文章编号:1004-0609(2016)-11-2440-09

罐式炉内石油焦煅烧过程的二维传热传质数学模型

肖 劲1, 2,黄金堤1, 2,张红亮1, 2,李 劼1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 难冶有色金属资源高效利用国家工程实验室,长沙 410083)

摘 要:建立24罐8层火道顺流式罐式炉温度场、残余挥发分浓度场的二维数学模型,模型中包含多孔介质渗流传热模型、固相活塞流模型、异相热解反应动力学模型及等效热流密度边界模型4个部分,并通过该模型研究罐式炉中石油焦热解传质传热过程。结果表明:在给定工况下,石油焦挥发分热解反应主要在二至五层火道高度对应的料罐内进行;在六至八层火道高度对应的料罐内,形成长度约为2.0 m的高温煅烧带(T>1423 K),满足石油焦进一步聚合并实现碳结构重排的煅烧温度要求。经生产数据对比验证表明:该模型基本能够反映炉内温度的分布情况,可为罐式炉的温度自动化调控提供一定的理论依据。

关键词:罐式炉;温度场;二维;高温煅烧带

中图分类号:TF806.1 文献标志码:A

石油焦是铝电解用炭素阳极的主要原料,石油焦的煅烧是阳极生产的首要工序。煅烧过程中,水分和挥发分排出,物料充分收缩、形成晶格,石油焦的物理化学性能显著提高。因此,煅烧质量的好坏,直接影响阳极质量[1]。目前,主要采用的石油焦煅烧设备为罐式炉(又称为罐式煅烧炉)和回转窑,前者因其能耗低、煅烧质量稳定、煅烧过程原料烧损低、煅烧热利用率高等优点成为近10年来中国铝用炭素工业中主要的石油焦煅烧设备[1-3]。

罐式炉中,每个煅烧罐(料罐)的左右两侧都有8层水平走向的加热火道,火焰不与原料直接接触,石油焦在整个煅烧过程都处于封闭的料罐内。实际生产中,采用非接触式红外测温仪或光电温度传感器测量火道温度,通过调节挥发分拉板,改变各层火道中的挥发分配比,间接控制罐内物料温度。然而,火道测量温度与料罐实际温度通常存在较大差异,易导致调节滞后,难以满足煅烧高质量石油焦的要求[4]。因此,使用计算机数值仿真技术[5-6],建立罐式炉煅烧石油焦过程中的传质传热数学模型,模拟计算罐式炉的温度和残余挥发分浓度分布,可实现对料罐内石油焦的温度变化和火道内挥发分析出情况的实时检测,为罐式炉自动化温度控制提供可靠理论依据和有效手段。

目前,对石油焦煅烧过程的数值模拟研究主要集中在炭素煅烧回转窑。MARTINS等[7]对炭素煅烧回转窑建立了一维温度场计算模型,对石油焦在回转窑中的热解过程及温度变化进行了数值模拟研究。王春华等[8]对回转窑内气体、料层进行了数值模拟,研究回转窑内速度场、温度场和组分浓度场的分布,着重研究了回转窑窑内的热工状态。ZHANG等[9]对回转窑的窑体倾角、空气入射角、石油焦各物性等多种因素进行了数值模拟,提出降低能耗的有效方案。相对于回转窑,目前对罐式炉煅烧过程仿真的研究较少。张忠霞等[10]和周善红等[11]对罐式炉火道气相燃烧及耐火砖、料罐固相区域的温度、压力分布进行仿真研究,对罐式炉炉体设计及优化具有一定的指导意义,但模型未考虑石油焦中水分、挥发分热解析出,无法充分反映炉内石油焦煅烧情况。

本文作者以24罐8层火道顺流式罐式炉煅烧石油焦过程为研究对象,针对罐式炉中石油焦热解反应[7]及气体渗流传质传热过程,建立包含多孔介质渗流传热模型、固相活塞流模型、异相热解反应动力学模型及等效热流密度边界模型的炉内温度场、残余挥发分浓度场的二维计算模型。使用生产经验数据[12]验证模型准确性,并利用该模型研究给定工况条件下罐式炉内温度及残余挥发分浓度的分布情况。

1 数学模型

石油焦煅烧过程模型作如下基本假设:

1) 料罐中的堆积石油焦为各向同性的多孔介质,满足连续介质条件[13];

2) 料罐中石油焦下移排料及静止过程交替进行,脉冲排料周期较短(<60 s),且石油焦自罐顶进料口到达罐底排料口的时间大于24 h,因此,可视为石油焦下移过程为连续运动;料罐的排料过程为罐内堆积石油焦在重力作用下的连续匀速向下运动[12],视为活塞流;由于气体渗流速度较低,可忽略气体对固相的作用力;气体为理想可压缩流体,在多孔介质中的流动为稳态低速非达西流[14];

3) 煅烧过程排料量、各层火道温度恒定[11],可视为稳态;

4) 料罐中的堆积石油焦多孔区域中固相颗粒层与气相流体之间不符合局部热平衡,即存在局部温差[13, 15];

5) 热解反应进程由化学反应速率控制,颗粒内外温度相同[13];

6) 火道中的热量传递方式以对流、热辐射为主,各层火道温度分布均匀[10-11];

7) 鉴于罐式炉结构对称及各组并行运行的特点,模型取一组料罐的四分之一区域进行模拟研究,忽略冷却水套区域[11],忽略长度方向(Y方向)的影响将几何结构简化为二维。

1.1 控制方程

模型分为料罐和炉体两个计算区域,通过建立的固相质量守恒、组分守恒、能量守恒方程来描述料罐中石油焦竖直下降运动和挥发分热解析出过程;采用气相质量守恒、动量守恒、组分守恒、能量守恒方程来描述料罐中析出的挥发分通过堆积石油焦层向上渗流传质传热过程。炉体区域通过能量守恒方程来描述由耐火砖(硅砖、耐火粘土砖)构成的非均质材料固相区域。

1.1.1 料罐区域固相控制方程

质量守恒方程:

(1)

(1)

式中:u、v分别为x、y方向上的运动速度。

石油焦运动按活塞流,因此,无需动量方程。

入口初始速度(vs0):

(2)

(2)

式中:ρs为密度;vs为速度;Qm为生焦的单位质量流量;Ac为料罐水平截面面积;Ri为生焦热解挥发质量源项;固相填充率α=1-εs;εs为堆积石油焦的空隙率。

石油焦中残余挥发分组分方程:

(3)

(3)

式中:Yi为i组分在石油焦中的残余质量分数;Ri为i组分热解反应的质量源项。

能量控制方程:

(4)

(4)

式中:λs,eff为等效导热系数;

;

; 为石油焦颗粒导热系数;

为石油焦颗粒导热系数; 为颗粒发射系数;dp为颗粒内孔直径[16];σ为Stefan-Boltzmann常数;T为温度;

为颗粒发射系数;dp为颗粒内孔直径[16];σ为Stefan-Boltzmann常数;T为温度; 为平均热容;Sh为热解能量源项;Qrad,sg为气固辐射换热能量源项;Qconv,sg为气固对流换热能量源项;下标s和g分别表示固相和气相。

为平均热容;Sh为热解能量源项;Qrad,sg为气固辐射换热能量源项;Qconv,sg为气固对流换热能量源项;下标s和g分别表示固相和气相。

1.1.2 炉体区域控制方程

能量控制方程:

(5)

(5)

式中: 为固相耐火砖的导热系数。

为固相耐火砖的导热系数。

1.1.3 料罐区域气相控制方程

质量守恒方程:

(6)

(6)

动量守恒方程:

(7)

(7)

式中:当动量方程为x方向时,f为ug,当动量方程为y方向时,f为vg; 为气相黏度系数;p为压力;g为重力加速度;Fd为多孔介质阻力源项,由Ergun方程[14]描述。

为气相黏度系数;p为压力;g为重力加速度;Fd为多孔介质阻力源项,由Ergun方程[14]描述。

(8)

(8)

组分守恒方程:

(9)

(9)

式中:Yg,i为气相中i组分质量分数;Dg,eff为气体有效扩散系数。

能量方程:

(10)

(10)

式中:气固辐射换热能量源项

;气固对流换热能量源项

;气固对流换热能量源项 ;ε′气固辐射黑度系数;λg,eff为气相有效导热系数[17];Sv为比表面积,

;ε′气固辐射黑度系数;λg,eff为气相有效导热系数[17];Sv为比表面积, ;dp为颗粒的内孔直径;

;dp为颗粒的内孔直径; 为气固对流换热系数,

为气固对流换热系数, 可由式(11)计算。

可由式(11)计算。

(11)

(11)

式中:Nu为Nusselt数;普朗特数 ;雷诺数

;雷诺数 。

。

1.2 生焦中水分蒸发及挥发分热解反应模型

随着料罐内物料温度的升高,生焦颗粒中的大分子团簇受热分解生成轻质气体,产生的水分、挥发分穿过石油焦孔隙析出。石油焦中挥发分的组成根据David的煤热解模型[17]思想,假定挥发分成分为CH4、H2、CO、N2[8],基于物料守恒[18]原理进行计算。

固定碳平衡方程:

(12)

(12)

元素平衡方程:

(13)

(13)

式中:Vloss为挥发分含量;mg,c为生焦质量;mc为煅后焦质量;Bj为j元素质量;Aij为i组分中j元素原子个数;mi为i组分质量;e为组分数。

焦中挥发分的析出量即固相与气相之间的物质组分质量交换源项见式(14),固相与气相热量交换源项见式(15)。

(14)

(14)

式中:ki为i组分反应速率动力学参数。

料罐中生焦热解反应引起的吸热:

(15)

(15)

式中:hi为i组分热解的标准焓值。

石油焦热解挥发过程的动力学过程遵循Arrhenius方程:

(16)

(16)

式中:Ai为指前因子;Ei为活化能;R为摩尔气体常数。

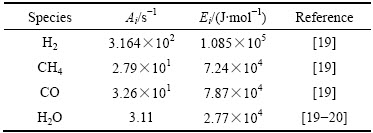

表1 生焦热解动力学参数

Table 1 Green coke pyrolysis kinetic parameters

1.3 燃烧火道壁面热量交换

由于烟气在火道中呈“Z”字形流动,各层火道温度分布基本一致[10],模型使用等效热流密度qw的第二类边界条件耦合火道壁面与高温烟气之间的热量传递。挥发分在火道中燃烧产生的热量根据物料守恒、能量守恒计算。

气相总质量守恒:

(17)

(17)

式中:Ai为反应物;Bj为生成物;nA为反应物数量;nB为生成物数量。

气相元素守恒:

,k=1,…,E (18)

,k=1,…,E (18)

气相能量守恒:

(19)

(19)

(20)

(20)

式中:Ti为反应物Ai的初始温度;T为生成物Bj的温度;H为焓值;cp为定压热容;Qloss为热损失量。

烟气与火道壁面之间的辐射对流换热方程[7]:

(21)

(21)

(22)

(22)

式中:Qrgw和Qcgw分别为烟气与火道壁面之间的辐射热流量与对流热流量;Tg和Tw分别为烟气和火道壁面温度;Af为火道的横截面积;εg和εw分别为烟气和火道壁面发射率;αg为气体吸收系数。

使用Dittus-Boelter方程[21]计算烟气与火道壁面的对流换热系数hcgw:

(23)

(23)

式中:d为火道当量直径;ug为烟气流速;μ为烟气黏度;n为经验常数。

(24)

(24)

对于Qother主要包括炉壁散热Qwall及观察孔等区域漏风Ql,a两部分引起的热损失。

(25)

(25)

(26)

(26)

式中:hf为炉外壁对流换热系数;εext为炉外壁黑度系数;ΔT为火道温度与环境温差;Tw、Tf、T∞分别为炉外壁、与炉外壁邻近的区域气相温度及环境温度。

火道壁面的等效边界条件:

(27)

(27)

式中:Afw为各层火道面积。

1.4 耦合模型计算流程

使用C#程序语言,基于数值传热学建立石油焦流动、热解及气相渗流传质传热的偏微分方程组。在直角坐标系下对求解空间区域使用内节点法进行区域离散化;使用有限体积法二阶上风QUICK差分格式建立离散方程,边界节点使用一阶混合差分格式;使用稀疏矩阵库UMFPACK[22]求解离散代数方程组,SIMPLE算法进行耦合计算。

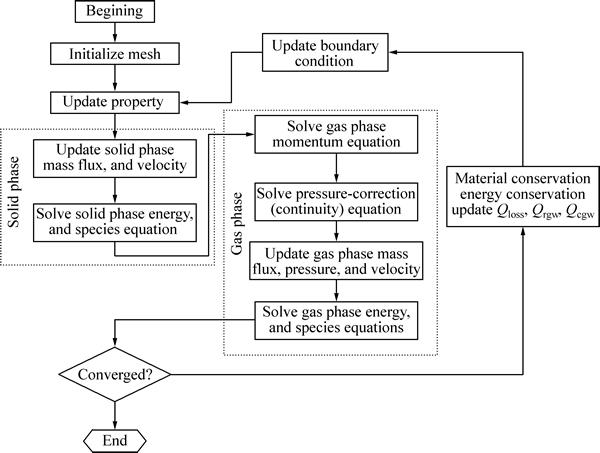

通过自顶向下逐级计算的方法,根据式(17)~(27)使用上一步火道炉壁温度场计算各层火道的气相温度及烟气对炉壁的散热量,并更新热流密度边界条件,更新各属性参数值后重新计算温度场、浓度场,具体计算流程见图1。各方程控制相对误差小于1.0×10-4,即视为收敛。

图1 二维罐式炉数学模型计算流程图

Fig. 1 Calculation flowchart of two-dimensional vertical shaft calciner model

2 物理参数

2.1 罐式炉几何尺寸

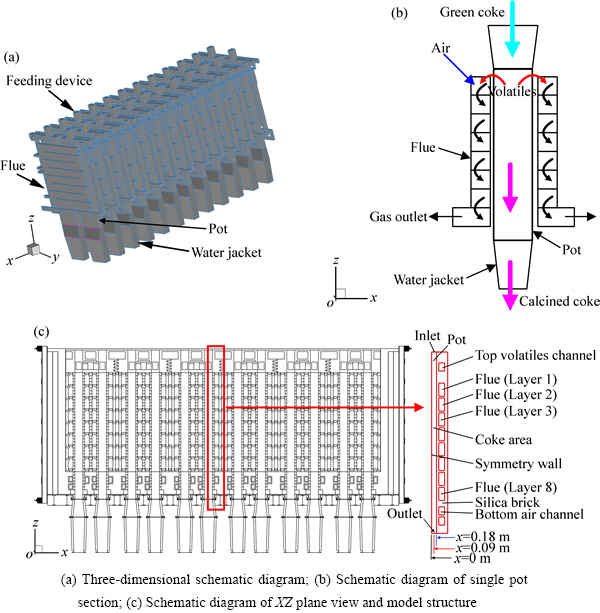

罐式炉由24个相同尺寸的煅烧罐(料罐)组成,分前后两排布置,每4个罐为一组(前后各2个罐),罐体顶部设有加料机构,罐体下部连接冷却水套及排料机构。每个料罐的左右两侧都有8层水平走向的加热火道,火焰不与原料直接接触,料罐及火道主要由硅砖和耐火粘土砖砌成,具体结构见图2。原料排出的挥发分汇集在炉上部的总烟道内,通过挥发分拉板引入火道内燃烧[1]。罐式炉料罐尺寸(长×宽×高)为1.660 m×0.360 m×6.827 m,火道尺寸(长×宽×高)为3.996 m×0.215 m×0.479 m,层数为8层,隔板厚度为0.065 m。由图2(c)可知,罐式炉XZ平面上为对称结构、各组并行运行,冷却水套只进行冷却过程,因此模型忽略冷却水套区域[11],取一组料罐的四分之一区域进行模拟研究。对硅砖区、耐火粘土砖区及料罐区采用多块结构化网格进行网格划分。

2.2 模拟工况条件及物理性质参数

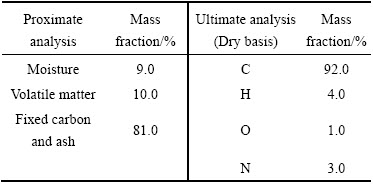

给定单位排料量为85 kg/h,入炉物料温度为300 K,挥发分在首层和二层的配比为6:4,空气过量系数为1.15,空气由首层火道入口处进入火道,石油焦炭质烧损为2.0%。石油焦工业及元素分析见表2。石油焦物理性质参数见表3。

表2 石油焦工业及元素分析

Table 2 Proximate and ultimate analysis of petroleum coke

图2 罐式炉结构示意图

Fig. 2 Detail structure of vertical shaft calciners

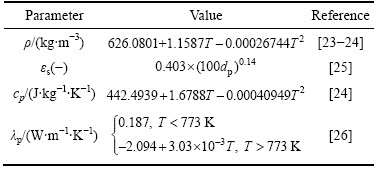

表3 石油焦的物理性质

Table 3 Properties of petroleum coke

3 结果与分析

3.1 网格无关性验证

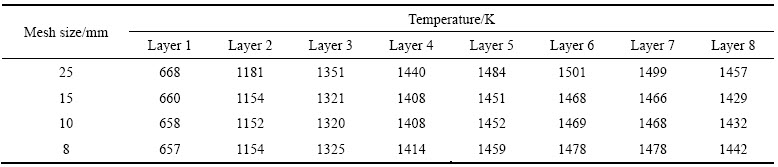

表4列出了不同网格尺寸下料罐物料区域的各层(与火道层相对应位置)温度平均值。由表4可知,当网格尺寸<15 mm时,不同网格尺寸下各层平均温度值基本一致(±10 K),表明在该计算条件下,满足网格无关性的计算要求。

3.2 模型验证

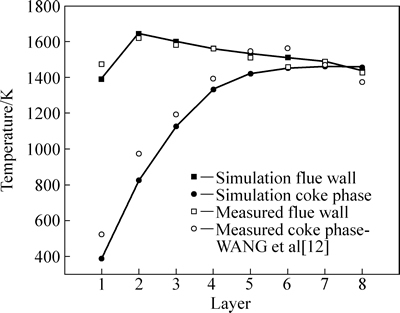

图3所示为模型计算获得的各层火道壁面与料罐中心位置的温度曲线,并将模拟值与测量值进行了对比,其中,火道壁面温度使用非接触式红外测温仪测量,料罐温度引自现有文献数据[12]。由图3可知,模拟的火道温度曲线的变化趋势与实际测量结果一致,呈现先增后降的趋势,误差<90 K。模拟的料罐中心温度曲线的变化趋势与王平甫等[12]的实验研究结果基本一致,在一至七层火道对应的料罐内,其温度经高温火道间接加热而不断升高,模拟值与测量值绝对误差<150 K。除测量带来的误差外,造成模型计算误差的主要来源有:1) 生产中生焦经过煅烧转变为煅后焦的真实堆积密度变化与经验公式的偏差,导致石油焦在料罐内运动速度存在差异,进一步引起温度分布偏差;2) 生焦原料模型简化了挥发分气体组成,计算值与真实燃烧热值的偏差;3) 模型中析出的挥发分与

颗粒、颗粒与颗粒之间的对流、扩散及辐射传热过于复杂,无法全面考虑造成的偏差;4) 模型中使用的比热、导热系数等物性参数与生产原料物性参数的偏差。总而言之,建立的模型相对合理,误差范围基本能够满足工程计算的精度要求[11],因此数值模拟结果与现场经验值具有较高的一致性,可作为罐式炉煅烧石油焦研究的有效工具。

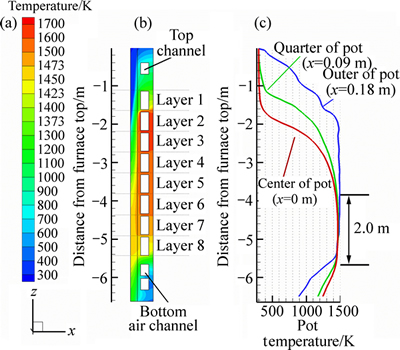

3.3 火道和料罐的温度场

图4所示为罐式炉的温度分布云图及罐内物料不同位置的温度曲线。由图4可知,首层火道壁面温度约为1300~1400 K,这是由于在首层火道,预热空气与顶层挥发分通道中的挥发分汇聚并剧烈燃烧,释放出大量热量;二层火道形成一个温度约为1600~1700 K的局部高温区域,这是由于首层火道产生的高温烟气(温度1300~1400 K,空气中O2浓度>10%)与二层火道挥发分通道中的挥发分混合燃烧放热,该热量在受限空间内不能及时扩散从而温度持续升高形成局部高温。

由罐内不同位置的温度曲线可知,一层、二层火道高度位置对应的料罐温度仅为400~800 K,这是由于石油焦中水分和挥发分的热解需要大量热量,导致石油焦升温需要吸收大量的热量,且由于料罐具有一定厚度(0.36 m)及石油焦在低温时的导热系数较低,使其热量传递缓慢从而导致料罐贴近火道侧的温度远大于料罐内侧的温度。在六至八层火道对应位置的料罐内形成了温度约为1423~1473 K、长度约为2.0 m的高温煅烧带,表明石油焦在此时达到最高煅烧温度。八层火道对应位置的料罐温度约1423~1450 K,在进入冷却水套区域前,罐内石油焦经炉底预热通道中的空气冷却使其温度下降至1000~1100 K。

3.4 残余挥发分浓度场

表4 网格无关性计算结果

Table 4 Grid independency results

图3 火道及料罐中心温度测量值与模拟值对比

Fig. 3 Comparison between simulation and measurement results of temperature in flue and center of pot

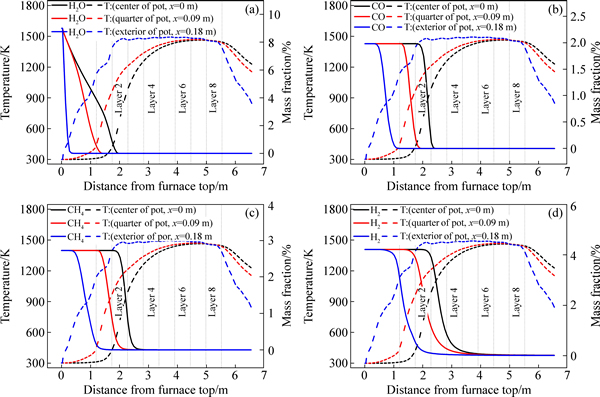

图5所示为料罐中水分和挥发分随温度变化的析出情况。由图5(a)可知,石油焦吸附的水分迅速挥发,在距离罐顶2.0 m处基本析出完成,此时石油焦温度约为400~700 K。

生焦热解析出的挥发分通过顶层挥发分管道进入火道,剧烈燃烧放热间接加热石油焦,促使其进一步析出挥发分。生焦挥发分的析出量是能否满足自热煅烧的重要因素,因此,以下着重分析焦中残余CO、CH4、H2浓度分布。

图4 温度分布云图及罐内不同位置温度曲线

Fig. 4 Contour of temperature distribution (a) and temperature curves ((b), (c))

图5 石油焦中残余挥发分含量曲线

Fig. 5 Concentration curves of residual volatile in petroleum coke

由图5(b)和(c)可知,在距离料罐中心(x=0、x=0.09 m、x=0.18 m)位置,石油焦在700~1000 K温度范围内主要析出CO、CH4,且在距罐顶约为2.4、2.6 m时,两者均基本析出完毕(含量≤0.5%(质量分数))。由图5(d)可知,在距离料罐中心(x=0.0 m、x=0.09 m、x=0.18 m)位置,石油焦中的H2主要在900~1200 K温度范围内析出,且在距离塔顶约为3.7、3.3、2.1 m时H2基本析出完毕(含量≤0.5%(质量分数))。这与文献[1]中石油焦挥发分析出主要发生在573~1173 K温度范围内基本一致,料罐中温度分布的不均匀是造成石油焦中CH4、H2在不同位置析出差异的主要原因。由此可知,石油焦挥发分热解反应主要在二至五层火道高度对应的料罐内进行。结合图4可知,在六至八层火道对应料罐位置形成的高温煅烧带中,此时由于水分、挥发分基本析出(含量≤0.5%(质量分数)),石油焦在该高温区域中体积进一步收缩,碳颗粒重新进行结构重组,促使石油焦碳化程度不断提高,煅后焦质量不断提升[1]。因此,该区域的温度分布是决定石油焦煅烧质量好坏的关键,实际生产中须严格控制煅烧带长度及最高煅烧温度。

4 结论

1) 石油焦热解析出挥发分主要在二至五层火道高度对应的料罐内进行;CO、CH4、H2等挥发分在距离塔顶小于3.7 m时已基本析出。

2) 在六、七、八层火道高度对应的料罐内,形成了长度约为2.0 m的高温煅烧带(T>1423 K),满足石油焦进一步聚合并实现碳结构重排的煅烧温度要求。

REFERENCES

[1] 姜玉敬, 郎光辉. 铝电解用炭素材料技术与工艺[M]. 北京: 冶金工业出版社, 2012: 40-168.

JIANG Yu-jing, LANG Guang-hui. Aluminum carbon material technology and process for electrolysis[M]. Beijing: Metallurgical Industry Press, 2012: 40-168.

[2] EDWARDS L. The history and future challenges of calcined petroleum coke production and use in aluminum smelting[J]. JOM, 2015, 67(2): 308-321.

[3] ZHAO J, ZHAO Q, ZHAO Q. The new generation of vertical shaft calciner technology[C]//LINDSAY S J. Light Metals 2011. San Diego, CA: TMS, 2011: 917-921.

[4] 王 敏, 毛 斌. 罐式炉煅烧生产中常见问题的分析与研究[J]. 轻金属, 2015, 2(2): 34-36.

WANG Min, MAO Bin. Analysis and research on common problems in operation processing of shaft kilns[J]. Light Metals, 2015, 2(2): 34-36.

[5] 李明周, 黄金堤, 童长仁, 张文海, 周孑民, 李贺松, 张 鹏. 铜电解槽内电解液流场的数值模拟[J]. 中国有色金属学报, 2015, 25(8): 2259-2267.

LI Ming-zhou, HUANG Jin-di, TONG Chang-ren, ZHANG Wen-hai, ZHOU Jie-min, LI He-song, ZHANG Peng. Numerical simulation of electrolyte flow in copper electrolytic cell[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2259-2267.

[6] 杨 帅, 张红亮, 邹 忠, 赖延清, 李 劼. 铝电解槽槽体与环境界面换热系数的计算[J]. 中国有色金属学报, 2015, 25(2): 515-522.

YANG Shuai, ZHANG Hong-liang, ZOU Zhong, LAI Yan-qing, LI Jie. Calculation of heat transfer coefficient between aluminum reduction cell surface and surroundings[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 515-522.

[7] MARTINS M A, OLIVEIRA L S, FRANCA A S. Modeling and simulation of petroleum coke calcination in rotary kilns[J]. Fuel, 2001, 80(11): 1611-1622.

[8] 王春华, 陈文仲, 贾冯睿, 田远航, 刘 裕. 回转窑内传热及燃烧过程的数值模拟[J]. 化工学报, 2010, 61(6): 1379-1384.

WANG Chun-hua, CHEN Wen-zhong, JIA Feng-rui, TIAN Yuan-hang, LIU Yu. Numerical simulation of heat transfer and combustion in carbon rotary kiln[J]. Journal of Chemical Industry and Engineering (China), 2010, 61(6): 1379-1384.

[9] ZHANG Z, WANG T. Investigation of combustion and thermal-flow inside a petroleum coke rotary calcining kiln with potential energy saving considerations[J]. Journal of Thermal Science and Engineering Applications, 2013, 5(1): 11008-1-10.

[10] 张忠霞, 龚石开, 杨运川. 基于PDF模型的罐式煅烧炉仿真研究[J]. 炭素技术, 2015, 4(4): 25-30.

ZHANG Zhong-xia, GONG Shi-kai, YANG Yun-chuan. Simulation study of pot calciner based on PDF model[J]. Carbon Techniques, 2015, 4(4): 25-30.

[11] 周善红, 孙 毅, 刘朝东. 罐式煅烧炉数值模拟研究[J]. 轻金属, 2013, 12(12): 33-36.

ZHOU Shan-hong, SUN Yi, LIU Chao-dong. Numerical simulation research of the shaft kiln[J]. Light Metals, 2013, 12(12): 33-36.

[12] 王平甫, 罗英涛, 宫 振, 李庆义, 谭芝运, 贾鲁宁, 于易如. 中国竖罐式炉煅烧石油焦技术分析与研讨[J]. 炭素技术, 2009, 28(4): 41-45.

WANG Ping-fu, LUO Ying-tao, GONG Zhen, LI Qing-yi, TAN Zhi-yun, JIA Lu-ning, YU Yi-ru. Analysis on calcining technologies for pot calciner in china[J]. Carbon Techniques, 2009, 28(4): 41-45.

[13] 胡国新, 许 伟, 范浩杰. 移动颗粒床中高温气体渗流传热数值计算[J]. 化工学报, 2001, 52(5): 401-405.

HU Guo-xin, XU Wei, FAN Hao-jie. Gas flow and heat transfer in moving particulate bed[J]. Journal of Chemical Industry and Engineering (China), 2001, 52(5): 401-405.

[14] NIVEN R K. Physical insight into the Ergun and Wen & Yu equations for fluid flow in packed and fluidised beds[J]. Chemical Engineering Science, 2002, 57(3): 527-534.

[15] LIN P, JI J, LUO Y, WANG Y. A non-isothermal integrated model of coal-fired traveling grate boilers[J]. Applied Thermal Engineering, 2009, 29(14): 3224-3234.

[16] 梁 鹏, 曲 旋, 田原宇, 乔英云, 毕继诚. 移动床粉煤干馏炉一维数学模型的建立[J]. 山东科技大学学报(自然科学版), 2009, 28(6): 79-84.

LIANG Peng, QU Xuan, TIAN Yuan-yu, QIAO Ying-yun, BI Ji-cheng. The establishment of one-dimensional mathematical model for moving-bed fine coal dist illation furnace[J]. Journal of Shandong University of Science and Technology (Natural Science), 2009, 28(6): 79-84.

[17] LIN P, JI J, LUO Y, WANG Y. A non-isothermal integrated model of coal-fired traveling grate boilers[J]. Applied Thermal Engineering, 2009, 29(14/15): 3224-3234.

[18] MERRICK D. Mathematical models of the thermal decomposition of coal: 1. The evolution of volatile matter[J]. Fuel, 1983, 62(5): 534-539.

[19] PATISSON F, LEBAS E, HANROT F, ABLITZER D, HOUZELOT J. Coal pyrolysis in a rotary kiln: Part I. Model of the pyrolysis of a single grain[J]. Metallurgical and Materials Transactions B, 2000, 31(2): 381-390.

[20] 肖国俊. 石油焦煅烧回转窑综合传热数学模型与数值模拟[D]. 武汉: 华中科技大学, 2007: 43-71.

XIAO Guo-jun. Modeling and simulation of heat transfer for petroleum coke calcining rotary kiln[D]. Wuhan: Huazhong University of Science and Technology, 2007: 43-71.

[21] SHRIRAO P N, SAMBHE D R U, BODADE P R. Experimental investigation on turbulent flow heat transfer enhancement in a horizontal circular pipe using internal threads of varying depth[J]. IOSR Journal of Mechanical and Civil Engineering, 2013, 5(3): 23-28.

[22] DAVIS T A. Algorithm 832: UMFPACK V4. 3-an unsymmetric-pattern multifrontal method[J]. ACM Transactions on Mathematical Software (TOMS), 2004, 30(2): 196-199.

[23] KOCAEFE D, CHARETTE A, CASTONGUAY L. Green coke pyrolysis: investigation of simultaneous changes in gas and solid phases[J]. Fuel, 1995, 74(6): 791-799.

[24] 王春华. 炭素煅烧回转窑热工过程及优化结构的研究[D]. 沈阳: 东北大学, 2009: 178.

WANG Chun-hua. Study of thermal process and optimum structure in carbon rotary kilns[D]. Shenyang: Northeastern University, 2009: 178.

[25] 王成善, 陈 磊. 对高炉内炉料运动势流模型及其流函数解法的发展[J]. 重庆大学学报: 自然科学版, 2011, 34(9): 73-80.

WANG Cheng-shan, CHEN Lei. The developing of the potential flow modelling of the burden flow in a blast furnace[J]. Journal of Chongqing University (Natural Science Edition), 2011, 34(9): 73-80.

[26] PATISSON F, LEBAS E, HANROT F, ABLITZER D, HOUZELOT J. Coal pyrolysis in a rotary kiln: Part I. Model of the pyrolysis of a single grain[J]. Metallurgical and Materials Transactions B, 2000, 31(2): 381-390.

Two-dimensional model for heat and mass transfer on petroleum coke calcination in vertical shaft calciner

XIAO Jin1, 2, HUANG Jin-di1, 2, ZHANG Hong-liang1, 2, LI Jie1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Central South University, National Engineering Laboratory of Efficient Utilization of

Refractory Nonferrous Metal Resources, Changsha 410083, China)

Abstract: The two-dimensional model for temperature field and residual volatile concentration field of petroleum coke calcination in vertical shaft calciner with 24 pots and 8 flues was developed. The model was mainly comprised of four parts, such as the model of seepage heat transfer in porous medium, solid phase plug flow model, heterogeneous pyrolysis reaction kinetics model and equivalent heat flux boundary model. In addition, the model was applied to research the heat and mass transfer process of petroleum coke pyrolysis. The results show that the volatile pyrolysis reaction mainly takes place in the pot at the heights of layers 2, 3, 4 and 5. A partial high-temperature zone with length of about 2.0 m (T>1423 K) is formed at the heights of layers 6, 7 and 8, which will further promote green coke polymerization and achieve carbon structure rearrangement. The model is validated based on measurement data, which can provide a theoretical basis for temperature automatic regulation of petroleum coke calcination in vertical shaft calciner.

Key words: vertical shaft calciner; temperature field; two-dimensional; high-temperature zone

Foundation item: Project(51374253, 51574289, 61533020) supported by National Natural Science Foundation of China; Project(2015CXS017) supported by the Innovation Driven Plan of Central South University, China

Received date: 2015-12-08; Accepted date: 2016-10-10

Corresponding author: XIAO Jin; Tel: +86-731-88876454; E-mail: changshaxiaojin@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374253,51574289,61533020);中南大学“创新驱动计划”资助项目(2015CXS017)

收稿日期:2015-12-08;修订日期:2016-10-10

通信作者:肖 劲,教授,博士;电话:0731-88876454;E-mail:changshaxiaojin@126.com