等径角挤压制备超细生物医用纯钛的静态力学性能和塑性

来源期刊:中国有色金属学报(英文版)2017年第9期

论文作者:Reza NASERI Mehran KADKHODAYAN Mahmoud SHARIATI

文章页码:1964 - 1975

关键词:工业纯钛;等通道转角挤压;抗拉强度;弯曲强度;断裂韧度

Key words:commercially pure titanium; equal channel angular pressing; tensile strength; bending strength; fracture toughness

摘 要:等径角挤压是制备超细晶和纳米晶材料最有效的工艺之一。由于工业纯钛具有极佳的生物相容性,因此它可用作生物植入体材料。然而,较低的静/动态强度是纯钛类材料的不足之处。利用等径角挤压工艺可消除此类缺陷。本文作者在室温和通道角为135°条件下进行3道次挤压得到2级工业纯钛试样(2级CP-Ti)。对经等径角挤压3道次的CP-Ti样品进行显微组织分析及拉伸、硬度、三点弯曲和夏比冲击等力学性能测试。样品的显微组织演变结果表明,经等径角挤压工艺后样品的粗晶组织转变成超细晶或纳米晶组织。此外,力学性能测试结果表明,等径角挤压工艺能显著提高工业纯钛的屈服强度、抗拉强度、弯曲强度、硬度和断裂韧度,因此用该工艺制得的钛可以作为金属合金的替代品用作生物医用材料。

Abstract: Equal channel angular pressing (ECAP) is one of the most effective processes to produce ultra-fine grain (UFG) and nanocrystalline (NC) materials. Because the commercially pure titanium exhibits excellent biocompatibility properties, it has a significant potential to be utilized as an implant material. The low static and dynamic strengths of the pure titanium are one of the weaknesses of this material. This defect can be removed by applying the ECAP process on the pure titanium. In this work, the commercially pure titanium Grade 2 (CP-Ti of Grade 2) was pressed at room temperature by the ECAP process via a channel angle of 135° for 3 passes. The microstructural analysis and mechanical tests such as tensile test, hardness test, three-point bending test and Charpy impact test were all carried out on the ECAPed CP-Ti through 3 passes. The microstructural evolution reveals that by applying the ECAP process, coarse grain (CG) structure develops to UFG/NC structure. Moreover, the results of the mechanical tests show that the process significantly increases the yield and ultimate tensile strengths, bending strength, hardness and fracture toughness of the commercially pure titanium so that it can be used as a replacement for metallic alloys used as biomaterials.

Trans. Nonferrous Met. Soc. China 27(2017) 1964-1975

Reza NASERI, Mehran KADKHODAYAN, Mahmoud SHARIATI

Department of Mechanical Engineering, Faculty of Engineering, Ferdowsi University of Mashhad, P. O. Box 9177948944, Mashhad, Iran

Received 13 July 2016; accepted 12 October 2016

Abstract: Equal channel angular pressing (ECAP) is one of the most effective processes to produce ultra-fine grain (UFG) and nanocrystalline (NC) materials. Because the commercially pure titanium exhibits excellent biocompatibility properties, it has a significant potential to be utilized as an implant material. The low static and dynamic strengths of the pure titanium are one of the weaknesses of this material. This defect can be removed by applying the ECAP process on the pure titanium. In this work, the commercially pure titanium Grade 2 (CP-Ti of Grade 2) was pressed at room temperature by the ECAP process via a channel angle of 135° for 3 passes. The microstructural analysis and mechanical tests such as tensile test, hardness test, three-point bending test and Charpy impact test were all carried out on the ECAPed CP-Ti through 3 passes. The microstructural evolution reveals that by applying the ECAP process, coarse grain (CG) structure develops to UFG/NC structure. Moreover, the results of the mechanical tests show that the process significantly increases the yield and ultimate tensile strengths, bending strength, hardness and fracture toughness of the commercially pure titanium so that it can be used as a replacement for metallic alloys used as biomaterials.

Key words: commercially pure titanium; equal channel angular pressing; tensile strength; bending strength; fracture toughness

1 Introduction

Biomaterials are either artificial or natural materials which are used to make the structures or implants so that they can be utilized as a replacement for lost/disease biological structures. Biomaterials could be from ceramics, polymers, composite materials and metals [1]. The design and selection of biomaterials depend on their medical applications. A biomaterial has to possess the attributes of suitable properties, excellent biocompatibility, high corrosion resistance, high wear resistance and osteointegration [2]. 70%-80% of implants are made of metallic biomaterials. The low density, elastic modulus close to the hard tissue, high static and dynamic strengths, excellent specific strength, suitable ductility, high fracture toughness and acceptable wear resistance are some of the desired properties for biomaterials [2,3]. Usually, metallic implants are made of 316L stainless steel, cobalt-chromium (Co-Cr) alloys, titanium and its alloys. Among them, titanium and its alloys exhibit higher biocompatibility properties, corrosion resistance and specific strength as compared to the other mentioned materials [2-7].

Nowadays, titanium and its alloys are broadly used in various industries. Some positive properties such as low density, high specific strength, low elastic modulus, excellent corrosion resistance, excellent biocompatibility, durability at elevated temperatures, acceptable castability and good weldability make titanium one of the most favorable and usable metals in the automotive industry, aerospace and biomedical as orthopedic and dental implants [2,8,9]. One of the improving methods of the mechanical properties is to add alloying elements to the metals such as titanium with hexagonal close packed (HCP) crystal system [10]. The Ti-6Al-4V alloy is one of the most prevalent and applicable alloys of titanium which has a significant percentage of aluminum (Al) and vanadium (V) [2,9]. It has been proved that these elements similar to some other alloying elements such as nickel (Ni), cobalt (Co), chrome (Cr) are toxic and by ion releasing in a long term cause neuropathy diseases, Alzheimer disease, carcinogenicity, dermatitis and osteomalacia [9,11]. Therefore, the demand for replacing the commercially pure titanium (CP-Ti), in which the amount of alloying elements is negligible and also has lower cost, instead of titanium alloys in biomedical applications is increasing [9,12]. The main disadvantage of the CP-Ti is its low mechanical strength as compared to the titanium alloys such as Ti-6Al-4V. In fact, this disadvantage is one of the most primary reasons for not widespread using in different industries, which leads to using titanium alloys instead of the CP-Ti [2].

In accordance with the Hall-Petch equation (Eq. (1)), in crystalline materials for example metals, the yield stress, as a criterion for the strength of polycrystalline materials, increases dramatically by grain refinement [13]

σy=σ0+kyd-1/2 (1)

where σy is the yield stress, σ0 is the friction stress, ky is the constant of yielding, and d is the grain size.

Severe plastic deformation (SPD) is known as one of the most important and common techniques in order to significantly reduce the gain size as well as to achieve bulk UFG/NC materials [14-16]. In this technique, grain sizes in sub-micrometer and nanometer ranges are generated via applying high strains on coarse-grained (CG) materials, producing a high density of dislocations together with re-arranging them to form new grain boundaries. Consequently, the static and dynamic strengths of the material increase intensively [13,14]. The enhancements of the corrosion resistance and biocompatibility [17-19], wear resistance [20,21], materials adhesion capability to living cells and their proliferation [13,22,23] are some benefits of the use of UFG/NC materials in the biomedical sciences.

Among methods of the SPD, the equal channel angular pressing (ECAP) is one of the most effective and applicable techniques [13,24,25]. This process introduced by SEGAL et al [26], can produce relatively large work-piece of homogeneous UFG/NC structures with high angle grain boundary in a reasonable geometry using simple tools [13,25,27]. During the ECAP process, a metallic sample is pressed through an intersecting channel with the same cross-sections and the material is subjected to a simple shear stress and an intense plastic strain is applied to the material as a result. The angle between two channels (die angle) and the fillet angle (corner angle) are defined by φ and ψ, respectively [28]. Because the billet cross-section does not change after the process, it is possible to repeat the process on that billet in different routes of A, BA, BC and C. Each repetition is called a pass. The applied equivalent strain (εeq) after N passes of the ECAP is expressed by Eq. (2) [13,29,30]:

(2)

(2)

Metals and alloys with HCP crystal system such as titanium (Ti) and magnesium (Mg) as well as age-hardenable alloys such as aluminum 7075 demonstrate little ductility especially at room and low temperatures due to the limited number of independent slip systems. These alloys are categorized as difficult-to-work alloys [31-34]. If cold work, e.g., ECAP at low temperatures, is applied on these alloys, the cracking and segmentation will occur due to the material unstable flow [31,34,35]. The conducted researches on applying the ECAP process on these alloys indicate that the mentioned problems could be resolved by increasing the die angle and processing temperature, decreasing pressing speed, using back pressure and controlled annealing [13,33,34,36,37].

Titanium and its alloys, similar to the other HCP metals, are very difficult to have plastic deformation at room temperature. Therefore, Ti billets require to be ECAPed at relatively high temperatures, i.e., 473-863 K, to reduce the deformation resistance [38,39]. Several researches have been carried out to fabricate the UFG CP-Ti at high temperatures [40-44]. Since the plastic deformation at room temperature (cold work) suppresses the recrystallization and grain growth [45], the ECAP at room temperature as compared to high temperatures is more effective for refining the grain size to UFG/NC scale and is also more convenient in operation. Hence, it is tried to obtain the UFG/NC CP-Ti at room temperature by modifying and conditions changing in the ECAP process [13,46].

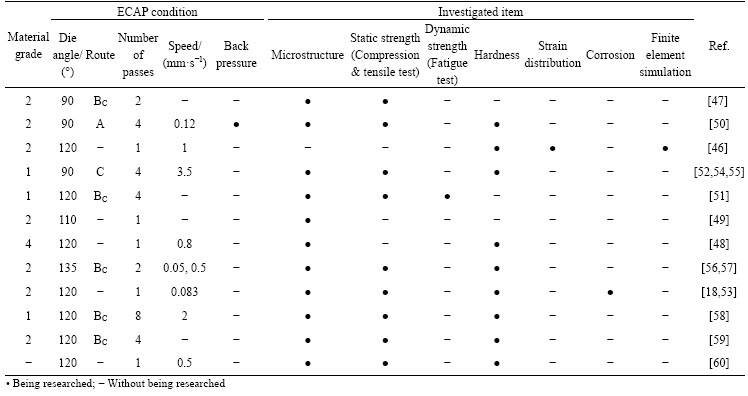

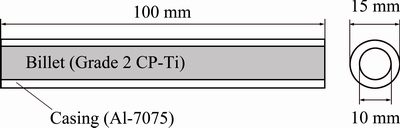

A few investigations have been conducted on applying the ECAP process on the CP-Ti at room temperature (see Table 1), which merely include evaluating the microstructure of UFG CP-Ti fabricated using the ECAP [47-49] and also investigation of the mechanical behavior of material including tensile and compression behaviors [47,50], fatigue behavior [51], hardness [46,50] and the hardness homogeneity [52]. In these studies, the static and dynamic strengths as well as the material hardness have been enhanced significantly. The corrosion resistance of the produced UFG CP-Ti via the ECAP has also been investigated and the improvement of the corrosion behavior has been observed [18,53]. Recently, in order to analyze the workability of the CP-Ti during the ECAP, the finite element simulation has been used and the optimal workpiece geometry for the ECAP at room temperature has been designed by investigation of damage factor and strain rate distribution [46]. Table 1 shows a summary of the studies carried out on ECAP process on the CP-Ti at room temperature. The CP-Ti grade, ECAP conditions and the investigated items are shown.

In most studies on the applying of ECAP process on CP-Ti at room temperature, the static mechanical properties such as the tensile and compression strengths and the hardness of UFG CP-Ti have been investigated as some of the most important properties of biomaterials and no study has been devoted to understanding of the ductility of material and fracture energy. In this study, the Grade 2 CP-Ti was deformed by an ECAP process for 3 passes without cracking at the BC route and room temperature. To study the ductility of the UFG CP-Ti, tensile, three-point bending and Charpy impact tests were performed.

Table 1 Summary of ECAP processing of CP-Ti at room temperature

2 Experimental

2.1 Materials

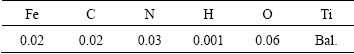

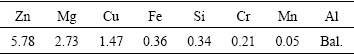

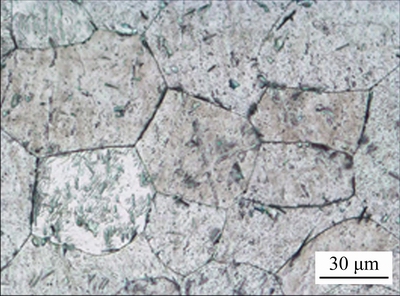

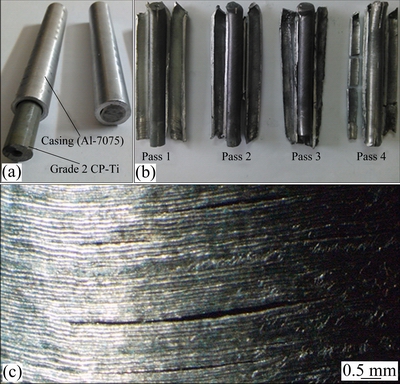

The material used in the present study is a bimetallic workpiece. The reduction of the pressing load, enhancement of mechanical properties, increasing of deformation homogeneity and uniformity of the effective strain distribution are the reasons for using the bimetallic specimen [32,61]. The Grade 2 CP-Ti rods, as a core or billet material, are inserted into casings made of Al-7075 with an interference fit. The schematic view and dimensions of the bimetallic specimen are shown in Fig. 1. The chemical compositions of the CP-Ti (Grade 2) and Al-7075 alloys obtained by the emission spectrometry method are also listed in Tables 2 and 3, respectively. To stabilize the microstructure, obtain the microstructure homogeneity and remove all residual stresses [47], the CP-Ti is annealed at 800 °C for 1 h and cooled in air in the shut-off furnace [62]. Al-7075 is also annealed at 415 °C for 1 h and cooled outside the furnace [32]. An equiaxed microstructure with an average coarse grain (CG) size of ~55 μm, is obtained using the described procedure, as shown in Fig. 2.

Table 2 Chemical composition of Grade 2 CP-Ti (mass fraction, %)

Table 3 Chemical composition of Al-7075 alloy (mass fraction, %)

Fig. 1 Schematic illustration and dimensions of bimetallic rod specimen for ECAP

Fig. 2 Optical microstructure of CP-Ti after annealing

2.2 ECAP process

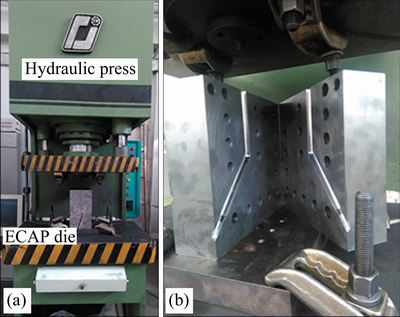

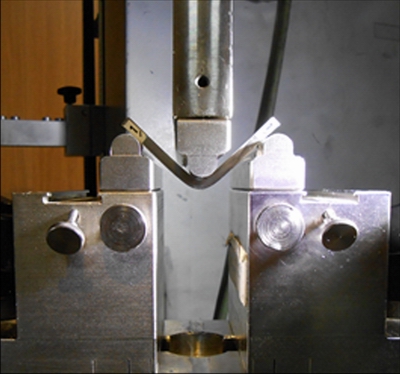

The ECAP processing at room temperature is conducted using a hydraulic press with a nominal capacity of 60 t at a ram speed of 9 mm/s. To perform the ECAP process, a die with a circular cross-section, a channel diameter of 15 mm, a channel angle of 135° and a corner angle of 20° is used. It can be proved from Eq. (2) that a strain of ~0.46 is imposed on the bimetallic specimen for each separate pass. Figure 3 shows the used ECAP process die and its set-up. To reduce the friction force between the specimen and the die wall, a lubricant, with the trade name of MOLYKOTE 1000 PASTE (Copper, graphite and white solids) is used. Firstly, the specimens are processed for 4 passes using the ECAP route BC [63] in which the specimen is rotated 90° in the same direction at each pass. This processing route is selected because it leads to the most expeditious formation of the homogeneous and reasonably equiaxed UFG/NC microstructures with a majority of grain boundaries having high angles of misorientation [64,65]. After removing the Al-7075 casings from titanium billets by sawing, cracks are observed on the upper surface of titanium billet in the 4th pass. To produce the UFG specimens without any defects and cracking, all the bimetallic specimens are pressed for 3 passes with BC route at room temperature and all the following experimental tests on the un-ECAPed/ECAPed specimens are performed for passes 1 to 3. Figure 4 depicts the bimetallic specimens before and after the ECAP process and also the optical macroscopic image of the surface cracks in the 4th pass. In order to observe the surface cracks, the Olympus SZX9 optical microscope is used.

Fig. 3 Hydraulic press set-up (a) and ECAP die with channel angle (φ) of 135° and corner angle (ψ) of 20°(b)

2.3 Experimental tests

In order to investigate the mechanical properties of CG/UFG CP-Ti, the tensile, three-point bending, Charpy impact and Vickers microhardness tests are conducted. The microstructure evaluation and comparison of the grain size are also performed on the un-ECAPed and ECAPed samples.

Fig. 4 Bimetallic specimens before ECAP process (a), after ECAP process (b), and optical macroscopic image of surface cracks after 4th pass ECAP (c)

To investigate the microstructural changes of pure titanium before and after ECAP and grain refinement confirmation, the Olympus BX60M optical microscope (OM) and LEO 1450VP scanning electron microscope (SEM) with the voltage of 20 kV are used. The metallographic samples for microstructure analysis are cut from the center of the ECAP billets and perpendicular to the pressing direction. Afterwards, they are ground using 100, 400, 600, 1000, 1200 and 2000 grit SiC papers and then automatically polished to mirror-like finishes with mechanical polishing using 0.3 μm alumina. These areas are then etched to reveal the grain boundaries via immersing in a solution containing 2 mL HF, 5 mL H2O2 (35%) and 100 mL water up to 70 s. The average grain size is determined by the line intercept method and using image analysis software MIP (Microstructural Image Processing) according to ASTM E 112-96 standard from the obtained microstructural images.

The mechanical strengths of CG and UFG CP-Ti are characterized by uniaxial tension test on a Zwick-Z250 universal testing machine. The round tension test specimens are machined from the center of billet when the longitudinal axes are set parallel to the ECAP pressing direction. The tensile test is carried out according to the ASTM E 8M-00 standard on the small-size specimens with the gage length, effective diameter, radius of fillet and length of reduced section of 30, 6, 6 and 36 mm, respectively. Each specimen is pulled to failure in tension at room temperature and a constant rate of cross-head displacement at an initial strain rate of 0.001 s-1 [51,56]. These tests are used to determine the yield strength (σy), the ultimate tensile strength (σu) and elongation to failure (δ) of CG and UFG CP-Ti. The values of the Vickers microhardness (HV) at the center of studied sections are measured using a Buehler microhardness tester with a load of 9.8 N and a dwell time of 15 s according to ASTM E 92 standard. To achieve a high degree of accuracy, each reported microhardness datum is at least the average of five separate measurements.

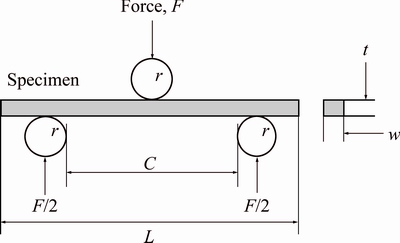

According to the ASTM E 290-97a standard, the bending test is a simple way to evaluate the quality of materials and their ability during continuous bend. In this test, the material ability in resisting against the cracking or other surface irregularities is investigated. The three-point bending test is made by supporting the specimen on radiused supports and applying a force through a plunger midway between two supports until the desired bend is formed. In Fig. 5, the C, r, t, w, L and F are the distance between the lower supports, radius of the end of plunger, beam specimen thickness, beam specimen width, beam length and applied load, respectively. The values of C, r, t, w and L are 43, 5, 3.8, 5 and 75 mm, respectively.

Fig. 5 Schematic fixture for three-point bending test

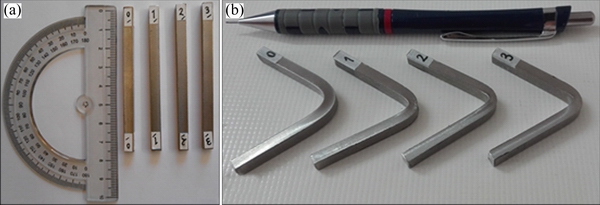

In this study, the bending specimens with the length of 75 mm, width of 5 mm and thickness of 3.8 mm are made using the un-ECAPed and ECAPed billets processed through 1, 2 and 3 passes. Three-point bending tests are performed on a Zwick-Z250 universal testing machine using a cross-head velocity of 1 mm/min [66] at room temperature in according with the ASTM E 290-97a standard. The three-point bending set-up is shown in Fig. 6. Figure 7 illustrates the bending specimens before and after the bending test.

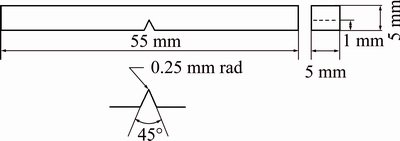

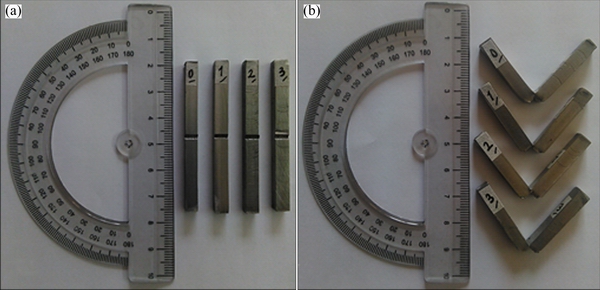

The impact toughness of the CG/UFG CP-Ti is evaluated by measuring the total absorbed energy using Charpy impact test before and after 1, 2 and 3 passes of ECAP process. Charpy V-notch test specimens are prepared according to ASTM E 23-02a standard and machined from the center of ECAP billets with longitudinal axes set parallel to the process direction. The size of the test specimens is 5 mm × 5 mm in cross-section and 55 mm in length, with a V-notch in the middle of specimen. A 45° groove is machined on the longitudinal plane in the middle of the specimen with a depth of 1 mm and a radius of 0.25 mm at the root. Schematic geometry and dimensions of Charpy impact test are demonstrated in Fig. 8. The impact test is conducted at room temperature on a Charpy impact test machine including software for measuring the absorbed energy of the materials with the maximum capacity of 200 J. Each impact experiment is also repeated on three subsequent specimens. Figure 9 shows the specimens before and after Charpy impact test. Fracture surfaces of specimens after impact test are examined using Olympus SZX9 optical microscope.

Fig. 6 Set-up for three-point bending test

Fig. 7 Appearance of bending specimens before (a) and after (b) three-point bending test

Fig. 8 Schematic geometry and dimensions of Charpy impact test specimens

3 Results and discussion

3.1 Microstructure

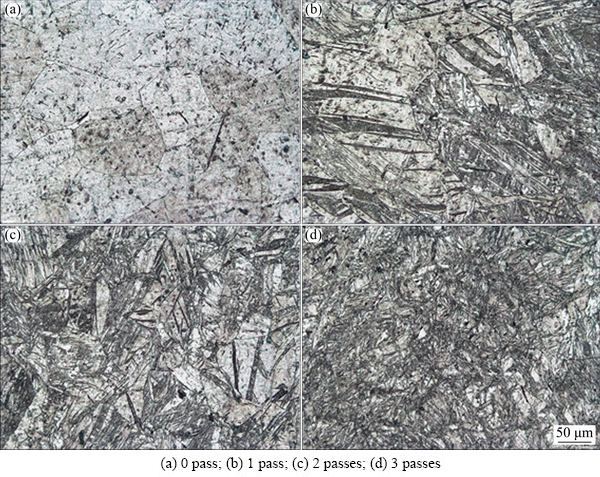

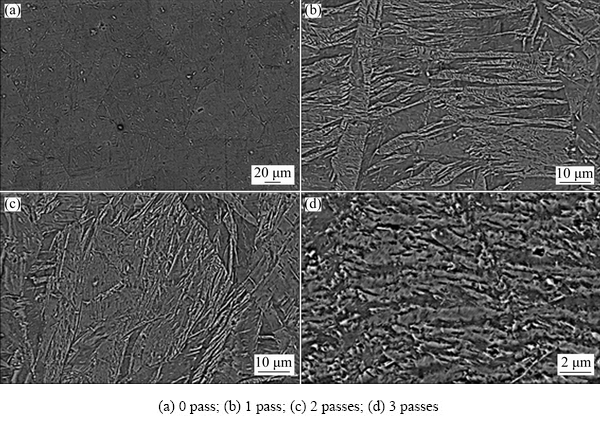

The microstructures of the Grade 2 CP-Ti before and after applying the ECAP process for 3 passes are presented in Figs. 10 and 11 which are the images obtained by the optical microscope and electron microscope in the back scatter mode, respectively. These images clearly reveal the grain refinement and elongated microstructure due to the cold severe plastic deformation. The magnitude of the average grain size (d) evolved from 55 μm in the un-ECAPed material down to 11 μm, 3 μm and 650 nm after 1, 2 and 3 passes, respectively. It can be easily observed from Figs. 10 and 11 that the grains are refined with increasing the number of ECAP passes. Figure 10 shows the OM images of the CG and UFG CP-Ti, which demonstrates the microstructures consisting of closely equiaxed and elongated grains. During the ECAP process, pure shear deformation is imposed on the grains which are elongated along the direction of pure shear line in the intersection of channels. It can be observed from Figs. 10 and 11 that the cold severe plastic deformation refines the initial microstructures and causes a large number of twins and macro-twins in grains. The direction of these twins is closely parallel to the elongation direction of the material [49,59]. Furthermore, it has been observed that by applying the ECAP process at room temperature a high density of dislocations and twins are formed, which lead to the significant improvement of mechanical properties of the material [60]. After the first pass, parallel shear bands containing high densities of dislocations, more complex bands in the intersection of two different directions and high density of twins lying parallel to the elongated microstructure are generated. The development of low-angle grain boundaries (LAGBs) to high-angle grain boundaries (HAGBs) occurs after a single pass in HCP metals like pure titanium [13,54,58,67]. After more passes, a complex banded structure is formed and the elongated and coarse grains do not get longer as the number of passes increases. In fact, by increasing the number of passes, the uniform microstructures without banded structures are produced [54,58].

Fig. 9 Appearance of specimens before (a) and after (b) Charpy impact test

Fig. 10 OM images showing microstructures before and after ECAP process

Fig. 11 SEM images of specimens before and after ECAP process

3.2 Tensile strength

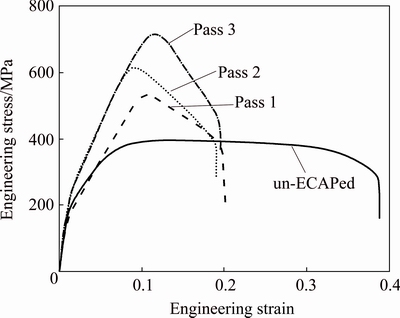

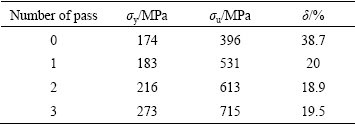

All of the tensile samples are tested in tension to failure at room temperature. The engineering stress- strain curves of the un-ECAPed and ECAPed CP-Ti covered with Al-7075 tube are shown in Fig. 12. The magnitudes of yield (σy) and ultimate (σu) tensile strength and elongation to failure (δ) for unpressed and pressed samples for 3 passes by route BC are listed in Table 4. As it can be observed, a significant enhancement in the tensile strength is obtained for the first pass and the elongation decreases. In the second and third passes, the strength increases gradually, but the elongation remains nearly constant. In general, after 3 passes by ECAP, a significant increase in the values of yield tensile strength by 57% from 174 to 273 MPa, and ultimate tensile strength by 81% from 396 to 715 MPa is obtained. There is also reasonable ductility of 19.5% elongation to failure after 3 passes as compared to 38.7% in the un-ECAPed CP-Ti. These results confirm that there are excellent strengthening and also reasonable ductility after ECAP process. Moreover, the results are in good agreement with previous studies [8,54,56,58,60,67]. The improvement of the mechanical properties of UFG structured metals, such as tensile strength and microhardness, is due to applying the ECAP process. Generally, by imposing the SPD process, the ultra-fined grains and the high fraction of homogeneous equiaxed microstructures and grain boundaries with high angles of misorientation are produced, which lead to the enhancement of static and dynamic mechanical properties of metals and alloys [13,60,68]. Moreover, using ECAP process at ambient temperature increases the densities of dislocation and twins and also strain hardening rate. Hence, the static mechanical properties of CP-Ti such as tensile and bending strengths and hardness are enhanced remarkably [60].

Fig. 12 Engineering stress-strain curves for un-ECAPed and ECAPed CP-Ti samples for 1-3 passes

Table 4 Tensile properties of un-ECAPed and ECAPed CP-Ti samples for 1-3 passes

3.3 Vickers microhardness

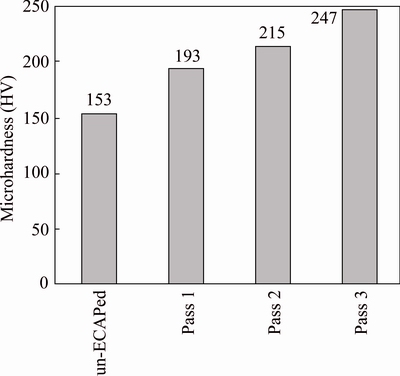

Vickers microhardness measurements are performed on the Grade 2 CP-Ti billets before and after the ECAP process. These tests are carried out on the cross-sectional surface of the ECAP samples after 1-3 passes. The effect of pass number on average Vickers microhardness of the ECAP processed CP-Ti samples by route BC is represented in Fig. 13. In the present investigation, an increase in Vickers microhardness from HV 153 to HV 193, HV 215 and HV 247 after 1, 2 and 3 passes of ECAP is obtained, respectively. Generally, the results of the present study are consistent with the earlier reports [56,58,60]. It is seen that the microhardness of Grade 2 CP-Ti is increased significantly after 1 pass of ECAP process and increasing the pass number leads to the improvement of the hardness value. These superior properties achieved after 3 passes of ECAP process at room temperature reveal that increasing the densities of dislocation and twins is due to the cold-work SPD process and also the increasing of strain rate of hardening [60].

Fig. 13 Average Vickers microhardness for un-ECAPed and ECAPed Grade 2 CP-Ti specimens through 1-3 passes

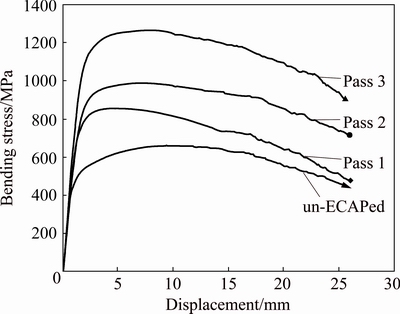

3.4 Bending strength

In order to investigate the bending strength and ductility of Grade 2 CP-Ti specimens before and after the ECAP process, three-point bending test is carried out at room temperature. The bending stress-displacement curves of un-ECAPed and ECAPed specimens for 1-3 passes at the displacement velocity of 1 mm/min under three-point bending condition are displayed in Fig. 14. To compare the bending strength, the displacement value is considered constant and equal to 26 mm for all specimens. Figure 14 shows that the required load for the three-point bending test of bending samples and the normal stress due to the bending increase by applying the ECAP process and the number of passes. The values of 427, 756, 749 and 957 MPa represent the bending yield strength and the values of 664, 867, 995 and 1275 MPa denote the values of the bending ultimate strength of the un-ECAPed and ECAPed material for the first to third pass, respectively. In addition to the tensile strength, the bending strength is also enhanced significantly which can be attributed to the grain refinement, evolution into an array of high-angle grain boundaries and the growing densities of dislocation and twins [13,60].

Fig. 14 Bending stress-displacement curves of un-ECAPed and ECAPed Grade 2 CP-Ti specimens for 1-3 passes

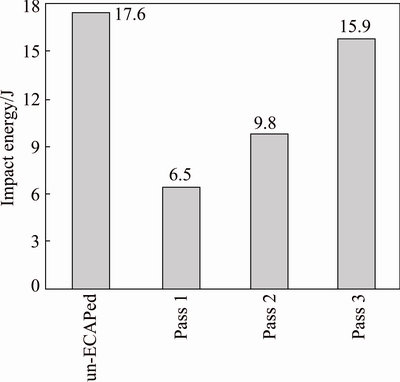

3.5 Charpy impact energy

The amount of the absorbed energy in the impact test can indicate the impact toughness [5]. Fracture and impact-toughness behaviors of metallic alloys are important factors in ensuring the safety of the selected material in structural applications [4].

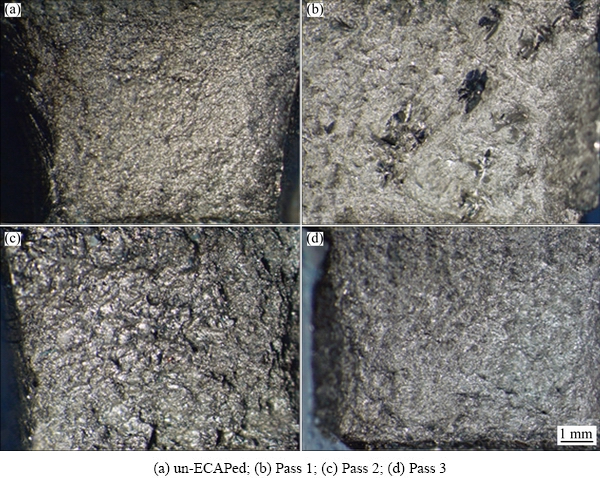

In the current study, the Charpy impact test is conducted on the CG and UFG CP-Ti processed by cold ECAP through 1-3 passes. The impact energy of these materials is 17.6, 6.5, 9.8 and 15.9 J for CP-Ti after 0-3 passes, respectively. It is apparent from the obtained results that the impact energy of CG Ti is higher than that of the UFG CP-Ti. The CP-Ti after the first pass of ECAP exhibits the least energy, however, by increasing the number of passes the impact energy is enhanced, as shown in Fig. 15. Moreover, the impact energy of CP-Ti after 3 passes is nearly equal to that of un-ECAPed material. Hence, the impact energy of CP-Ti can be remained almost constant in higher passes at room temperature. In fact, after the first pass, the strength of material increases and the elongation decreases, significantly. For the next passes, although the strength is enhanced more, the elongation does not change significantly [59]. The area under the stress-strain curve can be a good criterion for the amount of the absorbed impact energy which is more in the un-ECAPed CP-Ti compared to the ECAPed CP-Ti because of the greater elongation, as shown in Fig. 15. Moreover, by increasing the number of ECAP passes, the ultimate strength increases and the elongation remains almost constant, as show in Fig. 12. In three-pass ECAPed specimen, the impact energy is nearly equal to that of the un-ECAPed specimen. This shows that by applying the ECAP process on the CP-Ti, the strength increases while the impact energy does not have significant variations compared to the un-ECAPed material. The macroscopic images of the fracture surfaces of Charpy impact test samples are shown in Fig. 16. It is seen that the un-ECAPed specimen is fractured in a ductile manner. However, the fracture surface of the ECAPed samples in the first pass is a typical brittle fracture surface. These images signify brittle to ductile transition on the fracture surface of ECAPed CP-Ti through 0-3 passes.

Fig. 15 Impact energy of Grade 2 CP-Ti before and after ECAP process up to 3 passes

Fig. 16 Macroscopic images of fracture surfaces of CP-Ti in Charpy impact test

4 Conclusions

1) The Grade 2 CP-Ti is successfully processed through up to 3 passes by the ECAP process at room temperature using a die with a channel angle of 135° in the route BC. Because fine cracks are visible on the upper surface of the billet after the 4th pass, all of the tests are performed on the ECAPed billet for 3 passes.

2) The grain size of the CP-Ti decreases from ~55 μm under the un-ECAPed condition to ~11 μm, 3 μm and 650 nm after 1, 2 and 3 passes of the ECAP, respectively.

3) Both of the yield and ultimate tensile strengths in the billet processed by ECAP are enhanced as compared to the un-ECAPed CP-Ti. However, the elongation to failure of ECAPed materials decreases. For the first to the third ECAP, the elongation is nearly constant. Actually, by applying the first pass of ECAP, the elongation decreases and by increasing the number of passes up to 3 passes, the elongation variations are negligible.

4) The Vickers microhardness considerably increases by increasing the pass number.

5) The results of the three-point bending test show that the yield and ultimate bending strengths increase significantly by increasing the number of ECAP passes. This fact indicates that the ductility and resistance against the bending can be dramatically enhanced by applying the ECAP process on the CP-Ti. It should be noticed that the bending strength of the ECAPed CP-Ti has not been investigated so far.

6) After performing the Charpy impact, it is understood that the absorbed energy to fracture decreases significantly by applying the first pass of the ECAP, but by increasing the number of passes, the fracture toughness increases. In the third pass, the fracture toughness is almost equal to that of the un-ECAPed material. The results of the impact test reveal that by applying the ECAP process in the higher passes, it is possible to keep the fracture toughness constant and even to improve it. The study of the resistance against the impact of ECAPed CP-Ti has also not been performed yet.

References

[1] RAMAKRISHNA S, MAYER J, WINTERMANTEL E, LEONG K W. Biomedical applications of polymer-composite materials: A review [J]. Composites Science and Technology, 2001, 61(9): 1189-1224.

[2] GEETHA M, SINGH A K, ASOKAMANI R, GOGIA A K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review [J]. Progress in Materials Science, 2009, 54(3): 397-425.

[3] NIINOMI M, NAKAI M, HIEDA J. Development of new metallic alloys for biomedical applications [J]. Acta Biomaterialia, 2012, 8(11): 3888-3903.

[4] MEDVEDEV A E, NG H P, LAPOVOK R, ESTRIN Y, LOWE T C, ANUMALASETTY V N. Effect of bulk microstructure of commercially pure titanium on surface characteristics and fatigue properties after surface modification by sand blasting and acid-etching [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 57: 55-68.

[5] WANG C T, GAO N, GEE M G, WOOD R J K, LANGDON T G. Processing of an ultrafine-grained titanium by high-pressure torsion: An evaluation of the wear properties with and without a TiN coating [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 17: 166-175.

[6] GHAFARI-GOUSHEH S, NEDJAD S H, KHALIL-ALLAFI J. Tensile properties and interfacial bonding of multi-layered, high-purity titanium strips fabricated by ARB process [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 51: 147-153.

[7] BYELI A V, KUKAREKO V A, KONONOV A G. Titanium and zirconium based alloys modified by intensive plastic deformation and nitrogen ion implantation for biocompatible implants [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2012, 6: 89-94.

[8] RACK H J, QAZI J I. Titanium alloys for biomedical applications [J]. Materials Science and Engineering C, 2006, 26(8): 1269-1277.

[9] ROODPOSHTI P S, FARAHBAKHSH N, SARKAR A, MURTY K L. Microstructural approach to equal channel angular processing of commercially pure titanium—A review [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1353-1366.

[10] ZIAEI S, ZIKRY M A. Modeling the effects of dislocation–density interaction, generation, and recovery on the behavior of HCP materials [J]. Metallurgical and Materials Transactions A, 2015, 46(10): 4478-4490.

[11] NAG S, BANERJEE R, FRASER H L. Microstructural evolution and strengthening mechanisms in Ti-Nb-Zr-Ta, Ti-Mo-Zr-Fe and Ti-15Mo biocompatible alloys [J]. Materials Science and Engineering C, 2005, 25(3): 357-362.

[12] CHEN Y J, LI Y J, WALMSLEY J C, DUMOULIN S, SKARET P C, ROVEN H J. Microstructure evolution of commercial pure titanium during equal channel angular pressing [J]. Materials Science and Engineering A, 2010, 527(3): 789-796.

[13] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement [J]. Progress in Materials Science, 2006, 51(7): 881-981.

[14] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Progress in Materials Science, 2000, 45(2): 103-189.

[15] WANG C, LI F, CHEN B, YUAN Z, LU H. Severe plastic deformation techniques for bulk ultrafine-grained materials [J]. Rare Metal Materials and Engineering, 2012, 41(6): 941-946.

[16] LANGDON T G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement [J]. Acta Materialia, 2013, 61(19): 7035-7059.

[17] KIM T N, BALAKRISHNAN A, LEE B C, KIM W S, SMETANA K, PARK J K, PANIGRAHI B B. In vitro biocompatibility of equal channel angular processed (ECAP) titanium [J]. Biomedical Materials, 2007, 2(3): s117-s120.

[18] MENDES FILHO A A, ROVERE C A, KURI S E, SORDI V L, FERRANTE M. A general study of commercially pure Ti subjected to severe plastic deformation: Microstructure, strength and corrosion resistance [J]. Revista Materia, 2010, 15(2): 254-259.

[19] MALEKI-GHALEH H, HAJIZADEH K, HADJIZADEH A, SHAKERI M S, GHOBADI ALAMDARI S, MASOUDFAR S, AGHAIE E, JAVIDI M, ZDUNEK J, KURZYDLOWSKI K J. Electrochemical and cellular behavior of ultrafine-grained titanium in vitro [J]. Materials Science and Engineering C, 2014, 39: 299-304.

[20] PURCEK G, SARAY O, KUL O, KARAMAN I, YAPICI G G, HAOUAOUI M, MAIER H J. Mechanical and wear properties of ultrafine-grained pure Ti produced by multi-pass equal-channel angular extrusion [J]. Materials Science and Engineering A, 2009, 517(1): 97-104.

[21] CHERTOVSKIKH S V. Cuttability of UFG titanium BT1-0 obtained by ECAE [J]. Russian Engineering Research, 2007, 27(5): 260-264.

[22] ESTRIN Y, KASPER C, DIEDERICHS S, LAPOVOK R. Accelerated growth of preosteoblastic cells on ultrafine grained titanium [J]. Journal of Biomedical Materials Research: Part A, 2009, 90(4): 1239-1242.

[23] VALIEV R Z, SEMENOVA I P, LATYSH V V, RACK H, LOWE T C, PETRUZELKA J, DLUHOS L, HRUSAK D, SOCHOVA J. Nanostructured titanium for biomedical applications [J]. Advanced Engineering Materials, 2008, 10(8): B15-B17.

[24] SEGAL V M. Equal channel angular extrusion: from macromechanics to structure formation [J]. Materials Science and Engineering A, 1999, 271(1): 322-333.

[25] HORITA Z, FUJINAMI T, LANGDON T G. The potential for scaling ECAP: Effect of sample size on grain refinement and mechanical properties [J]. Materials Science and Engineering A, 2001, 318(1): 34-41.

[26] SEGAL V M, REZNIKOV V I, DROBYSHEVSKII A E, KOPYLOV V I. Plastic working of metals by simple shear [J]. Russian Metallurgy, 1981(1): 99-105.

[27] KIM I, JEONG W S, KIM J, PARK K T, SHIN D H. Deformation structures of pure Ti produced by equal channel angular pressing [J]. Scripta Materialia, 2001, 45(5): 575-580.

[28] FURUKAWA M, IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON T G. The shearing characteristics associated with equal-channel angular pressing [J]. Materials Science and Engineering A, 1998, 257(2): 328-332.

[29] BEYERLEIN I J,  C N. Analytical modeling of material flow in equal channel angular extrusion (ECAE) [J]. Materials Science and Engineering A, 2004, 380(1): 171-190.

C N. Analytical modeling of material flow in equal channel angular extrusion (ECAE) [J]. Materials Science and Engineering A, 2004, 380(1): 171-190.

[30] KIM W J, NAMKUNG J C. Computational analysis of effect of route on strain uniformity in equal channel angular extrusion [J]. Materials Science and Engineering A, 2005, 412(1): 287-297.

[31] ROSHAN M R, JAHROMI S A J, EBRAHIMI R. Predicting the critical pre-aging time in ECAP processing of age-hardenable aluminum alloys [J]. Journal of Alloys and Compounds, 2011, 509(30): 7833-7839.

[32] SHAERI M H, DJAVANROODI F, SEDIGHI M, AHMADI S, SALEHI M T, SEYYEDEIN S H. Effect of copper tube casing on strain distribution and mechanical properties of Al-7075 alloy processed by equal channel angular pressing [J]. The Journal of Strain Analysis for Engineering Design, 2013, 48(8): 512-521.

[33] FIGUEIREDO R B, CETLIN P R, LANGDON T G. The processing of difficult-to-work alloys by ECAP with an emphasis on magnesium alloys [J]. Acta Materialia, 2007, 55(14): 4769-4779.

[34] SEMIATIN S L, DELO D P, SEGAL V M, GOFORTH R E, FREY N D. Workability of commercial-purity titanium and 4340 steel during equal channel angular extrusion at cold-working temperatures [J]. Metallurgical and Materials Transactions A, 1999, 30(5): 1425-1435.

[35] CETLIN P R, AGUILAR M T P, FIGUEIREDO R B, LANGDON T G. Avoiding cracks and inhomogeneities in billets processed by ECAP [J]. Journal of Materials Science, 2010, 45(17): 4561-4570.

[36] KRASIL NIKOV N A. Strength and ductility of copper subjected to equal-channel angular pressing with backpressure [J]. Russian Metallurgy, 2005, 3: 220-226.

[37] KIM W J, WANG J Y. Microstructure of the post-ECAP aging processed 6061 Al alloys [J]. Materials Science and Engineering A, 2007, 464(1): 23-27.

[38] LUO P, MCDONALD D T, ZHU S M, PALANISAMY S, DARGUSCH M S, XIA K. Analysis of microstructure and strengthening in pure titanium recycled from machining chips by equal channel angular pressing using electron backscatter diffraction [J]. Materials Science and Engineering A, 2012, 538(2): 252-258.

[39] KIM I, KIM J, SHIN D H, LEE C S, HWANG S K. Effects of equal channel angular pressing temperature on deformation structures of pure Ti [J]. Materials Science and Engineering A, 2003, 342(1): 302-310.

[40] MEDVEDEV A, NG H P, LAPOVOK R, ESTRIN Y, LOWE T C, ANUMALASETTY V N. Comparison of laboratory-scale and industrial-scale equal channel angular pressing of commercial purity titanium [J]. Materials Letters, 2015, 145: 308-311.

[41] ZHANG S, WANG Y C, ZHILYAEV A P, GUNDEROV D V, LI S, RAAB G I, KORZNIKOVA E, LANGDON T G. Effect of temperature on microstructural stabilization and mechanical properties in the dynamic testing of nanocrystalline pure Ti [J]. Materials Science and Engineering A, 2015, 634(1): 64-70.

[42] MATYKINA E, ARRABAL R, VALIEV R Z, MOLINA-ALDAREGUIA J M, BELOV P, SABIROV I. Electrochemical anisotropy of nanostructured titanium for biomedical implants [J]. Electrochimica Acta, 2015, 176: 1221-1232.

[43] MEREDITH C S, KHAN A S. The microstructural evolution and thermo-mechanical behavior of UFG Ti processed via equal channel angular pressing [J]. Journal of Materials Processing Technology, 2015, 219: 257-270.

[44] RODRIGUEZ-CALVILLO P, CABRERA J. Microstructure and mechanical properties of a commercially pure Ti processed by warm equal channel angular pressing [J]. Materials Science and Engineering A, 2015, 625(2): 311-320.

[45] PODOLSKIY A V, NG H P, PSARUK I A, TABACHNIKOVA E D, LAPOVOK R. Cryogenic equal channel angular pressing of commercially pure titanium: Microstructure and properties [J]. Journal of Materials Science, 2014, 49(19): 6803-6812.

[46] XIAOMEI W, YINJIA C, QICHEN H, AIYING C, XIANG L, FANG L, DENG P. Design of RT equal channel angular pressing pure titanium workpiece by finite element simulation [J]. Rare Metal Materials and Engineering, 2015, 44(5): 1082-1087.

[47] ZHANG S, WANG Y C, ZHILYAEV A P, KORZNIKOVA E, LI S, RAAB G I, LANGDON T G. Effect of grain size on compressive behaviour of titanium at different strain rates [J]. Materials Science and Engineering A, 2015, 645(2): 311-317.

[48] DHEDA S S, MOHAMED F A. Effect of initial microstructure on the processing of titanium using equal channel angular pressing [J]. Materials Science and Engineering A, 2011, 528(28): 8179-8186.

[49] CHEN Y J, LI Y J, XU X J, HJELEN J, ROVEN H J. Novel deformation structures of pure titanium induced by room temperature equal channel angular pressing [J]. Materials Letters, 2014, 117: 195-198.

[50]  Microstructure and anisotropy of the mechanical properties in commercially pure titanium after equal channel angular pressing with back pressure at room temperature [J]. Materials Science and Engineering A, 2015, 644(1): 114-120.

Microstructure and anisotropy of the mechanical properties in commercially pure titanium after equal channel angular pressing with back pressure at room temperature [J]. Materials Science and Engineering A, 2015, 644(1): 114-120.

[51] FIGUEIREDO R B, BARBOSA E R D C, ZHAO X, YANG X, LIU X, CETLIN P R, LANGDON T G. Improving the fatigue behavior of dental implants through processing commercial purity titanium by equal-channel angular pressing [J]. Materials Science and Engineering A, 2014, 619(2): 312-318.

[52] ZHAO X, YANG X, JIA J, QI B. The evolution of hardness homogeneity in commercially pure Ti processed by ECAP [J]. Journal of Wuhan University of Technology: Materials Science Edition, 2014, 29(3): 578-584.

[53] MENDES FILHO A A, SORDI V L, FERRANTE M. The effects of severe plastic deformation on some properties relevant to Ti implants [J]. Materials Research, 2012, 15(1): 27-31.

[54] ZHAO X, YANG X, LIU X, WANG C T, HUANG Y, LANGDON T G. Processing of commercial purity titanium by ECAP using a 90 degrees die at room temperature [J]. Materials Science and Engineering A, 2014, 607(2): 482-489.

[55] LIU X Y, ZHAO X C, YANG X R, XIE C, WANG G J. Compression deformation behaviours of ultrafine and coarse grained commercially pure titanium [J]. Materials Science and Technology, 2013, 29(4): 474-479.

[56] ZHANG Y, FIGUEIREDO R B, ALHAJERI S N, WANG J T, GAO N, LANGDON T G. Structure and mechanical properties of commercial purity titanium processed by ECAP at room temperature [J]. Materials Science and Engineering A, 2011, 528(25): 7708-7714.

[57] ZHANG Y, ALHAJERI S N, FIGUEIREDO R B, GAO N, WANG J T, LANGDON T G. Contribution of twins to the strengthening of commercial purity titanium after equal-channel angular pressing [J]. Materials Science Forum, 2011, 667-669: 719-724.

[58] ZHAO X, YANG X, LIU X, WANG X, LANGDON T G. The processing of pure titanium through multiple passes of ECAP at room temperature [J]. Materials Science and Engineering A, 2010, 527(23): 6335-6339.

[59] YANG X R, ZHAO X C, FU W J. Deformed microstructures and mechanical properties of CP-Ti processed by multi-pass ECAP at room temperature [J]. Rare Metal Materials and Engineering, 2009, 38(6): 955-957.

[60] ZHAO X, FU W, YANG X, LANGDON T G. Microstructure and properties of pure titanium processed by equal-channel angular pressing at room temperature [J]. Scripta Materialia, 2008, 59(5): 542-545.

[61] DJAVANROODI F, DANESHTALAB M, EBRAHIMI M. A novel technique to increase strain distribution homogeneity for ECAPed materials [J]. Materials Science and Engineering A, 2012, 535(1): 115-121.

[62] KIM W J, HYUN C Y, KIM H K. Fatigue strength of ultrafine-grained pure Ti after severe plastic deformation [J]. Scripta Materialia, 2006, 54(10): 1745-1750.

[63] WANG C T, FOX A G, LANGDON T G. Microstructural evolution in ultrafine-grained titanium processed by high-pressure torsion under different pressures [J]. Journal of Materials Science, 2014, 49(19): 6558-6564.

[64] STOLYAROV V V, ZHU Y T, ALEXANDROV I V, LOWE T C, VALIEV R Z. Influence of ECAP routes on the microstructure and properties of pure Ti [J]. Materials Science and Engineering A, 2001, 299(1): 59-67.

[65] ALHAJERI S N, GAO N, LANGDON T G. Hardness homogeneity on longitudinal and transverse sections of an aluminum alloy processed by ECAP [J]. Materials Science and Engineering A, 2011, 528(10): 3833-3840.

[66] KIM I K, HONG S I. Effect of component layer thickness on the bending behaviors of roll-bonded tri-layered Mg/Al/STS clad composites [J]. Materials & Design, 2013, 49: 935-944.

[67] LI Y, NG H P, JUNG H D, KIM H E, ESTRIN Y. Enhancement of mechanical properties of grade 4 titanium by equal channel angular pressing with billet encapsulation [J]. Materials Letters, 2014, 114: 144-147.

[68] VALIEV R. Nanostructuring of metals by severe plastic deformation for advanced properties [J]. Nature Materials, 2004, 3(8): 511-516.

Reza NASERI, Mehran KADKHODAYAN, Mahmoud SHARIATI

Department of Mechanical Engineering, Faculty of Engineering, Ferdowsi University of Mashhad, P. O. Box 9177948944, Mashhad, Iran

摘 要:等径角挤压是制备超细晶和纳米晶材料最有效的工艺之一。由于工业纯钛具有极佳的生物相容性,因此它可用作生物植入体材料。然而,较低的静/动态强度是纯钛类材料的不足之处。利用等径角挤压工艺可消除此类缺陷。本文作者在室温和通道角为135°条件下进行3道次挤压得到2级工业纯钛试样(2级CP-Ti)。对经等径角挤压3道次的CP-Ti样品进行显微组织分析及拉伸、硬度、三点弯曲和夏比冲击等力学性能测试。样品的显微组织演变结果表明,经等径角挤压工艺后样品的粗晶组织转变成超细晶或纳米晶组织。此外,力学性能测试结果表明,等径角挤压工艺能显著提高工业纯钛的屈服强度、抗拉强度、弯曲强度、硬度和断裂韧度,因此用该工艺制得的钛可以作为金属合金的替代品用作生物医用材料。

关键词:工业纯钛;等通道转角挤压;抗拉强度;弯曲强度;断裂韧度

(Edited by Wei-ping CHEN)

Corresponding author: Mehran KADKHODAYAN; Tel: +98-9153111869; E-mail: kadkhoda@um.ac.ir

DOI: 10.1016/S1003-6326(17)60221-8