DOI:10.19476/j.ysxb.1004.0609.2018.01.13

船用螺旋桨材料镍铝青铜的热处理强化

康全飞,胡树兵,曾思琪,程光坤

(华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074)

摘 要:采用OM、SEM、EDS、拉伸测试、疲劳裂纹扩展测试、电化学腐蚀测试等研究退火、正火和固溶时效处理对镍铝青铜合金的微观结构、力学性能以及电化学腐蚀行为的影响。结果表明:675 ℃退火可以消除β′相,显著提高材料的塑性和耐蚀性,但强度稍微降低。固溶时效处理试样强度最高(812 MPa),但伸长率只有2.9%,且腐蚀阻抗最低。适当地正火处理可以提高材料的综合力学性能,同时不降低材料的耐蚀性能。镍铝青铜在空气中的疲劳裂纹扩展速率由高至低的顺序依次为铸态、固溶时效态、正火态。铸态试样的疲劳裂纹主要沿着α相和κⅢ相界面扩展,正火态试样的裂纹一般穿越α晶粒扩展,而固溶时效试样的裂纹既在α相内又在α相和κ相的界面间扩展。

关键词:镍铝青铜;热处理;电化学腐蚀;疲劳裂纹扩展特性

文章编号:1004-0609(2018)-01-0107-09 中图分类号:TG166.2 文献标志码:A

镍铝青铜(NAB)是一种以Ni、Fe、Mn为主要合金元素的铝青铜(AB),因其具有优异的耐海水腐蚀性能和良好的抗疲劳性能,成为铸造船用螺旋桨的主流材料[1-2]。由于铸态的NAB基本能满足螺旋桨的性能要求,它一般在铸态条件下使用。然而,NAB合金元素较多、组织比较复杂以及铸件尺寸极大,极易造成成分偏析、疏松和缩孔等缺陷[3]。成分偏析会加速电化学腐蚀,孔洞会降低材料的疲劳极限,尤其是靠近材料表面的孔洞[4]。铸态NAB主要由基体α相、残余β′和几种κ相组成[5]。大量研究表明[6-8],NAB螺旋桨在服役过程主要遭到电化学腐蚀、空蚀-腐蚀、冲刷腐蚀、应力腐蚀以及腐蚀疲劳等形式的损伤。为此,国内外学者在镍铝青铜的热处理强化方面做了一些研究,采取的热处理工艺主要包括退火、正火以及固溶时效处理。李振亚等[9]研究了时效温度对镍铝青铜的硬质相演变规律以及力学性能的影响,提出合金的最佳时效温度为420~450 ℃。陈瑞萍等[10]的研究表明,时效处理可以大幅提升合金的抗拉强度,但降低其塑性和耐蚀性能,而退火处理可以改善合金的耐腐蚀性能。吴忠等[11]的研究表明,热处理对镍铝青铜合金的电化学腐蚀性能影响不大,但适当的正火和固溶时效处理可以提高材料的耐冲刷腐蚀性能。此外,还有相关学者研究第二相的大小、形状和分布对合金的选相腐蚀,力学性能以及疲劳裂纹萌生、扩展路径的影响[12-13]。但大多采用实验室自行熔炼的小型铸件作为研究对象,其性能一般优于螺旋桨加工用大型铸件的性能[14-16]。因此,本文作者采用与螺旋桨同批次浇注的NAB作为研究对象,通过不同的热处理方式改善其显微组织,分析其对电化学腐蚀性能和抗疲劳裂纹扩展速率的影响,从而优化NAB的热处理强化工艺,为实际工业应用奠定基础。

1 实验

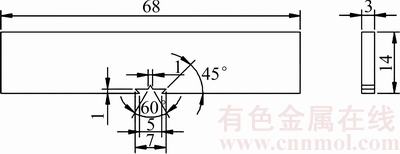

试验所用镍铝青铜材料牌号为ZCuAl9Fe4Ni4Mn2,经XRF测得其化学成分为79.76%Cu、9.89%Al、4.20%Ni、4.12%Fe和2.03Mn% (质量分数),符合GB 1176—1987的成分要求。热处理试验在SX-5-12型箱式电阻炉上进行,具体热处理制度列于表1。各试样在热处理后去除氧化皮,再用线切割截取金相试样、电化学腐蚀试样、拉伸试样和疲劳裂纹扩展试样。试样的显微组织通过超景深显微镜和扫描电镜分析。电化学腐蚀测试采用SCE三电极系统在CS310型电化学工作站上进行,测试过程腐蚀环境为3.5%NaCl(质量分数)溶液,温度为25 ℃。拉伸测试按照GB/T 228.1—2010要求,在Zwick电子万能试验机上进行,拉伸速率为2.5 mm/min,每组试验至少采用3个试样拉伸取平均值。疲劳裂纹扩展试验参考GB/T 6398—2000,在岛津EHF-UV100k2-040-1A型疲劳试验机上进行,采用三点弯曲单边缺口试样(如图1所示),应力比R为0.4,频率为10 Hz。并利用扫描电镜观察拉伸和疲劳裂纹扩展试样的断口。

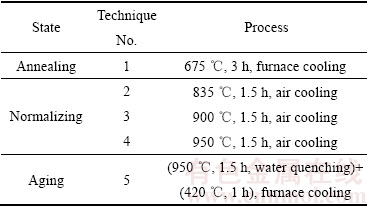

表1 镍铝青铜热处理工艺

Table 1 Heat treatment process of NAB

图1 疲劳裂纹扩展试样

Fig. 1 Schematic diagram of NAB specimen for fatigue crack growth test (Unit: mm)

2 结果与分析

2.1 热处理对材料微观组织的影响

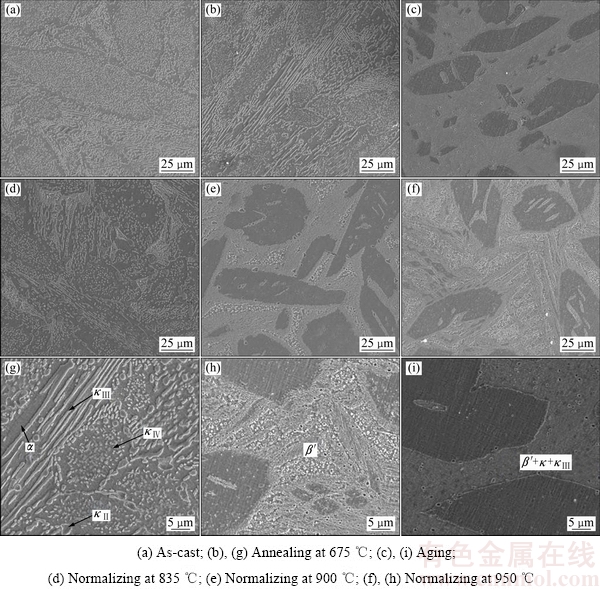

图2 不同热处理状态下NAB合金的显微组织

Fig. 2 Microstructures of NAB alloys subjected to different heat treatments

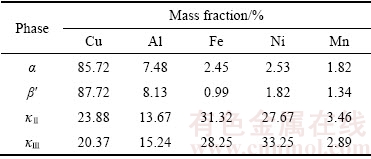

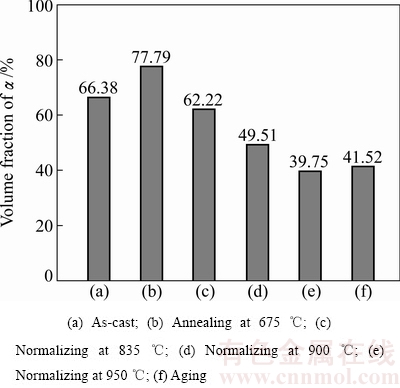

不同热处理状态下NAB合金的显微组织如图2所示。铸态组织由α相、κ相(κⅡ、κⅢ以及κⅣ)和少量残余β′组成。结合相关文献可知,κ相一般根据其大小、形状以及分布的位置可以分为4类:κⅠ、κⅡ、κⅢ以及κⅣ。其中κⅠ相呈树枝状或花瓣状,大小约20~50 μm,一般存在于α晶粒内。κⅡ相形状类似于κⅠ,约为5~10 μm,分布于α和β相界。κⅢ是β相发生共析转变的产物,一般呈层状或断续状,分布于晶界。κⅣ是分布在α晶粒内的细小颗粒。该合金组织中未见明显的κⅠ相,这是因为κⅠ相一般存在于铁含量较高的合金中[5]。铸态组织中各相的化学成分通过EDS测定,列于表2中。合金组织中α相的比例通过Image-pro plus金相分析软件统计计算,结果如图3所示。合金经675 ℃退火后,α相比例增加,残余β′消失,如图2(b)和(g)所示,这是因为在600~800 ℃温度范围可以发生共析转变:β′→α+κⅢ。当正火温度为835 ℃时,只得到少量的β′相,κⅣ呈球形长大。随着正火温度的提高,β′的比例有所增加,α相比例减少并且晶粒细化,这是因为保温过程中,部分α相溶解转变成β相。当正火温度达950 ℃时,出现大量针状α相。合金经固溶时效处理后主要由条状α相、针状β′相和κ相组成,在时效过程中,一些β′转变为α+κⅢ,此外可以发现一些细小的κ相从β′和α中析出。

表2 铸态合金中各相化学成分

Table 2 Chemical composition of different phases in as-cast alloys

图3 不同热处理状态合金组织中α相的比例

Fig. 3 Proportion of α phase in NAB alloys under various heat treatments

2.2 热处理对材料力学性能的影响

2.2.1 拉伸力学性能

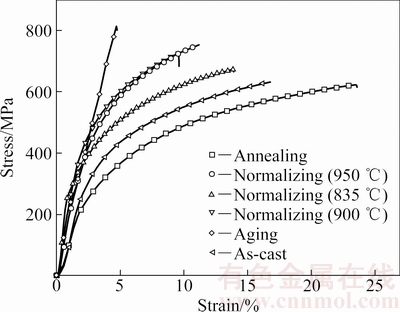

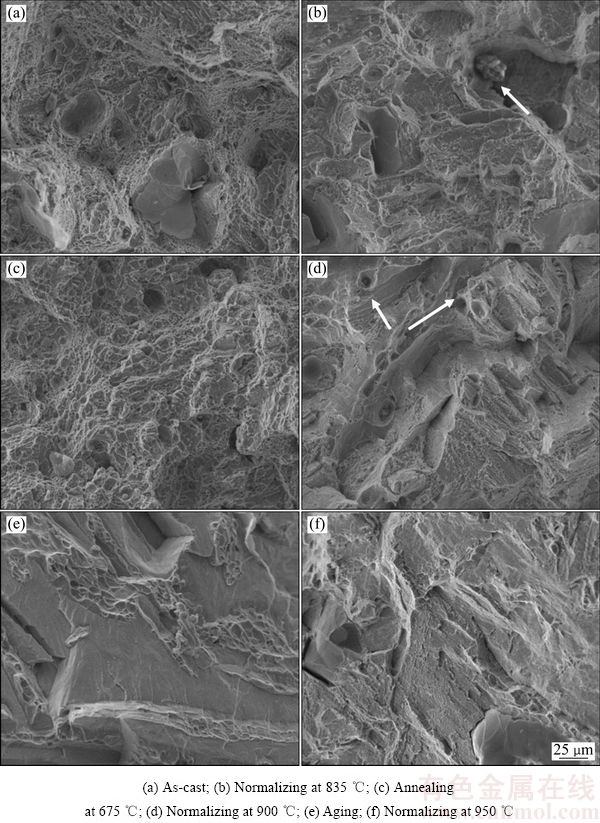

图4所示为不同热处理状态的NAB在室温下的应力-应变曲线,其抗拉强度和断后伸长率列于表3。从表3可以看出,固溶时效可以显著提高材料的抗拉强度,但伸长率最低;退火处理伸长率最高,但强度有所降低;正火试样的强度相比铸态试样的也较大提高,塑性稍微下降,且随着正火温度的提高,材料的强度随之增加。热处理改变了NAB的显微组织,从而影响材料的力学性能。正火试样相比铸态,含有更多的β′相和更少的α相,而β′相相对α相是硬相,并且随着正火温度的提高,β′相含量随之增加,因此表现出较高的强度和较低的塑性。同样,固溶处理得到更多的β′相,经过时效后只有部分β′转变为α和κ,再者从β′和α中析出的κ相极其细小,可以阻碍位错运动,因此,材料的强度比正火试样的还要高,但塑性极大地降低。退火处理消除了铸态的β′相,软质且塑性良好的α相含量有所提高,并且晶粒稍微长大,因此,材料的塑性提高的同时,强度有所降低。

图4 热处理试样的应力-应变曲线

Fig. 4 Stress-strain curves of heat treated samples

表3 热处理试样的拉伸力学性能

Table 3 Tensile mechanical properties of NAB alloys under various treatments

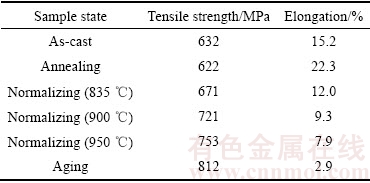

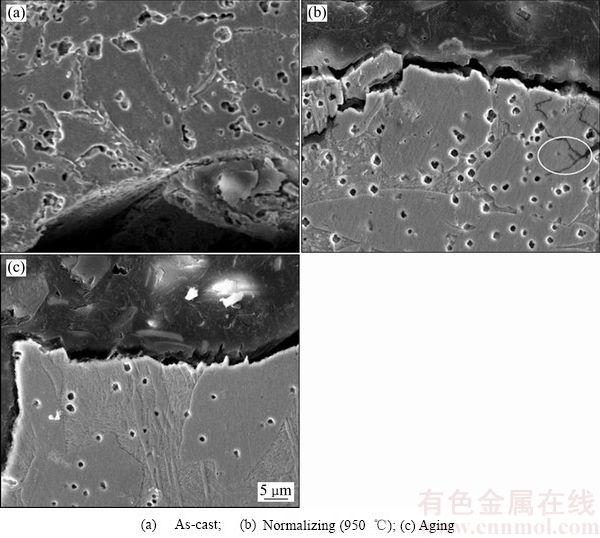

各拉伸试样的断口形貌通过扫描电镜观察,结果如图5所示。退火试样断口表现出完全塑性断裂的形貌,可以发现大量的韧窝。铸态和正火试样基本上表现出塑性断裂的形貌,只有少量的解理刻面,此外发现一些凹坑(见图5中白色箭头所指),这是κ相从基体中脱离留下的空洞。而固溶时效试样的拉伸断口基本呈齐平,表现出脆性断裂的形貌,可以发现光亮的解理刻面,只有极少量的细小的韧窝。这些基本和前面的断口伸长率数据相符合。

2.2.2 疲劳裂纹扩展特性

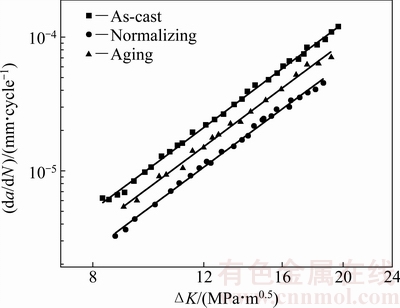

螺旋桨在循环载荷的工况下运转,因此材料的疲劳性能显得尤为重要。传统的疲劳强度指标是由光滑试样或切口试样得到,它反映的是试样表面不产生裂纹的最高应力,事实上,螺旋桨叶片表面由于氧化夹杂或应力腐蚀很容易产生微裂纹。因此,传统的疲劳强度指标不能全面地衡量材料的疲劳性能。为此,本文作者根据以上拉伸试验的结果,选取强度明显提高的正火(950 ℃)处理、固溶时效处理试样进行疲劳裂纹扩展试验,并和铸态对比。它们各自的疲劳裂纹扩展速率da/dN与应力强度因子幅度△K描绘在如图6所示的双对数坐标系上,近似呈一条直线,因此,可以用Paris方程拟合曲线。

图5 热处理试样的拉伸断口形貌

Fig. 5 Fracture morphologies of NAB alloys under different heat treatments

图6 NAB疲劳裂纹扩展曲线

Fig. 6 Fatigue crack growth curves of NAB alloy

(1)

(1)

式中:c和m均为与材料相关的常数。拟合得到的c、m的值以及拟合的程度R2列于表4中。从图6和表4中可以看出,这3条曲线基本上互相平行,即热处理对材料的m值没什么影响,但不同热处理状态下材料的c值有明显差异。铸态试样的疲劳裂纹扩展速率最高,其次为固溶时效试样,正火试样的最低。

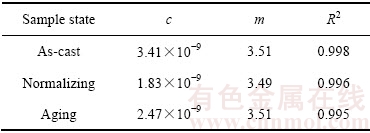

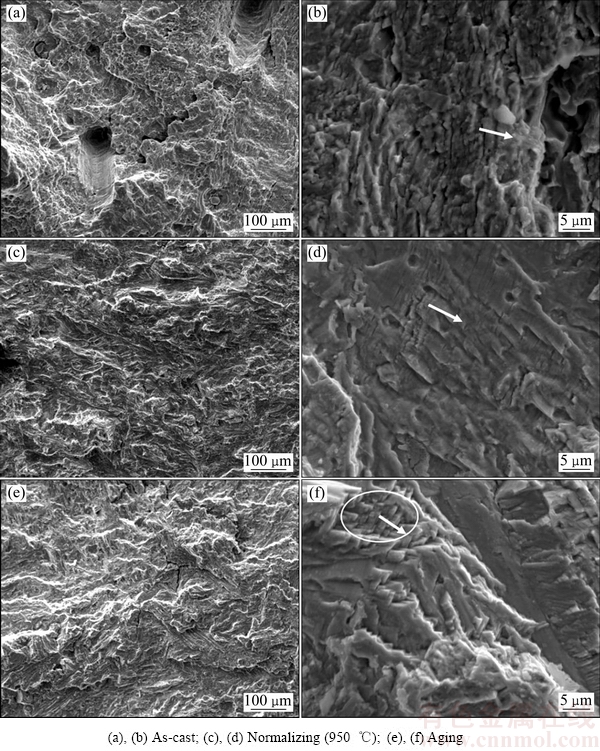

图7和8所示分别为各试样疲劳裂纹扩展区断口的表面和侧面形貌。从图7(a)可以看到一些空洞,这是因为κ相从基体中脱离[12],从图8(a)也可以看出,裂纹主要沿着α和κⅢ相界面扩展,这是因为铸态组织晶界分布较多的κⅡ和κⅢ相,层片状的α+κⅢ容易诱发裂纹的萌生。观察图7(c)可以发现正火试样的断口表现出更多塑性断裂的痕迹,而很少发现因κ相脱离而留下的空洞,图8(b)表明其裂纹基本上穿越α晶粒扩展。正火组织主要由α、β′以及少量的颗粒状的κ相组成,而α+κⅢ的层片状组织很少,因此裂纹容易在较软的α晶粒内扩展。由图8(b)中白色圆圈可以发现裂纹分叉的现象,这可以有效地降低疲劳裂纹扩展速率。此外针状的α相组织可以导致裂纹偏折,诱发裂纹闭合效应[17]。由于α相塑性好,裂纹尖端的塑性区较大,应力集中可以得到一定的松弛,所以表现出较高的裂纹扩展抗力。固溶时效组织由于时效过程部分β′相分解为α和κⅢ,裂纹除在α晶粒内扩展外也在α和κⅢ相界面扩展(见图8(c)),并且由前面的拉伸试验可知固溶时效试样塑性最低,裂纹尖端的塑性区尺寸较小,因此相比正火试样,疲劳裂纹扩展速率较高。但时效过程在α和β′中析出的细小的κ相可以有效地阻碍位错运动,提高疲劳裂纹扩展抗力,因此,相比铸态,疲劳裂纹扩展速率有所降低。此外,铸态、正火和固溶时效试样的疲劳裂纹扩展区均能找到疲劳辉纹,在相同裂纹长度附近的微观形貌分别如图7(b)、(d)和(f)所示,白色箭头所指为疲劳裂纹扩展方向。它们的疲劳辉纹平均间距分别为0.25、0.17和0.20 μm。疲劳辉纹是每次循环载荷留下的痕迹,辉纹间距越大表明疲劳裂纹扩展速率越大。正火和固溶时效试样的疲劳辉距相比铸态试样的更小,即疲劳抗力提高,这和实验得到的结果一致。

表4 不同热处理状态下NAB试样的相关常数c、m

Table 4 Material related constants c and m for NAB samples under different heat treatments

2.3 热处理对材料腐蚀性能的影响

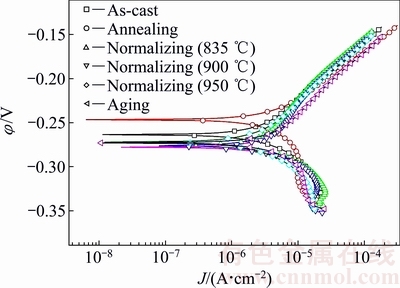

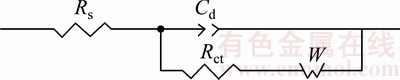

图9所示为不同热处理状态下合金NAB在3.5%(质量分数)NaCl溶液中的动电位极化曲线。采用CView软件对其进行塔菲拟合,得到的腐蚀电位、腐蚀电流列于表5中。从图9可以看出,退火处理可以一定程度地提高腐蚀电位,这是因为退火可以使铸态组织更加均匀,消除了耐蚀性能较差的β′相,只含电位差异最小的α和κ相[18]。此外,退火过程中晶粒的长大减少了晶界和腐蚀原电池的数量。正火和固溶时效处理的组织相比铸态组织含有较多的β′相,且晶粒细化,腐蚀电位稍微降低,尤其时效过程β′相和α相中析出的细小的κ颗粒增加了腐蚀原电池的数量,不利于材料的耐腐蚀性能。

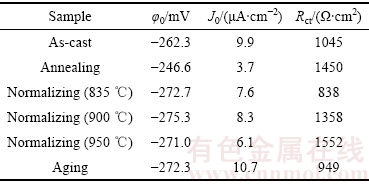

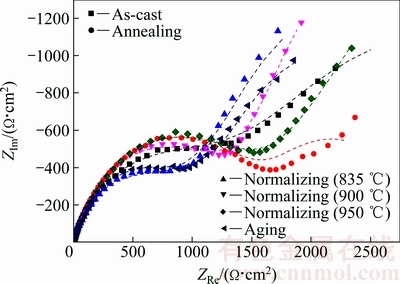

为了进一步评价不同组织腐蚀性能,本实验测定了各组织的阻抗曲线(见图10)。从电化学阻抗谱曲线可以看出,相比铸态,退火和正火(900和950 ℃)试样的容抗弧半径有所增大,而时效和较低温度的正火试样的容抗弧半径减小。但各状态下的阻抗谱图形状相似,即热处理对NAB腐蚀过程的机理影响不大,它们都是由高频部分的一段容抗弧和低频部分的直线组成,说明其腐蚀电极过程为混合控制。采用ZView软件,选取图11中的等效电路[19]拟合阻抗谱得到的曲线如图10虚线所示,RS代表溶液电阻,Cd表示腐蚀电极表面与腐蚀液之间的双电层电容,Rct表示电荷传递电阻,WS表示瓦伯格扩散阻抗。其拟合的程度通过卡方检验χ2来评价,χ2值基本在10-3至10-4之间。拟合结果表明,退火和适当温度的正火可以提高NAB的电荷传递电阻Rct,而固溶时效处理会降低NAB的Rct。

图7 NAB疲劳裂纹扩展区断口表面形貌

Fig. 7 Fracture surface morphologies of fatigue crack growth region of NAB alloy

图8 NAB合金中疲劳裂纹扩展路径

Fig. 8 Fatigue crack growth path of NAB alloys

图9 不同热处理状态下NAB合金在3.5%NaCl溶液中的动电位极化曲线

Fig. 9 Potentiodynamic polarization curves of NAB alloys under different heat treatments in 3.5% NaCl solution

表5 不同热处理状态下NAB合金的电化学腐蚀数据拟合结果

Table 5 Fitting results of electrochemical corrosion date of NAB alloys under different heat treatments

图10 NAB合金的的电化学阻抗谱

Fig. 10 Experimental and simulated EIS diagrams of NAB alloy

图11 混合控制下的等效电路图

Fig. 11 Electrical circuit analogues for mixed kinetic and diffusion control

3 结论

1) 退火可以消除铸态组织中的残余β′相。随着正火温度的提高,组织中α相含量降低,β′相含量增加,且当正火温度达950 ℃时,出现α相针状组织。固溶时效处理可以使得部分β′分解成α+κⅢ,并且在α和β′中析出非常细小的κ相。

2) 退火和适当温度的正火可以有效地提高材料的腐蚀阻抗,而固溶时效处理由于形成大量的腐蚀原电池腐蚀阻抗相比铸态的有所降低。

3) 退火处理可以改善材料的塑性但会降低材料的强度。随着正火温度的提高,材料的强度增加,但伸长率比铸态的有所降低。固溶时效处理的试样强度最高但伸长率最低。

4) 铸态试样的疲劳裂纹基本上沿着α和κⅢ界面扩展,疲劳裂纹扩展速率最高。正火试样的疲劳裂纹一般在α晶粒内扩展,并出现二次裂纹和裂纹偏折现象,其疲劳裂纹扩展速率最低。固溶时效处理试样的疲劳裂纹扩展速率介于它们之间,裂纹除在α晶粒内扩展外,也沿着α和κⅢ界面扩展。

REFERENCES

[1] 张化龙. 国内外镍铝青铜螺旋桨材料在舰船上的应用[J]. 机械工程材料, 1996, 20(1): 33-35.

ZHANG Hua-long. The application of Ni-Al bronze propeller material to naval vessel at home and abroad[J]. Materials for Mechanical Engineering, 1996, 20(1): 33-35.

[2] 宋德军, 胡光远, 卢 海, 胡伟民. 镍铝青铜合金的应用与研究现状[J]. 材料导报, 2007, 21: 450-459.

SONG De-jun, HU Guang-yuan, LU Hai, HU Wei-min. Survey of progress on the research and practice of nickel-aluminum braze[J].Materials Review, 2007, 21: 450-459.

[3] CHAKRABARTI A, SARKAR A, SARAVANAN T, NAGESHA A, SANDHYA R, JAYAKUMAR T. Influence of mean stress and defect distribution on the high cycle fatigue behavior of cast Ni-Al bronze[J]. Procedia Engineering, 2014, 86: 103-110.

[4] TAYLOR D, KNOTT J F. Growth of fatigue cracks from casting defects in nickel-aluminum bronze[J]. Metals Technology, 1982, 9(1): 221-228.

[5] JAHANAFROOZ A, HASAN F, LORIMER G W, RIDLEY N. Microstructural development in complex nickel-aluminum bronzes[J]. Metallurgical & Materials Transactions A, 1983, 14(10): 1951-1956.

[6] WHARTON J A, BARIK RC, KEAR G, WOOD R J K, STOKES K R, WALSH F C. The corrosion of nickel-aluminum bronze in seawater[J]. Corrosion Science, 2005, 47(12): 3336-3367.

[7] 孙飞龙, 李晓刚, 卢 琳, 万红霞, 杜翠薇, 刘志勇. 铜合金在中国南海深海环境下的腐蚀行为研究[J]. 金属学报, 2013, 49(10): 1211-1218.

SUN Fei-long, LI Xiao-gang, LU Lin, WAN Hong-xia, DU Cui-wei, LIU Zhi-yong. Corrosion behavior of copper alloys in deep ocean environment of south China sea[J]. Acta Metallurgica Sinica, 2013, 49(10): 1211-1218.

[8] 许晓静, 陈树东, 楚满军, 潘 励, 魏建, 侍国防. 钪、锆和锶复合微合金化铸态镍铝青铜的显微组织与性能[J]. 中国有色金属学报, 2013, 23(12): 3381-3386.

XU Xiao-jing, CHENG Shu-dong, CHU Man-jun, PAN Li, WEI Jian, SHI Guo-fang. Microstructures and properties of micro-alloyed nickel-aluminum bronze ingot by scandium, zirconium and strontium composite[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3381-3386.

[9] 李振亚, 杨丽景, 许 赪, 冒守栋, 宋振纶. 时效温度对镍铝青铜合金的硬质相演变的影响[J]. 中国有色金属学报, 2016, 26(4): 766-772.

LI Zhen-ya, YANG Li-jing, XU Cheng, MAO Shou-dong, SONG Zhen-lun. Effect of aging temperature on hard phase evolution of nickel aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 766-772.

[10] CHEN Rui-ping, LIANG Ze-qin, ZHANG Wei-wen, ZHANG Da-tong, LUO Zong-qiang, LI Yuan-yuan. Effect of heat treatment on microstructure and properties of hot-extruded nickel-aluminum bronze[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1254-1258.

[11] WU Zhong, CHENG Y F, LIU Lei, LV Wei-jie, HU Wen-bin. Effect of heat treatment on microstructure evolution and erosion-corrosion behavior of a nickel–aluminum bronze alloy in chloride solution[J]. Corrosion Science, 2015, 98: 260-270.

[12] XU Xiao-yan, Lü Yu-ting, HU Meng, XIONG Di, ZHANG Le-fu, WANG Li-qiang, Lü Wei-jie. Influence of second phases on fatigue crack growth behavior of nickel aluminum bronze[J]. International Journal of Fatigue, 2016, 82: 579-587.

[13] FONLUPT S, BAYLE B, DELAFOSSE D, HEUZE J L. Role of second phases in the stress corrosion cracking of a nickel-aluminum bronze in saline water[J]. Corrosion Science, 2005, 47(11): 2792-2806.

[14] 金云学, 都春燕, 王 磊. 镍铝青铜组织在热处理过程中的演变规律[J]. 特种铸造及有色合金, 2014, 34(9): 1004-1008.

JIN Yun-xue, DU Chun-yan, WANG Lei. Microstructural evolution of nickel-aluminum bronze during heat treatment process[J]. Special Casting & Nonferrous Alloys, 2014, 34(9): 1004-1008.

[15] 林高用, 王 莉, 许秀芝, 曾菊花. 固溶时效对QAl9-4-3铝青铜组织和性能的影响[J]. 中国有色金属学报, 2013, 23(3): 679-686.

LIN Gao-yong, WANG Li, XU Xiu-zhi, ZENG Ju-hua. Effect of solution and aging treatment on microstructure and properties of QAl9-4-3 aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 679-686.

[16] 林高用, 曾菊花, 王 莉, 金一伟, 宋佳胜. 新型Cu-Al-Fe-Ni变形铝青铜的固溶和时效强化[J]. 中国有色金属学报, 2012, 22(6): 1586-1593.

LIN Gao-yong, ZENG Ju-hua, WANG Li, JIN Yi-wei, SONG Jia-sheng. Solution and aging strengthening of novel Cu-Al-Fe-Ni wrought aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1586-1593.

[17] VERDHAN N, BHENDE D D, KAPOOR R, CHAKRAVARTTY J K. Effect of microstructure on the fatigue crack growth behaviour of a near-α Ti alloy[J]. International Journal of Fatigue, 2015, 74: 46-54.

[18] NAKHAIE D, DAVOODI A, IMANI A. The role of constituent phases on corrosion initiation of NiAl bronze in acidic media studied by SEM-EDS, AFM and SKPFM[J]. Corrosion Science, 2014, 80(3): 104-110.

[19] KLASSEN R D, HYATT C V, ROBERGE P R. Passivation of laser-treated nickel aluminum bronze as measured by electrochemical impedance spectroscopy[J]. Canadian Metallurgical Quarterly, 2000, 39(2): 235-246.

Heat treatment strengthening of nickel-aluminum bronze alloy for marine propeller

KANG Quan-fei, HU Shu-bing, ZENG Si-qi, CHENG Guang-kun

(State Key Laboratory of Material Processing and Die and Mould Technology, Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The effect of heat treatment on the microstructure and mechanical properties, as well as the electrochemical corrosion behavior of nickel-aluminum bronze alloy was investigated by OM, SEM, EDS, tensile, fatigue crack growth and electrochemical corrosion tests. The heat treatment processes include annealing, normalizing, and aging. The results show that annealing at 675 ℃ could eliminate the β′ phase, which remarkably improves the plasticity and corrosion resistance of the alloy, while its strength degrades slightly. The aged sample demonstrates the highest tensile strength (812 MPa), but its elongation is only 2.9%, and the corrosion resistance diminishes greatly. The experimental alloy normalized properly could possess good combinations of strength and toughness, and its noncorrodibility keeps good. Fatigue cracks in as-cast sample prefer to propagate through α and κ phase interface. However, the fatigue cracks in normalized alloy mainly propagate through the ductile α grain, and have the lowest crack growth rate. For the aged sample, crack extends through α and κ interface, as well as in α grain.

Key words: nickel-aluminum bronze; heat treatment; electrochemical corrosion; fatigue crack growth characteristics

Foundation item: Project (2014CB046704) supported by the National Basic Research Program of China; Project (51375005) supported by the National Natural Science Foundation of China

Received date: 2016-11-29; Accepted date: 2017-04-10

Corresponding author: HU Shu-bing; Tel: +86-13995667466; E-mail: hushubing@mail.hust.edu.cn

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2014CB046704);国家自然科学基金资助项目(51375005)

收稿日期:2016-11-29;修订日期:2017-04-10

通信作者:胡树兵,教授,博士;电话:13995667466;E-mail:hushubing@mail.hust.edu.cn