DOI:10.19476/j.ysxb.1004.0609.2019.08.13

热处理对高钴ZL40.5硬质合金组织与性能的影响

董定乾1, 2, 3, 向 新1, 黄新杰1,黄 伟2, 时凯华2, 张 立3

(1. 四川理工学院 机械工程学院,宜宾 644000;

2. 自贡硬质合金有限责任公司,自贡 643011;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以冲模用高钴ZL40.5硬质合金作为研究对象,采用扫描电镜(SEM)、X射线衍射(XRD)等方法对系列热处理试样进行分析,基于晶体学理论并结合Image J、Jade软件研究ZL40.5硬质合金微观组织结构参数(粘结相体积分数、晶粒度、邻接度、残余应力及晶格常数)、断口形貌及其性能。结果表明:淬火处理使WC晶粒形貌变圆润,降低应力集中的发生,减少断裂源;淬火回火处理后,粘结相中α-Co含量大幅提升,WC邻接度降低,合金在保证硬度的同时强度和韧性得到提升;热处理后合金断裂以沿晶和韧性复合形式为主,淬火回火后表面压应力提升最高。

关键词:硬质合金;热处理;微观组织;断口形貌;综合性能

文章编号:1004-0609(2019)-08-1684-09 中图分类号:TG166.7 文献标志码:A

硬质合金被誉为工业的“牙齿”,其主要以高熔点难熔金属W、Mo、Ti、Ta、Hf等的碳化物等作为基体相,铁族金属Co、Ni作为粘结相,采用粉末冶金方法烧结制成的硬质材料。硬质合金因其具有高硬度、高弹性模量、抗冲击强、良好耐磨性、耐腐蚀性好等诸多优点而广泛地应用于切削工具、模具(成形工具)、地质矿山工具以及耐磨零件等方面[1-4]。当硬质合金制品成分相对固定时,采用热处理技术强化硬质合金制品已被确认为一种提高其整体性能的有效方法。该方法能改善各相的应力状态和时效粘结相,或者改变粘结相的微观结构,以实现既能保证合金高硬度、高耐磨,又能提高韧性的目的。合金中的粘结相Co对硬质基体WC具有极佳的润湿性和粘结性,并当WC固溶于Co相时能起到显著强化Co相效果。因此,粘结相Co的含量、微观组织和结构对最终硬质合金制品的综合性能有着重要影响[5-6]。

目前,硬质合金热处理研究多集中于含钴量15%以下的中低钴合金,对于含钴量22%的高钴合金热处理研究鲜有报道。硬质合金中高钴较之于低钴具有更好的韧性和抗弯强度,但硬度和耐磨性有所降低,主要是因为高钴合金中WC含量和邻接度降低[7]。高钴ZL40.5硬质合金主要用于制造各种钢丝的拉丝模、拔丝模、多工位级进模具及冷镦模具。硬质合金模具零件要求材质具有良好的硬度、耐磨性,同时还要求有优异的整体韧性,而热处理已被证明能在不损失WC-Co合金硬度、耐磨性的前提下提高其整体韧性,改善合金的组织结构与性能。钴存在两种结构,室温下为密排六方结构,高温下则为面心立方结构,因为面心立方钴性能优于密排六方钴,所以通过改善热处理工艺进而提高面心立方钴含量,可以提高硬质合金综合性能。

国内外学者针对WC-Co系硬质合金中的γ相转变(Co相WC固溶体)已经做了诸多研究。研究表 明[8-9],WC与Co相膨胀系数不同会形成压应力的“刚性骨架”,并对γ相有机械约束作用,从而增加WC-Co合金FCC γ相的稳定性,致使常温下γ相全为FCC型。Co相中固溶的W会降低α-Co相热力学稳定性,使得FCC γ→HCP γ转变温度高于纯Co相,约在1000 K左右。刘寿荣[10]研究表明,WC-Co硬质合金在冷却过程中FCC γ→HCP γ主要以扩散型为主,而非扩散型转变点Ms在室温之上并接近室温。前人的研究多是针对于一种热处理对合金组织性能的影响,未进行对比实验。本文作者以同一批冲模用高钴ZL40.5硬质合金为研究对象,研究了淬火和深冷处理对烧结态、回火和深冷处理对淬火态硬质合金微观结构、物相变化、综合性能的影响,并结合SEM和XRD进行组织结构参数定性和定量分析,以期为高钴ZL40.5硬质合金生产规范的制定提供参考。

1 实验

实验所使用原料WC的FSSS粒度为20 μm,粘结相采用普通Co粉,其FSSS粒度1.5~1.8 μm,含碳总量(质量分数,%)为6.05%。原料的成分配比如表1所列。

表1 实验原料配比

Table 1 Experimental raw material ratio

将原始粉末WC、Co按配方称好后置入硬质合金球磨罐中,加入湿磨介质己烷120 L,成形剂采用石蜡并按质量比2.0%称取,加入少量表面活性剂硬脂酸(质量的0.2%),采用600型可倾式球磨机进行湿磨,球磨时间为60 h。湿磨工艺结束后卸下浆料,并在真空炉中干燥后过筛。称量混合料粉末并在万能试验机上压制成形,其压制作用力为250 MPa,合金压坯尺寸为16 mm×16 mm×4 mm。进行氢气脱蜡后在5 MPa氩气作载体压力下的烧结,工艺为低压一次烧结,其烧结温度为1430 ℃下保温1.5 h,随炉冷却后得到ZL40.5硬质合金试样。

样品分为5组,试样a烧结后不做热处理,试样b和试样c为烧结后淬火和深冷处理,试样d和试样e为烧结淬火后回火和深冷处理。试样a于1430 ℃保温1.5 h后随炉冷却至室温;试样b先于900 ℃保温50 min后升温至1200 ℃保温1 h,然后于油性介质中急冷;试样c于-185 ℃保温28 h后缓慢回复至室温;试样d于500 ℃回火处理4.5 h,随炉冷却至室温;试样e于-185 ℃保温28 h,缓慢回复至室温。分析设备采用型号为BRUKER TESCAN-3扫描电镜观察其微观组织形貌,采用Image J和MDI Jade5.0软件作为数据分析处理软件。利用日本理学公司的D/max-Ultima Ⅳ型X射线衍射仪检测试样物相,其测量电压、电流分别为40 kV、40 mA, 扫描速度为6 (°)/min,波长为0.15406 nm,步距为0.01°。利用Wilson-Wolpert 401MVA维氏硬度机测量显微硬度,利用法国塞塔拉姆公司制造的D6025型钴磁仪测量各试样的钴磁平均值。

2 结果与分析

2.1 微观组织结构定量分析

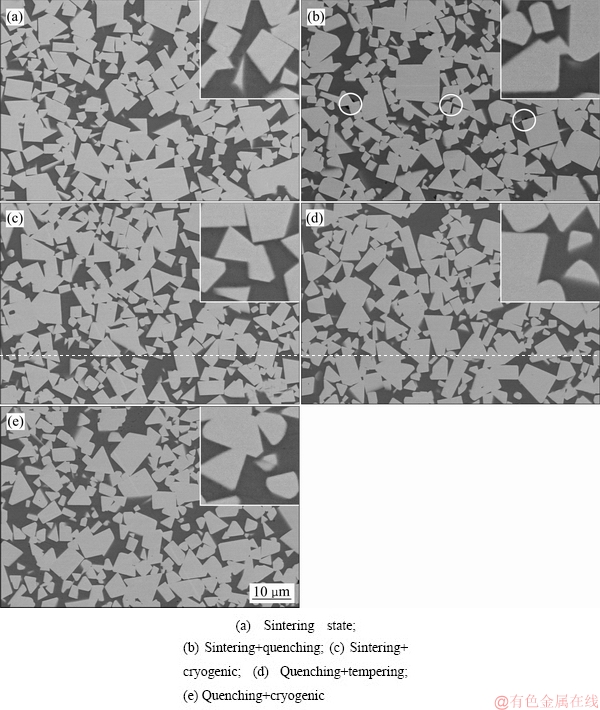

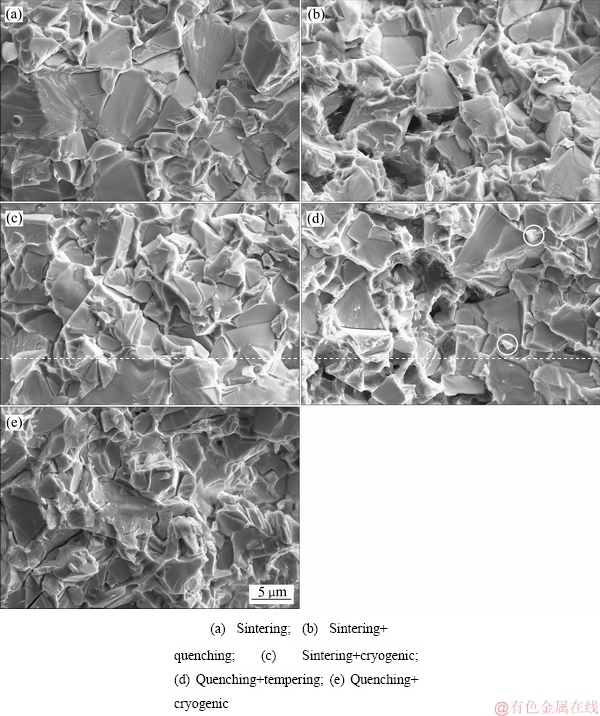

图1所示为烧结态及热处理后的扫描电镜(SEM)像,其右上角为局部放大图。由图1可知,不规则三角形或梯形灰色区域为硬质相WC,黑色区域为粘结相Co。图1(a)为烧结态的微观组织图,可以观察到WC晶粒分布较为密集,且棱角处尖角明显。图1(b)为烧结态淬火处理的图,能观察到一些WC晶粒的尖角变得圆润,中小尺寸WC晶粒于Co相中分布更加均匀。其形貌变化主要由于WC晶粒尖角处能量最高,故溶解优先发生在曲率半径较小的尖角处,且尖角溶解能避免应力集中,减少裂纹源,提高合金综合性能。图1(b)中还出现了一些深黑色斑点(红圈所示),该类黑点是微孔洞且均分布在WC和Co相交界处,孔洞会导致合金密度减小,降低合金的性能。微孔洞的产生是由于WC和Co相热膨胀系数差异很大,其WC 为4.4×10-6 /℃,而Co为1.42×10-5 /℃,且Co是WC的3倍之多,其试样钴含量很高。在高温淬火时,Co相急剧收缩,Co很难填充Co相收缩后留下的孔隙,因而在两相交界处出现孔洞[11]。图1(c)所示为烧结态深冷处理的组织形貌,相对于烧结态变化不大,而淬火处理对WC形貌的影响相对于深冷处理工艺而言更加明显。图1(d)和(e)组织形貌变化与图1(b)一样,其晶粒尖角变得圆润,并且黑色区域面积增加。

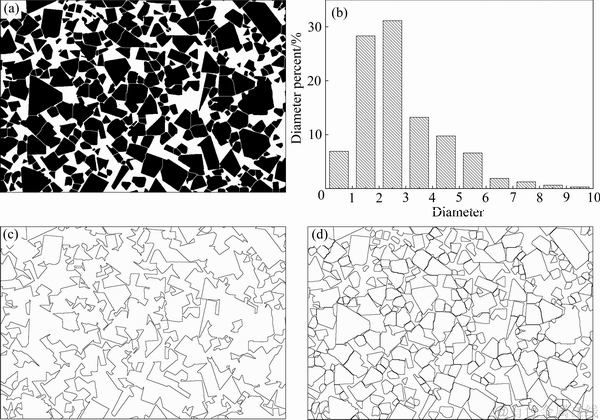

根据体视学原理和微观组织图的特征[12],利用Image J软件对SEM像参数化定量分析,研究不同热处理下ZL40.5硬质合金的粘结相Co体积分数、WC晶粒形状因子(接近正多边形的程度)、WC晶粒邻接度(WC晶界占比)和Co相的平均自由程(Co相平均厚度)。组织参数的计算以烧结态合金为例,具体如下:

1) Co相的体积分数:虽然材料晶粒不规则,体积分数不能直接测量,但根据体视学公式:fV=AA=LL=PP,合金中WC和Co的体积分数fV等于单位测试面积上被测相所占面积的百分比AA,即等于显微组织图中被测相所占面积。将烧结态合金SEM像通过Image J软件二值化处理,利用图像分析功能统计出黑色区域面积百分比。

2) 晶粒尺寸和分布:先将SEM图二值化处理,再WC晶粒反选为黑色,除去干扰的噪点,基于分水岭分割法将图中WC晶粒进行分割,得到图2(a)所示晶粒分布图,再统计出每个晶粒的等效圆直径,得到WC晶粒度的分布图,如图2(b)所示。

3) WC邻接度:WC晶粒邻接度计算表达式如下[13]:

(1)

(1)

式中:Lbc为图中WC/Co相的相界长度;Lcc为图中

WC/WC的晶界长度。图2(c)和(d)所示为基于Image J软件分别提取Lbc和Lcc的图。

4) Co相平均自由程:采用如下公式计算Co相的平均自由程[14]:

(2)

(2)

式中:d为WC平均晶粒尺寸,μm;c为WC相的邻接度;f为WC相的体积分数。

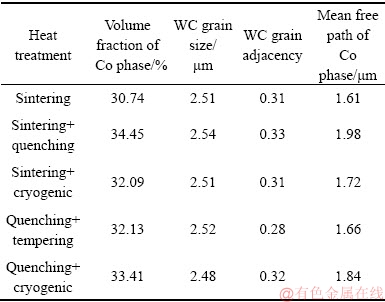

表2所列为基于以上分析方法所得计算结果。由表2可知烧结态粘结相Co的体积分数在淬火处理后提高了3.71%,深冷处理后提高了1.35%;将淬火处理后的试样进行回火和深冷处理,相较于淬火态Co相体积分数有着不同程度降低。淬火时Co相体积分数改变主要是因为高温下W、C原子在Co中的溶解度增大,冷却时高的冷却速度阻碍WC析出,因而冷却到室温时Co相中固溶有大量W、C原子,故其体积分数增大;淬火态回火时Co的过饱和固溶体分解,W、C原子析出使Co相体积分数降低;淬火态后进行

深冷处理时有大量α-Co(FCC)转变为ε-Co(HCP),而同一温度下W在α-Co中的溶解度高于ε-Co的,故深冷处理后W原子大量析出,进而降低Co相体积分数降低。

图1 烧结态及热处理的SEM像

Fig. 1 SEM images of sintering and heat treatment

图2 分水岭分割图像、等效圆直径分布图、WC/Co相界提取图和总界面提取图

Fig. 2 Watershed segmentation image(a), equivalent circle diameter distribution map(b), WC/Co phase boundary extraction diagram(c) and total interface extraction(d)

表2 烧结及热处理组织结构参数计算结果

Table 2 Calculation results of structural parameters of sintering and heat treatment

由表2分析可知,相对于烧结态而言,试样热处理后获得的晶粒尺寸变化很小,数值在误差范围之内,不能得到规律,这表明硬质合金热处理不能明显改善硬质相WC的晶粒度。热处理后,试样的WC邻接度变化很小,仅淬火态回火后与淬火态相比有所降低,其主要原因为回火促进W、C从Co相中析出,致使WC相和Co相的界面增加,降低了WC的邻接度。在硬质合金中高邻接度是造成高硬度值的重要原因,但回火不会影响合金中α-Co含量,故回火后处理试样硬度有所降低而整体性能却有提升。Co相的平均自由程在热处理后都有不同程度的提升,其最明显的是淬火处理,而淬火后再进行回火处理的影响相对较小。平均自由程增大有利于γ相在变形中的位错运动和增值,可协调γ相中的应力状态,故可提高合金的断裂韧性和抗弯强度。

2.2 XRD分析

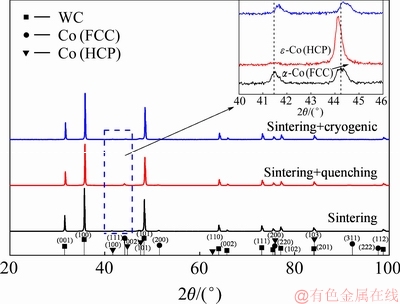

图3 所示为烧结态及淬火和深冷处理后的XRD谱。结合X射线衍射原理,其具有特征衍射峰的滑移面,当其晶胞内原子排列为理想状态时,衍射峰最强,而当其晶胞内原子位置发生变化时,衍射峰强度会减小甚至消失[15],XRD反映合金中各相的晶格常数和原子的排列情况。由图3可知,样品中包含有3种结构物相:硬质相WC、粘结相α-Co(FCC)和ε-Co(HCP)。Co相在室温下为HCP结构,塑性较差,但低温下组织稳定;当加热至≥427 ℃时,转变为FCC结构α-Co,具有较高的塑性与强韧性。硬质相WC的结晶形态较完整,内部组织缺陷较少,且不会发生结构改变,所以各衍射峰都很明显但其变化不明显。而两种结构Co相的转变对合金组织性能影响较大而且衍射峰有较明显区别。图3右上角图形为图3蓝色虚线框内的放大图(2θ为40°~46°),从局部放大图中的烧结态XRD曲线可看出,粘结相由α-Co和ε-Co组成,将烧结态试样进行淬火处理,其XRD曲线中ε-Co衍射峰消失了,只剩下α-Co的衍射峰,这表明淬火能促使烧结态中ε-Co大部分甚至完全转变为α-Co,将烧结态试样进行深冷处理则两种钴的含量未发生完全转变。

图3 烧结态及淬火和深冷处理的XRD谱

Fig. 3 XRD patterns of sintering and quenching and cryogenic

当烧结温度在427 ℃以下时,ε-Co自由能更低,但由于Co相中固溶了W、C原子增加了相的转变阻力,故淬火后常温下仍存在大量α-Co。深冷处理后,两种物相含量未发生明显变化,但深冷促使部分Co中溶解的异种原子以化合物形式析出,起到第二相粒子强化作用。

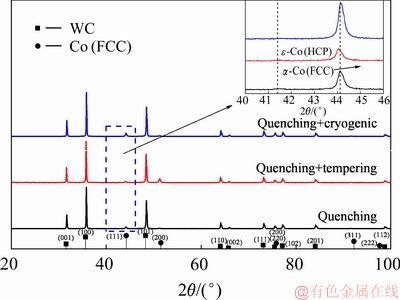

图4所示为淬火态及回火与深冷处理的XRD谱,其右上角图形为图4蓝色虚线框内的放大图(2θ为40°~46°)。在局部放大图中看到,淬火态回火处理后α-Co峰强有所降低,深冷处理后α-Co峰强升高,且只有α-Co衍射峰,ε-Co衍射峰完全消失。研究表明[16]:硬质合金Co相中固溶的W含量越高,马氏体转变温度Ms点越高,纯钴的Ms约在427 ℃,WC-Co硬质合金Ms一般在730 ℃左右。在低温下α-Co马氏体转变为ε-Co需要较长的时间,一般至少回火20 h才开始出现ε-Co,本实验进行的是低温短时间回火,故回火XRD曲线没有ε-Co衍射峰出现。深冷处理后,α-Co衍射峰得到明显增强,这说明深冷处理使合金粘结相的(111)晶面FCC结构Co的原子排列更加整齐一致。采用淬火处理后微观组织存在着很大的缺陷和应力,这些缺陷和内应力为深冷时原子迁移提供了驱动力,使得晶胞中各原子分布更均匀,排列更加紧密。

图4 烧结淬火后回火与深冷处理的XRD谱

Fig. 4 XRD patterns of tempering and cryogenic treatment after sintering and quenching

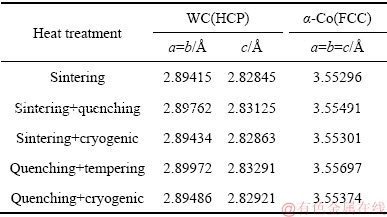

表3所列为烧结态及热处理后试样利用MDI Jade软件测得的WC和α-Co晶格常数,其中WC晶胞为简单六方结构,α-Co晶胞为面心立方结构。由表4可以看出,烧结态试样热处理后,WC和α-Co晶格常数变化趋势一致;淬火处理后,WC和α-Co的晶格常数略有升高,深冷处理后晶格常数变化很小,而对于淬火态试样,回火处理后WC和α-Co晶格常数升高,深冷处理后降低。当存在压应力时,晶面间距变小,衍射峰向高角度偏移,反之,当存在拉应力时,晶面间距拉大,衍射峰位向低角度偏移,表3中晶格常数的变化与图3和4中衍射峰的偏移相符合。试样淬火后,α-Co晶格常数变大主要由于α-Co中溶解有大量的W、C原子,且因淬火急冷阻碍其析出而保留到室温,致使α-Co晶格产生畸变。深冷条件下原子的扩散由于极低的温度条件而很难进行,因此,深冷处理后,α-Co的晶胞参数与烧结态和淬火态差异很小。

表3 WC和α-Co的晶格常数

Table 3 Lattice parameter of WC and α-Co

2.3 断口形貌

图5所示为烧结态及热处理后各试样的断口形貌图。在图5中表面平整、立体感很强的部分为硬质相WC颗粒,表面凹凸不平的部分为粘结相Co基,粘结相中的白色脊线为撕裂棱。图5(a)所示为烧结态断口形貌,可以看到其断面较为平整,伴随有少量的韧窝存在,由此可知其断裂主要发生在WC晶粒和粘结相的界面,同时也有少量穿晶断裂。发生沿晶断裂是由于WC和Co在界面处原子排列差异较大,因此两相交界处容易发生断裂。图5(b)所示为烧结态淬火处理的断口形貌,可看到其与图5(a)烧结态相比,韧窝数量增多,且出现了一些孔隙,这说明孔隙对合金的断裂有着较大影响。产生孔隙的主要原因可能是由于试样淬火冷却时WC刚性骨架阻碍了Co相的收缩,致使Co不能填满收缩产生的孔隙,此外烧结过程中成形剂分布不均匀所产生的气体也可能是造成孔隙的原因[17-18]。图5(c)所示为烧结态深冷处理的断口形貌,其与图5(a)为烧结态断口形貌没什么差异,为沿晶和韧性复合形式的断裂。图5(d)所示为淬火后回火处理的断口形貌,可看到试样断面有较多表面平整的WC晶粒,同时存在孔隙。此外,在WC和粘结相界面处出现了较多的白色颗粒(白圈所示),这些白色颗粒是回火时Co相中析出的弥散分布的新相,这些新相起到提高合金韧性、强度的作用。图5(e)所示为淬火后深冷处理的断口形貌,可看到断裂形式主要为沿晶和韧性复合形式。

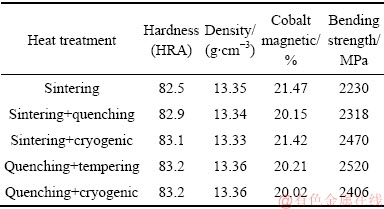

2.4 力学性能

表4所列为烧结态及热处理试样测得的硬度、密度、钴磁和抗弯强度。从表4可以看到,烧结态试样热处理后硬度值略有上升,密度几乎没变。硬度的主要因素有合金成分、晶粒尺寸、致密度,热处理不会使合金成分发生变化,且热处理对合金晶粒尺寸的影响很小,故硬度值变化很小。试样淬火处理后,抗弯强度由2230 MPa提升到2300 MPa;试样深冷处理后,抗弯强度提升到2470 MPa;对淬火的试样进行回火处理后抗弯强度为2520 MPa;试样深冷处理后,抗弯强度为2400 MPa。烧结态试样淬火回火处理后抗弯强度提升最多,提高了13%。抗弯强度用于硬质合金强韧性的一般测定,是合金受到的剪切应力、拉应力、压应力的集中体现,其主要取决于WC晶粒尺寸、分布情况、邻接度、粘结相的成分结构及内应力。淬火回火后,WC晶粒尺寸变化很小,而邻接度却有明显降低,因此降低了合金内应力集中的发生,减少裂纹源;而淬火后粘结相中α-Co含量和W原子的固溶度大幅增加,显著提高粘结相韧性和固溶强化效果。此外,回火消除了部分因淬火产生的内应力,且回火时析出的弥散分布的新相产生弥散强化,从而使合金的强度进一步强化。因此,虽然淬火回火处理后粘结相内孔隙数量增加,亦增加了裂纹源数量,但其对合金强度和韧性的影响要小于粘结相变化的贡献,故合金抗弯强度大幅提高。

图5 各试样的断口形貌

Fig. 5 Fracture morphologies of each specimen

表4 不同热处理下ZL40.5硬质合金的性能

Table 4 Performance of ZL40.5 cemented carbide under different heat treatment

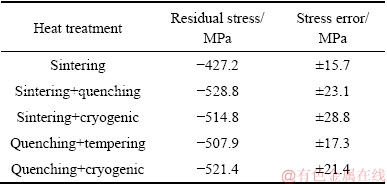

2.5 残余应力分析

由于硬质合金淬火、深冷时具有很大的冷却速度,且Co相膨胀系数是WC的3倍,冷却时,Co相的收缩程度大于WC的,由此会产生残余应力,其中粘结相Co受到拉应力,硬质相WC受到压应力。残余应力对工件的力学性能和使用寿命有着重要影响,本实验中选择WC相测量其残余应力,其原因为WC含量相对于Co高得多、其衍射峰强度很高且衍射峰之间干涉较小,有利于进行残余应力的测量。同时,合金中WC相结晶形态更加完整,内部微观缺陷较少,能够增加残余应力测量的准确性和可靠性[19]。

本文中采用X射线衍射法测量WC相的残余应力,其基本原理为以测量衍射线位移作为原始数据,所测结果实为残余应变,通过虎克定律进而计算得到残余应力。用波长0.15406 nm的X射线,先后以0°、15°、30°、45°四次入射角ψ照射到试样上,测出相应的衍射角2θ,求出2θ对sin2ψ的斜率M,通过式(3)便可算出表面残余应力σ。

(3)

(3)

(4)

(4)

(5)

(5)

式中:E、 是试样的弹性模量和泊松比;θ0为无应力试样衍射峰的布拉格角。K只与材料本质、选定衍射面HKL有关,当选定的衍射面指数不变时,K为定值,M为

是试样的弹性模量和泊松比;θ0为无应力试样衍射峰的布拉格角。K只与材料本质、选定衍射面HKL有关,当选定的衍射面指数不变时,K为定值,M为 直线的斜率,通过测得的K和M值计算出的WC残余应力值如表5所示。

直线的斜率,通过测得的K和M值计算出的WC残余应力值如表5所示。

表5 不同热处理下的残余应力

Table 5 Residual stress under different heat treatment

由表5可知淬火、深冷处理都会使烧结态试样表面残余应力增加,且淬火处理增幅更高,对淬火态试样回火、深冷处理则使表面残余应力略有降低。淬火后W在Co中的固溶度增加,且Co相分布更均匀,故表面压应力增大。此外,淬火后WC棱角处尖角溶解,以圆润角接触Co相,降低了组织内部的应力集中,也利于表面应力的提高[20]。深冷过程中发生α-Co向ε-Co的转变,产生的微观应力有助于残余压应力的提高,而且深冷降温过程中,合金表面温度变化比之内部快的多,因此,热胀冷缩效应使得合金表面压应力增加。

3 结论

1) 硬质合金烧结态淬火后能改善WC晶粒形貌,使晶粒变得圆润,降低合金应力集中发生的可能,减少裂纹源。

2) 热处理不能改善WC晶粒度,但能增加粘结相体积分数。相对于深冷,淬火回火后WC邻接度降低幅度最大,抗弯强度提升最高,硬度也未有降低,综合性能最好。

3) 热处理后断裂形式以沿晶和韧性断裂复合形式为主,但淬火后粘结相内出现了一些孔隙,这些孔隙对合金裂纹的产生有较大影响。

4) 热处理使合金表面压应力有着不同程度的增加,淬火处理后增加幅度最大。

REFERENCES

[1] MARSHALL J M, GIRAUDEL M. The role of tungsten in the Co binder: Effects on WC grain size and hcp-fcc Co in the binder phase[J]. International Journal of Refractory Metals & Hard Materials, 2015, 49(1): 57-66.

[2] FANG Z Z, WANG X, RYU T, HWANG K S, SOHN H Y. Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide—A review[J]. International Journal of Refractory Metals & Hard Materials, 2009, 27(2): 288-299.

[3] CHEN X, LIU H, GUO Q, SUN S P. Oxidation behavior of WC-Co hard metal with designed multilayer coatings by CVD[J]. International Journal of Refractory Metals & Hard Materials, 2012, 31(3): 171-178.

[4] PANKAJ K M, MIZGALSKI K P, SANTHANAM A T. Recent advances in tungsten-based hardmetals[J]. International Journal of Powder Metallurgy, 2007, 43(2): 33-40.

[5] FRYKHOLM R, ANDREN H O. Development of the microstructure during gradient sintering of a cemented carbide[J]. Materials Chemistry & Physics, 2001, 67(1): 203-208.

[6] ARMSTRONG R W. The hardness and strength properties of WC-Co composites[J]. Materials, 2011, 4(7): 1287-1308.

[7] 王丽利, 李海艳, 刘 宁. Co含量对硬质合金组织和性能的影响[J]. 稀有金属与硬质合金, 2011, 39(1): 66-69.

WANG Li-li, LI Hai-yan, LIU Ning. Effects of Co Content on microstructure and mechanical properties of cemented carbides[J]. Rare Metals and Cemented Carbides, 2011, 39(1): 66-69.

[8] VISWANADHAM R K, GURLAND J, ROWCLIFFE D J. Science of hard materials[J]. New York: Plenum Publishing Corp New York Plenum, 1983, 87(5): 1749-1751.

[9] MARSHALL J M, GIRAUDEL M. The role of tungsten in the Co binder: Effects on WC grain size and hcp-fcc Co in the binder phase[J]. International Journal of Refractory Metals & Hard Materials, 2015, 49(1): 57-66.

[10] 刘寿荣. WC-Co硬质合金γ相相变[J]. 稀有金属, 2000(2): 101-105.

LIU Shou-rong. Binder phase transformation in WC-Co Cemented carbides[J]. Chinese Journal of Rare Metals, 2000(2): 101-105.

[11] 王忆民, 李 锐, 曹 群. 淬火回火热处理对WC-25%Co硬质合金组织与性能的影响[J]. 硬质合金, 2014, 31(3): 148-154.

WANG Yi-ming, LI Rui, CAO Qun. Effects of quenching and tempering on microstructure and properties of WC-25%Co cemented carbide[J]. Cemented Carbide, 2014, 31(3): 148-154.

[12] 朱骥飞, 张 立, 徐 涛, 张忠健, 刘向中, 王 喆. 基于Image J软件的硬质合金显微组织参数化定量分析[J]. 粉末冶金材料科学与工程, 2015, 20(1): 26-31.

ZHU Ji-fei, ZHANG Li, XU Tao, ZHANG Zhong-jian, LIU Xiang-zhong, WANG Zhe. Quantificational characterization of microstructural parameters of cemented carbides based on Image J software[J]. Materials Science and Engineering of Powder Metallurgy, 2015, 20(1): 26-31.

[13] KIM C, MASSA T R, ROHRER G S. Interface character distributions in WC-Co composites[J]. Journal of the American Ceramic Society, 2010, 91(3): 996-1001.

[14] ROEBUCK B, BENNETT E G. Phase size distribution in WC/Co hardmetal[J]. Metallography, 1984, 19(1): 27-47.

[15] 常铁军, 祁 欣. 材料近代分析测试方法[M]. 哈尔滨: 哈尔滨工业大学出版社, 2005: 10-17.

CHANG Tie-jun, QI Xin. Modern analysis and testing method of materials[M]. Harbin: The Polytechnic University of Harbin Press, 2005: 10-17.

[16] 刘寿荣. 硬质合金的粘结相及其相变[J]. 硬质合金, 1998(4): 200-207.

LIU Shou-rong. Binder phase cemented cardides and its phase transformation[J]. Cemented Carbide, 1998(4): 200-207.

[17] PARANOSENKOV V P, KELINA I Y, PLYASUNKOVA L A, BYKOV Y V. Preparation of dense ceramics based on silicon nitride nanopowders[J]. Refractories & Industrial Ceramics, 2003, 44(4): 223-226.

[18] BELLOSI A, VICENS J, MEDRI V, GVICCIARDI S. Nanosize silicon nitride: Characteristic of doped powders and of the related sintered materials[J]. Applied Physics A, 2005, 81(5): 1045-1052.

[19] 黄钧声, 吴惕言. 热处理硬质合金的微观应力的测量研究[J]. 硬质合金, 1997(2): 65-68.

HUANG Jun-sheng, WU Ti-yan. Measuring microstress and researching heat-treatment of cemented carbides[J]. Cemented Carbide, 1997(2): 65-68.

[20] 唐云锋, 黄继武, 左 锐, 谢晨辉, 谷立宁. 淬火与深冷处理对YG6硬质合金微观结构与性能的影响[J]. 硬质合金, 2015, 32(6): 372-378.

TANG Yun-feng, HUANG Ji-wu, ZUO Rui, XIE Chen-hui, GU Li-ning. Influence of quenching and cryogenic treatment on microstructure and properties of YG6 cemented carbide[J]. Cemented Carbide, 2015, 32(6): 372-378.

Effect of heat treatment on microstructure and properties of high cobalt ZL40.5 cemented carbide

DONG Ding-qian1, 2, 3, XIANG Xin1, HUANG Xin-jie1, HUANG Wei2, SHI Kai-hua2, ZHANG Li3

(1. College of Mechanical Engineering, Sichuan University of Science and Technology, Yibin 644000, China;

2. Zigong Cemented Carbide Corporation Limited, Zigong 643011, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The effects of heat treatment processing on microstructure of high cobalt ZL40.5 cemented carbide synthesized by gas pressing sintering were investigated using scanning electron microscopy (SEM) and X-ray diffractometry (XRD). Based on the crystallography theory and combined with Image J and Jade software, the properties of the alloy, such as hardness, bending strength and residual stress, were measured. The results show that the quenching treatment makes the morphology of WC grain round and smooth, reduces the occurrence of stress concentration and reduces the source of fracture. After quenching and tempering, the content of α-co in the bonding phase increases greatly, WC adjacency decreases, and the strength and toughness of the alloy are improved while the hardness is guaranteed. The fracture of the alloy after heat treatment is mainly in the form of intergranular and ductile composite,after quenching and tempering, the surface compressive stress increases to the highest.

Key words: cemented carbide; heat treatment; microstructure; fracture morphology; combination property

Foundation item: Project(18ZL0355) supported by Scientific Research Fund of Sichuan Provincial Education Department, China; Project (2017RCL08) supported by Doctoral Program Foundation of Sichuan University of Science and Technology, China; Project(201710622068) supported by College Student’s Innovation Research Fund of Sichuan Province, China

Received date: 2018-07-18; Accepted date: 2018-10-16

Corresponding author: DONG Ding-qian; Tel: +86-831-5980346;E-mail:jdddq2012@163.com

(编辑 李艳红)

基金项目:四川省教育厅基金资助项目(18ZL0355);四川理工学院博士基金资助项目(2017RCL08);四川省大学生创新项目(201710622068)

收稿日期:2018-07-18;修订日期:2018-10-16

通信作者:董定乾,高工,博士;电话:0831-5980346;E-mail:jdddq2012@163.com