文章编号:1004-0609(2008)07-1274-06

超细(W,Ni,Fe,Y)复合粉末制备过程中稀土Y的

物相形态变化

范景莲,彭石高,刘 涛,丁 飞,田家敏

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用溶胶?喷雾干燥?氢还原法制备稀土Y含量分别为0,0.4%,5%,10%和20%的超细(W,Ni,Fe,Y)复合粉末,采用XRD研究煅烧温度和还原温度以及稀土Y含量变化时复合粉末体在制备过程中的相结构变化规律。结果表明:喷雾干燥前驱体随煅烧温度的升高渐渐从非晶体向复合氧化物晶化转变,添加稀土Y的粉末前驱体经煅烧后,Y与W形成复合氧化物Y2W3O12,且稀土Y可以有效地抑制粉末颗粒长大;随着Y含量的增加,Y和W的复合氧化物明显增加,Y2W3O12在700 ℃才能被还原成低氧复合氧化物相;含5%稀土Y粉末中的Y2W3O12被还原生成新相Y2WO6;当稀土Y增加到10%以上时,不仅生成Y2WO6,还生成另一种新相Y6W2O15。

关键词:W-Ni-Fe复合粉末;纳米粉末;稀土;Y

中图分类号:TF 123 文献标识码:A

Phase transformation of Y in fabricating ultra-fine (W, Ni, Fe, Y) composite powders

FAN Jing-lian, PENG Shi-gao, LIU Tao, DING Fei, TIAN Jia-min

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Ultra-fine (W, Ni, Fe, Y) composite powders containing rare earth element Y of 0, 0.4%, 5%, 10% and 20%, respectively were fabricated by sol-spray drying calcination and subsequent hydrogen reduction process. X-ray diffractrometry(XRD) was used to analyze the phase transformation of composite powders during calcination and hydrogen reduction. The results show that the amorphous spray-dried precursors transform into composite-oxide powders, composite oxide phase of Y and W forms as Y2W3O12, and the addition Y can control the grain growth effectively. With the increase of Y contents composite oxide increase obviously. When temperature is 700 ℃, the Y2W3O12 phase is reduced into low-oxygen composite-oxide. A new phase Y2WO6 forms with addition of 5%Y, and when the amount of additions increase up to 10%, the new phases Y2WO6 and Y6W2O15 are formed.

Key words: W-Ni-Fe composite powder; nanopowder; rare earth; Y

用作动能穿透器的W-Ni-Fe合金要求材料具有较好的动态力学性能和较好的穿甲自锐性[1?2]。细化W-Ni-Fe合金中钨晶粒组织结构不仅可以大大提高合金的拉伸力学性能,更重要的是有利于提高合金的动态力学性能和穿甲自锐性[3],因而,用纳米复合粉末制备高性能细晶钨合金成为近年来国内外关注的焦点,并在这方面开展了大量研究[4?7]。研究结果证明,纳米W-Ni-Fe合金复合粉末在固相烧结容易得到比传统钨合金晶粒小10倍的细晶钨合金,但在液相烧结会发生快速晶粒粗化、长大、产生孔洞和致密度下降[8?9],采用瞬时液相烧结[10]或添加微量Y和La等稀土元素可以有效地抑制这一现象的发生,使合金的拉伸强度和伸长率大大提高[11?13]。同时还有资料研究表明,添加稀土氧化物可以提高钨合金在不需要形成大量局部绝热剪切带条件下的穿甲自锐化能力[14?16]。但由于稀土元素含量太少,难以分析,其在合金中的存在形态和作用机制尚不清楚,为此,本文作者以稀土元素Y为研究对象,稀土Y含量在较大范围内变化,采用溶胶?喷雾干燥?氢还原法制备含稀土元素Y的超细/纳米(W,Ni,Fe)复合粉末[16],研究了稀土Y对纳米级W-Ni-Fe复合粉末过程中物相变化的影响规律,为进一步深入研究稀土改性高密度钨基合金提供一定的理论与实验基础。

1 实验

以AMT、Ni(NO3)2?6H2O、Fe(NO3)3?9H2O为原料按90W-7Ni-3Fe(质量分数)成分配比配制前驱体母液,稀土元素Y以易溶解的Y(NO3)3形式加入到前驱体母液中,Y质量分数为0、0.4%、5%、10%和20%,搅拌均匀,加入表面活性剂并调节pH值形成溶胶体,然后送入喷雾干燥器以20 000 r/min的速度进行喷雾干燥。将喷雾干燥前驱体在150、300、450、550和600 ℃煅烧2 h,然后在氢气气氛中不同的温度下还原60 min,采用X 射线衍射Cu Kα靶分析喷雾干燥前驱体在不同煅烧和还原温度下的相结构变化及晶粒尺寸,同时对比不同Y含量的粉末体在还原过程中的物相变化。

2 结果与分析

2.1 煅烧粉末体的物相结构特征

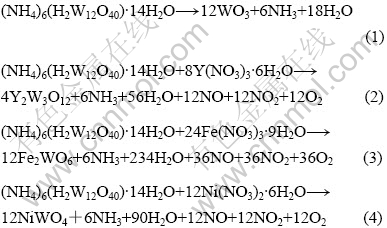

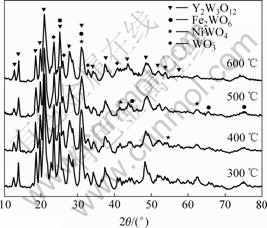

图1所示为含20%Y的(W,Ni,Fe,Y)喷雾干燥非晶前驱体粉末分别在150、300、450、550和600 ℃煅烧2 h的XRD谱。从图1中可以看出,煅烧温度在150、300和450 ℃时,XRD谱中没有尖锐的衍射峰,说明非晶前驱体粉末在450 ℃以下煅烧,粉末仍然呈现非晶态,主要是脱水和释放氨气,形成非晶态复合氧化物前驱体;当煅烧温度达到550 ℃时,非晶前驱体发生了强烈的晶化反应,并生成Y2W3O12、WO3、Fe2WO6和NiWO4 4种物相;随着温度进一步升高至600 ℃,晶化反应更为明显,形成尖锐的晶化峰。根据煅烧后粉末的物相组成,可以推断发生了以下4个反应:

图1 不同温度煅烧2 h后粉末(20%Y)的XRD谱

Fig.1 XRD patterns of precursor powders (90W-7Ni-3Fe) with 20%Y after calcining for 2 h at different temperatures

·

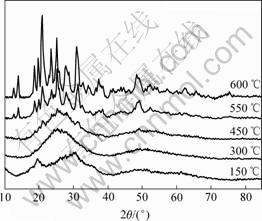

图2 600 ℃煅烧2 h后粉末(20%Y)的XRD谱

Fig.2 XRD pattern of powders with 20%Y after calcining for 2 h at 600 ℃

因此,喷雾干燥前驱体经煅烧后形成复合氧化物粉末,稀土Y与W以Y2W3O12复合氧化物形式存在。

2.2 还原过程中粉末的物相结构变化

为了弄清楚还原过程中(W,Ni,Fe,Y)复合粉末的物相变化规律,将在600 ℃煅烧后的不含Y和含20%Y复合氧化物粉末在300、400、500、600、700和800 ℃还原60 min,以分析Y对物相变化的影响。

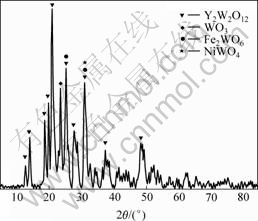

图3所示为600 ℃煅烧后不含稀土Y的复合氧化物前驱体在不同温度下还原60 min的XRD谱。从图3(a)中可看出,煅烧后不含Y的复合氧化物前驱体在400 ℃以下还原时,粉末体由WO3,NiWO4和Fe2WO6 3种物相组成,NiWO4和Fe2WO6的含量都比较少,衍射峰较弱。由图3(b)中可知,当还原温度达到500 ℃时,Fe2WO6的衍射峰已经消失,与此同时出现了比较弱的WO2和NiO峰。由图3(c)中可知,当温度达到600 ℃时,WO3已经全部都被还原成了WO2和W,但此时W的衍射峰还比较弱,粉末体主要以WO2为主,γ-(Ni, Fe)相的含量非常少,因此也难以看到。由图3(d)可知,当还原温度升高到700 ℃时,氧化物相全部消失,粉末体全部由W和γ-(Ni, Fe)两种相组成,基本被还原完全了,随着温度进一步升高到800 ℃,与700 ℃相比,相组成没有变化,衍射峰更加尖锐,也就是说粉末还原得更加完全,粉末晶粒发生明显长大。

图3 不含Y粉末不同温度一步还原60 min 的XRD谱

Fig.3 XRD patterns of powders without Y after reduction for 60 min at different temperatures by one-stage

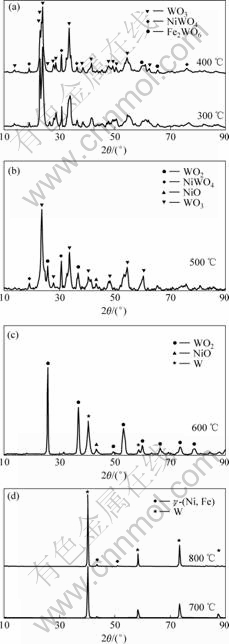

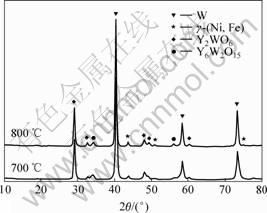

图4和5所示为600 ℃煅烧后含20%Y复合氧化物前驱体在不同温度下还原60 min的XRD谱。

图4 含20%Y粉末不同温度一步还原60 min的XRD谱

Fig.4 XRD patterns of powders with 20%Y after reduction for 60 min at different temperatures by one-stage

图5 含20%Y粉末不同温度一步还原60 min的XRD谱

Fig.5 XRD patterns of powders with 20%Y after reduction for 60 min at 700 and 800 ℃by one-stage

从图4中可以看出,当还原温度低于600 ℃时,粉末的衍射峰完全相同,物相组成跟煅烧后粉末体的物相组成完全相同;随着还原温度的升高,有些衍射峰弱化,但Y2W3O12的衍射峰依然非常尖锐,也没有出现WO2和其他新相的衍射峰,这说明在此温度下Y2W3O12基本没有发生还原反应。而NiWO4和Fe2WO6的含量都比较少,衍射峰与Y2W3O12的衍射峰重叠,因此只能看到有些衍射峰弱化。同时含20%Y的粉末体中WO3的含量比较少,被大量的Y2W3O12包围其中,这就使得WO3与氢气接触量大大减少,只有极少量被还原成WO2,因此,在XRD图谱中难以看出WO2的衍射峰。

由图5可以看出,当温度升至700和800 ℃时,粉末体的物相组成发生了明显变化,煅烧后粉末体中的Y2W3O12、Fe2WO6、NiWO4和WO3全部消失,出现了W、γ-(Ni,Fe)、Y2WO6和Y6W2O15 4种新相。由此可知,当温度在600 ℃以下时,煅烧后粉末中的Y2W3O12相非常稳定,很难被氢气还原;当温度为 700 ℃时,Y2W3O12相会分解,一部分W被还原出来并生成新相Y2WO6和Y6W2O15。

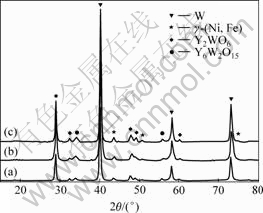

图6所示为450 ℃+750 ℃两步还原和直接在700和800 ℃一步还原的物相结构特征。

图6 含20%Y粉末 700和800 ℃一步还原和450 ℃+ 750 ℃两步还原的XRD谱

Fig.6 XRD patterns of powders with 20%Y after reducing at 700 and 800 ℃ by one step and at 450 ℃+750 ℃ by tow-stage: (a) 450 ℃+750 ℃, two-stage; (b) 700 ℃, one step; (c) 800 ℃, one step

结果表明,一步还原和两步还原的物相组成相同,800 ℃一步还原的XRD衍射峰比700 ℃的衍射峰更为明显,这说明800 ℃粉末的还原更加完全。

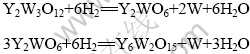

根据还原后Y在粉末中的物相特征可以推断,煅烧后粉末中的新相Y2W3O12在还原过程中发生了如下反应:

2.3 稀土Y含量对(W,Ni,Fe)复合粉末相生成的影响规律

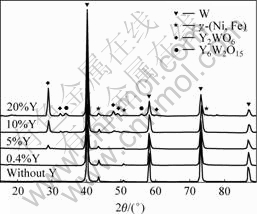

不同Y含量(0%、0.4%、5%、10%、20%)的前驱体粉末经过600 ℃煅烧后,再在氢气气氛下采用氢气450 ℃(30 min)+750 ℃(90 min)两步还原,其XRD谱如图7所示。

图7 不同Y含量粉末两步还原的XRD谱

Fig.7 XRD patterns of powders with different Y contents after reduction by two-stage

由图7中可看出,当Y含量在0.4%时,由于Y含量过低,没有发现与Y有关的新相生成;而当Y含量为5%时,可以明显的看到新相Y2WO6的衍射峰;当Y含量增加到10%时,新相Y2WO6的衍射峰更加明显,还出现了另外一种新相Y6W2O15;当Y含量增加到20%时,衍射峰更加明显,物相组成与Y含量为10%的相同。

随着还原过程的进行,还原过程中生成的水蒸气增多,当氢气流量不够大时,钨的氧化物与水蒸气化合成易挥发的水合物WOx·nH2O,一般认为是WO2(OH)2。随后通过气相迁移,沉积在低价氧化钨或金属钨粉表面上,导致颗粒长大。添加稀土Y 以后,稀土以钨酸盐Y2W3O12的形式包围着钨颗粒,阻止了还原过程中钨的氧化物与水蒸气化合成易挥发水合物WO2(OH)2的生成速度;当稀土Y的含量达到20%时,煅烧后的粉末体中已经存在大量的Y2W3O12,WO3的含量已经比较少,还原所生成的水蒸气比不添加Y的要少很多,从而减少了其气相迁移,同时由于Y2W3O12在600 ℃以下时非常稳定,分布在整个粉末体中,对还原过程中的挥发沉积作用起到了很强的抑制作 用,有效地阻止了粉末颗粒的长大。而只有当温度达到700 ℃时,Y2W3O12中的部分钨才能被还原出来,也就是说在整个还原过程中,W的还原是分阶段进行的,所生成的水蒸气也是分阶段平稳产生, 从而钨的氧化物与水蒸气化合成易挥发水合物WO2(OH)2的生成速度得到了很好的控制,有效地抑制了粉末的长大。

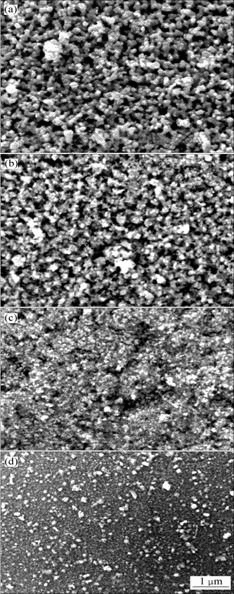

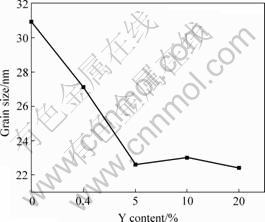

图8所示为不同Y含量粉末的SEM像。从图8中可看出,随着Y含量的增加,粉末明显变细。图9所示为根据XRD谱W最强衍射峰采用Sherrer法计算出来的晶粒尺寸大小。由图9可看出,还原粉末的晶粒尺寸随稀土Y 含量的增加而下降,当Y 含量小于5%时,下降明显;而当稀土Y含量超过5%以后,粉末晶粒尺寸不再变小,这主要是由于受到原始粉末晶粒尺寸的限制;同时当稀土Y含量达到5%时,钨晶粒之间的稀土复合氧化物晶粒在700 ℃以上还原时生成大量的微细钨晶粒,而这些微细钨晶粒极易与周围已经被还原出来的钨晶粒聚集长大,也就削弱了原本的抑制长大的作用。

图8 不同Y含量还原粉末的SEM像

Fig.8 SEM images of powders with different Y contents after reduction by 450 ℃+750 ℃ two-stage: (a) Without Y; (b) 0.4%Y; (c) 5%Y; (d) 20%Y

图9 Y含量对两步还原粉末晶粒尺寸的影响

Fig.9 Effect of Y content on grain size of powders reduced by tow stage

3 结论

1) 以喷雾干燥法制备的含有不同稀土Y的(W,Ni,Fe,Y)前驱体粉末为原料,在600 ℃煅烧120 min,得到高度晶化的复合粉末,添加20%Y的复合粉末经700 ℃还原后粉末由Y2W3O12、WO3、Fe2WO6和NiWO4相组成。

2) 经600 ℃煅烧后的粉末(20%Y)采用氢气在700和800 ℃保温60 min一步还原和450 ℃(30 min)+750℃(90 min)两步还原,制得了含Y2WO6和Y6W2O15的纳米级(W,Ni,Fe,Y)复合粉末。

3) 当不加稀土Y 时,还原粉末由W 和γ-(Ni, Fe)两相组成;添加一定量稀土Y,还原粉末由W,γ-(Ni, Fe)和新相组成;当Y含量为5%时,新相为Y2WO6;当Y含量为10%和20%时,新相为Y2WO6和Y6W2O15。

4) 当添加Y 质量分数在0%~20%范围内时(占90W-7Ni-3Fe复合粉末的质量分数),随着Y含量的增加,粉末晶粒尺寸逐渐减小;当添加5%和20%时,(W,Ni,Fe,Y)复合粉末晶粒尺寸约为23 nm。

REFERENCES

[1] 范景莲. 钨合金及其制备新技术[M]. 北京: 冶金工业出版社, 2006.

FAN Jing-lian. Tungsten alloy and new fabricating technique[M]. Beijing: Metallurgical Industry Press, 2006.

[2] BOSE A, HERVE R A C, LANGFORD JR J. Development and properties of new tungsten-based composites for penetrators[J]. The International Journal of Powder Metallurgy, 1992, 28(4): 383?394.

[3] DONG-KUK K, SUNGHAK L, JIN H, HYUNG H S, JOON-WOONG N. Correlation of microstructure with dynamic deformation behavior and penetration performance of tungsten heavy alloys fabricated by mechanical alloying[J]. Metall and Mater Trans A, 2000, 31: 2475?2489.

[4] FAN J L. Preparation and sintering of nano-sized W-Ni-Fe powder by sol-spray drying process[J]. Materials Science Forum, 2007, 534/536: 1409?1412.

[5] FAN J L, HUANG B Y, XIAO L, KEAR B H. Sintering behavior of nanostructured W based composite powder[J]. Int J Powder Metallurgy, 2005, 41(6): 49?55.

[6] RYU H J, HONG S H, BACK W H. Mechanical alloying process of 93W-5.6Ni-1.4Fe tungsten heavy alloy[J]. Journal of Materials Processing Technology, 1997, 63(2): 292?297.

[7] SOON S H, RYU H J. Combination of mechanical alloying and two-stage sintering of a 93W-5.6Ni-1.4Fe tungsten heavy alloy[J]. Mater Sci & Eng A, 2003, 344(1): 253?260.

[8] FAN J L, HUANG B Y. Densification and microstructure characteristics of mechanically alloyed W-Ni-Fe composite powders[J]. Journal of Advanced Materials, 2004, 36(4): 48?52.

[9] FAN J L, HUANG B Y, QU X H. Microstructure evolution during densification of the nano-structured W-Ni-Fe composite powders[C]// HANADA S, ZHONG Z, NAM S W, WRIGHT R N. The Fourth Pacific Rim International Conference on Advanced Materials and Processing (PRICM4). Sendai: The Japan Institute of Metals, 2001: 2301?2304.

[10] 范景莲, 汪登龙, 曹建虎. 90W-7Ni-3Fe纳米晶粉末的瞬时液相烧结强化特征[J]. 中国有色金属学报, 2005, 15(2): 217?223.

FAN Jing-lian, WANG Deng-long, CAO Jian-hu. Transient liquid enhanced sintering characteristics of nanostructured 90W-7Ni-3Fe powders[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 217?223.

[11] 范景莲, 汪登龙, 刘 涛. 细晶钨合金制备工艺的研究[J]. 兵器材料科学与工程, 2006, 29(2): 1?5.

FAN Jing-lian, WANG Deng-long, LIU Tao. Preparing process of fine-grain tungsten heavy alloy with high mechanical properties[J]. Ordnance Material Science and Engineering, 2006, 29(2): 1?5.

[12] FAN J L. Preparation of fine grain tungsten heavy alloy with high properties by mechanical alloying and yttium oxide addition[J]. Materials Science Forum, 2007, 534/536: 1261?1264.

[13] PARK S, KIM D K, LEE S, RYU H J, HONG S H. Dynamic deformation behavior of an oxide-dispersed tungsten heavy alloy fabricated by mechanical alloying[J]. Metall and Mater Trans A, 2001, 32A(8): 2011?2020.

[14] RYU H J, HONG S H. Fabrication and properties of mechanically alloyed oxide dispersed tungsten heavy alloys[J]. Mater Sci & Eng A, 2003, 363(1): 179?184.

[15] 范景莲, 祁美贵, 刘 涛, 成会朝. 细晶钨合金动态力学性能与组织结构[J]. 稀有金属材料与工程, 2007, 36(4): 633?635.

FAN Jing-lian, QI Mei-gui, LIU Tao, CHENG Hui-chao. Dynamic mechanics properties and micro-structure for fine-grain tungsten heavy alloy[J]. Rare Metal Materials and Engineering, 2007, 36(4): 633?635.

[16] 马运柱, 黄伯云, 范景莲, 熊 翔, 汪登龙. 稀土元素钇对纳米级W-Ni-Fe 复合粉末制备的影响[J]. 稀有金属材料与工程, 2005, 34(7): 1135?1138.

MA Yun-zhu, HUANG Bai-yun, FAN Jing-lian, XIONG Xiang, WANG Deng-long. Effect of rare earth Y on preparation of nanometer W-Ni-Fe composite powder[J]. Rare Metal Materials and Engineering, 2005, 34(7): 1135?1138.

基金项目:国家高技术研究发展计划资助项目(2004AA33G060);国家自然科学基金资助项目(50704012)

收稿日期:2007-10-20;修订日期:2008-04-01

通讯作者:李 兵,博士研究生;电话:024-83686462;E-mail: liyufeng13@163.com

(编辑 李艳红)