DOI:10.19476/j.ysxb.1004.0609.2018.03.05

激光快速成形Ti64.52Fe29.32Zr5.86Y0.30医用合金组织与性能

韩立影1, 2,王存山1,羌建兵1

(1. 大连理工大学 三束材料改性教育部重点实验室,大连 116024;

2. 辽宁科技大学 激光先进制造技术研发中心,鞍山 114051)

摘 要:利用“团簇+连接原子”结构模型构建了Ti-Fe-Zr-Y合金化双团簇模型,由此设计出成分为Ti64.52Fe29.32Zr5.86Y0.30的四元共晶合金,并利用激光快速成形技术在纯钛板上制备了该合金的成形体。利用X射线衍射仪、扫描电镜、电子探针、3D表面轮廓仪、显微硬度计、纳米压痕仪和电化学工作站,系统研究合金成形体的显微组织、表面粗糙度、硬度、弹性模量和耐蚀性能,并与Ti70.60Fe29.40二元共晶合金成形体进行了对比分析。结果表明:Ti64.52 Fe29.32 Zr5.86Y0.30合金呈现出细小的树枝状共晶组织形貌特征。钇的添加有效地抑制了Ti4Fe2O氧化物的形成,并增加了合金的成形性。Ti64.52Fe29.32Zr5.86Y0.30合金的硬度较Ti70.60Fe29.40合金的硬度提高了14%,弹性模量降低了32%,且该四元合金在Hank’s溶液中的耐蚀性明显优于Ti70.60Fe29.40二元共晶合金。

关键词:钛合金;激光快速成形;成分设计;组织;性能

文章编号:1004-0609(2018)-03-0474-09 中图分类号:TG146.2 文献标志码:A

激光快速成形技术是结合了快速原型和激光熔覆技术的一种先进制造技术。利用该技术可实现医用植入体的设计与制造,兼具个性化、高柔性、低成本、短周期、成形性与组织性能控制一体化等优点,在现代生物医学工程领域有很大的应用价值[1-5]。当前,国内外用于激光快速成形的生物医用材料多为传统的合金材料,研究结果表明,某些相关的性能指标还不能满足临床和激光快速成形工艺的要求[6-8]。这些问题的发现,对新型激光快速成形生物医用材料的研发有着积极的促进作用。

众所周知,钛合金是当前生物医学领域应用较多的合金体系之一,也是当前激光快速成形领域研究较为深入的合金体系。其中Ti-6Al-4V合金应用最为广泛,而该合金中含有生物毒性元素Al与V,同时合金的弹性模量远高于骨骼的弹性模量。由此种合金制备的植入体与骨骼间弹性模量的不匹配,极易出现“应力屏蔽”现象,从而使植入体周围的骨组织功能退化并吸收,进而导致植入体松动或断裂[9-10]。由此可见,生物学性能是生物医用合金设计需要考虑的重要因素之一。而最新发展的第三代β型钛合金虽然具有良好的生物相容性和较低的弹性模量,但由于其强化机制主要以固溶强化为主,因此强度较低,耐磨性不理想。另外,β型钛合金固溶体的凝固温度范围相对较宽,合金的流动性较差,在快的冷却条件下极易产生枝晶偏析,成形精度和质量难以保证,因而难以满足激光快速成形的工艺要求[11-13]。因此,激光快速成形生物医用材料的成形性是合金成分设计过程中需要考量的另一个重要因素。

理想的激光快速成形钛合金医用材料,除了具备优异的生物学、力学性能、液态流动性,还应具有优异的抗氧化性和低的成分偏析等性质,方能适应高质量的激光快速成形的要求。近期有研究表明,Ti-Fe二元共晶合金除具有良好的综合力学性能外,还具有良好的流动性及低的成分偏析性,且合金中无生物毒性元素,具有成为激光快速成形医用合金材料的潜 力[14-16]。然而,该合金尚具有以下两点不足:一是易于氧化,在激光快速成形过程中,虽然采取严格保护措施,但因原始粉末颗粒中氧的吸附,易形成脆性Ti4Fe2O氧化物[17-18];二是弹性模量(149~154 GPa)远大于骨的弹性模量,难以满足临床要求[17]。如何有效改善合金的脱氧性并降低弹性模量,是该合金能否作为激光快速成形医用材料的关键所在。

合金化是克服该合金上述缺陷的有效方法之一。众所周知,无生物毒性钇与氧的电负性要远高于钛、铁与氧的电负性,选取钇为合金化元素可以很好的净化液相成分,从而抑制脆性Ti4Fe2O氧化物的形成。弹性模量是取决于原子间结合力的力学性能指标,为有效降低合金的弹性模量,需从选择合金的原子特性考虑,以低弹性模量、无生物毒性元素为优先选择原则之一,通过合金成分的优化设计,以此调整组元间的结合状态,进而达到降低合金弹性模量的目的。无生物毒性锆元素则具备上述特性。但问题是如何对其进行有效的合金化。目前,钛合金成分设计方法主要有钼当量法、d-电子理论合金设计法、基于BP算法的合金设计方法等[19-21]。这些方法对钛合金成分设计有着很好的理论指导作用,但无法实现定量的成分设计。前期,DONG等[22]通过对一系列共晶合金进行结构解析,提出了双团簇结构模型。该模型将结构与成分信息有机统一于合金相的团簇成分式中。通过合理地确定出最具反映合金相结构特征团簇式,可以直接用于指导合金成分的定量设计,从而为多元共晶合金的开发提供了一条简单、易行的途径。

为此,本文作者利用“团簇+连接原子”模型,以Ti-Fe二元共晶基础团簇为构建基元,以低弹性模量的锆和钇为合金化元素,设计了Ti-Fe-Zr-Y四元共晶合金,并利用激光快速成形技术制备该合金的成形体,系统分析了在非平衡凝固条件下合金的微观组织和性能特征,并与Ti70.60Fe29.40二元共晶合金进行了对比,探讨了合金化元素对合金组织和性能影响的内在机制。

1 合金成分设计

弹性模量是取决于原子间结合力的力学性能指标。为有效降低Ti-Fe合金的弹性模量,需以低弹性模量、无生物毒性元素为优先选择原则之一,通过合金成分的优化设计来调整组元间的结合状态,从而达到降低合金弹性模量的目的。无生物毒性锆元素的弹性模量(68 GPa)远低于钛和铁的弹性模量(116和211 GPa),且原子半径(0.162 nm)要比钛的原子半径(0.145 nm)大,锆在β-Ti固溶体中的固溶将会增大晶胞的晶格常数,削弱组元间的结合力,从而降低合金体弹性模量,是理想的合金化元素之一。而无生物毒性的钇元素,因其与氧之间的化学亲和力高于钛、铁与氧的化学亲和力(三者与氧的电负性差分别为2.22、1.90和1.61),因而具有良好的脱氧性,可有效抑制脆性氧化物的形成。但问题是如何实现合金元素的优化设计,在保持或提高二元Ti-Fe共晶合金优异性能的同时,有效改善合金的脱氧性并降低弹性模量。

任何多组元体系材料的结构应含有构成体系的亚组元的结构信息,如果找到了两者间的内在联系,即合金化的路径,也就能对多元合金的成分及结构做出推测。基于该思想,在长期的合金成分设计研究中,从原子团簇的局域结构角度,提出了复杂多组元合金成分设计模型—“团簇+连接原子”结构模型。此模型将合金结构分为两部分:团簇部分和连接原子部分,其中团簇为第一近邻配位多面体,通常为具有高配位数的密堆结构,其间由连接原子搭接。构成团簇的组元之间具有强相互作用,而团簇与团簇之间的连接为相对弱的交互作用。团簇模型给出一个简化的[团簇][连接原子]x成分式,即由一个团簇加上x个连接原子构成[22-24]。

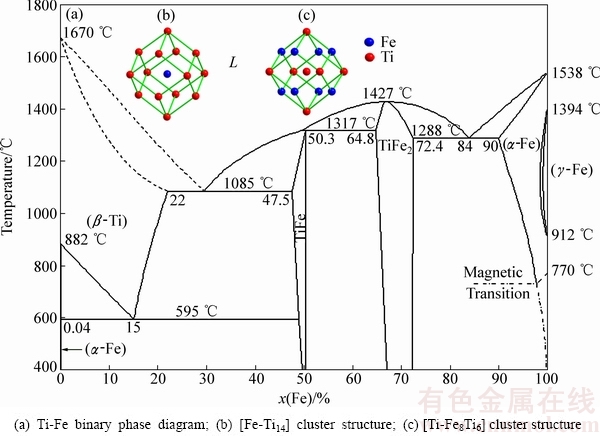

任何二元共晶液相是由两个成分不同的液相基元所构成,每个液相基元各自描述一种稳定的熔体,并向对应的共晶相转变。对于可描述为[团簇][连接原子]x的液相基元,团簇在超元胞中的堆垛模式主要有两种:一种是团簇按照类似面心立方结构(FCC-like)进行堆垛,团簇占据FCC-like元胞中原子阵点位置,而连接原子则占据八面体间隙位置,一个团簇将与一个连接原子相对应,这种1:1结构模型给出的团簇成分式为[团簇][连接原子]1;另一种团簇按照类似体心立方结构(BCC-like)进行堆垛,团簇占据BCC-like元胞中原子阵点位置,连接原子则占据八面体间隙位置,一个团簇将与3个连接原子相对应,与这种结构模型相对应的团簇成分式为[团簇][连接原子]3。由此衍生的二元共晶双团簇表达式为:[团簇1][连接原子]1或3+ [团簇2] [连接原子]1或3=[团簇1+团簇2][连接原子]2或4或6[22]。这具体到Ti-Fe二元合金体系中,在Ti70.60Fe29.40共晶点附近分别存在以铁为心的CN14 [Fe-Ti14]团簇和以钛为心的CN14 [Ti-Fe8Ti6]团簇(见图1)。通过解析β-Ti和TiFe两个共晶相的结构,可以推导出与其相对应的两个液相基元团簇成分式:[Fe-Ti14]Fe1和 [Ti-Fe8Ti6]Ti3。据此构成的Ti70.60Fe29.40二元共晶的团簇成分式则可表达为:[Fe-Ti14]Fe1+[Ti-Fe8Ti6]Ti3= Ti24Fe10=Ti70.60Fe29.40 (摩尔分数,%),其恰好落在Ti-Fe二元合金的共晶点上。当对此二元基础团簇进行合金化时,合金化元素要根据其作用进入[Fe-Ti14]Fe1或[Ti-Fe8Ti6] Ti3团簇式中,使其稳定或者失稳。锆与钛为同族元素,具有相似的电子结构特性,二者的混合焓为零,且与铁不形成CsCl结构。因此,锆将进入[Fe-Ti14]Fe1团簇成分式中,并基于团簇密堆性原则,直接取代两个钛原子占据团簇第一壳层位置。由此构建三元共晶合金的团簇成分式为:[Fe-Ti12Zr2]Fe1+[Ti-Fe8Ti6]Ti3=Ti22Fe10Zr2= Ti64.71Fe29.41Zr5.88。而钇元素与钛和铁皆不互溶,因此将不进入团簇式,其适量的添加可起到净化液相成分、抑制有害氧化物形成的作用,但过多钇的添加则易形成有害的脆性相,反而会降低合金的强度与塑性。通过前期优化实验表明,钇的最佳添加量为0.3%。因而最终的合金原子计量比为Ti64.52Fe29.32Zr5.86Y0.30。

图1 Ti-Fe二元相图及团簇结构

Fig. 1 Ti-Fe binary phase diagram and cluster structures

2 实验

选取尺寸为30 mm×30 mm×20 mm的纯钛板为基体材料。以钛(99.99%,质量分数;<45 μm),铁(99.90%,质量分数;<45 μm),锆(99.90%,质量分数;<45 μm)和钇 (99.90%,质量分数;<150 μm) 金属粉末为成形原料。将Ti64.52Fe29.32Zr5.86Y0.30和Ti70.60Fe29.40摩尔分数换算成质量分数进行称量配料,然后将其置于球磨机,在氩气保护下混合8 h,以使其成分均匀化。在惰性气体氩气保护下,利用5 kW横流CO2激光快速成形系统在纯钛基板上沉积合金成形体。具体的成形工艺参数为:激光功率2500 W,扫描速率4 mm/s,光斑直径4 mm,搭接率30%,单层预置层厚度约1 mm。激光快速成形时,采用Z字形扫描策略,且上下层扫描方向垂直,以此获得尺寸为25 mm×25 mm×15 mm的合金成形体。

利用XRD-6000型X射线衍射仪、Zeiss Supra55(VP) 型扫描电子显微镜和EPMA-1720型电子探针对合金成形体的相组成、微观组织形貌和微区成分进行分析。采用NV5000 5022S型表面轮廓仪测试合金成形体表面粗糙度。测试时,每个试样选取8个不同测试点,取其算数平均值。采用DMH-2LS型显微硬度计测量合金成形体的显微硬度,载荷0.981 N,加载时间30 s,每个试样沿井字形路径测试20个不同点,取其算术平均值。采用Nano Indenter XP纳米压痕仪进行合金成形体弹性模量的测量,压头为玻氏压针,每个试样取20个点测量,取其平均值。为了验证数据的可靠性,对Ti-6Al-4V和Ti-Ta-Zr 块体合金的弹性模量进行了相同的测试,所测得的数据与报道的用传统方法获得的数据基本相符,这表明采用该法测量块体材料的弹性模量是可行的。采用CS310型电化学工作站对试样表面的耐腐蚀性能进行研究,参比电极为饱和甘汞电极,辅助电极为Pt电极,扫描速度5 mV/s,腐蚀介质为Hank’s溶液。

3 结果与分析

3.1 显微组织

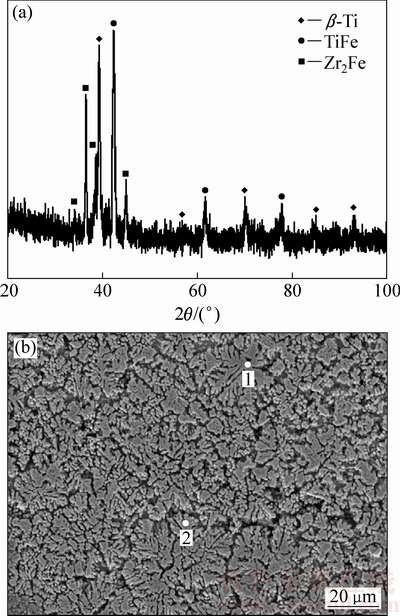

图2(a)所示为Ti70.60Fe29.40二元共晶合金成形体的XRD谱。可见合金成形体主要是由BCC结构的 β-Ti固溶体和CsCl结构的TiFe金属间化合物所构成。基于最小二乘法计算表明,合金成形体中β-Ti固溶体和TiFe金属间化合物的点阵常数分别为0.319 nm和0.298 nm,前者较纯 β-Ti点阵常数(0.331 nm)有所减小,而后者则较标准化学剂量比的TiFe点阵常数(0.297 nm)略有增大。这分别与铁在β-Ti中的固溶、TiFe金属间化合物中Ti/Fe摩尔比发生变化有关。此外,在激光快速成形过程中,尽管采取了严格保护措施,防止外来氧的侵入,但因原始粉末颗粒的吸附氧,致使组织中尚有一定数量的Ti4Fe2O形成。在扫描电镜下进行组织观察发现,该合金成形体在非平衡凝固条件下呈现出放射状共晶组织形态特征,其平均层片间距约为0.88 μm(见图2(b))。EPMA分析表明,共晶组织中浅色β-Ti固溶体中的铁含量(质量分数)高达22.89%,超过其在β-Ti固溶体中的最大溶解度,意味着该固溶体为过饱和固溶体;而深色的TiFe金属间化合物中钛的含量则较标准化学计量比增加了6.0%。这一结果很好地诠释了共晶组成相晶格常数变化的原因。正如前所述,在共晶合金的高温液相中存在两个稳定的液相基元[Fe-Ti14]Fe和[Ti-Fe8Ti6]Ti3,当液态合金快速冷却至共晶温度时,两个液相基元将会向各自对应的晶化相转变,即[Fe-Ti14]Fe→β-Ti、[Ti-Fe8Ti6]Ti3→TiFe,形成胞状(β-Ti+TiFe)共晶团。在胞状共晶团生长过程中,由于原始粉末颗粒所吸附的氧被逐渐排挤至共晶团边界处,导致该微区氧的富集,致使在共晶团边界处生成了许多形状不规则的Ti4Fe2O氧化物。该氧化物又称以氧稳定的Ti2Fe金属间化合物,其高的脆性将会降低合金成形体的强度与塑性。而在进一步固态冷却过程中,β-Ti固溶体因高的冷却速度本应发生马氏体相变,形成α′、α″或ω相,但因高铁含量对β-Ti固溶体的稳定作用,使这一转变被有效抑制,致使高温亚稳相被保留至室温。

图2 Ti70.60Fe29.40合金XRD谱及组织形貌

Fig. 2 XRD pattern (a) and microstructure (b) of Ti70.60Fe29.40 alloy

图3(a)所示为Ti64.52Fe29.32Zr5.86Y0.30合金成形体的XRD谱。除BCC结构的β-Ti固溶体和CsCl结构的TiFe金属间化合物外,还发现有少量的Zr2Fe金属间化合物形成,而Ti4Fe2O氧化物则因钇对合金液相良好的净化作用而消失。利用最小二乘法计算表明,该合金成形体中β-Ti和TiFe相的晶格常数分别为0.321 nm和0.299 nm,较Ti70.60Fe29.40合金成形体中的β-Ti和TiFe的晶格常数均有所增大。这主要源于原子半径较大的锆元素在β-Ti和TiFe中的固溶。图3(b)所示为该四元合金成形体典型的组织形貌。由图3(b)可见,该合金成形体具有典型的树枝状共晶组织形态特征,且组织中未发现有Ti4Fe2O氧化物的形成。结合XRD和EPMA分析可知,共晶组织中的枝晶相为β-Ti固溶体,其平均化学成分为Ti73.85Fe21.79Zr4.36(摩尔分数)。由共晶组织中组成相的形态和大小可以判断,在非平衡凝固过程中,溶入了锆元素的液相基元 [Fe-Ti12Zr2]Fe1将优先析出树枝状的β-Ti固溶体,并在其生长的固/液界面前沿造成溶质富集区,从而为[Ti-Fe8Ti6]Ti3液相基元向其对应的TiFe相转化创造了有利的成分条件。然而从热力学角度看,锆和铁之间的混合焓(-25 kJ/mol)要较钛和铁之间的混合焓(-17 kJ/mol)为负,在竞争生长过程中,势必会导致少量的Zr2Fe相的析出,进而形成由β-Ti、TiFe和少量的Zr2Fe构成的多元共晶合金组织。由于该合金第三组元锆的浓度较高,加之钇对合金液相的净化作用增大了液相的过冷度[25],致使共晶组织发展为树枝状共晶,并使其平均层片间距降低至0.59 μm,组织得到进一步细化。上述实验结果充分证明了“团簇+连接原子”模型的有效性,即可通过二元共晶基础团簇设计出多元共晶合金。同时也表明团簇结构具有普适遗传性,其不仅存在于稳定相中,也存在于亚稳相中,因此可用于非平衡凝固条件下合金成分的设计。

图3 Ti64.52Fe29.32Zr5.86Y0.30合金XRD谱及组织形貌

Fig. 3 XRD pattern (a) and microstructure (b) of Ti64.52Fe29.32Zr5.86Y0.30 alloy

3.2 成形性

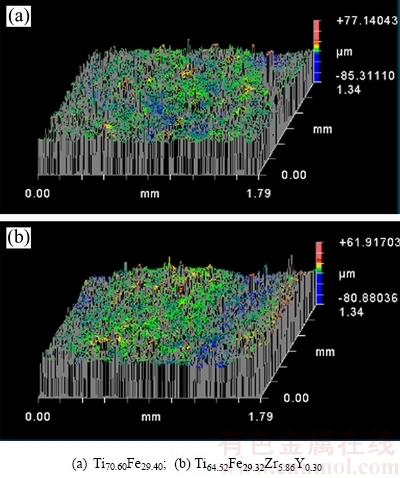

合金的成形性是指合金适于激光快速成形制造的难易程度和获得优质构件的能力[26],其通常用成形构件的表面粗糙度来表征。表面粗糙度越小,成形构件的成形性越好。图4所示为有代表性的Ti70.60Fe29.40和Ti64.52Fe29.32Zr5.86Y0.30合金成形体表面三维轮廓示意图。选取8个不同测试点所获得的Ti70.60Fe29.40和Ti64.52Fe29.32Zr5.86Y0.30合金成形体表面平均粗糙度分别为4.721和4.389 μm,即Ti64.52Fe29.32Zr5.86Y0.30合金的成形性要优于Ti70.60Fe29.40合金的。由金属凝固学理论可知,二元共晶合金的凝固温度范围要小于多元共晶合金的凝固温度范围,前者的成形性本应优于后者的成形性,但实验结果并非如此。这可能与Ti70.60Fe29.40二元共晶合金中Ti4Fe2O的形成有关。因为Ti4Fe2O的存在,将会增加液相合金的粘滞性,进而导致液相合金流动性变差[27],成形性降低。因此,有效控制Ti4Fe2O氧化物的形成将有利于合金成形性的提高。

3.3 显微硬度与弹性模量

硬度是生物合金的一项重要力学性能指标。高的硬度可保证合金在使用过程中具有高的强度和良好的耐磨性,进而提高合金的使用寿命。显微硬度测试表明,Ti70.60Fe29.40合金成形体的平均硬度值为HV658,

而Ti64.52Fe29.32Zr5.86Y0.30合金成形体因受固溶强化、细晶强化和多种金属间化合物的增强作用,其平均显微硬度达到766HV,较前者提高了14%。不仅如此,Ti64.52Fe29.32Zr5.86Y0.30合金成形体的硬度也远高于目前已报道的钛合金硬度。如商用Ti-6Al-4V合金的硬度约为340HV~370HV,而β型钛合金的硬度则介于250HV~570HV [14, 28]。

图4 合金表面三维轮廓示意图

Fig. 4 Typical 3D profile of alloy surfaces

正如前述,生物合金植入体与骨骼间弹性模量的不匹配,极易出现“应力屏蔽”现象,从而使植入体周围的骨组织功能退化并吸收,进而导致植入体松动或断裂。因此,弹性模量是评价生物合金性能优劣的一项重要的性能指标。纳米压痕测试显示,Ti70.60Fe29.40和Ti64.52Fe29.32Zr5.86Y0.30合金成形体的弹性模量分别为150 GPa和101 GPa,后者弹性模量较前者弹性模量降低32%。这主要归因于以下几个方面:1) 锆具有低的弹性模量,且其在β-Ti和TiFe相中的固溶,增大这两相的晶格常数,弱化了组元间的结合力,从而有利于合金弹性模量的降低;2) 晶界和相界是原子排列不规则的区域,其原子配位数要比晶粒和合金相内的原子配位数少,原子间距较大,原子间的作用力相对较小。因此,Ti64.52Fe29.32Zr5.86Y0.30合金成形体晶粒的细化,也有助于合金弹性模量的降低;3) 钇对合金液相良好的净化作用,有效抑制高弹性模量Ti4Fe2O的形成,可在一定程度上降低合金的弹性模量。受上述因素的综合影响,致使Ti64.52Fe29.32Zr5.86Y0.30合金成形体的弹性模量较Ti70.60Fe29.40合金成形体的弹性模量有明显降低。此外,与Ti-6Al-4V合金的弹性模量(120~130 GPa)[1, 13]相比,Ti64.52Fe29.32Zr5.86Y0.30合金成形体的弹性模量是低的,但仍高于β-Ti合金的弹性模量(60~80 GPa)[14, 28]。这说明利用单一元素合金化来降低弹性模量是有限的。而多元合金化是进一步降低Ti-Fe基合金的弹性模量有效手段之一,相关工作正在进行之中。

3.4 耐腐蚀性

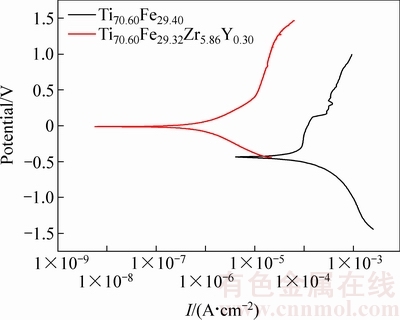

图5所示为Ti70.60Fe29.40和Ti64.52Fe29.32Zr5.86Y0.30合金成形体在Hank’s溶液中的动电位极化曲线。由Ti64.52Fe29.32Zr5.86Y0.30合金成形体的阳极极化曲线可见,在腐蚀的起始阶段,合金成形体的腐蚀电流密度急速增加。当腐蚀电压(SCE)达到0.3876 V时,合金成形体的腐蚀电位开始进入钝化电位区,腐蚀电流密度的增加随之趋于平缓,钝化膜逐渐形成,腐蚀进入阳极钝化阶段。Ti70.60Fe29.40合金成形体的阳极极化曲线则有所不同,在腐蚀电压(SCE)为0.0921~0.3386 V的区间内,动电位极化曲线出现了明显的阳极峰,钝化膜被击穿,且在其区间出现二次钝化区。阳极峰出现可能是由于钝化膜中的相变造成的。二者另一重要差异是腐蚀电位和腐蚀电流密度的不同。根据塔菲尔直线外推法测得的Ti64.52Fe29.32Zr5.86Y0.30合金成形体的腐蚀电位(SCE)和腐蚀电流密度分别为-0.0892 V和9.1041×10-8 A/cm2,而Ti70.60Fe29.40合金成形体的腐蚀电位(SCE)和腐蚀电流密度分别为-0.5156 V和8.2860×10-5 A/cm2。这表明Ti64.52Fe29.32Zr5.86Y0.30合金成形体在Hank’s溶液中的耐蚀性要明显优于Ti70.60Fe29.40合金成形体的耐蚀性。另外,Ti64.52Fe29.32Zr5.86Y0.30合金成形体耐蚀性也明显优于常规Ti-6Al-4V合金的,而与报道的β-Ti合金相当。其中Ti-6Al-4V合金腐蚀电压(SCE)和腐蚀电流密度分别为-0.668 V和6.055×10-6 A/cm2[29],而典型的Ti-Nb基、Ti-Mo基b钛合金的腐蚀电压(SCE)和腐蚀电流密度则分别为-0.609~-0.701 V和7.26×10-6~4.1×10-7 A/cm2[30]。

图5 Ti64.52Fe29.32Zr5.86Y0.30和Ti70.60Fe29.40合金在Hank’s溶液中的动电位极化曲线

Fig. 5 Potentiodynamic polarization curves of Ti64.52Fe29.32Zr5.86Y0.30 and Ti70.60Fe29.40 alloys in Hank’s solution

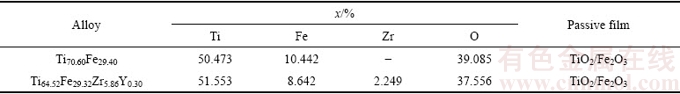

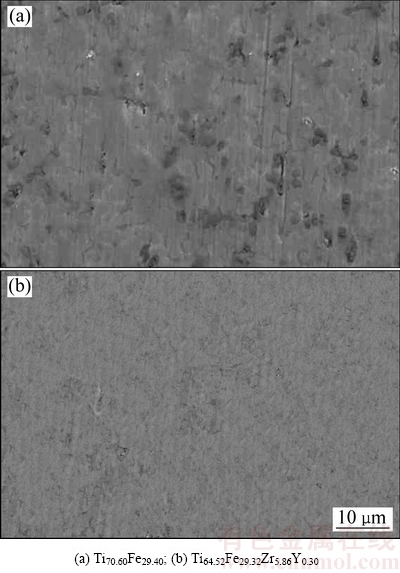

图6所示为Ti70.60Fe29.40和Ti64.52Fe29.32Zr5.86Y0.30合金成形体的腐蚀表面形貌。如前所述,Ti70.60Fe29.40合金成形体是由β-Ti+TiFe共晶组织及分布于共晶团交界处的Ti4Fe2O氧化物所组成。在以β-Ti和TiFe两相构成的共晶组织中,β-Ti固溶体的电极电位要较TiFe金属间化合物的为低。因此,β-Ti与TiFe组成原电池时,β-Ti固溶体为阳极,而TiFe金属间化合物为阴极,β-Ti固溶体将优先腐蚀,致使腐蚀表面形成了一些TiFe共晶相的浮凸。同时,位于共晶团界面处Ti4Fe2O氧化物的存在,不仅破坏了钝化膜的连续性,而且其在电化学腐蚀过程中的溶解,致使一些Ti4Fe2O上形成了较大的腐蚀坑(见图6(a))。EPMA分析表明,该合金成形体表面腐蚀产物主要是由TiO2和Fe2O3所组成(见表1)。相关研究表明[30],Fe2O3的化学稳定性要较TiO2的化学稳定性为低,其形成同样会破坏TiO2钝化膜的连续性,进而导致合金成形体耐蚀性的降低。而Ti64.52Fe29.32Zr5.86Y0.30合金成形体则是由纯共晶组织所构成。一方面钇对合金液相良好的净化作用,有效地抑制Ti4Fe2O氧化物的形成,增加了钝化膜的连续性;另一方面晶粒的细化增强了共晶组织的“屏蔽效应”[31],可在很大程度上抑制Hank’s溶液对合金成形体的侵蚀。此外,由表1所示的EPMA分析结果可知,该合金成形体腐蚀表面的Fe2O3含量也有所降低,这对提高该合金成形体的耐蚀性有着一定促进作用。受这些因素的综合影响,该合金成形体腐蚀表面所形成的钝化膜是非常致密和连续的(见图6(b)),其耐蚀性较Ti70.60Fe29.40合金成形体的有明显提高。

表1 Ti-Fe合金表面腐蚀产物EPMA定量分析结果

Table 1 EPMA quantitative analysis results of corroded surface for Ti-Fe alloys

图6 两种合金在Hank’s溶液中的腐蚀表面形貌

Fig. 6 Corroded surface morphologies of two alloys in Hank’s solution

4 结论

1) 在激光快速成形非平衡凝固条件下,Ti64.52Fe29.32Zr5.86Y0.30合金成形体是由树枝状(β-Ti+ TiFe+Zr2Fe)共晶组织所组成。钇对合金液相良好的净化作用,有效抑制了Ti4Fe2O脆性氧化物的形成。

2) 与Ti70.60Fe29.40二元共晶合金成形体相比较,Ti64.52Fe29.32Zr5.86Y0.30合金成形体成形性有所提高,硬度提高14%,弹性模量降低32%,且该四元合金在Hank’s溶液中的耐蚀性明显优于Ti70.60Fe29.40二元共晶合金。

REFERENCES

[1] 来佑彬, 刘伟军, 孔 源, 王福雨, 赵宇辉. 激光快速成形TA15残余应力影响因素的研究[J]. 稀有金属材料与工程, 2013, 42(7): 1526-1530.

LAI You-bin, LIU Wei-jun, KONG Yuan, WANG Fu-yu, ZHAO Yu-hui. Influencing factors of residual stress of Ti-6.5Al-1Mo-1V-2Zr alloy by laser rapid forming process[J]. Rare Metal Materials and Engineering, 2013, 42(7): 1526-1530.

[2] 卞宏友, 雷 洋, 李 英, 杨 光, 钦兰云, 王 维. 预热对激光沉积修复TAl5钛合金形貌尺寸和组织的影响[J]. 中国有色金属学报, 2016, 26(2): 310-316.

BIAN Hong-you, LEI Yang, LI Ying, YANG Guang, QIN Lan-yun, WANG wei. Effects of preheating on morphology size and microstructure of laser deposition repair TAl5 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 310-316.

[3] AVERYANOVA M, BERTRAND P H, VERQUIN B. Studying the influence of initial powder characteristics on the properties of final parts manufactured by the selective laser melting technology[J]. Virtual Phys Prototyp, 2011, 6(4): 215-223.

[4] FACCHINI L, MAGALINI E, ROBOTTI P, MOLINARI A, HOGES S, WISSENBACH K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders[J]. Rapid Prototyp J, 2010, 16(6): 450-459.

[5] 苏海军, 尉凯晨, 郭 伟, 马菱薇, 于瑞龙, 张 冰, 张 军, 刘 林, 傅恒志. 激光快速成形技术新进展及其在高性能材料加工中的应用[J]. 中国有色金属学报, 2013, 23(6): 1567-1574.

SU Hai jun, WEI Kai chen, GUO Wei, MA Ling wei, YU Rui long, ZHANG Bing, ZHANG Jun, LIU Lin, FU Heng zhi. New development of laser rapid forming and its application in high performance materials processing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1567-1574.

[6] CONTIERI R J, LOPES E S N, CRUZ M T D L, COSTA A M, AFONSO C R M, CARAM R. Microstructure of directionally solidified Ti-Fe eutectic alloy with low interstitial and high mechanical strength[J]. J Cryst Growth, 2011, 333(1): 40-47.

[7] 颉芳霞, 何雪明, 吕彦明, 武美萍, 何新波, 曲选辉. 生物医用多孔钛及钛合金激光快速成形研究进展[J]. 材料导报, 2016, 30(4): 109-114.

XIE Fang-xia, HE Xue-ming, LU Yan-ming, WU Mei-ping, HE Xin-bo, QU Xuan-hui. Research progress in laser rapid forming of porous titanium and its alloys for biomedical applications[J]. Materials Review, 2016, 30(4): 109-114.

[8] MURR L E, QUINONES S A, GAYTAN S M, LOPEZ M I, RODELA A, MARTINEZ E Y, HERNANDEZ D H, MARTINEZ E, MEDINA F, WICKER R B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications[J]. J Mech Behav Biomed Mater, 2009, 2(1): 20-32.

[9] 张兴东, 刘立斌, 王建丽, 熊 翔. 高效组合材料设计方法在生物钛合金领域的应用[J]. 中国有色金属学报, 2014, 24(11): 2836-2843.

ZHANG Xing-dong, LIU Li-bin, WANG Jian-li, XIONG Xiang. Application of high-efficiency combinatorial approach in biomedical titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2836-2843.

[10] 王 松, 廖振华, 刘伟强. 医用钛合金热氧化处理工艺及其耐磨损、耐腐蚀性能和生物活性的研究进展[J]. 中国有色金属学报, 2014, 24(6): 1466-1473.

WANG Song, LIAO Zhen-hua, LIU Wei-qiang. Research progress on thermal oxidation process and wear, corrosion resistance and bioactivity of biomedical grade titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1466-1473.

[11] ZHANG Ling-bo, WANG Ke-zheng, XU Li-juan, XIAO Shu-long, CHEN Yu-yong. Effect of Nb addition on microstructure, mechanical properties and castability of β-type Ti-Mo alloys[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2214-2220.

[12] NIINOMI M. Mechanical properties of biomedical titanium alloys[J]. Mater Sci Eng A, 1998, 243(1/2): 231-236.

[13] OKAZAKI Y, ITO Y. New Ti alloy without Al and V for medical implants[J]. Adv Eng Mater, 2000, 2(5): 278-281.

[14] LOUZGUINE D V, KATO H, INOUE A. High strength and ductile binary Ti-Fe composite alloy[J]. J Alloy Comp, 2004, 384: L1-L3.

[15] WANG C S, ZHANG K S, PANG H J, CHEN Y Z, DONG C. Laser-induced self-propagating reaction synthesis of Ti-Fe alloys[J]. J Mater Sci, 2008, 43(1): 218-221.

[16] PANDELAERS L, BLANPAIN B, WOLLANTS P. An optimized diffusion database for the disordered and ordered bcc phases in the binary Fe-Ti system[J]. Calphad, 2011, 35(4): 518-522.

[17] 庆先龙. 稀土Y对激光快速成形Ti-Fe共晶组织与性能的影响[D]. 大连: 大连理工大学, 2014: 14-15.

QING Xian-long. Influence of rare-earth Y on microstructure and properties of laser rapid prototyping Ti-Fe eutectic[D]. Dalian: Dalian University of Technology, 2014: 14-15.

[18] YAN M, DARGUSCH M S, KONG C, KIMPTON J A, KOHARA S, BRANDT M, QIAN M. In situ synchrotron radiation study of TiH2-6Al-4V and Ti-6Al-4V: accelerated alloying and phase transformation, and formation of an oxygen-enriched Ti4Fe2O phase in TiH2-6Al-4V[J]. Metall Mater Trans A, 2015, 46(1): 41-45.

[19] 王光荣, 高 颀, 刘继雄, 杨 奇, 王鼎春, 姚 锐, 廖松义, 郑 峰. β钛合金成分设计: 理论、方法、实践[J]. 材料导报, 2017, 31(2): 44-51.

WANG Guang-rong, GAO Qi, LIU Ji-xiong, YANG Qi, WANG Ding-chun, YAO Rui, LIAO Song-yi, ZHENG Feng. Composition design of beta-titanium alloys: Theoretical, methodological and practical advances[J]. Materials Review, 2017, 31(2): 44-51.

[20] 李 群, 王 清, 董 闯, 王英敏, 羌建兵. 亚稳β-Ti合金设计方法[J]. 钛工业进展, 2013, 30(5): 1-5.

LI Qun, WANG Qing, DONG Chuang, WANG Ying-min, QIANG Jian-bing. Composition design method of metastable β-Ti alloys[J]. Titanium, 2013, 30(5): 1-5.

[21] DAI Shi-juan, WANG Yu, CHEN Feng, YU Xin-quan, ZHANG You-fa. Design of new biomedical titanium alloy based on d-electron alloy design theory and JMatPro software[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 3027-3032.

[22] MA Y P, DONG D D, DONG C, LUO L J, WANG Q, QIANG J B, WANG Y M. Composition formulas of binary eutectics[J]. Sci Report, 2015, 5: 1-16.

[23] DONG C, WANG Q, QIANG J B, WANG Y M, JIANG N, HAN G, LI Y H, WU J, XIA J H. From clusters to phase diagrams: Composition rules of quasicrystals and bulk metallic glasses[J]. J Phys D: Appl Phys, 2007, 40(15): R273-R291.

[24] DONG Chuang, WANG Qing, CHEN Wei-rong, ZHANG Qing-yu, QIAN Jian-bing, WANG Ying-min. Cluster-based composition rules for ternary alloy systems[J]. J Univ Sci Technol Beijing, Miner Metall Mater, 2007, 14(1): 1-3.

[25] 回春华, 李廷举, 金文中. 稀土对4137H钢纯净度、过冷度、组织及性能的影响[J]. 钢铁研究学报, 2009, 21(4): 8-12.

HUI Chun-hua, LI Ting-ju, JIN Wen-zhong. Effect of RE on cleanliness, undercooling, structure and properties of steel 4137H[J]. Journal of Iron and Steel Research, 2009, 21(4): 8-12.

[26] 胡孝昀, 沈以赴, 李子全, 顾冬冬, 史长根. 金属粉末激光快速成形的工艺及材料成形性[J]. 材料科学与工艺, 2008, 16(3): 378-383.

HU Xiao-yun, SHEN Yi-fu, LI Zi-quan, GU Dong-dong, SHI Chang-gen. Process and material considerations in laser rapid manufacturing of metal parts[J]. Materials Science & Technology, 2008, 16(3): 378-383.

[27] 束奇峰, 胡晓军, 侯新梅, 周国治. 高炉渣流动性的计算研 究[J]. 中国稀土学报, 2010, 28: 131-135.

SHU Qi-feng, HU Xiao-jun, HOU Xin-mei, ZHOU Guo-zhi. Calculation on fluidity of blast furnace slag[J]. Journal of the Chinese Rare Earth Society, 2010, 28: 131-135.

[28] DAI Shi-juan, WANG Yu, CHEN Feng, YU Xin-quan, ZHANG You-fa. Influence of Zr content on microstructure and mechanical properties of implant Ti-35Nb-4Sn-6Mo-xZr alloys[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1299-1303.

[29] ZHAO C L, ZHANG X N, CAO P. Mechanical and electrochemical characterization of Ti-12Mo-5Zr alloy forbiomedical application[J]. J Alloy Comp, 2011, 509(32): 8235-8238.

[30] BAI Y, HAO Y L, LI S J, HAO Y Q, YANG R, PRIMA F, Corrosion behavior of biomedical Ti-24Nb-4Zr-8Sn alloy in different simulated body solutions[J]. Mater Sci Eng C, 2013, 33(4): 2159-2167.

[31] TSAO L C. Effect of Sn addition on the corrosion behavior of Ti-7Cu-Sn cast alloys for biomedical applications[J]. Mater Sci Eng C, 2015, 46: 246-252.

Microstructure and properties of Ti64.52Fe29.32Zr5.86Y0.30 biomedical alloy produced by laser rapid prototyping

HAN Li-ying1, 2, WANG Cun-shan1, QIANG Jian-bing1

(1. Key Laboratory for Materials Modification by Laser, Ion, and Electron Beams, Ministry of Education, Dalian University of Technology, Dalian 116023, China;

2. Laser Advanced Manufacturing Technology Center, University of Science and Technology Liaoning, Anshan 114051, China)

Abstract: A Ti64.52Fe29.32 Zr5.86Y0.30 alloy was designed through a “cluster-plus-glue-atom” model, and then was prepared by laser rapid prototyping on pure titanium substrate. The microstructure, formability, hardness, elastic modulus, and corrosion resistance of the alloy were investigated by X-ray diffraction, scanning electron microscopy, 3D surface profiler, micro-hardness tester, nano indenter and electrochemical work station, and comparative analysis with Ti70.60Fe29.40 binary eutectic alloy was conducted. The results show that the microstructure of the Ti64.52Fe29.32 Zr5.86Y0.30 alloy is featured with dendritic eutectic structure. Y addition not only suppresses the formation of Ti4Fe2O oxide, but also improves the formability of the alloy. The hardness of the Ti64.52Fe29.32 Zr5.86Y0.30 alloy is improved by 14% compared with that of Ti70.60Fe29.40 alloy. Whereas the elastic modulus is reduced by 32%. Moreover, the corrosion resistance of Ti64.52Fe29.32- Zr5.86Y0.30 alloy is superior to that of Ti70.60Fe29.40 alloy in Hank’s solution.

Key words: titanium alloy; laser rapid prototyping; composition design; microstructure; property

Foundation item: Project (51371041) supported by the National Natural Science Foundation of China

Received date: 2016-12-21; Accepted date: 2017-05-16

Corresponding author: WANG Cun-shan; Tel: +86-411-84707930; E-mail: laser@dlut.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51371041)

收稿日期:2016-12-21;修订日期:2017-05-16

通信作者:王存山,副教授,博士;电话:0411-84707930;E-mail:laser@dlut.edu.cn