滑移系与拉伸轴平行时,晶粒在伸长的方向上只受到单纯的剪切应力作用,且此方向上的变形阻力最小,这样保证了晶粒在拉伸方向上能够顺利进行延伸变形。而当拉伸轴方向上的滑移阻力比其他方向上的滑移阻力大时,引起其他方向上的滑移系抢先启动,必然会以扭转来调整取向因子进而协调变形,结果即导致晶体发生转动。对于晶粒转动的研究[19-21],郑为为等[19]在室温下以8个不同初始取向的B2结构Fe3Al单晶进行拉伸试验,其EBSD观察结果表明:不论单晶体初始位向如何,晶体拉伸轴均趋于向<110>方向转动(其中<110>为稳定取向),且转动的角度相对较小(在10°以内)。该实验证明多滑移系共同作用导致晶粒发生转动。本模拟的计算结果与之类似,晶体在拉伸过程中发生转动。区别于邓为为实验中所测晶轴的转动,本模拟中通过剪切应变的计算给出了塑性变形中具体的转动角度。表明本研究中建立的晶体塑性本构模型可以有效地描述γ-TiAl单晶塑性变形中的晶粒转动现象。

0]普通滑移系与拉伸轴平行时,晶粒在伸长的方向上只受到单纯的剪切应力作用,且此方向上的变形阻力最小,这样保证了晶粒在拉伸方向上能够顺利进行延伸变形。而当拉伸轴方向上的滑移阻力比其他方向上的滑移阻力大时,引起其他方向上的滑移系抢先启动,必然会以扭转来调整取向因子进而协调变形,结果即导致晶体发生转动。对于晶粒转动的研究[19-21],郑为为等[19]在室温下以8个不同初始取向的B2结构Fe3Al单晶进行拉伸试验,其EBSD观察结果表明:不论单晶体初始位向如何,晶体拉伸轴均趋于向<110>方向转动(其中<110>为稳定取向),且转动的角度相对较小(在10°以内)。该实验证明多滑移系共同作用导致晶粒发生转动。本模拟的计算结果与之类似,晶体在拉伸过程中发生转动。区别于邓为为实验中所测晶轴的转动,本模拟中通过剪切应变的计算给出了塑性变形中具体的转动角度。表明本研究中建立的晶体塑性本构模型可以有效地描述γ-TiAl单晶塑性变形中的晶粒转动现象。

图8 旋转角度随工程应变变化曲线

Fig. 8 Variation curves of rotation angle with engineering strain

图9 等效应力随工程应变变化曲线

Fig. 9 Variation curves of Mises stress with engineering strain

4 结论

1) 基于晶体塑性有限元方法,建立γ-TiAl单晶的数值本构关系模型,并采用此模型模拟不同取向(超滑移方向[ 01]、普通滑移方向[1

01]、普通滑移方向[1 0]、孪生方向[11

0]、孪生方向[11 ]以及与任意取向[

]以及与任意取向[ 01])的单向拉伸变形行为。

01])的单向拉伸变形行为。

2) 拉伸变形中,晶粒内的剪切应变由中心到边界逐渐增大,剪切应变的最大值出现在边界处,表明晶粒在塑性变形中以心部为中心发生显著的转动。该结果与实验现象相吻合,表明本数值模型可较为准确地描述γ-TiAl单晶塑性变形中的晶粒转动现象。

3) 取向不同时,各晶粒沿拉伸轴方向上的滑移阻力也不尽相同。晶粒平行于[1 0]普通滑移拉伸时,其拉伸方向上的变形阻力很小,晶粒变形中基本不发生转动。而其余取向的晶粒沿拉伸轴方向上的滑移阻力较大,引起其他方向上的滑移系抢先启动,迫使晶粒须以扭转来调整取向因子进而协调变形。

0]普通滑移拉伸时,其拉伸方向上的变形阻力很小,晶粒变形中基本不发生转动。而其余取向的晶粒沿拉伸轴方向上的滑移阻力较大,引起其他方向上的滑移系抢先启动,迫使晶粒须以扭转来调整取向因子进而协调变形。

4) 拉伸取向不同时,各滑移系对变形的贡献不同,滑移系的启动与晶粒取向关系密切。其中普通滑移系对变形的贡献最大,孪生系和超滑移系对变形的影响较小。

REFERENCES

[1] YANG He, WU Chuan, LI Hong-wei, FAN Xiao-guang, ZHANG Da-wei, JI Zhe. Review on development of key technologies in plastic forming of titanium alloy[J]. Materials China, 2011, 30(6): 6-13.

[2] LI Cui, LI Bin, WU Ze-feng, QI Xiao-yong, YE Bing, WANG Ai-hua. Stitch welding of Ti-6Al-4V titanium alloy by fiber laser[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 91-101.

[3] FOJT J, JOSKA L,  J. Corrosion behaviour of porous Ti-39Nb alloy for biomedical applications[J]. Corrosion Science, 2013, 71(3): 78-83.

J. Corrosion behaviour of porous Ti-39Nb alloy for biomedical applications[J]. Corrosion Science, 2013, 71(3): 78-83.

[4] 罗媛媛, 毛小南, 奚正平, 杨英丽, 吴金平, 苏航标. 新型γ-TiAl基合金在高温变形过程中的组织演变[J]. 中国有色金属学报, 2014, 24(2): 403-408.

LUO Yuan-yuan, MAO Xiao-nan, XI Zhen-ping, YANG Ying-li, WU Jin-ping, SU Hang-biao. Microstructure evolution of new γ-TiAl alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 403-408.

[5] KAD B K, DAO M, ROBERT J A. Numerical simulations of stress-strain behavior in two-phase α2+γ lamellar TiAl alloys[J]. Materials Science and Engineering A, 1995, 192/193: 97-103.

[6] ZAMBALDI C, ROTERS F, RAABE D. Analysis of the plastic anisotropy and pre-yielding of (γ/α2)-phase titanium aluminide microstructures by crystal plasticity simulation[J]. Intermetallics, 2011, 19: 820-827.

[7] FALLAHI A, ATAEE A. Effects of crystal orientation on stress distribution near the triple junction in a tricrystal γ-TiAl[J]. Materials Science and Engineering A, 2010, 527: 4576-4580.

[8] 陈守东, 刘相华, 刘立忠, 宋 孟. Cu极薄带轧制中滑移与变形的晶体塑性有限元模拟[J]. 金属学报, 2016, 52(1): 120-128.

CHEN Shou-dong, LIU Xiang-hua, LIU Li-zhong, SONG Meng. Crystal plasticity finite element simulation of slip and deformation in ultrathin copper strip rolling[J]. Acta Metallurgica Sinica, 2016, 52(1): 120-128.

[9] 邓运来, 张新明, 刘 瑛, 唐建国, 周卓平. 冷轧高纯铝柱状晶粒的组织与微取向的不均匀性[J]. 中国有色金属学报, 2005, 15(8): 1173-1178.

DENG Yun-lai, ZHANG Xin-ming, LIU Ying, TANG Jian-guo, ZHOU Zhuo-ping. Inhomogeneities of microstructures and micro-orientations in cold-rolled high purity Al columnar grains[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1173-1178.

[10] AKHTAR A. Basal slip and twinning in α-titanium single crystals[J]. Metallurgical Transactions A, 1975, 6: 1105-1113.

[11] MARKETZ W T, FISCHER F D, CLEMENS H. Deformation mechanisms in TiAl intermetallics—Experiments and modeling[J]. International Journal of Plasticity, 2003, 19: 281-321.

[12] APPEL F, WAGNER R. Microstructure and deformation of two-phase γ-titanium aluminides[J]. Materials Science and Engineering, 1998, R22: 187-268.

[13] SCHLOGL S M, FISCHER F D. Micromechanical modelling of TiAl intermetallics[J]. Computational Materials Science, 1996, 7: 34-39.

[14] 徐东生, 王 皞, 杨 锐, SACHDEV A K. 钛铝中<011]超位错的非对称形核及运动的分子动力学模拟[J]. 科学通报, 2013, 58(35): 3722-3732.

XU Dong-sheng, WANG Hao, YANG Rui, SACHDEV A K. MD simulation of asymmetric nucleation and motion of <011] superdislocations in TiAl[J]. Chinese Science Bulletin, 2013, 58(35): 3722-3732.

[15] ASARO R J, NEEDLEMAN A. Texture development and strain hardening in rate dependent polycrystals[J]. Acta Metall, 1985, 33(6): 923-953.

[16] 周益春. 材料固体力学(上册) [M]. 北京: 科学出版社, 2005: 55-63.

ZHOU Yi-chun. Solid mechanics in materials (I)[M]. Beijing: Science Press, 2005: 55-63.

[17] HUANG Yong-gang. A user-subroutine incorporation single crystal plasticity in the ABAQUS finite element program[D]. Cambridge, MA: Harvard University, 1991.

[18] 黄 文, 汪 洋, 葛 鹏, 黄中伟. 单晶纯钛的细观力学性能模拟[J]. 稀有金属材料与工程, 2010, 39(3): 469-472.

HUANG Wen, WANG Yang, GE Peng, HUANG Zhong-wei. Meso-scale simulation on mechanical behavior of single crystal titanium[J]. Rare Metal Materials and Engineering, 2010, 39(3): 469-472.

[19] 郑为为, 杨王玥, 孙祖庆. B2结构Fe3Al单晶在室温拉伸过程中的取向转动[J]. 金属学报, 2000, 36(11): 1161-1164.

ZHENG Wei-wei, YANG Wang-yue, SUN Zu-qing. The rotation of the B2 ordered Fe3Al single crystal during room temperature tensile[J]. Acta Metallurgica Sinica, 2000, 36(11): 1161-1164.

[20] EDWARDS T E J, GIOACCHINO F D,  M, CLEGG W J. Deformation of lamellar TiAl alloys by longitudinal twinning[J]. Scripta Materialia, 2016, 118: 46-50.

M, CLEGG W J. Deformation of lamellar TiAl alloys by longitudinal twinning[J]. Scripta Materialia, 2016, 118: 46-50.

[21] GIOACCHINO F D, CLEGG W J. Mapping deformation in small-scale testing[J]. Acta Materialia, 2014, 78: 103-113.

CPFEM simulations on grain rotation of γ-TiAl single crystal during plastic deformation

ZHAO Wen-juan1, 2, ZHANG Lu1, 2, LI Xiao-bin3, PENG Yuan-yi1, 2, HUANG Ming-li4, LIN Qi-quan1, 2

(1.School of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China;

2. Key Laboratory of Welding Robot and Application Technology of Hunan Province, Xiangtan University, Xiangtan 411105, China;

3. Building and Construct Research Institute Co. Ltd. of MCC, Beijing 100088, China;

4. Northeastern University at Qinhuangdao, Qinhuangdao 066004, China)

Abstract: A meso-scale numerical constitutive model was established by the theory of crystal plasticity and finite element method to describe the mechanical behavior of the face-centered tetragonal (L10) metal. Based on this model, uniaxial tension of γ-TiAl single crystal at room temperature was simulated. The tensile orientation was ordinary slip orientation [1 0], super slip orientation [

0], super slip orientation [ 01], twin slip orientation [11

01], twin slip orientation [11 ] and arbitrary orientation [

] and arbitrary orientation [ 01], respectively. The results show that the single crystals rotate along the central axis during the tensile deformation. Moreover, orientation has dramatic effect on the grain rotation. The single crystal with tensile orientation of [1

01], respectively. The results show that the single crystals rotate along the central axis during the tensile deformation. Moreover, orientation has dramatic effect on the grain rotation. The single crystal with tensile orientation of [1 0] (ordinary slip) has less rotation angle. However, the others have larger rotation angle. With tension along the orientation of [1

0] (ordinary slip) has less rotation angle. However, the others have larger rotation angle. With tension along the orientation of [1 0] (ordinary slip), less tensile resistance leads to easy activation of slipping of the ordinary dislocation. Furthermore, the activation of ordinary slip system is primary during the tensile process. With tension along the other orientations, the crystals should adjust the orientation factor to accommodating the deformation by grain torsion, which shows larger rotation angle.

0] (ordinary slip), less tensile resistance leads to easy activation of slipping of the ordinary dislocation. Furthermore, the activation of ordinary slip system is primary during the tensile process. With tension along the other orientations, the crystals should adjust the orientation factor to accommodating the deformation by grain torsion, which shows larger rotation angle.

Key words: γ-TiAl alloy; crystal plastic; orientation; grain rotation; plastic deformation; finite element

Foundation item: Projects(51201147, 51301032) supported by the National Natural Science Foundation of China; Project(14JJ6016) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2017-01-03; Accepted date: 2017-07-21

Corresponding author: ZHAO Wen-juan; Tel: 13787031201; E-mail: wjzhao1024@xtu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51201147,51301032);湖南省自然科学基金资助项目(14JJ6016)

收稿日期:2017-01-03;修订日期:2017-07-21

通信作者:赵文娟,副教授,博士;电话:13787031201;E-mail:wjzhao1024@xtu.edu.cn