DOI:10.19476/j.ysxb.1004.0609.2018.03.08

热塑性变形对Mg-Zn-Zr-Ce合金组织与性能的影响

雷少帆1,文九巴1, 2,贺俊光1, 2,刘 亚1

(1. 河南科技大学 材料科学与工程学院,洛阳 471023;

2. 有色金属共性技术河南省协同创新中心,洛阳 471023)

摘 要:利用光学显微镜、扫描电子显微镜、透射电子显微镜、失重测试、电化学测试与拉伸试验研究热挤压与退火温度对Mg-Zn-Zr-Ce生物镁合金组织与性能的影响。结果表明:热塑性变形后合金发生动态再结晶,合金的组织由细小的再结晶晶粒与未再结晶的晶粒组成;退火后变形晶粒发生再结晶,随着退火温度的升高,晶粒逐渐长大。当退火温度高于200 ℃时,合金的腐蚀电流密度(Jcorr)与平均晶粒尺寸(d)满足Jcorr=a+bd-1/2方程。由该方程可推测出经200 ℃退火3 h后,合金的腐蚀电流密度最低,合金的综合性能最好,抗拉强度与伸长率分别达到245.8 MPa和16.2%,腐蚀速率为0.7235 mm/a。

关键词:生物镁合金;细晶强化;耐蚀性;力学性能

文章编号:1004-0609(2018)-03-0502-07 中图分类号:TG146.2 文献标志码:A

由于高的比强度、优异的生物相容性与可降解的特性,镁合金作为可降解生物材料受到了广泛的关注。镁合金用作生物材料不仅可以有效避免应力遮挡效应,还能避免二次手术取出,这使得镁合金成为21世纪最有应用前景的生物材料之一[1-4]。然而镁合金差的耐蚀性是其临床应用的最大障碍,因此提高镁合金耐蚀性的研究成为了镁合金研究的重要方向[5-6]。镁合金在热加工过程中容易发生动态再结晶,从而细化晶粒,细化晶粒可提高镁合金的强度,同时也会改变其耐蚀性[7-9]。目前,有关镁合金耐蚀性的研究取得较大的进展,然而热加工对镁合金耐蚀性的影响仍需更多的研究。GOLLAPUDI[10]研究晶粒尺寸对镁合金腐蚀电流的影响,指出腐蚀电流Jcorr与晶粒尺寸d满足以下关系:Jcorr=a+bd-1/2(其中a、b均为常数,在可钝化的环境中,b取负值)。并将在可钝化环境中细化晶粒降低镁合金腐蚀电流现象的原因归咎于镁合金表面形成一层稳定、致密的MgO膜。然而,SONG等[11]研究EPCA对纯镁耐蚀性的影响,结果表明由于热加工过程中引入了高密度的位错,纯镁的耐蚀性降低。CHOI等[12]研究了超细晶ZK60合金的腐蚀行为,热加工后ZK60合金的组织中存在粗晶区与细晶区,热加工后合金的耐蚀性并非是最优的,随后的退火处理降低了位错密度,消除了内应力,进一步提高了合金的耐蚀性。因此,细化晶粒可降低镁合金的腐蚀电流,而热加工过程中引入的高密度位错会降低镁合金的耐蚀性。Mg-Zn-Zr系合金属于典型的变形镁合金,本研究在考虑到稀土Ce对生理与健康的影响后,添加了适量的稀土Ce以提高镁合金的耐蚀性与强度,通过热塑性变形工艺对进一步提高Mg-Zn-Zr-Ce合金的耐蚀性,研究了热塑性变形及随后的退火处理对Mg-Zn-Zr-Ce合金组织与性能的影响,并讨论了位错密度与晶粒尺寸对镁合金耐蚀性的影响。

1 材料与方法

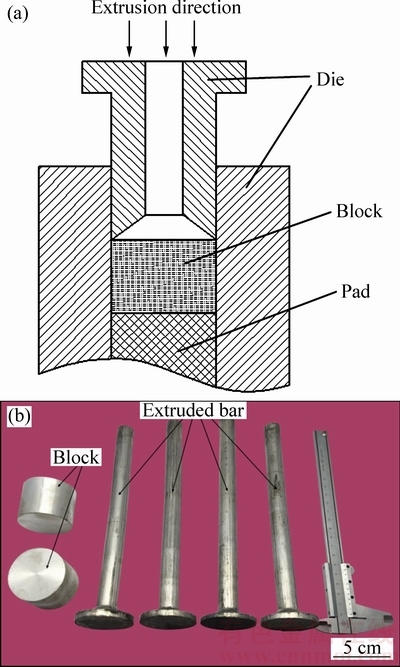

以纯镁、纯锌、Mg-25%Zr和Mg-20%Ce中间合金为原材料,配制出成分为Mg-2Zn-0.4Zr-0.6Ce(质量分数,%)的镁合金,在感应熔炼炉内熔炼,以SF6+CO2混合气体为保护气氛,加热至720 ℃,保温静置5 min后,在预热的金属模具中浇铸成型。将铸锭加工成d 50 mm×35 mm的圆柱用于热挤压,热挤压示意图与挤压后棒分别如图1(a)和(b)所示。工装温度为490 ℃,总变形量约为87%,挤压速度为5 mm/s。随后将挤压棒在电阻炉中分别在150、200、250、300 ℃退火3 h。

图1 挤压示意图以及挤压坯料与挤压棒

Fig. 1 Schematic illustration of extrusion (a) and blocks and extruded bars (b)

利用光学金相显微镜与透射电子显微镜分析合金的组织。质量损失测试的腐蚀介质选用模拟体液(SBF)。模拟体液的组成如下:8.0 g/L NaCl,0.14 g/L CaCl2,0.4 g/L KCl,0.35 g/L NaHCO3,0.1 g/L MgCl2·6H2O,1.0 g/L Glucose,0.06 g/L MgSO4·7H2O,0.06 g/L Na2HPO4,0.06 g/L KH2PO4。模拟体液与试样表面积比取35 mL/cm2。在质量损失测试过程中,模拟体液温度用水浴锅维持在37 ℃,每24 h更换一次模拟体液。试样浸泡5 d后,用铬酸清除腐蚀产物。将清洗干净的试样吹干并称取质量,通过公式v=87.6m·(S·t·ρ)-1算出合金的平均腐蚀速率。其中,m为试样的质量损失,以mg为单位;S为试样的表面积,以cm2为单位;t为浸泡时间,以h为单位;ρ为镁合金的密度,取1.74 g/cm3。电化学试样尺寸为d11.3 mm×8 mm,沿挤压方向线切割,不同状态合金分别在NOVA Autolab上测试交流阻抗谱与极化曲线。电化学测试采用三电极系统,即参比电极为甘汞电极(SCE),辅助电极为石墨电极,试样为工作电极。

2 实验结果

2.1 组织分析

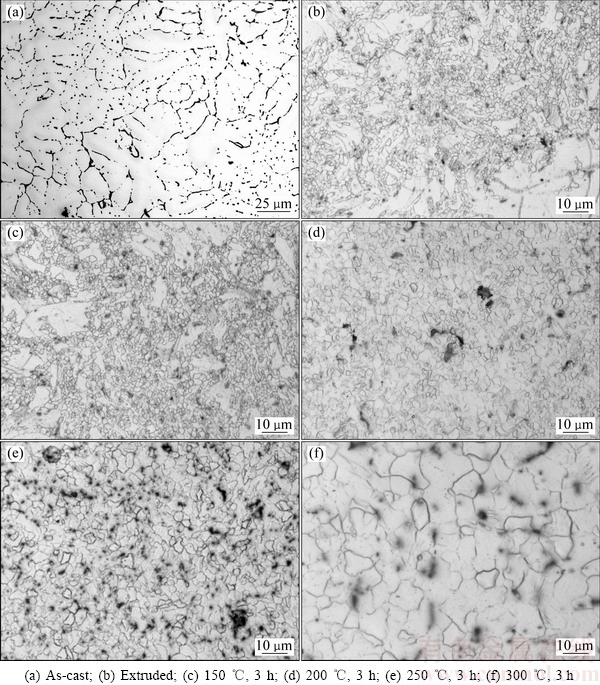

图2所示为不同状态Mg-Zn-Zr-Ce合金的显微组织。图2(a)和(b)分别为铸态、热挤压后合金的显微组织,由于热变形过程中合金发生动态再结晶,热挤压后合金的组织由细小的再结晶晶粒与变形晶粒组成,与铸态合金比较,热挤压后合金的组织明显细化。图2(c)~(d)所示为在不同温度下退火后合金的组织,由图2可看出,由于变形晶粒储存较大的应变能,在退火过程中变形晶粒发生了再结晶,变形晶粒逐渐消失。根据ASTM E112-12标准,可测得不同温度退火后合金晶粒的平均直径分别约为3.4、2.8、4.6、8.7 μm。当退火温度较低(150 ℃)时,合金组织中仍有部分未发生再结晶的粗晶区;当退火温度较高(≥200 ℃)时,合金组织由细小的等轴晶组成,变形晶粒消失,且随着退火温度的升高,晶粒逐渐长大。

图3所示为铸态、热挤压后合金Mg-Zn-Zr-Ce的TEM明场像。图3(a)所示为铸态合金的TEM像,图3(b)和(c)所示热挤压后合金不同区域的TEM像。比较3(a)和(b)可看出,合金经热挤压后组织中出现高密度的位错团。同时,由图3(c)可看到一个细小的等轴晶,在细小的等轴晶旁边有高密度的位错区与低密度的位错区,细小等轴晶旁边黑色的区域为高密度位错变形晶粒区,白色的区域可能为再结晶晶粒。DU等[13]在有关挤压态Mg-5.3Zn-0.2Ca-0.5Ce合金的强化机制的研究中指出,细晶区的位错密度较低,粗大的变形晶粒中位错密度较高,该区域位错密度高达2×1014 m-2。本实验结果与DU等[13]的研究一致。

2.2 耐蚀性

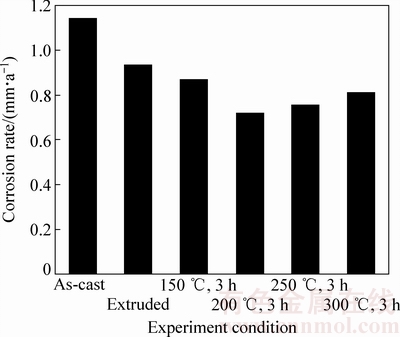

图4所示为不同状态合金Mg-Zn-Zr-Ce的平均腐蚀速率。铸态、热挤压后合金的腐蚀速率分别为1.142、0.9337 mm/a,由于发生动态再结晶,热挤压后合金的耐蚀性优于铸态合金。低温退火降低了合金的位错密度,消除了内应力的不利影响[14-16],因此低温退火(150 ℃)后合金的腐蚀速率得到一定程度的降低。由图2(c)~(f)可看出退火温度≤200 ℃时,未再结晶晶粒发生再结晶,而当退火温度>200 ℃时,合金中细小的再结晶晶粒开始长大。当退火温度(>200 ℃)升高时,合金的腐蚀速率逐渐升高,在200 ℃退火3 h后,合金的腐蚀速率最小,腐蚀速率约为0.7235 mm/a。这是由于再结晶与晶粒长大的缘故[10, 17]。

图2 测试合金的光学显微组织

Fig. 2 Optical images of tested alloys

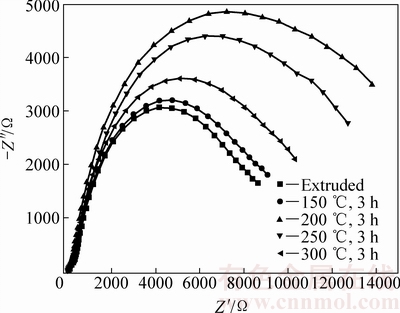

2.3 电化学性能

图5所示为热挤压后、退火后Mg-Zn-Zr-Ce合金在SBF中的交流阻抗谱。由图5可以看出,不同状态合金的交流阻抗谱形状相似,仅仅容抗弧半径不同,表明不同状态的合金在SBF中的腐蚀机制相同,耐蚀性不同。交流阻抗谱中高频容抗弧的半径可表示合金的腐蚀过程中的电荷转移阻力,容抗弧半径越大,合金的耐蚀性越好[18-22]。可以看出,热挤压合金态经退火处理后容抗弧半径增大,且随着退火温度的升高,合金的容抗弧半径先增大后减小,其中在200 ℃退火后的合金的容抗弧半径最大,合金表现出较好的耐蚀性。

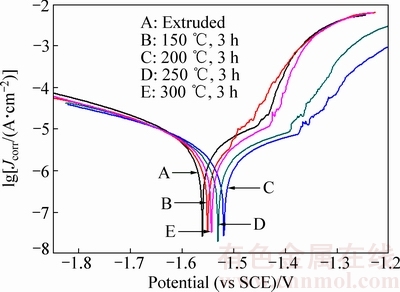

对镁合金而言,阴极极化表示析氢反应,阳极极化表示镁基体的溶解。图6所示为热挤压后、退火后Mg-Zn-Zr-Ce合金在SBF中的极化曲线。由图6可以看出,不同状态的合金在阳极极化区均存在一个平台,这表明镁合金在SBF中发生了钝化现象[6, 10]。镁合金发生钝化主要与其表面具有保护作用的MgO膜有关。腐蚀电位φcorr与腐蚀电流密度Jcorr如表1所列,其中腐蚀电流密度由塔菲尔外推法得到。事实上,腐蚀电流密度能较为准确地反映合金的腐蚀速率,根据Faraday定律可知,腐蚀电流密度越大,合金的腐蚀速率越大,合金的耐蚀性越差。由表1可看出,挤压态合金退火后腐蚀电位φcorr正移,腐蚀电流密度Jcorr降低;随着退火温度的升高,腐蚀电位φcorr先正移后负移,腐蚀电流密度Jcorr先降低后升高,在200 ℃退火后的合金的腐蚀电位φcorr最正,腐蚀电流密度Jcorr最小,合金表现出较好的耐蚀性,这与质量损失测试结果一致。

图3 铸态、挤压态合金的TEM像

Fig. 3 TEM images of as-cast and extruded alloys

图4 测试合金的腐蚀速率

Fig. 4 Corrosion rate of tested alloys

图5 挤压态、退火态合金的交流阻抗谱

Fig. 5 Lyquist plots of extruded and annealed alloys

图6 挤压态、退火态合金的极化曲线

Fig. 6 Potentiodynamic polarization curves of extruded and annealed alloys

表1 动电位极化曲线拟合结果

Table 1 Fitted result of potentiodynamic polarization curves

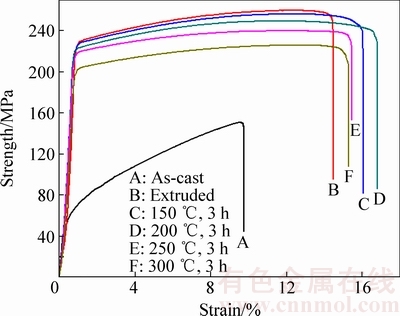

2.4 力学性能

不同状态Mg-Zn-Zr-Ce合金的拉伸曲线如图7所示。由图7可看出,挤压态合金的力学性能与铸态合金相比得到了明显的提高,热挤压后合金的强度与伸长率分别约为259.1 MPa、14.1%。随后的退火处理进一步提高了合金的伸长率,随着退火温度的升高,合金的强度逐渐降低,伸长率先升高后降低,在200 ℃退火后合金的综合力学性能较优,强度约为245.8 MPa,伸长率约为16.2%。挤压态、退火态合金的力学性能主要由两个因素影响:位错密度与晶粒尺寸;热塑性变形主要引入细晶强化与位错强化,两者均可提高材料的强度,但后者会阻碍位错的滑移,降低材料的塑性[23-24]。由组织分析可知,挤压态合金的组织由细小等轴晶与高密度的变形晶粒组成,因此挤压态合金展现出较高的强度与较低的伸长率。随后的退火处理一方面降低了位错密度,另一方面会引起晶粒的长大,所以合金的强度逐渐降低,伸长率先升高后降低。

图7 测试合金的拉伸曲线

Fig. 7 Tensile cueves of tested alloys

3 分析与讨论

腐蚀与金属和电解质之间的界面有着直接的联系。ASCENCIO等[25]指出镁合金与m-SBF之间组成的界面主要可以分为两层。外层为多孔的Mg(OH)2层,可阻止电解质接触镁基体,对内部镁基体表现出部分保护作用;内层为MgO膜,可对内部镁基体起较好的保护作用,也是镁合金钝化的主要原因。但MgO属于立方晶体结构,内部镁基体属于密排六方晶体结构,这种晶体结构的差异会导致镁合金表面形成的MgO膜不稳定,容易破裂。很多的研究均指出,热挤压、热轧等工艺可细化镁合金的晶粒,进而提高镁合金在可钝化环境中的耐蚀性,并将这种耐蚀性的提高归咎于表面形成稳定、致密的MgO膜[11-15]。当引入大量细小的晶粒,MgO与内部镁基体之间晶体结构的差异就会降低,镁合金表面形成的MgO膜就会趋于稳定、致密,进而镁合金的耐蚀性得到提高[12, 26]。

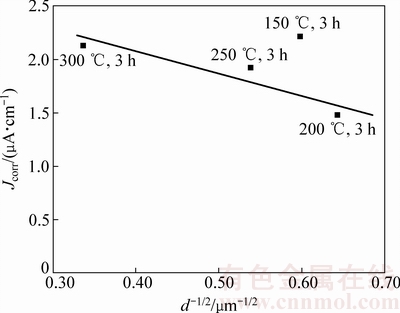

由图6中的极化曲线可知,镁合金在SBF中发生了明显的钝化现象,因此腐蚀电流密度Jcorr与平均晶粒尺寸d之间应满足Jcorr=a+bd-1/2方程。图8所示为不同退火温度下合金的腐蚀电流密度与平均晶粒尺寸的平方根d-1/2之间的关系。由图8可以看出,在200、250、300 ℃下退火的镁合金腐蚀电流密度Jcorr与平均晶粒尺寸的平方根d-1/2基本上呈线性关系,即Jcorr=a+bd-1/2,且斜率为负值。这表明这些合金的腐蚀电流密度仅仅受晶粒尺寸影响,细化晶粒可降低镁合金的腐蚀电流密度。而在150 ℃下退火的镁合金的腐蚀电流密度偏离了线性关系,高于线性关系预测的腐蚀电流密度,这说明在150 ℃下退火的镁合金腐蚀电流密度还受另一因素影响。一般而言,铸态合金的位错密度约为1×10-7~1×10-8 m-2,DU等[13]研究表明未发生动态再结晶的粗晶区的位错密度达到1×1014 m-2,远高于铸态合金的位错密度,因此,当退火温度过低时,镁合金中仍存在较高密度的位错,较高密度的位错正是造成150 ℃退火后镁合金腐蚀电流密度高于预测值的原因。在200 ℃退火后的合金晶粒尺寸最小,表面形成的MgO膜更稳定、更致密,因此表现出最优的耐蚀性;而随后升高退火温度引起晶粒的长大,致使MgO膜的稳定性与致密性降低,所以合金的腐蚀电流密度升高。

由图8所示的关系可得出以下结论:细化晶粒可以提高镁合金的耐蚀性,然而热加工过程中引入的高密度位错对镁合金的耐蚀性不利,随后的退火处理可进一步提高镁合金的耐蚀性,通过线性关系可推测出在200 ℃退火3 h后合金表现出最佳的耐蚀性。

图8 Jcorr与平均晶粒尺寸平方根(d-1/2)之间的关系

Fig. 8 Relationship between Jcorr and reciprocal square root of average grain size (d-1/2)

4 结论

1) 热挤压后合金Mg-Zn-Zr-Ce发生动态再结晶,合金的晶粒细化,组织由细小的等轴晶与变形晶粒组成,与铸态合金相比,热挤压后力学性能与耐蚀性均得到提高,合金的强度与伸长率分别为259.1 MPa、14.1%,合金的腐蚀速率为0.9337 mm/a。

2) 退火处理后,挤压态Mg-Zn-Zr-Ce合金的伸长率与耐蚀性得到进一步提高。随着退火温度的升高,合金的强度逐渐下降,合金的伸长率先上升后下降,合金的腐蚀速率先减小后上升。

3) 由Jcorr=a+bd-1/2方程可知,挤压态的合金在200 ℃退火3 h后腐蚀腐蚀电流密度最小,合金表现出较好的综合力学性能,合金的伸长率与强度分别为16.2% and 245.8 MPa,合金的腐蚀速率为0.7235 mm/a。

REFERENCES

[1] 巫瑞智, 张景怀, 尹东松. 先进镁合金制备与加工技术[M]. 北京: 科学出版社, 2012.

WU R Z, ZHANG J H, YI D S. Advanced magnesium alloy preparation and processing technology[M]. Beijing: Science Press, 2012.

[2] 石 凯, 王日初, 彭超群, 解立川, 金和喜, 冯 艳, 陈雅谨. 退火温度对镁合金阳极板材组织和性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1642-1649.

SHI K, WANG R C, PENG C Q, XIE L C, JIN H X, FENG Y, CHEN Y J. Effect of annealing temperatures on microstructure and properties of magnesium alloy anode sheet[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1642-1649.

[3] 袁广银, 章晓波, 牛佳林, 陶海荣, 陈道运, 何耀华, 蒋 垚, 丁文江. 新型可降解生物医用镁合金JDBM的研究进展[J]. 中国有色金属学报, 2011, 21(10): 2476-2488.

YUAN G Y, ZHANG X B, NIU J L, TAO H R, CHEN D Y, HE Y H, JIANG Y, DING W J. Research progress of new type of degradable biomedical magnesium alloys JDBM[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2476-2488.

[4] WANG Y P, HE Y H, ZHU Z J, JIANG Y, ZHANG J, NIU J L, MAO L, YUAN G Y. In vitro degradation and biocompatibility of Mg-Nd-Zn-Zr alloy[J]. Materials Science, 2012, 157(17): 2163-2170.

[5] STAIGER M P, PIETAK A M, HUADMAI J, DIAS G. Magnesium and its alloys as orthopedic biomaterials: A review[J]. Biomaterials, 2006, 27(9):1728-1734.

[6] 袁广银, 张 佳, 丁文江. 可降解医用镁基生物材料的研究进展[J]. 中国材料进展, 2011, 30(2): 44-50.

YUAN G Y, ZHANG J, DING W J. Research progress of Mg-based alloy as degradable biomedical materials[J]. Material China, 2011, 30(2): 44-50.

[7] 章晓波, 王章忠, 袁广银. 二次挤压对Mg-Nd-Zn-Zr生物镁合金组织与性能的影响[J]. 材料热处理学报, 2013, 34(2): 103-107.

ZHANG X B, WANG Z Z, YUAN G Y. Effects of double extrusion on microstructure and properties of Mg-Nd-Zn-Zr bio-magnesium alloy[J]. Transactions of Materials and Treatment, 2013, 34(2): 103-107.

[8] LI X, JIANG J H, ZHAO Y H, MA A B, WEN D J, ZHU Y T. Effect of equal-channel angular pressing and aging on corrosion behavior of ZK60 Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 3909-3920.

[9] LI Ji-bao, WANG Feng, MAO Ping-li. Evolution of microstructure and tensile properties of extruded Mg-4Zn-1Y alloy[J]. Journal of Rare Earths, 2014, 32(12): 1189-1195.

[10] GOLLAPUDI S. Grain size distribution effects on the corrosion behaviour of materials[J]. Corrosion Science, 2012, 62(1): 90-94.

[11] SONG D, MA A B, JIANG J H. Corrosion behavior of equal-channel-angular-pressed pure magnesium in NaCl aqueous solution[J]. Corrosion Science, 2010, 52(2): 481-490.

[12] CHOI H Y, KIM W J. Effect of thermal treatment on the bio-corrosion and mechanical properties of ultrafine-grained ZK60 magnesium alloy[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 51(11): 291-301.

[13] DU Y Z, QIAO X G, ZHENG M Y, WU K, XU S W. The microstructure, texture and mechanical properties of extruded Mg-5.3Zn-0.2Ca-0.5Ce (wt%)alloy[J]. Materials Science and Engineering A, 2015, 620: 164-171.

[14] LIAO H J, ZHOU X F, LI H Z, DENG M, LIANG X P, LIU R M. Effect of aging time on corrosion behavior of as-forged AZ80 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 3921-3927.

[15] LI X, JIANG J H, ZHAO Y H, WEN D J. Effect of equal-channel angular pressing and aging on corrosion behavior of ZK60 Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 3909-3920.

[16] KIM H S, KIM W J. Enhanced corrosion resistance of ultrafine-grained AZ61 alloy containing very fine particles of Mg17Al12 phase[J]. Corrosion Science, 2013, 75(11): 228-238.

[17] SHI F, WANG C Q, ZHANG Z M. Microstructure, corrosion and mechanical properties of as-cast Mg-Zn-Y-(Gd) alloys[J]. Transactions of Nonferrous Metals Society of China, 2015, 25 (7): 2172-2180.

[18] SONG Y W, HAN E H, SHAN D Y, YIM C D. The role of second phases in the corrosion behavior of Mg-5Zn alloy[J]. Corrosion Science, 2012, 60(7): 238-245.

[19] LU Y, BRADSHAW A R, CHIU Y L. The role of precipitates in the bio-corrosion performance of Mg-3Zn in simulated body fluid[J]. Journal of Alloys and Compounds, 2014, 614(25): 345-352.

[20] JAMESH M I, WUA G S. Electrochemical corrosion behavior of biodegradable Mg-Y-RE and Mg-Zn-Zr alloys in Ringer’s solution and simulated body fluid[J]. Corrosion Science, 2015, 91(2): 164-189.

[21] ZHANG X, ZHANG K, LI X G, DENG X. Comparative study on corrosion behavior of as-cast and extruded Mg-5Y-7Gd-1Nd-0.5Zr alloy in 5% NaCl aqueous solution[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1018-1027.

[22] YIN D S, ZHANG E L, ZENG S Y. Effect of Zn on mechanical property and corrosion property of extruded Mg-Zn-Mn alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 763-768.

[23] 刘 莹, 王炳德, 王忠堂. 挤压变形对镁合金组织与力学性能的影响[J]. 材料热处理学报, 2011, 32 (5): 51-54.

LIU Y, WANG B D, WANG Z T. Influence of extrusion deformation on microstructure and mechanical properties of magnesium alloy[J]. Transactions of Materials and Treatment, 2011, 32 (5): 51-54.

[24] WANG Y D, WU G H, LIU W C. Influence of heat treatment on microstructures and mechanical properties of gravity cast Mg-4.2Zn-1.5RE-0.7Zr magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3611-3620.

[25] ASCENCIO M, PEKGULERYUZ M. An investigation of the corrosion mechanisms of WE43 Mg alloy in a modified simulated body fluid solution: The influence of immersion times[J]. Corrosion Science, 2014, 87(9): 489-503.

[26] LIU D X, GUO C G, CHAI L Q. Mechanical properties and corrosion resistance of hot extruded Mg-2.5Zn-1Ca alloy[J]. Materials Science and Engineering B, 2015, 195: 50-58.

Effect of hot plastic deformation on microstructure and properties of Mg-Zn-Zr-Ce alloys

LEI Shao-fan1, WEN Jiu-ba1, 2, HE Jun-guang1, 2, LIU Ya1

(1. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Collaborative Innovation Center of Nonferrous Metals of Henan Province, Luoyang 471023, China)

Abstract: The effects of hot extrusion process and annealing temperature on the microstructure and properties of Mg-Zn-Zr-Ce biomedical alloy were investigated by OM (Optical microscope), SEM (Scanning electron microscope), TEM (Transmission electron microscope), immersion test, electrochemical measures and tensile tests. The result shows that dynamic recrystallization occurs during hot plastic deformation, and the microstructure of extruded alloy is consisted of fine DRXed (Dynamic recrystallized) grain and unDRXed grain. The recrystallization occurs in deformed grains and the recrystallized grains grow subsequently after annealing treatment. When annealing temperature is over 200℃, the corrosion current (Jcorr) and grain size (d) meet the following equation: Jcorr=a+bd-1/2. According to the equation, it concludes that the alloy annealed at 200 ℃ for 3 h possesses the lowest corrosion current, and exhibits the optimized comprehensive properties. The elongation, tensile strength and corrosion rate are about 16.2%, 245.8 MPa and 0.7235 mm/a, respectively.

Key words: biomedical Mg alloy; grain refinement; corrosion resistance; mechanical property

Foundation item: Project(2012IRTSTHN008) supported by the New Nonferrous Metal Material Program of Science and Innovation Team of Henan Province University, China; Project(15A430024) supported by the Major Program of Education Department of Henan Province, China

Received date: 2016-12-29; Accepted date: 2017-05-22

Corresponding author: WEN Jiu-ba; Tel: +86-13838829072; E-mail: wenjiuba12@163.com

(编辑 王 超)

基金项目:河南省“新型有色金属材料”高校科技创新团队支持计划(2012IRTSTHN008);河南省教育厅重点项目(15A430024)

收稿日期:2016-12-29;修订日期:2017-05-22

通信作者:文九巴,教授,博士;电话:13838829072;E-mail:wenjiuba12@163.com