DOI:10.19476/j.ysxb.1004.0609.2018.03.01

TC4钛合金表面搅拌摩擦加工制备Ti-Cu阻燃改性层

李 博1,沈以赴2

(1. 上海市特种设备监督检验技术研究院,上海 200062;

2. 南京航空航天大学 材料科学与技术学院,南京 211106)

摘 要:在TC4钛合金基板表层开槽并预植入塑性的金属Cu粉体,采用搅拌摩擦加工工艺,利用Cu粉体与搅拌区钛基热塑性组织的反应扩散行为、β-Ti相稳定元素Cu对搅拌区α+β双相钛组织α/β相变行为的影响,在优化的加工工艺参数下制备TC4钛合金表面Ti-Cu合金化改性层,获得搅拌区内富β-Ti相区结构,基于Ti、Cu的二元反应扩散和固溶-析出等行为,生成了Ti2Cu等Ti-Cu中间相,通过改变TC4基板表层的成分组成和物相结构,实现在普通TC4钛合金表层具有一定的阻燃性能。采用激光点烧蚀法对Ti-Cu改性层耐烧蚀性能进行评价,进而揭示改性层的阻燃机理:通过调控钛基体表层的α/β两相比例以提高搅拌摩擦加工冷却过程后的搅拌区β-Ti相占比,通过添加阻燃合金元素Cu在改性层内生成Ti-Cu中间相及Ti-Cu合金化层区。

关键词:搅拌摩擦加工;钛合金;阻燃机理;表面改性;合金化

文章编号:1004-0609(2018)-03-0435-11 中图分类号:TG146 文献标志码:A

常规钛合金的熔点一般要高于其燃点,在特定条件下有“自发燃烧”倾向,产生的“钛火”蔓延速度极快,很大程度上限制了其在航空发动机等工业领域的应用[1]。对此,美国、俄罗斯等国从20世纪70年代就积极开展阻燃钛合金的研究,我国对阻燃钛合金的研究始于20世纪90年代初,先后自行研制或仿制了Ti-V-Cr系、Ti-Cu-Al系、Ti-Cu系、Ti-Nb系阻燃钛合金[2-5]。研究认为:单相β-Ti组织对抗燃烧是有利的[6];Al、V、Cr等元素可在燃烧前沿快速形成一层致密的氧化膜,有效隔离氧向钛基体输送;A1、Mg、Cu等具有较高的氧化生成热和燃烧热,在燃烧前会发生软化或熔化,可大量吸热以降低局部温度[7]。

采用整体阻燃钛合金不仅会增加航空机件质量,且还会大大增加材料成本和工艺成本。因此,有研究者提出在钛表面制备阻燃涂层,在保持钛合金基体材料优异性能的同时,对钛表面起到阻燃、隔热、断氧等作用,还可减少增重[1, 5]。欧洲一些国家及美国均较早进行了钛合金燃烧敏感性等专项研究,并在此基础上进行了不同材料成分的阻燃涂层筛选和性能验证工作[1, 4-5]。徐重等[8-9]利用双辉等离子技术在钛表面渗入Cu、Cr、Nb等金属元素,形成表面Ti-Cu、Ti-Cr、Ti-Nb阻燃合金层,并具有一定的抗氧化和阻燃性能。北京矿冶研究总院对钛合金基体上阻燃涂层的阻燃机理进行了总结,包括隔、阻、导、滑、吸5个方面[4-5]。沈以赴等[10]采用表面机械合金化方法在TC4钛合金表面制备出Ti-Cr、Ti-Cu涂覆层并获得较好的涂层/基体界面结合力,激光点蚀实验结果表明制备的这两种体系涂覆层能够在一定程度上改善TC4钛合金表面的耐烧蚀能力。

搅拌摩擦加工(Friction stir processing,FSP)工艺是由搅拌摩擦焊(Friction stir welding,FSW)技术衍生而来[11-16]。近年来,FSP的工艺内涵已延伸拓展至颗粒增强金属基复合材料的制造、铸态合金组织强韧化改性、新型金属间化合物的制备、金属材料表面改性等加工领域。面向α+β双相钛合金基体组织,李博 等[16-18]曾利用FSP工艺制备出TiCp/TC4改性层、Ti3Alp/TC4改性层,改善TC4表层的耐磨性能,这种利用FSP搅拌区形成的“基体内生型”改性层结构可实现与TC4基体的良好过渡,并可通过预植粉的工艺调控和FSP搅拌头的几何设计,实现改性层厚度的可控性。基于上述研究进展,本文作者提出在TC4钛合金表层预植入塑性的Cu金属粉体,采用FSP工艺,利用Cu粉体与搅拌区钛基热塑性组织的反应扩散行为、β-Ti相稳定元素Cu对于搅拌区双相钛组织α/β相变行为的影响,改变TC4基板表层的成分组成和物相结构,实现在普通TC4钛合金的表层制备出具有一定阻燃性能的Ti-Cu合金化改性层,并对其耐烧蚀性能进行评价,揭示其阻燃机理。

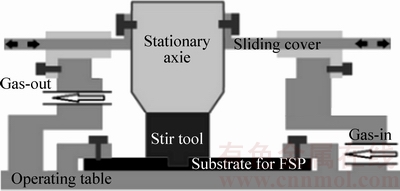

1 实验

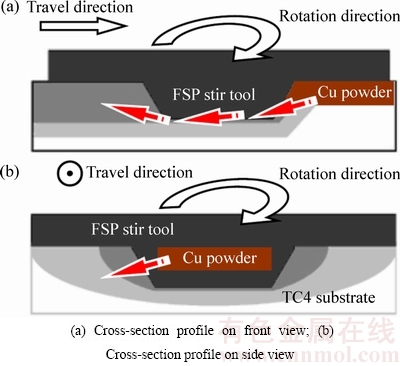

母材为4 mm厚Ti-6Al-4V钛合金板材(退火态TC4,退火温度约650 ℃),选用Cu金属粉末作为预植入粉体(粉体平均粒径约为8 μm,纯度≥99.9%),FSP搅拌头材料为WC-Co硬质合金(Co含量约13%(质量分数)),搅拌头圆柱形轴肩直径为15 mm,搅拌针为圆台形,圆台顶部直径4 mm、根部直径6 mm,搅拌针长2.2 mm。FSP实验装置如图1所示,为防止高温加工过程中搅拌区的严重氧化,通过保护气罩装置在加工前预通气5 min,并在FSP过程中持续通入氩气(纯度≥99.9%,流量0.3 L/min)。作为对比实验分析,首先对TC4基板进行不植入粉体的直接FSP,并进行工艺优化获得与良好成形匹配的FSP工艺参数窗口。在植粉FSP前通过铣削加工在TC4基板表层开槽,槽宽4 mm,槽深0.8 mm,在槽中填加Cu粉体后再用机械方法压实,并扫除多余粉体。在优化的FSP工艺参数窗口中进一步工艺优化,选取最优参数以获得植粉FSP的最佳成形。最终选定用于植粉FSP的工艺参数:搅拌头转速(r)350 r/min;搅拌头行进速度(v)210 mm/min;搅拌头轴肩下压量(d)0.05 mm;搅拌头前倾角0°。本研究仅制备单道次FSP试样进行分析,需要指出的是,根据FSP工艺特点,也可通过平行多道次FSP获得大面积的改性层。图2给出了FSP加工过程中槽内的粉体被搅拌作用引入搅拌区(也即是改性层芯部)的示意图(红色箭头示意粉体随搅拌针运动的迁移路径)。

图1 FSP加工装置及保护气罩示意图

Fig. 1 Illustration of FSP and shielding atmosphere device

图2 金属粉体被搅拌引入改性层芯部过程示意图

Fig. 2 Schematic diagram of powder migration path with stir tool behavior

FSP制备的试件通过电火花线切割方法取样并对搅拌区横截面进行金相制样,并选用HF、HNO3和H2O体积比为1:2:47的HF+HNO3+H2O的混合酸试剂腐蚀对钛基试样进行腐蚀。通过XTL-2200体视显微镜(Integrated microscope,IM)、QMW550光学显微镜(Optical microscope,OM)观察试样宏观形貌及金相微观组织;借助QUANTA200型扫描电子显微镜(Scanning electron microscope,SEM)观察和分析试样的二次电子像;利用描电镜所配置的X射线能量密度散射谱(Energy dispersive X-ray spectroscope,EDXS)分析试样指定点、指定微区的化学成分,EDXS探测器出射窗为铍窗;采用BRUKER D8 ADVANCE型X射线衍射仪(X-ray diffraction,XRD)表征,XRD的Cu Kα衍射波长λ为0.15418 nm,工作电压和电流分别为40 kV、40 mA,探测扫描范围2θ为30°~90°,扫描方式为连续扫描,扫描速率为2 (°)/min。

目前,国内外对阻燃钛合金及普通钛合金阻燃涂层的耐烧蚀能力或阻燃性能的评价标准并不统一[19]。对于TC4表面引入金属粉体FSP所制备的Ti-Cu阻燃改性层,本文作者采用激光点烧蚀法评价其耐烧蚀性能。选用输出功率100 W、光斑直径0.15 mm的脉冲YAG固体激光器(脉冲能量5 J/ms、脉冲宽度50 ms),对TC4母材基板和FSP改性层表面进行30~60 s的连续点烧,并对烧蚀坑的形貌、几何尺寸等进行检测分析。

2 实验结果

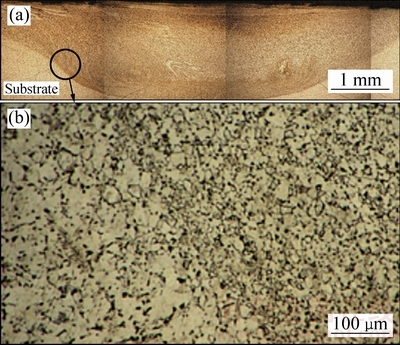

2.1 直接搅拌摩擦加工宏观结构与显微组织特征

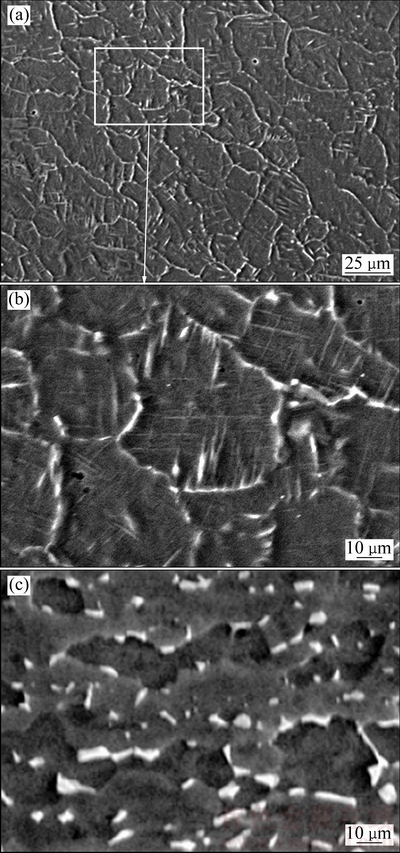

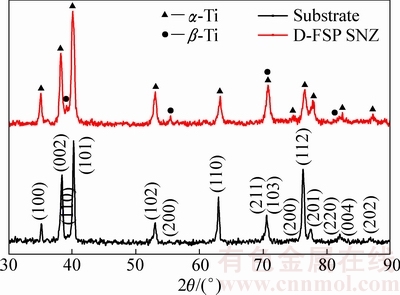

图3(a)所示为优化工艺参数(r=350 r/min;v=210 mm/min;d=0.05 mm)条件下不预植入Cu粉单道次直接FSP搅拌区(也称“焊核区”,Stir nugget zone,SNZ)截面结构,其最大深度略大于搅拌针针长。图3(b)所示为图3(a)中FSP前进侧白色圆圈标注位置微区金相组织,图中右上区域的搅拌区组织晶粒度明显小于母材基体(图中左下区域),二者的过渡区域为FSP热机械影响区。如图4所示,通过SEM观察可知,搅拌区组织呈α+β双相组织,析出的细片状α相分布于大量的β相晶粒的晶间和晶内,从而形成特殊的β相区结构(见图4(a)和(b)),FSP生成的β相区尺寸从10 μm到50 μm不等。相比而言,搅拌区与退火态TC4母材微观组织中的α+β双相组织特征大不一样,如图4(c)中白色的β相晶粒尺寸均在10 μm以下,且主要沿母材中α晶粒的晶界弥散分布。图5所示为母材和直接FSP搅拌区XRD物相衍射峰,从α相、β相衍射峰的相对强度比较可知,FSP搅拌区的α/β相比例发生了改变,在经历FSP后的搅拌区中的β相比例明显上升。这说明在该组工艺参数下的FSP过程中,TC4组织经历了α/β相变,FSP加工峰值温度应已超过了TC4合金的β相变点,从而为α-Ti→β-Ti转变过程提供了热力学条件,并在搅拌区形成后的冷却过程中,部分β相再次转变为α相,其他β相则来不及完全转变为α相并被保留到室温状态,也即在冷却过程中发生了β-Ti→α-Ti+β-Ti转变。

图3 TC4钛合金直接FSP搅拌区宏观结构及微观形貌

Fig. 3 Macro (a) and micro (b) morphologies of direct-FSP of Ti6Al4V alloy

图4 直接FSP搅拌区及TC4母材的SEM像

Fig. 4 SEM images of direct-FSP SNZ ((a), (b)) and Ti6Al4V alloy substrate (c)

图5 TC4母材和直接FSP搅拌区XRD谱

Fig. 5 XRD patterns of TC4 substrate and direct-FSP (D-FSP) SNZ

2.2 植粉搅拌摩擦加工宏观结构与微观组织特征

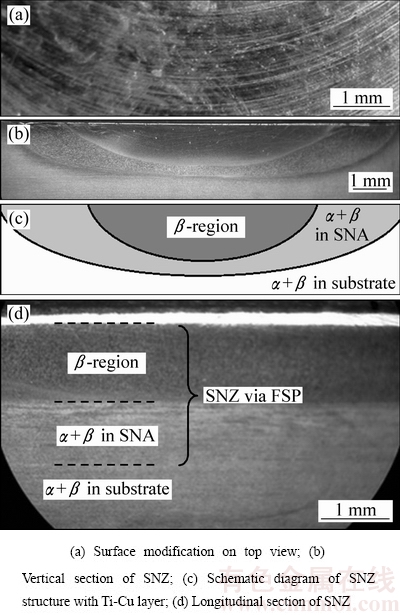

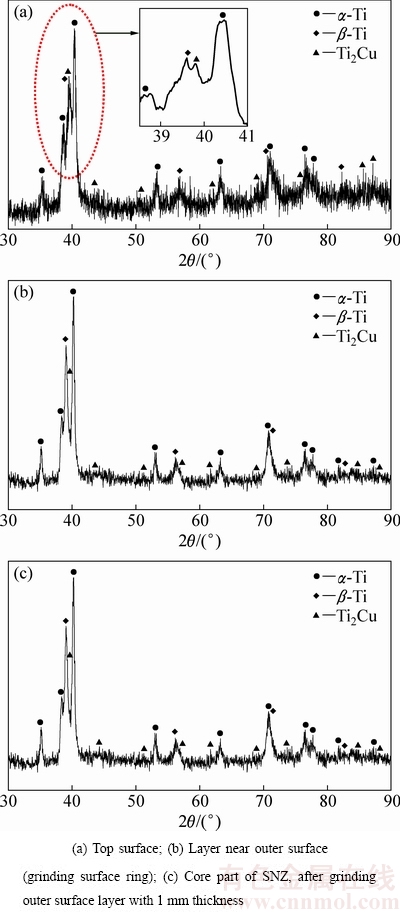

在优化的工艺参数条件下,单道次植粉FSP获得的TC4钛合金表面Ti-Cu改性层表面形貌及宏观结构如图6所示。通过IM观察的改性层表面环纹分布均匀(见图6(a)),其截面结构与TC4直接FSP的搅拌区不同,Ti-Cu改性层搅拌区显示出不同的分区特征(见图6(b)、(c)和(d)):搅拌区分为中部靠近外表面的新生富β相区及其周围的新生α+β双相区(区别于母材原有的α+β双相TC4钛合金组织),二者的分区界线可在IM下清晰地观察到(见图6(b)和(d))。对单道次Ti-Cu改性层最外表面(含表面环纹)、近外表层(研磨去除表面环纹)、搅拌区芯部(研磨去除表层1 mm厚度)进行XRD检测,衍射图谱及主要物相标定如图7所示。对比相同工艺参数条件下TC4直接FSP的XRD结果(见图5)可知,由于Ti-Cu改性层中β-Ti稳定元素Cu的存在,其外表层中新生富β相区的β相比例明显提高。Ti-Cu改性层的XRD谱中,相对于各自试样的α-Ti衍射峰,其β-Ti衍射峰的相对强度(见图7),明显高于不引入Cu粉的直接FSP搅拌区中β-Ti衍射峰的相对强度(见图5)。此外,在XRD衍射峰中,能检测出较为明显的Ti2Cu相,根据Ti2Cu相衍射峰强度的变化,可发现改性层中Ti2Cu相含量会随着与最外表面距离的增加而减少(见图7)。在图7的XRD衍射峰中,也出现了大量强度较弱的衍射峰型,说明除α-Ti、β-Ti、Ti2Cu相外,仍有其他杂相存在,其中也可能包括相对含量较低的其他Ti-Cu中间相。另外,由于TC4母材中含约6%(质量分数)的Al元素(Al为重要的α-Ti稳定元素),故在搅拌区从加工峰值温区冷却到室温状态的过程中,Ti-Cu改性层的钛基组织也不可避免地发生β→α的转变,并能在室温状态下保证一定α-Ti相的存在,因此,在其XRD衍射峰中仍然存在明显的α-Ti衍射峰。

图6 单道次FSP制备Ti-Cu改性层搅拌区截面结构

Fig. 6 Cross-section macrostructures of Ti-Cu modified layer by single FSP

图7 TC4表面FSP制备Ti-Cu改性层XRD谱

Fig. 7 XRD patterns of FSP produced Ti-Cu modified layer on TC4 surface

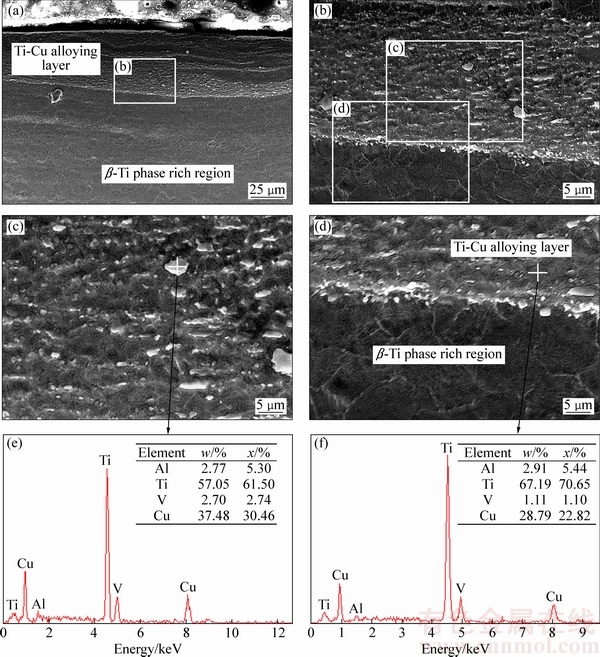

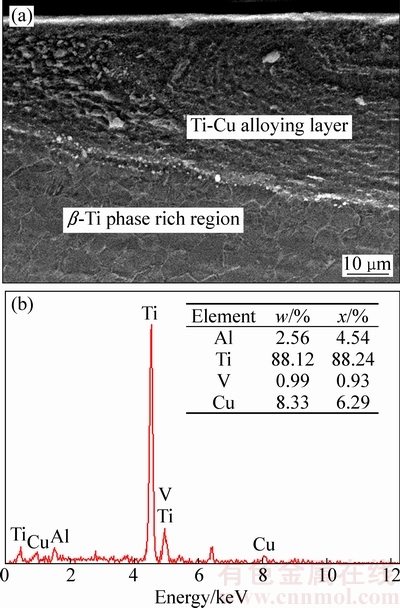

图8所示为Ti-Cu改性层的近表层SEM及微区EDXS。在富β相区近外表层存在一层厚度约为80~100 μm的Ti-Cu合金化层区,其厚度远小于整个富β相区的最大厚度(富β相区最大厚度约2 mm,如图6所示),故可将其视为富β相区的组成部分。根据XRD(见图7)及EDXS(见图8)检测结果,Ti-Cu合金化层区含有大量Ti-Cu金属间化合物相。图9所示为最外表层Ti-Cu合金化层区下部的富β相区的EDXS检测结果,对比图8中EDXS结果,并从搅拌区内的分区特征、富β相区内的分层特征可知,Cu粉在改性层搅拌区中的整体分布并不均匀,作为β-Ti稳定元素,Cu在富β相区内单位体积的含量要高于其周围的α+β双相区,而Cu在Ti-Cu合金化层区内单位体积的含量则高于其周围的富β相区。Ti-Cu合金化层区下部的富β相区微观组织特征呈典型的β-Ti相晶粒形态,晶粒平均尺寸约为10 μm。富β相区的晶粒微观形态也明显不同于在同样工艺参数条件下获得的直接FSP搅拌区中的TC4钛合金β相区群,相比之下前者并无较多的层片状或针状α相析出形态。虽然富β相区的XRD衍射峰中α-Ti相的衍射峰依然存在(见图7),说明室温状态下富β相区中仍然存在一定的α-Ti相,只是存在的形态与TC4直接FSP的搅拌区不同,引入Cu进行FSP后搅拌区的α-Ti相比例明显下降;富β相区中的α-Ti相主要存在于β-Ti相晶粒的晶界部位,且晶界α-Ti相的厚度较薄。之所以在室温状态下,富β相区比TC4直接FSP搅拌区出现更多的稳定β-Ti相晶粒,很大程度上是由于β-Ti稳定元素Cu能够在高温FSP的过程中,固溶到搅拌区的钛基晶粒中,不仅可降低α/β相变的温度点,使得在加工过程中发生相变并获得全β相组织更加容易(也即发生α-Ti→β-Ti转变所需要的热输入更少),而且可在冷却时β-Ti→α-Ti+β-Ti转变的过程中,保留更多的稳态β-Ti晶粒至室温条件。

图8 TC4表面FSP制备Ti-Cu改性层近外表层SEM像和EDXS结果

Fig. 8 SEM images ((a), (b), (c), (d)) and EDXS results ((e), (f)) of FSP produced Ti-Cu layer near outer surface on TC4 surface

图9 Ti-Cu合金化层区的SEM像及其下部富β相的EDXS谱

Fig. 9 SEM image of FSP produced Ti-Cu alloying layer (a) and EDXS spectrum of β-Ti phase rich region (b)

2.3 改性层耐烧蚀性能评价

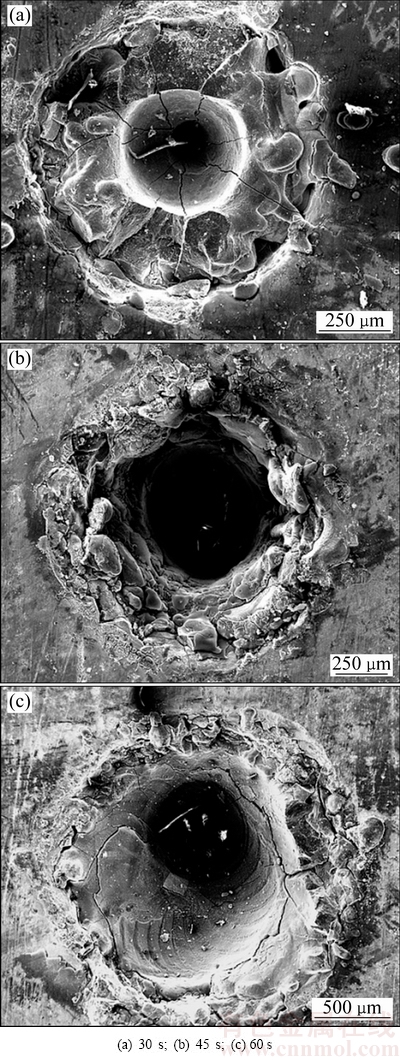

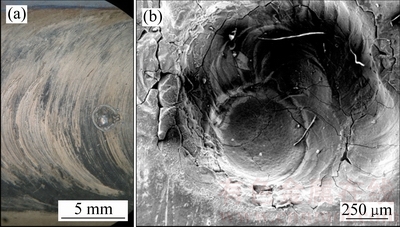

图10所示为设定的激光参数下对TC4母材表面进行30~60 s连续点烧的烧蚀坑形貌。烧蚀坑由类圆形盲孔及其周围的熔融体和氧化产物构成,烧蚀时间分别为30、45、60 s时,对应的蚀坑直径分别约为350 μm(见图10(a))、550 μm(见图10(b))、800 μm(见图10(c));在烧蚀坑内壁及其周围的熔融体和氧化物上,均出现了明显的宽化裂纹,这是在激光持续烧蚀和快速冷却的过程中材料发生冷裂的结果;当烧蚀时间为30 s时,烧蚀坑周围存在较宽范围的熔融体和氧化物,而随着烧蚀时间的延长,更多的钛基材料发生剧烈氧化而被烧损,或转化为飞溅而损耗,其遗留下的烧蚀坑都具有较大深度和直径。

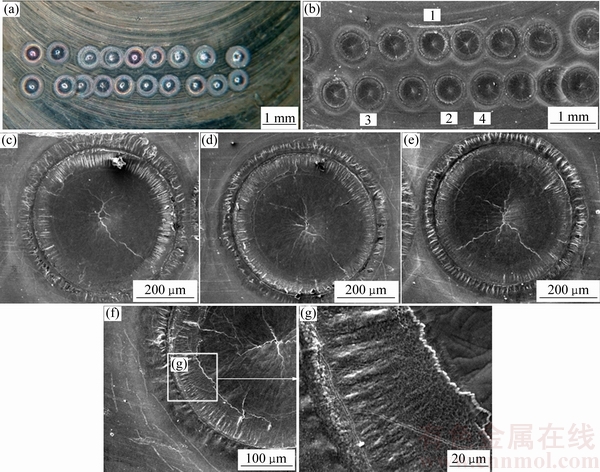

图11所示为烧蚀时间30 s后在Ti-Cu改性层表面中部位置的激光烧蚀坑形貌。对比TC4母材烧蚀结果(见图10(a)、11(a)和11(b))可知,Ti-Cu改性层的烧蚀坑深度更浅,烧蚀坑芯部更趋平坦。根据图11(b)中随机选取的烧蚀坑1、2、3的SEM像(见图11(c)、(d)和(e)),Ti-Cu改性层烧蚀坑周围的熔融体和氧化物范围更小,并呈现向烧蚀坑四周放射的“花环状”形貌。

图10 不同激光烧蚀时间条件下TC4钛合金母材激光点烧蚀坑的SEM像

Fig. 10 SEM images of laser burning pitting on TC4 alloy substrates at different laser burning time

图11 激光30 s连续脉冲点烧条件下Ti-Cu改性层表面点烧蚀坑形貌

Fig. 11 Surface morphology (a) and SEM image (b) of laser continuous pulse burning pitting after 30 s period on FSP produced Ti-Cu modified layer and SEM images of points 1 (c), 2 (d), 3 (e) and 4 (f) laser burning pitting and magnified morphology of point 4 (g)

图12 激光45 s连续脉冲点烧条件下Ti-Cu改性层表面点烧蚀坑形貌

Fig. 12 SEM image of laser continuous pulse burning pitting after 45 s on FSP produced Ti-Cu modified layer

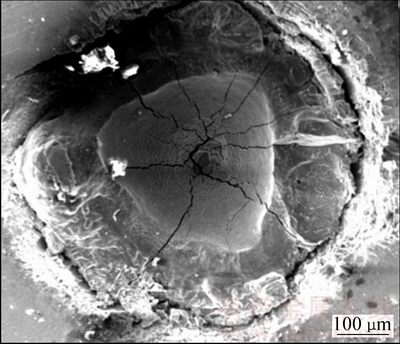

对图11(b)中随机选取的烧蚀坑4的SEM像(见图11(f)),烧蚀坑周围的环状熔融体表面还存在着大量的微细熔融坑(见图11(g)),而这与如图10中TC4母材烧蚀坑周围的熔融体和氧化物形貌形成鲜明对比,说明Ti-Cu改性层在30s同等烧蚀时间条件下的熔融、氧化程度更低。图12所示为烧蚀时间45s后在Ti-Cu改性层表面中部位置的烧蚀坑形貌。对比图11烧蚀坑形貌可知,随着激光烧蚀时间的延长,烧蚀坑直径增加,蚀坑芯部周围的熔融体和氧化物的范围也明显加宽,但烧蚀坑的深度依然小于经过同等烧蚀时间后的TC4母材(见图10(b))。当激光烧蚀时间进一步延长至60 s,如图13所示,烧蚀坑直径进一步加大,烧蚀坑周围熔融体和氧化物的范围进一步加宽,同时出现明显宽化的裂纹,但其烧蚀坑深度的增加幅度并不明显,其直径和深度也显著小于经过同等烧蚀时间后的TC4母材(见图10(c))。

图13 激光60 s连续脉冲点烧条件下Ti-Cu改性层表面点烧蚀坑形貌

Fig. 13 Surface morphology (a) and SEM image (b) of laser continuous pulse burning pitting on FSP produced Ti-Cu modified layer after 60 s

综上所述可知,在同等激光光源物理参数、不同激光烧蚀持续时间的条件下,经过对TC4母材表面、FSP制备Ti-Cu改性层表面的烧蚀坑形貌特征进行对比,可以基本判断出:Ti-Cu改性层在选取的烧蚀测试激光能量输入的过程中,能够起到一定的抗烧蚀作用,虽不能完全避免钛基组织的熔化和氧化,但在板厚方向上可阻滞烧蚀范围的扩展,延缓“钛火”向普通钛合金芯部的蔓延。因此,即使普通钛合金表面的阻燃层在服役过程中被烧损消耗,但也能在一定时间内延缓芯部钛基材料的烧损失效进程,从而起到阻燃作用。

3 分析与讨论

3.1 改性层富β相区及Ti-Cu中间相的形成机理

Cu作为重要的β-Ti稳定元素,在FSP过程中可被搅拌针卷带进入高温的钛基搅拌区中,极易扩散进入正在发生相变和塑性流变过程中的钛晶粒中,在冷却后能在搅拌区中保留较高的β-Ti相比例。根据Ti-Cu改性层富β相区所占搅拌区的比例可知,引入Cu粉后能够对钛基组织的物相组成产生主要影响的范围要小于整个搅拌区,这也说明Cu粉在搅拌区中的有效分散范围并不足以均匀地覆盖整个搅拌区,但对于阻燃性能来说,靠近外表面、且在搅拌区中占据较大体积分数的富β相区是有利于表层组织的导热和散热性的,换言之,TC4钛合金FSP制备Ti-Cu阻燃改性层的有效区域即为富β相区。根据对富β相区显微组织及化学成分的分析,可以推断,大量的Cu元素在FSP过程中能够扩散固溶进入钛基晶粒,有效降低在搅拌区钛合金体系中的α-Ti→β-Ti转变温度点,使钛基搅拌区发生α/β相变的热力学条件降低并且在冷却过程中保证更多的β-Ti相稳定地保留至室温状态。

另外也需指出,Cu是共析型β-Ti稳定元素,只能在β-Ti中有限固溶,并引起共析转变;根据Ti-Cu二元相图[20],当微区钛基组织中的Cu元素含量较低时,优先生成Ti2Cu相。Ti2Cu的形成机制可以是Cu粉体与Ti基体在FSP加工过程中通过直接反应生成,也可能是由于钛晶粒中固溶了过饱和的Cu元素后,在冷却过程中以第二相形态析出。在此FSP工艺参数下,TC4钛合金FSP的加工峰值温度均在α/β相变点以上,因此,可满足上述Ti/Cu反应扩展和“固溶-析出”行为的热力学条件。同时,在微区的Cu粉体及其周围Ti基组织间的界面处,由于高温的影响和FSP搅拌头的搅拌挤压作用,极易建立Ti/Cu二元扩散界面,在较短的反应扩散时间内也能满足Ti2Cu形成所需的动力学条件。分而论之,对于改性层中出现的颗粒尺寸过大的Ti2Cu,则主要是通过Cu粉体与Ti基体的直接原位反应生成,而非在冷却过程中Ti(Cu)过饱和固溶体的析出,这是因为FSP后的冷却时间较短,不满足大尺寸二次相颗粒的析出长大(熟化机制)所需要的动力学条件;而对于改性层中出现的微细尺寸Ti2Cu相,则可能是以二次析出的粒子形态存在于富β相区中。

Ti2Cu相是改性层中主要的Ti-Cu中间相,但并非唯一的Ti-Cu中间相,除Ti2Cu相以外的其他Ti-Cu中间相的XRD衍射峰强度极弱,在搅拌区XRD谱中不能明显地呈现(见图7)。在富β相区的最外表层存在较薄厚度的Ti-Cu合金化层区,其物相结构不仅由多种Ti-Cu中间相颗粒构成,而且也应含有固溶Cu的钛基固溶体。但在不同的微区内,Cu元素的含量则不尽相同。表层Ti-Cu合金化层区的形成主要是由于该区域内的Cu粉团聚较多,不能完全地固溶进入钛基晶粒,而是主要通过Ti、Cu的冶金反应生成Ti-Cu中间相。在Ti-Cu合金化层区下部的其他富β相区范围内,却并无较大尺寸或明显聚集的Ti-Cu中间相颗粒,这说明,搅拌头在“旋转-搅拌-顶锻行进”力学行为中,贴近搅拌头轴肩正下方的少量Cu粉不易被搅拌针“卷带”进入其下部的搅拌区芯部。同时,Ti-Cu合金化层区也存在具有流体方向性特征的条带结构(见图8(a)),而这种流体特征的结构也表明,该层区Cu粉体以及形成的中间相颗粒的流动和迁移,多以与搅拌头轴肩平面平行的“层流”形态为主,而缺少自上而下或自下而上的、沿板厚方向的迁移路径。

3.2 改性层阻燃机理

TC4表面FSP制备Ti-Cu阻燃改性层的组织特征直接决定了其阻燃性能的实现。本文作者认为,对于TC4等普通的α+β双相钛合金表层进行以阻燃为目标的组织调控,主要应从两方面着手:1) 调控钛基体表层的α/β两相比例,2) 添加一定的阻燃合金元素(如Al、Nb、V、Cr、Mo、Cu等)。而这两方面均可通过FSP的工艺手段来实现。

在双相钛合金基体α/β相比例调控方面:1) 多相共存的钛合金中,相比例是影响其阻燃性能的重要因素,已有研究表明[19],对不同类型的钛合金而言,在低温条件下纯钛的导热系数最高,但在高温条件下,β型钛合金的导热系数要高于α和α+β型钛合金(例如基于β相组织的阻燃钛合金Alloy C的导热系数是TC4钛合金的10倍左右[2-3, 21])。2) 对于单相钛晶体而言,晶体结构越复杂,导热系数越小,导致局部热量不易传导、耗散,体心立方结构的β-Ti相要比密排六方结构的α-Ti相具有更高的导热系数;这是因为,据固体物理学相关理论[22],晶格结构越复杂,晶格振动的非简谐性程度越大,格波间的相互作用也越强,格波收到的散射越大,故声子平均自由程越小,高温下声子平均自由程更易达到最小极限值,所以高温下复杂晶体结构材料的导热系数更低。3) 还有研究表明[23],由于α相的线膨胀系数与β相不同,若为两相钛合金,α晶粒在热诱发α/β转变上的膨胀会破坏任何可阻止燃烧的氧化层的形成,α晶粒上氧化层的裂纹是氧扩散的途径,而β晶粒上的氧化物保持初始点燃的热量而未损失,可继续提供抗燃能力,故全β钛合金具有良好的抗燃能力。

因此,增加复相钛合金组织中的β相比例,可以改善和提高阻燃性能。引入FSP搅拌区的Cu是重要的β-Ti相稳定元素,可降低Ti的α/β转变温度点,调控α+β双相TC4表层的α/β相比例,以形成更多的、比α-Ti相导热性更好的β-Ti相。

在添加阻燃合金元素方面:成本相对较低的Cu不仅具有较高的导热性能(Cu金属的导热系数是Ti的近20倍),而且在发生燃烧时,无论是在FSP过程中已形成的Ti-Cu中间,还是在燃烧前沿Cu元素在955~990 ℃共晶温度与Ti形成的低熔点共晶体(如Ti2Cu),均会在燃烧前沿先于钛基晶体发生熔融或熔化,形成的共晶液相不仅能吸收局部微区内大量的热,而且,局部或整体的熔化可使干摩擦转变为有液相润滑的摩擦,降低摩擦因数,减少摩擦产热。此外,在燃烧前沿的Cu氧化物生成的放热量要远低于Ti氧化物[19],特别地,当生成气相的CuO时,则会逸出带走一定的热量进入外界气相环境中,可起到吸热作用。

鉴于以上分析,本文作者认为,通过在普通TC4板材表层预植入Cu粉并利用FSP方法制备的Ti-Cu阻燃改性层,其获得的组织调控结果是有利于钛合金阻燃的。

4 结论

1) 在TC4钛合金基板表层开槽并预植入Cu金属粉体,通过FSP的方法在优化的工艺参数(r=350 r/min;v=210 mm/min;d=0.05 mm)条件下,可制备Ti-Cu合金化改性层以改善TC4钛合金表层的阻燃性能。对比在相同的工艺参数下不植入粉体的TC4钛合金直接FSP搅拌区组织结构,Ti-Cu合金化改性层组织以富β相区为主,β-Ti相晶粒平均尺寸约为10 μm,富β相区内的层片状或针状α-Ti相较少,α-Ti相层片更薄,改性层内的β-Ti相比例提升明显。改性层富β相区的近外表层生成了含大量Ti2Cu等中间相的Ti-Cu合金化层区。

2) 采用激光点烧蚀法评价改性层的耐烧蚀性能,选用输出功率100 W、光斑直径0.15 mm的脉冲YAG固体激光器(脉冲能量5 J/ms,脉冲宽度50 ms),对TC4母材基板和Ti-Cu改性层表面进行30、45、60 s的连续点烧后发现,改性层对应的烧蚀坑直径、烧蚀坑深度、烧蚀坑周围的熔融体和氧化物范围,均小于在相同激光烧蚀时间后的TC4母材,改性层可在板厚方向上阻滞或延缓烧蚀范围向芯部钛基材料的扩展。

3) 金属Cu粉体在TC4钛合金的FSP搅拌区中发生分散、扩散反应和固溶-析出等行为,在加工冷却后可获得比α-Ti相、α+β双相钛组织导热性更好的富β相区组织形态,Ti-Cu改性层中含有富Cu成分及生成的Ti2Cu等Ti-Cu中间相,可在发生局部燃烧时在燃烧前沿优先熔融吸热,降低燃烧微区的环境温度,从而有利于提高组织的耐烧蚀能力。

REFERENCES

[1] 罗秋生, 李世峰, 裴会平. 航空发动机钛火预防技术研究的进展[J]. 航空动力学报, 2012, 27(12): 2763-2768.

LUO Qiu-sheng, LI Shi-feng, PEI Hui-ping. Progress in titanium fire resistant technology for aero-engine[J]. Journal of Aerospace Power, 2012, 27(12): 2763-2768.

[2] 刘彩利, 赵永庆, 曲恒磊, 朱康英, 吴 欢. Ti40合金热稳定性能的初步研究[J]. 金属学报, 2002, 38(z1): 233-235.

LIU Cai-li, ZHAO Yong-qing, QU Heng-lei, ZHU Kang-ying, WU Huan. Study of thermal stability of Ti40 alloy[J]. Acta Metallurgica Sinica, 2002, 38(z1): 233-235.

[3] 赵永庆, 周 廉, 邓 炬. 合金元素Cr对钛合金燃烧行为的影响[J]. 稀有金属材料与工程, 1999, 28(3): 132-135.

ZHAO Yong-qing, ZHOU Lian, DENG Ju. Effect of alloying element, Cr, on the burning behavior of titanium alloys[J]. Rare Metal Materials and Engineering, 1999, 28(3): 132-135.

[4] 张 乐, 于月光, 任先京, 马江虹, 谢旭霞. 钛合金基体上阻燃涂层的研究进展[J]. 钛工业进展, 2008, 25(6): 6-10.

ZHANG Le, YU Yue-guang, REN Xian-jing, MA Jiang-hong, XIE Xu-xia. Research progress of sustained combustion coatings on titanium substrates[J]. Titanium Industry Progress, 2008, 25(6): 6-10.

[5] 舒 滢, 曾卫东, 张学敏, 赵永庆, 周义刚, 周 廉. Ti40阻燃钛合金热变形的开裂预测[J]. 稀有金属材料与工程, 2006, 35(12): 1900-1903.

SHU Ying, ZENG Wei-dong, ZHANG Xue-min, ZHAO Yong-qing, ZHOU Yi-gang, ZHOU Lian. Fracture predicting of Ti40 burn resistant titanium alloy in hot forming[J]. Rare Metal Materials and Engineering, 2006, 35(12): 1900-1903.

[6] 赵永庆, 舒 滢, 曾卫东, 吴玮璐, 吴 欢, 周义刚, 杨海瑛, 李倩. 高度稳定化β型Ti40阻燃钛合金的动态再结晶行为[J]. 稀有金属材料与工程, 2009, 38(8): 1432-1436.

ZHAO Yong-qing, SHU Ying, ZENG Wei-dong, WU Wei-lu, WU Huan, ZHOU Yi-gang, YANG Hai-ying, LI Qian. Dynamic recrystallization behavior of highly stabilized β Ti40 titanium alloy[J]. Rare Metal Materials and Engineering, 2009, 38(8): 1432-1436.

[7] 赵永庆, 周 廉, 邓 炬. 阻燃钛合金的阻燃模型[J]. 材料科学与工程学报, 2000, 18(z2): 888-891.

ZHAO Yong-qing, ZHOU Lian, DENG Ju. Flame retardant model of flame retardant titanium alloy[J]. Materials Science & Engineering, 2000, 18(z2): 888-891.

[8] 徐 重, 张高会, 张平则, 张艳梅, 池成忠, 袁庆龙. 双辉等离子表面冶金技术的新进展[J]. 中国工程科学, 2005, 7(6): 73-78.

XU Zhong, ZHANG Gao-hui, ZHANG Ping-ze, ZHANG Yan-mei, CHI Cheng-zhong, YUAN Qing-long. New development of double glow plasma surface metallurgy technology[J]. Engineering Sciences, 2005, 7(6): 73-78.

[9] 张平则, 徐 重, 张高会, 贺志勇, 李争显. Ti-Cu表面阻燃钛合金研究[J]. 稀有金属材料与工程, 2005, 34(1): 162-165.

ZHANG Ping-ze, XU Zhong, ZHANG Gao-hui, HE Zhi-yong, LI Zheng-xian. Study of surface burn-resistant Ti-Cu titanium alloy[J]. Rare Metal Materials and Engineering, 2005, 34(1): 162-165.

[10] LI Bo, DING Run-dong, SHEN Yi-fu, HU Yong-zhi, GUO Yan. Preparation of Ti-Cr and Ti-Cu flame-retardant coatings on Ti-6Al-4V using a high-energy mechanical alloying method: A preliminary research[J]. Materials & Design, 2012, 35: 25-36.

[11] 徐国富, 段雨露, 钱 健, 唐 磊, 邓英, 尹志民. Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头显微组织、力学性能及腐蚀性能[J]. 中国有色金属学报, 2017, 27(2): 225-233.

XU Guo-fu, DUAN Yu-lu, QIAN Jian, TANG Lei, DENG Ying, YIN Zhi-min. Microstructure, mechanical properties and corrosion properties of friction stir welded Al-Mg-Mn-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 225-233.

[12] 徐国富, 彭小燕, 段雨露, 曹晓武, 邓 英, 尹志民. 新型Al-Mg-Sc-Zr和Al-Zn-Mg-Sc-Zr合金的研究进展[J]. 中国有色金属学报, 2016, 26(8): 1577-1587.

XU Guo-fu, PENG Xiao-yan, DUAN Yu-lu, CAO Xiao-wu, DENG Ying, YIN Zhi-min. Research advance on mew Al-Mg-Sc-Zr and Al-Zn-Mg-Sc-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1577-1587.

[13] 谢永辉, 杨新岐, 崔 雷. 6061-T4铝合金单双道搅拌摩擦焊T型接头组织及性能[J]. 中国有色金属学报, 2015, 25(1): 72-79.

XIE Yong-hui, YANG Xin-qi, CUI Lei. Microstructure and property of 6061-t4 aluminum alloy T-joints by friction stir welding under single pass and double passes[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 72-79.

[14] 刘 强, 王 淼, 张亚雄, 刘满平. 多道搭接FSP6061铝合金的组织与性能[J]. 中国有色金属学报, 2015, 25(3): 602-610.

LIU Qiang, WANG Miao, ZHANG Ya-xiong, LIU Man-ping. Microstructure and properties of 6061 aluminium alloy processed by multi-pass friction stir process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 602-610.

[15] 刘奋成, 熊其平, 钱 涛, 刘 强, 邢 丽, 柯黎明. 旋转摩擦挤压加工CNTs/Al复合材料的线材组织和性能[J]. 中国有色金属学报, 2017, 27(1): 112-117.

LIU Fen-cheng, XIONG Qi-ping, QIAN Tao, LIU Qiang, XING Li, KE Li-ming. Microstructure and properties of CNTs/Al matrix composites prepared by rotational friction extruded processing[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 112-117.

[16] LI B, SHEN Y, LUO L, HU W. Fabrication of TiCp/Ti-6Al-4V surface composite via friction stir processing (FSP): Process optimization, particle dispersion-refinement behavior and hardening mechanism[J]. Materials Science and Engineering A, 2013, 574: 75-85.

[17] LI Bo, SHEN Yi-fu, LUO Lei, HU Wei-ye. Fabrication and evaluation of Ti3Alp/Ti-6Al-4V surface layer via additive friction-stir processing[J]. Materials and Manufacturing Processes, 2014, 29(4): 412-417.

[18] 骆 蕾, 沈以赴, 李 博, 胡伟叶. 搅拌摩擦焊搭接法制备 TC4 钛合金表面 Al 涂层及其高温氧化行为[J]. 金属学报, 2013, 49(8): 996-1002.

LUO Lei, SHEN Yi-fu, LI Bo, HU Wei-ye. Preparation and oxidation behavior of aluminized coating on tc4 titanium alloy via friction stir lap welding method[J]. Acta Metallurgica Sinica, 2013, 49(8): 996-1002.

[19] CHRISTOPH L, PETERS M. Titanium and titanium alloys[M]. Weinheim: Wiley-Vch, 2003: 296.

[20] 赵永庆, 周 廉, 周义刚, 曲恒磊, 吴 欢, 杨海英. Ti40阻燃钛合金的基础研究[J]. 航空材料学报, 2006, 26(3): 233-237.

ZHAO Yong-qing, ZHOU Lian, ZHOU Yi-gang, QU Heng-lei, WU Huan, YANG Hai-ying. Research on basic theories of Ti40 burn resistant titanium alloy[J]. Journal of Aeronautical Materials, 2006, 26(3): 233-237.

[21] 黄 昆, 韩汝琦. 固体物理学[M]. 北京: 北京大学出版社, 2009: 151.

HUANG Kun, HAN Ru-qi. Solid state physics[M]. Beijing: Peking University Press, 2009: 151.

[22] ALEXANDER B. Thermochemical data for combustion calculations[M]. New York: Combustion Chemistry, Springer US, 1984: 225.

[23] MICHAEL B. Thermochemical data of elements and compounds[M]. Weinheim: Wiley-VCH, 2002: 637.

Ti-Cu flame-retardant modified layer prepared by friction stir processing on surface of TC4 Ti alloy

LI Bo1, SHEN Yi-fu2

(1. Shanghai Institute of Special Equipment Inspection and Technical Research, Shanghai 200333, China;

2. College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: The common titanium alloys are prone to spontaneous combustion under a certain service condition of high temperature. The rapid spread of titanium-fire will damage the titanium matrix component. The problem can be effectively solved by the preparation of flame-retardant modified layer on the surface of common titanium alloy. The plastic metal Cu powder was pre-implanted in the grooving prepared in the surface layer on the Ti6Al4V alloy substrate. The friction stir processing was utilized to produce the Ti-Cu alloying modified layer on the surface of Ti6Al4V substrate. The thermal reaction diffusion behavior between the thermoplastic Ti matrix and Cu powder in stir nugget zone benefits to the formation of alloying layer. Meanwhile, β-Ti phase stabilization element of Cu favored for the α-Ti/β-Ti phase proportion modification, aiming to produce more β-Ti phase after the α-Ti/β-Ti transformation during the processing. After the process optimization, the surface modification layer is formed with the β-Ti phase rich zone. The intermetallic phase of Ti2Cu and other Ti-Cu intermediate phases are formed based on the Ti/Cu reaction diffusion and solid solution and precipitation behaviors. The flame-retardant property of the common Ti6Al4V alloy with the modified layer is obtained. The flame-retardant property is evaluated by laser ablation method. Moreover, the flame-retardant mechanism is elucidated in detail. The modification of α/β phase proportion contributes to the increment of β-Ti phase proportion after the friction stir processing cooling procedure. The formation of Ti-Cu intermediate phases and Ti-Cu alloying zone in the modified layer is conducted by adding flame-retardant alloying element of Cu.

Key words: friction stir processing; titanium alloy; flame-retardant mechanism; surface modification; alloying

Foundation item: Project(16QB1403200) supported by Shanghai Rising-Star Program, China; Project(51505293) supported by the National Natural Science Foundation of China

Received date: 2016-12-21; Accepted date: 2017-05-16

Corresponding author: LI Bo; Tel: +86-21-32584934; E-mail: libo@ssei.cn

(编辑 李艳红)

基金项目:上海市青年科技启明星计划资助项目(16QB1403200);国家自然科学基金资助项目(51505293)

收稿日期:2016-12-21;修订日期:2017-05-16

通信作者:李 博,高级工程师,博士;电话:021-32584934;E-mail:libo@ssei.cn