文章编号: 1004-0609(2005)05-0768-07

BT18y钛合金等轴组织与

全片层组织的室温拉伸塑性

杨 义, 黄爱军, 徐 峰, 李阁平

(中国科学院 金属研究所钛合金研究部, 沈阳 110016)

摘 要: 测试了两种温度固溶后锻态Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si(BT18y)钛合金棒的室温拉伸性能。 利用金相显微镜、 透射电镜和扫描电镜研究了该合金的室温拉伸塑性与显微组织的关系。 结果表明: 经920℃、 2h空冷处理的材料为细晶等轴组织, 变形时晶粒间的协调性好, 具有优良的室温拉伸性能, 塑性尤其突出; 经1020℃、 2h空冷处理的材料为具有晶界α相的粗晶片层组织, 在拉伸变形时, 同时要求相邻晶粒之间、 晶粒内部的相邻α片束团之间相互协调, 增加了塑性变形的阻力, 但残余β相使得材料保持了一定的塑性。 多个视角观察表明: α片束团表现出了方向性, 与拉伸轴夹角较小的片束具有良好的拉伸性能, 与拉伸轴夹角较大的片束内的β相中间层是拉伸时裂纹的优先形成区。

关键词: Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金; 热处理; 显微组织; 室温拉伸塑性 中图分类号: TG166.5; TG113.12

文献标识码: A

Room-temperature tensile plasticity of BT18y titanium alloy with equiaxed structure and fully lamellar structure

YANG Yi, HUANG Ai-jun, XU Feng, LI Ge-ping

(Titanium Alloy Laboratory, Institute of Metal Research, Chinese Academy of Science,

Shenyang 110016, China)

Abstract: Tensile properties of forging Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si titanium alloy after two types of heat treatments were tested at room temperature. Optical microscope, transmission electron microscope (TEM) and scanning electron microscope (SEM) were used to investigate the relationship between microstructures and room-temperature tensile plasticity. The microstructure of the sample solutionized at 920℃ for 2h followed by cooling in air is fine equiaxed structure. Compatibility among grains is easy during deformation, so it has good tensile properties at room temperature, especially better tensile plasticity. The sample solutionized at 1020℃ for 2h followed by cooling in air possesses a coarse and lamellar structure with continuous grain boundary α phase. In the tensing process, coordinations among adjacent grains and among α colonies in grains are needed at the same time, so the plastic deformation becomes difficult. But β phase interlayer makes the material maintain some plasticity. α colony has anisotropy. The one that has small included angle to the tensile direction possesses better tensile properties. β phase interlayer in the one that has big included angle to the tensile direction is vulnerable area in the material, and cracks arise in this place firstly while tensing.

Key words: Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si titanium alloy; heat treatment; microstructure; room-temperature tensile plasticity

Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si变形热强钛合金, 即俄BT18Y, 属近α钛合金, 它是Ti-Al-Zr-Sn-Mo-Nb-Si合金系中最具代表性的合金之一。 该合金具有优良的综合性能, 以Sn部分代替Zr降低了Al含量, 提高了其工艺塑性、 蠕变强度、 冲击韧性和热稳定性[1], 同时保持了600℃的持久强度。 该合金不能通过热处理进行强化[2], 但调整热处理制度, 可获得具有不同性能的显微组织, 从而使得材料的性能可以通过不同显微组织的搭配达到使用要求。 目前对高温钛合金的显微组织与性能关系的研究主要针对α+β两相合金, 如Kubiak等[3] , Filip等[4]曾对Ti-6Al-4V和Ti-6Al-2Mo-2Cr两相钛合金的显微组织与疲劳性能以及与拉伸性能和断裂韧性的关系进行了研究, L[5] 曾研究了一些两相钛合金的显微组织对力学性能的影响, 而对于近α钛合金的研究相对较少, 而且主要集中于Ti-1100[6, 7]和Ti6242Si[8]的研究, 对于另外一种著名的近α钛合金BT18Y却极少有报道。 因此, 本文作者以室温拉伸实验为基础对Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si近α钛合金的两种最典型的显微组织—等轴组织和全片层组织与室温拉伸塑性的关系进行了研究, 以对合金的选材以及工艺的优化等提供参考。

1 实验

实验选用d20mm轧制态Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金棒, 用金相法测得其相变点温度约1015℃。 从同一支棒材上下料, 试样毛坯使用三段管式热处理炉进行热处理, 处理制度列于表1。

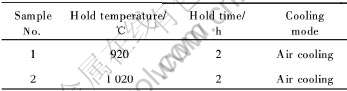

表1 试样毛坯的热处理参数

Table 1 Parameters of heat treatments for alloy

采用标距尺寸为d10mm×50mm的圆形比例标准拉伸试样, 在DCS-25T拉伸实验机上进行拉伸实验。 从拉伸实验后的试样上切取金相样品, 金相观察在MEF-4型显微镜上进行, 采用Kross腐蚀液腐蚀。 在LU61450型扫描电镜和S360型扫描电镜上进行拉伸断口、 侧面形貌观察及能谱分析。 精细结构形貌在PhilipSEM420型分析电子显微镜上进行, 透射电镜试样先使用机械方法减薄至20~30μm, 再使用MTP-1A型磁力驱动双喷电解减薄器减薄, 双喷液为20%高氯酸+30%正丁醇+50%甲醇(体积分数), 双喷时使用液氮冷却双喷液, 温度在-30℃左右, 工作电压15~20V。

拉伸实验后, 先通过金相显微镜观察合金显微组织形貌, 使用透射电镜深入观察晶粒内部及晶界和相界的形貌, 分析显微组织特点, 然后使用扫描电镜观察拉伸断裂后试样的断口和断口附近侧表面的形貌, 分析显微组织与材料的变形和断裂机制的关系。

2 结果与分析

经过不同热处理制度处理的材料表现出不同的拉伸性能。 表2中所列数据显示, 经1020℃、 2h空冷处理的试样2除抗拉强度σb与经920℃、 2h空冷处理的试样1相当外, 其它性能均不及试样1, 特别是试样1的延伸率和断面收缩率比试样2高出了一倍左右。 由于材料的成分一致, 所以这种差异显然是由于热处理后显微组织不同引起的。

表2 材料的室温拉伸性能

Table 2 Room-temperature tensile properties of alloy

图1(b), (c)所示分别为Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金棒按表1所示的热处理制度处理后的显微组织。 从图中发现, 不同热处理制度处理后的合金显微组织显然不同, 且均与锻态组织(图1(a))有明显差异。

图1 实验合金的显微组织

Fig.1 Microstructures of test alloys

锻态Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金棒晶粒内有许多不同取向的α片束团, 团内α片近似平行地分布于β基体上, 由于锻造的原因, α片和α镶边均发生了扭曲变形, 其中一部分α镶边已经破碎、 消失。 锻造过程破坏了铸态组织, 组织的均匀性有了一定程度的改善, 同时引入了大量位错、 界面等变形缺陷, 为热处理提供了再结晶动力[9]。

经过920℃、 2h空冷处理的材料晶粒尺寸(5~15μm)较锻态明显减小, 没有α镶边, 变形的α相(变形α镶边、 晶内变形α片以及两者内破碎的α相)再结晶球化成了等轴α晶粒(图1(b)), 球化的驱动力是表面能和变形缺陷的减少[2]。 α晶粒的晶界处有残余β相存在(图2(a)), 在α晶粒内部、 晶界以及晶间β相中均有球状硅化物析出(图2(a), (b)), 硅化物的类型和作用有待进一步研究。

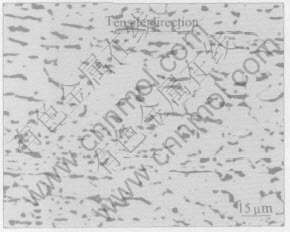

经过1020℃、 2h空冷处理的试样2晶粒尺寸(500~1500μm)较试样1要大得多, 有连续平直的晶界α相, 晶内有许多不同取向的平直α片束团(图1c), α片内存在位错, 各α片由残余β相分开(图3(a), (b))。

图2 试样1在透射电镜下的明场像

Fig.2 TEM bright field images of Sample 1

图3 试样2在透射电镜下的明场像

Fig.3 TEM bright field images of Sample 2

出现这种组织的原因是由于热处理温度(1020℃)超过了该合金的相变点温度(1015℃), 原始α相消失, β晶粒显著长大。 在固溶后冷却发生β→α转变时, α相首先在缺陷较多处(β晶粒的晶界上和晶粒内部的位错、 层错区)析出形成晶界α相和少量α片, 同时新生成的晶界α相将阻碍晶粒长大[2]。 随着温度的降低, 转变的驱动力加大, 更多的β相便以较快的速度转变成了α片束团, 形成α片时β相稳定元素的排出导致α片之间最终有少量β相保留下来。 同一晶粒内的残余β相中间层是连续的, 且具有相同的晶体学取向, 这使得各个α片束团以及各个α片既相互分离, 又通过β相中间层紧密地相互联系在一起。

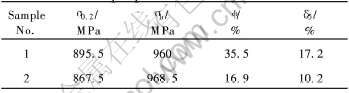

热处理后两试样的显微组织存在的这些巨大差异, 使得材料在拉伸时的裂纹形核和扩展方式不同, 这是影响材料塑性等性能的主要因素[4, 10], 其差异更直观地表现在拉伸后的断口与侧面的形貌上。 图4所示为断裂区的低倍形貌。 由图4(a), (b)可见, 试样1具有明显的剪切唇和缩颈, 宏观表现为韧性断裂。 试样2断口具有较大的不规则起伏峰, 无明显的缩颈(图4(c), (d)), 宏观表现为脆性断裂。

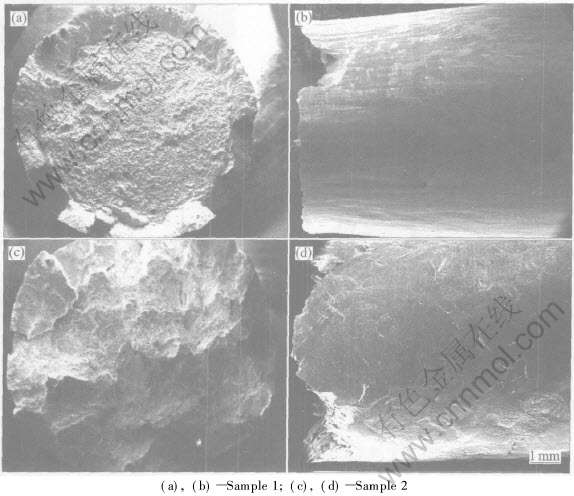

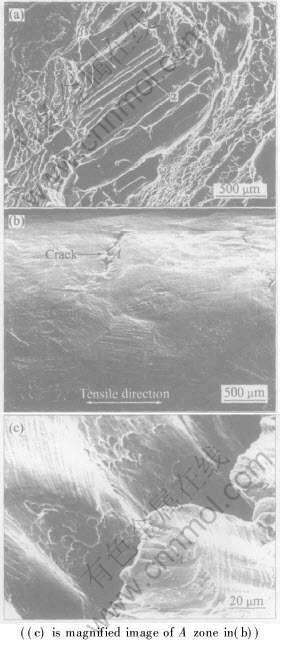

对试样断裂区进行较高倍数的SEM观察, 发现试样1断面具有细小的韧窝形貌(图5(a)), 整个侧表面观察不到深裂纹, 在缩颈区的侧表面可以看到有很细密均匀的长条状起伏(图5(b)), 远离缩颈区的侧表面则比较平缓, 这表明试样1在拉伸时的变形主要集中在断口附近。 缩颈区侧表面的这种形貌特征是由于多晶体金属塑性变形的特点造成的[11]。 多晶体中, 各晶粒变形具有不同时性。 相邻各晶粒具有不同的位向, 材料在拉伸时, 处于软取向的晶粒会首先发生塑性变形, 其塑性变形过程必然会受到周围晶粒的约束和限制, 使其变形阻力加大, 同时它将带动周围处于硬取向的晶粒向软取向转动, 它们的这种相互协调行为最终使得材料作为一个整体产生塑性变形[12]。 从图6可以看到等轴α晶粒沿拉伸方向被拉长。

试样2的断口形貌分为平行片束区和韧窝区两个部分(图7(a))。 对片束区进行能谱分析, 发现较宽的黑色板条的铝含量比白色细条的铝含量高出2%左右, 由此可以判断, 黑色的宽板条是被拉断的α片, 白色细条是α片间的β相中间层。 对韧窝区进行能谱分析, 发现铝含量与β相中间层的铝含量相当, 它是α片束团内相邻α片从β相中间层处被撕开所形成的形貌。 图8所示是试样2拉伸后断口附近的纵剖面的显微组织, 可以看到α镶边、 晶内α片束均发生了扭曲变形。

图4 断口的低倍形貌

Fig.4 Macrofracture images of rupture samples

图5 试样1断口和缩颈区侧面的形貌

Fig.5 Fracture(a) and side face morphology(b) at bottleneck of sample 1

图6 试样1拉伸后缩颈区的纵剖面的显微组织

Fig.6 Microstructure at bottleneck of sample 1 after tension

图7 试样2断口和侧面的形貌

Fig.7 Fracture(a) and side face morphology(b) of sample 2

图8 试样2拉伸后的显微组织

Fig.8 Microstructure of sample 2 after tension

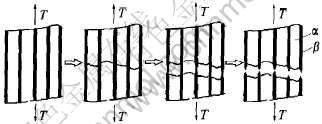

在拉伸过程中, α片束团表现出方向性。 大量观察表明, 当裂纹抵达与拉伸轴成较小角度(0°~30°)的α片束团时, 塑性较好的β相会松弛裂纹尖端应力, 从而阻碍裂纹的扩展, 提高了材料的韧性。 继续增加外力, α片中的应力会首先达到α相的强度极限, 出现裂纹, 而β相中间层则会发生更大的塑性变形直至最终被拉断, 这时片束便完全断裂, 图9所示为这一类型的特殊方向的α片束(与拉伸轴同向)的断裂过程示意图。 图7(a)中被拉断的α片处下凹表明了这一过程。 这一类型的α片束团力学性能较好, 其中相互平行的α片起到了增强β基体的作用, 而β相则改善了材料的塑性和韧性。

图9 与拉伸轴同向的α片束断裂过程示意图

Fig.9 Schematic diagram of rupturing of

α colony along tensile direction

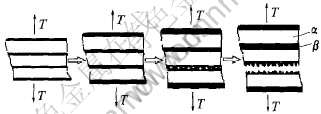

多个视场观察表明, 与拉伸轴成较大角度(60°~90°)的α片束团内, α片增强β基体的作用基本消失, 主要原因是α片与β相中间层在拉伸轴方向上相互隔离, 使得在拉伸时α片层之间的联系大大减弱。 在拉伸过程中, 裂纹不再萌生于或通过α片, 而是β相首先发生塑性变形, 达到一定程度后形成微孔, 微孔长大连接最终β相断裂形成撕裂韧窝(图7(a)), 所以这一类型的α片束团的塑性变形主要来自β相的变形, 但是其中的β相也是该类型的α片束团内乃至整个材料中的弱区, 降低了材料的强度, 在拉伸时裂纹将首先在这些区域形成[13]。 图10所示为这一类型的特殊方向的α片束(与拉伸轴垂直)的断裂过程示意图。 在试样侧表面上可以观察到较深的裂纹(图7(b), (c)), 且裂纹与拉伸轴的夹角均大于60°, 裂纹面上为撕裂状韧窝形貌(如图7(c)), 这一现象证明了上述变形机制。

图10 与拉伸轴垂直的α片束断裂过程示意图

Fig.10 Schematic diagram of rupturing of

α colony vertical to tensile direction

根据以上结果和分析, 具有晶间β相的细晶等轴组织的Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金表现出了良好的综合室温拉伸性能, 塑性尤其突出, 这是由于两个细小的等轴晶粒之间接触区较片层组织要小得多, 且晶间塑性较好的β相可以通过塑性变形松弛晶粒转动所产生的内应力, 使得应力再分布[14], 所以试样1材料晶粒之间的协调性比粗晶片状组织的试样2材料的好, 材料的塑性也因此而得到改善。 而具有α镶边的粗晶片状组织的试样2 Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金塑性不如等轴组织材料, 对于具有β相中间层的α片层组织与等轴α组织塑性的差异, Ambard等[15]曾做过研究, 认为是α/β片界面的作用。 本文作者认为α片束团表现出的方向性和内部单元尺寸较大且层次多也是其中的一个重要原因, 这使得拉伸时的变形和断裂机制较细晶等轴组织材料复杂得多。 试样2在拉伸变形时, α镶边、 晶内α片束并非只是沿拉伸方向被拉长, 而是均发生了不同程度的扭曲变形(图8)。 各个晶粒之间的相互协调是通过晶粒内部不同取向的各α片束团之间的协调实现的, 而α片束团之间的相互协调又是通过α片束团内的α片与β相中间层之间的协调实现的, 只有这些条件同时具备, 材料才能够继续进行塑性变形, 这无疑使得材料的塑性变形变得困难起来。 由于上述原因, 对于成分相同的合金, 具有粗晶片状组织的材料的塑性总是要比细晶等轴组织材料的差。

3 结论

1) 经920℃、 2h空冷处理的Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金为具有少量晶间β相的细晶等轴组织, 有良好的综合室温拉伸性能, 延伸率和断面收缩率分别达17.2%和35.5%, 比经1020℃、 2h空冷处理得到的具有α镶边的粗晶片状组织材料高出1倍左右。

2) 等轴组织的Ti-6.9Al-3.6Zr-2.7Sn-0.7Mo-0.6Nb-0.21Si钛合金在拉伸断裂时为纯延性断裂; 片状组织的合金在宏观上表现为脆性断裂, β相中间层区域为延性断裂。 β相的存在对两种组织的材料的塑性均有所改善。

3) 与拉伸轴夹角较小(0~30°)的α片束具有良好的拉伸性能, 与拉伸轴夹角较大(60°~90°)的α片束团内的β相中间层虽然对塑性贡献较大, 但也是拉伸时裂纹的优先形成区。

4) 片状组织在拉伸变形时, 各个晶粒之间、 晶粒内部的各α片束团之间以及α片束内的各α片与β相中间层之间需要同时协调, 材料才能够发生塑性变形, 导致塑性变形较细晶等轴材料困难。

REFERENCES

[1]李成功, 傅恒志, 于翘, 等. 航空航天材料[M]. 北京: 国防工业出版社, 2002. 83-84.

LI Cheng-gong, FU Heng-zhi, YU Qiao, et al. Aerospace Materials[M]. Beijing: Defense Industrial Press, 2002. 83-84.

[2]Bolisowa E A. 钛合金金相学[M]. 陈石卿 译. 北京: 国防工业出版社, 1986. 199-212.

Bolisowa E A. Metallography of Titanium Alloys[M]. CHEN Shi-qin transl. Beijing: Defense Industrial Press, 1980. 199-212.

[3]Kubiak K, Sieniawski J. Development of the microstructure and fatigue strength of two phase titanium alloys in the processes of forging and heat treatment[J]. Journal of Materials Processing Technology, 1998, 78: 117-121.

[4]Filip R, Kubiak K, Ziaja W, et al. The effect of microstructure on the mechanical properties of two-phase titanium alloys[J]. Journal of Materials Processing Technology, 2003, 133: 84-89.

[5]Lü tjering G. Influence of processing on microstructure and mechanical properties of (α+ β) titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 32-45.

[6]Lee D H, Nam S W, Choe S J. Effect of α lamellae width on creep-fatigue behavior in Near-α Ti-1100 with lamellar structure[J]. Scripta Materialia, 1999, 40 (3): 265-270.

[7]Lee D H, Nam S W, Choe S J. Effect of microstructure and relaxation behavior on the high temperature low cycle fatigue of near-α-Ti-1100[J]. Materials Science and Engineering A, 2000, 291: 60-67.

[8]Es-Souni M. Primary, secondary and anelastic creep of a high temperature near α-Ti alloy Ti6242Si[J]. Materials Characterization, 2000, 45: 153- 164.

[9]崔忠圻. 金属学与热处理[M]. 北京: 机械工业出版社, 1995. 205.

CUI Zhong-qi. Metallography and Heat Treatment[M]. Beijing: Machine Industry Press, 1995. 205.

[10]Sauer C, Lü tjering G. Influence of α layers at β grain boundaries on mechanical properties of Ti-alloys[J]. Mater Sci Eng A, 2001, 319-321: 393-397.

[11]束德林. 金属力学性能[M]. 北京: 机械工业出版社, 1999. 12.

SHU De-lin. Mechanical Properties of Metal[M]. Beijing: Machine Industry Press, 1999. 12.

[12]侯增寿, 卢光熙. 金属学原理[M]. 上海: 上海科学技术出版社, 1989. 177.

HOU Zeng-shou, LU Guang-xi. Metallography Theory[M]. Shanghai: Shanghai Science and Technology Press, 1989. 177.

[13]陆永浩, 张永刚, 乔利杰, 等. γ-TiAl片层界面在裂纹形核中的双重作用[J]. 中国有色金属学报, 2000, 10(6): 774-778.

LU Yong-hao, ZHANG Yong-gang, QIAO Li-jie. Twofold effects of lamellar interface on crack nucleation in fully lamellar TiAl based alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 774-778.

[14]Evans W J. Optimising mechanical properties in alpha+beta titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 89-96.

[15]Ambard A, Gue′taz L, Louchet F. Role of interphases in the deformation mechanisms of an α/β titanium alloy at 20K[J]. Mater Sci Eng A, 2001, A319-321: 404-408.

收稿日期: 2004-07-20; 修订日期: 2005-01-27

作者简介: 杨 义(1980-), 男, 硕士研究生.

通讯作者: 杨 义; 电话: 024-23971962; E-mail: yiyang@imr.ac.cn

(编辑龙怀中)