文章编号:1004-0609(2012)08-2181-06

热处理工艺对2A97铝锂合金拉伸性能和腐蚀性能的影响

林 毅,郑子樵,韩 烨,张海锋

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:研究不同热处理工艺对2A97铝锂合金拉伸性能和腐蚀性能的影响。结果表明:合金经热处理工艺C(5%预变形+100 ℃, 1.5 h+5%中间变形+160 ℃, t)处理后,获得较好的强度与塑性的配比,在峰时效状态下,合金抗拉强度和伸长率分别为597 MPa和7.4%。同时,合金耐晶间腐蚀性能优异,平均晶间腐蚀深度为22 μm。在分步变形和双级时效的综合作用下,合金在峰时效晶内获得大量弥散细小的T1相和少量的S′相,晶界处析出相稀少,无沉淀析出带不明显,使2A97合金获得高强度的同时,改善塑性和耐晶间腐蚀性能。

关键词:2A97铝锂合金;微观组织;晶间腐蚀;双级时效

中图分类号:TG 116.3 文献标志码:A

Effects of heat treatment process on tensile and corrosion properties of 2A97 Al-Li alloy

LIN Yi, ZHENG Zi-qiao, HAN Ye, ZHANG Hai-feng

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of various heat treatment processes on tensile and corrosion properties of 2A97 Al-Li alloy were investigated. The results show that, undertaken with heat treatment process C (pre-deformation 5%+100 ℃, 1.5 h+mid-deformation 5%+160 ℃, t), the alloy obtains preferable combination of strength and ductility. At the peak-aged condition of heat treatment process C, the tensile strength and elongation of 2A97 Al-Li alloy are 597 MPa and 7.4%, respectively. Meanwhile, the intergrannular corrosion resistant is excellent, and the average intergranular corrosion depth is 22 μm. Under the comprehensive function of multi-step deformation and two-step aging, the large quantities of T1 precipitate dispersedly in grain with some S′ phase, few second phases precipitate in grain boundary, and the precipitation free zone is not obviously near grain boundary, which respond to the favorable tensile properties and corrosion properties of 2A97 Al-Li alloy at peak-aged.

Key words: 2A97 Al-Li alloy; microstructure; intergrannular corrosion; two-step aging

Al-Cu-Li系合金为时效强化型变形铝合金。合金中由于Li元素的添加,使其与传统铝合金相比具有低密度,高弹性模量和高比强度,同时拥有良好的疲劳性能和耐腐蚀性能。Al-Cu-Li系合金作为结构件被广泛应用于航天航空领域,成为减轻飞行器质量、提升飞行器有效载重和提高燃油效率的重要途径。

Al-Cu-Li系合金沉淀析出过程复杂,受合金元素的影响,合金沉淀析出相有δ′(Al3Li)、θ′(Al2Cu)、S′(Al2CuMg)和T1(Al2CuLi)等。不同的析出相具有不同的结构特点以及析出特征,从而给合金性能带来不同的影响。

球状相δ′具有L12结构,与基体共格[1-2],为合金时效初期主要强化相。在塑性变形过程中,δ′相被位错切过引起共面滑移,造成位错在晶界塞积,导致晶界应力集中,恶化合金塑性[3]。半共格盘状相θ′对合金具有一定的强化作用。由于θ′相电位比Al基体的高,在腐蚀环境下,发生以θ′相为阴极,基体为阳极的原电池反应,引起θ′相周围的基体产生点蚀[4]。半共格强化相S′被认为是S相(Al2CuMg)的一种畸变形式[5]。片状S′相在淬火形成的位错上形核,通过奥罗万机制强化合金[6]。半共格T1相具有P6/mmm的空间点阵[7],对合金的时效强化效果最大。时效过程中,T1相以消耗δ′和θ′相的方式长大。T1相的存在使δ′相层错能增加,位错从切割机制变为绕过机制[8-9],同时T1相为不可切割的第二相粒子[10],大大提高合金强度。此外,T1相为脆性相,分散共面滑移的效果不大,大量的T1相不利于合金塑性的改善[3]。

合金性能为析出相特性综合作用的结果,而析出相特性又与热处理工艺密切相关。Al-Cu-Li系合金通常进行T8处理,即合金在固溶处理后先预变形再时效的形变热处理工艺。时效前的预变形使合金中的位错增殖,位错为θ′、S′和T1相的析出提供低能形核位置[11-12]。传统T8工艺的预变形量较低,一般不超过7%。随着预变形量的增加,强化相增多带来合金强度提高的同时将导致塑性的恶化。因此,开发一种既能提高合金强度又不损害塑性并能在一定程度上改善合金其他性能如耐腐蚀性的新型形变热处理工艺对挖掘Al-Cu-Li系合金潜力,扩大其在航天航空领域的应用有着重要的意义。本文作者通过对2A97铝锂合金进行新型的形变热处理研究,以期合金获得理想的强度和塑性的配比以及良好的耐腐蚀性能,且对热处理工艺影响合金性能的相关机理进行探讨。

1 实验

将2 mm厚2A97铝锂合金板材置于520℃盐浴中进行固溶处理,保温2 h,水淬至室温。将固溶处理后的合金板进行冷轧,一部分合金板轧至1.90 mm,变形量为5%,将其中一部分置于160 ℃时效,另一部分于100 ℃时效1.5 h,随后再冷轧至1.81 mm,变形量为5%,然后将其置于160 ℃下时效;另一部分固溶处理后的合金板轧至1.81 mm,变形量为9.5%,然后置于160 ℃下时效。合金热处理工艺如表1所列。

合金室温拉伸参照标准ASTM E 8进行,试样沿板材轧制方向截取并加工成骨状,试样标距为40 mm,平行段长度宽为10 mm。室温拉伸在电液伺服万能材料试验机MTS 858下进行,拉伸速率为2 mm/min。合金晶间腐蚀按照标准ASTM G 110-92进行,以合金轧制表面为腐蚀面,腐蚀面依次经砂纸打磨、抛光、丙酮除油、去离子水清洗,非腐蚀面用环氧树脂密封,腐蚀介质采用(1 mol NaCl+10 mL 30% H2O2)/L的溶液(IGC溶液)。

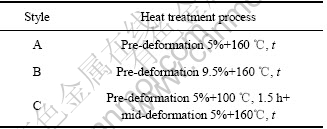

表1 2A97合金热处理工艺

Table 1 Heat treatments processes of 2A97 alloy

合金显微组织在TecnaiG2 200透射电镜上进行观察,其加速电压为200 kV。透射试样用砂纸机械减薄至100 μm,然后在MT-PI型双喷电解减薄仪上进行双喷,工作温度低于-30 ℃,工作电压为12~15 V,工作电流为70~80 mA。双喷电解液用硝酸和甲醇按体积比为1:3进行配制。

2 实验结果

2.1 力学性能

图1所示为合金经A、B、C 3种热处理工艺处理后室温拉伸性能与时效时间的关系曲线。由图1可看出,经工艺A处理,合金在160 ℃下时效30 h达峰时效(A-30),峰时效抗拉强度和伸长率分别为584 MPa,6.2%。经工艺B处理,合金在160 ℃下经16 h达峰时效(B-16),峰时效抗拉强度为592 MPa,伸长率为5.2%。在工艺C条件下,预变形5%的合金在100 ℃保温1.5 h,经5%中间变形,然后在160 ℃下经16 h达峰时效(C-16),峰时效抗拉强度为597 MPa,伸长率为7.4%。与工艺A相比,工艺B和C在一定程度上提高合金的抗拉强度,缩短合金时效响应时间,但经工艺B处理的合金塑性不高。工艺C在保持工艺B总变形量不变的条件下,对合金进行两次变形,使合金在时效后强度进一步提高的同时保持了较好的塑性。表2所列为合金不同峰时效下的室温拉伸性能。

图1 不同热处理工艺下2A97合金拉伸性能与时效时间的关系

Fig. 1 Relationship between tensile properties and aging time of 2A97 alloy at different heat treatment processes

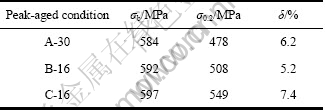

表2 不同峰时效下2A97合金拉伸性能

Table 2 Tensile properties of 2A97 alloy at different peak-aged conditions

2.2 腐蚀性能

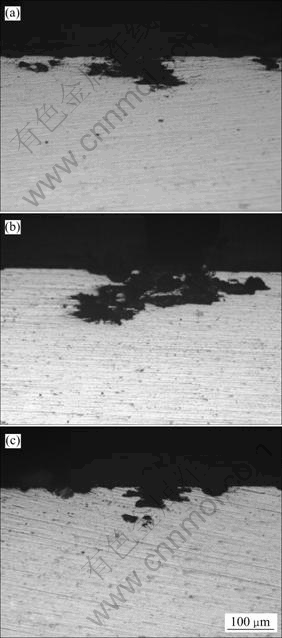

图2所示为合金经3种工艺处理在(A-30)、(B-16)和(C-16)3种峰时效下的晶间腐蚀形貌。3种状态下合金的晶间腐蚀形貌具有相似特点,腐蚀面上都产生了深浅不一的腐蚀坑,但晶间腐蚀不明显。晶间腐蚀深度如表3所列,C-16时,合金平均晶间腐蚀深度和最大腐蚀深度最小,分别为22和95 μm。B-16时,合金平均晶间腐蚀深度和最大腐蚀深度最大,分别为35和106 μm。与工艺A和B相比,工艺C明显提高合金晶间腐蚀抗力,改善合金耐腐蚀性能。

2.3 微观组织观察

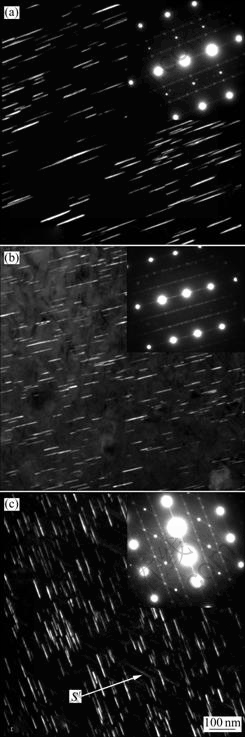

图3所示为2A97合金在不同峰时效下 方向暗场TEM像及选区电子衍射(SAED)花样。由图3可知,合金分别经3种工艺处理后,在峰时效下,主要析出相都为T1相。合金经5%预变形后在160 ℃下进行单级人工时效,峰时效(A-30)下合金析出稀疏粗大的T1相。随着预变形量提高到9.5%,合金进行160 ℃单级时效,峰时效(B-16)下析出的T1相更细小弥散。合金经5%预变形和100 ℃、1.5 h时效后进行5%中间变形,然后在160 ℃下时效,峰时效(C-16)下合金较时效态(B-16)的具有更弥散、体积分数更大的T1相,同时合金中还析出少量的S′相。因此可知,预变形促进T1相的析出以及改变了T1相的析出特征,随着变形量的提高,T1相的析出量增大,分布更弥散,并伴随少量的S′相析出。

方向暗场TEM像及选区电子衍射(SAED)花样。由图3可知,合金分别经3种工艺处理后,在峰时效下,主要析出相都为T1相。合金经5%预变形后在160 ℃下进行单级人工时效,峰时效(A-30)下合金析出稀疏粗大的T1相。随着预变形量提高到9.5%,合金进行160 ℃单级时效,峰时效(B-16)下析出的T1相更细小弥散。合金经5%预变形和100 ℃、1.5 h时效后进行5%中间变形,然后在160 ℃下时效,峰时效(C-16)下合金较时效态(B-16)的具有更弥散、体积分数更大的T1相,同时合金中还析出少量的S′相。因此可知,预变形促进T1相的析出以及改变了T1相的析出特征,随着变形量的提高,T1相的析出量增大,分布更弥散,并伴随少量的S′相析出。

图2 2A97合金不同峰时效下晶间腐蚀形貌

Fig. 2 Intergranular corrosion morphologies of 2A97 alloy at different peak-aged conditions: (a) A-30; (b) B-16; (c) C-16

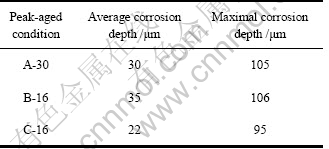

表3 2A97合金不同峰时效下晶间腐蚀深度

Table 3 Intergranular corrosion depth of 2A97 alloy at different peak-aged conditions

图3 2A97合金不同峰时效下 T1相的TEM像及衍射斑点

T1相的TEM像及衍射斑点

Fig. 3 TEM images of T1 phase and corresponding SAD patterns of 2A97 alloy at different peak-aged conditions from  : (a) A-30; (b) B-16; (c) C-16

: (a) A-30; (b) B-16; (c) C-16

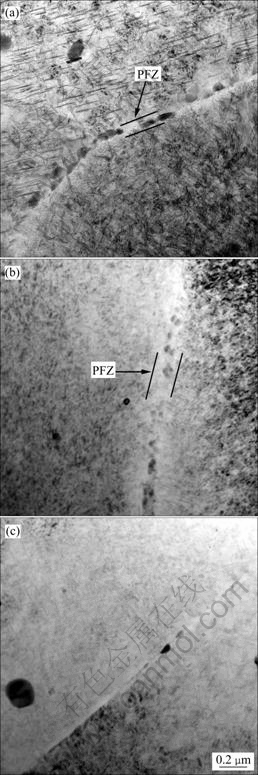

图4所示为2A97合金在不同峰时效下的晶界微观组织。由图4可知,在3种峰时效下,晶界上都析出第二相,且在晶界附近形成无沉淀析出区(PFZ),但3种峰时效下,合金晶界微观组织又各具特点。合金在峰时效(B-16)下无沉淀析出区最宽,而峰时效(C-16)下的最不明显,3种峰时效下无沉淀析出区宽度由大到小顺序为(B-16)、(A-30)、(C-16)。在峰时效(A-30)和(B-16)下,晶界析出相粗大连续。在峰时效(C-16)下,晶界较为干净,晶界析出相细小、稀少。

图4 2A97合金不同峰时效下晶界微观组织

Fig. 4 Microstructures around grain boundaries of 2A97 alloy at different peak-aged conditions: (a) A-30; (b) B-16; (c) C-16

3 分析与讨论

3.1 热处理工艺对合金力学性能的影响

随着预变形量的增大,基体中析出的T1相变得更细小、体积分数更大。这是由于预变形量的增加,使基体中的位错密度增大,为T1相的沉淀析出提供良好的形核位置[11]。大量细小弥散的T1相提高了合金的强度,合金抗拉强度由峰时效(A-30)的584 MPa增加到峰时效(C-16)的597 MPa。位错密度的增加提高了T1相非均匀形核率,加快了合金时效响应速率,峰时效时间缩短了14 h。工艺C将较大的变形量通过预变形和中间变形分两次施加给合金,两次变形之间穿插一个低温预时效,保证了合金变形均匀,位错在基体中的分布更均匀,合金在160 ℃下形成更弥散细小量大的T1相,获得最大强度。

经工艺C处理的合金在峰时效析出一定量的S′相,由于S′相为宽松堆垛结构,该结构中没有与基体平行的可用作滑移面的均匀紧密堆垛的原子面,位错很难以切过的方式通过。S′相的存在阻碍了位错运动,抑制共面滑移,促进合金的均匀变形[3, 13-14]。因此,与工艺A和B相比,工艺C改善合金塑性一定程度上源于析出的S′相对滑移的分散作用。

分别经3种工艺处理,峰时效下合金无沉淀析出区宽度由大到小顺序为(B-16)、(A-30)、(C-16)。与沉淀相强化的晶内相比,无沉淀析出区较软,流变应力低,塑性变形易在该区域发生[15-16]。拉伸实验中,合金在轴向拉应力作用下发生塑性变形,变形优先在无沉淀析出区发生将引起该区域应力集中。在无沉淀析出区局部应力作用下,晶界微裂纹和微孔将沿无沉淀析出区扩展和粗化,降低晶界结合力,导致合金韧性恶化,引发材料低能沿晶断裂[3, 17]。

研究表明[16]沿晶断裂受晶内和晶界应变、无沉淀析出区,界面能和晶界析出相影响,晶界断裂应变εf可用以下数学模型表示:

(1)

(1)

式中:q为无沉淀析出区与晶内应变比;k为Edelsion实验估算的常数;k′为晶界析出相与晶界界面能和晶界析出相与基体界面能之比;W为无沉淀析出区宽度;D为晶界析出相尺寸;N晶界单位面积析出相数量。

由式(1)可知,无沉淀析出区越宽,晶界应变就越高。随着晶界应变的增加,晶界应力集中程度提高。晶界,特别是三角晶界处的高应力将诱发该区域微孔的萌生和扩展,最终导致裂纹沿晶界扩展。经工艺C处理的合金由于窄小的无沉淀析出区而降低了晶界应力集中程度,延缓了合金因晶界分裂而失效。因此,经工艺C处理的合金塑性最好,工艺A处理的次之,工艺B处理的最差。

3.2 热处理工艺对合金腐蚀性能的影响

合金中的第二相与周围基体化学成分的差异使彼此间电位不一致,电位高低不同的临近区域构成原电池,在腐蚀介质中发生阳极溶解,导致合金产生局部腐蚀。2A97合金晶间腐蚀形貌与其时效析出相密切相关。2A97合金峰时效下沉淀析出相有T1、θ′和S′。T1、θ′和S′相以及无沉淀析出区的电位大小关系可以表示为φθ′>φPFZ>φS′>φT1[18-19]。在腐蚀环境中,晶界形成的无沉淀析出区电位比晶界析出相θ′的低,导致无沉淀析出区发生阳极溶解,引起晶间腐蚀。当合金在晶内析出电位更负的T1相时,晶内的T1相优先发生腐蚀,降低了晶间阳极溶解动力[20]。合金分别经3种热处理工艺处理,峰时效下,晶内都析出了合金T1相。在腐蚀溶液中,T1相充当阳极,其周围的基体充当阴极,形成原电池,发生T1相的阳极溶解。T1相的析出降低晶界与晶内的电位差,晶内和晶界发生均匀腐蚀,合金获得如图2所示的腐蚀形貌。与另外两种峰时效(A-30)、(B-16)的合金相比,峰时效(C-16)合金中形成大量的弥散分布的T1相并伴随有少量较低电位的S′相[19],此外,晶界析出相不连续且稀少,有效切断了晶界连续腐蚀通路,因此,经工艺C处理的合金在峰时效(C-16)下获得最好的耐晶间腐蚀性能。

4 结论

1) 2A97铝锂合金分别经热处理工艺A、B、C处理,峰时效下合金抗拉强度分别为584、592和597 MPa,伸长率分别为6.2%、5.2%和7.4%。

2) 热处理工艺C通过分步变形与双级时效的结合,使合金获得较大变形量的情况下保证了变形均匀,促进合金在时效过程中析出大量、弥散、细小的T1相从而获得较高的强度。

3) 时效过程中形成一定量的S′相和窄小的无沉淀析出区有助于分散滑移和减轻晶界应力集中程度,抑制合金在塑性变形过程中产生共面滑移,改善合金塑性。

4) 大量弥散分布的T1相以及稀少不连续分布的晶界析出相使合金的耐腐蚀抗力得到提高。与热处理工艺A、B相比,热处理工艺C有效地提高合金强度和塑性,改善了合金的耐腐蚀性。

REFERENCES

[1] GAYLE F W, HEUBAUM F H, PICKENS J R. Structure and properties during aging of an ultra-high strength Al-Cu-Li-Ag-Mg alloy[J]. Scripta Metallurgica, 1990, 24(1): 79-84.

[2] 魏修宇, 郑子樵, 潘峥嵘, 陈圆圆, 李世晨, 陈秋妮. 预变形对2197铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

WEI Xiu-yu, ZHENG Zi-qiao, PAN Zheng-rong, CHEN Yuan-yuan, LI Shi-chen, CHEN Qiu-ni. Effect of predeformation on the microstructure and mechanical properties of 2197 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1996-1999.

[3] GREGSON P J, FLOWER H M. Microstructural control of toughness in aluminium-lithium alloys[J]. Acta Metallurgica, 1985, 33(3): 527-537.

[4] LI J F, ZHENG Z Q, JIANG N,TAN C Y. Localized corrosion mechanism of 2××× series Al alloy containing S(Al2CuMg) and θ′(Al2Cu) precipitates in 4.0% NaCl solution at pH 6.1[J]. Materials Chemistry and Physics, 2005, 91(2/3): 325-329.

[5] SILCOCK J. The structural ageing characteristics of Al-Cu-Mg alloys with copper: Magnesium weight ratios of 7:1 and 2.2:1[J]. J Inst Met, 1960, 89: 203-210.

[6] KIM H J, NIINOMI M. The role of microstructures on the strengthening mechanisms of a thermomechanically processed 2091 Al-Li alloy[J]. Materials Science and Engineering A, 2000, 284(1/2): 14-24.

[7] HUANG J, ARDELL A. Crystal structure and stability of T1 precipitates in aged Al-Li-Cu alloys[J]. Materials Science and Technology, 1987, 3(3): 176-188.

[8] HUANG J C, ARDELL A J. Addition rules and the contribution of δ′ precipitates to strengthening of aged Al-Li-Cu alloys[J]. Acta Metallurgica, 1988, 36(11): 2995-3006.

[9] 黄兰萍, 郑子樵, 黄永平. 2197 铝-锂合金的组织和性能[J]. 中国有色金属学报, 2004, 14(12): 2066-2072.

HUANG Lan-ping, ZHENG Zi-qiao, HUANG Yong-ping. Microstructure and properties of 2197 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2066-2072.

[10] TOSTEN M, VASUDEVAN A, HOWELL P. The aging characteristics of an Al-2 Pct Li-3 Pct Cu-0.12 Pct Zr alloy at 190 ℃[J]. Metallurgical and Materials Transactions A, 1988, 19(1): 51-66.

[11] CASSADA W, SHIFLET G, STARKE E. Mechanism of Al2CuLi (T1) nucleation and growth[J]. Metallurgical and Materials Transactions A, 1991, 22(2): 287-297.

[12] RINGER S, MUDDLE B,POLMEAR I. Effects of cold work on precipitation in Al-Cu-Mg-(Ag) and Al-Cu-Li-(Mg-Ag) alloys[J]. Metallurgical and Materials Transactions A, 1995, 26(7): 1659-1671.

[13] LUO A, YOUDELIS W. Microstructure and mechanical behavior of Al-Li-Cu-Mg alloy 8090 microalloyed with V and Be[J]. Metallurgical and Materials Transactions A, 1993, 24(1): 95-104.

[14] GHOSH K, DAS K, CHATTERJEE U. Characterization of retrogression and reaging behavior of 8090 Al-Li-Cu-Mg-Zr alloy[J]. Metallurgical and Materials Transactions A, 2004, 35(12): 3681-3691.

[15] LIN F, CHAKRABORTTY S, STARKE E. Microstructure- property relationships of two AI-3Li-2Cu-0.2Zr-XCd alloys[J]. Metallurgical and Materials Transactions A, 1982, 13(3): 401-410.

[16] KAWABATA T, IZUMI O. Ductile fracture in the interior of precipitate free zone in an Al-6.0%Zn-2.6%Mg alloy[J]. Acta Metallurgica, 1976, 24(9): 817-825.

[17] LAVERNIA E J, SRIVATSAN T S, MOHAMED F A. Strength, deformation, fracture behaviour and ductility of aluminium- lithium alloys[J]. Journal of Materials Science, 1990, 25(2): 1137-1158.

[18] BIRBILIS N, BUCHHEIT R G. Electrochemical characteristics of intermetallic phases in aluminum alloys[J]. Journal of the Electrochemical Society, 2005, 152(4): B140-B151.

[19] BUCHHEIT R G. A compilation of corrosion potentials reported for intermetallic phases in aluminum alloys[J]. Journal of the Electrochemical Society, 1995, 142(11): 3994-3996.

[20] 李劲风, 张 昭, 朝发和, 程英亮. 峰时效AA2090及AA8090铝-锂合金晶间腐蚀与剥蚀性能[J]. 中国腐蚀与防护学报, 2004, 24(3): 135-138.

LI Jin-feng, ZHANG Zhao, CHAO Fa-he, CHENG Ying-liang. Intergranular corrosion and exfoliation corrosion properties of peak-aged AA2090 and AA8090 Al-Li alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2004, 24(3): 135-138.

(编辑 李艳红)

收稿日期:2011-08-01;修订日期:2011-09-18

通信作者:郑子樵,教授,博士;电话:0731-88830270;E-mail: s-maloy@csu.edu.cn