Assessing environmental impact of magnesium production using Pidgeon process in China

GAO Feng(高 峰), NIE Zuo-ren(聂祚仁), WANG Zhi-hong(王志宏),

GONG Xian-zheng(龚先政), ZUO Tie-yong(左铁镛)

College of Materials Science and Engineering, Beijing University of Technology, Beijing 100022, China

Received 4 June 2007; accepted 29 August 2007

Abstract: Based on the practice of magnesium production in China, a quantitative evaluation of the environment impact was carried out according to the theory and framework of life cycle assessment(LCA) study. The major gaseous pollutants including CO2, SO2, NOx, CH4, HF and particulates were calculated. The accumulative environmental performances of different energy use strategies and the characterization results, including abiotic depletion potential(ADP), global warming potential(GWP), acidification potential(AP) and human-toxicity potential(HTP) were compared. The results show that the direct emission of fuel combustion in the process is the major contributor to the pollutants emission of magnesium production. Global warming potential and acidification potential make the main contribution to the accumulative environmental impact. The different fuel use strategies in the practice of magnesium production cause much different impacts on the environmental performance. The accumulative environmental impact of coal burned directly is the highest, and that of producer-gas comes to the next, while that of coke-oven gas is the lowest.

Key words: magnesium production, Pidgeon process, life cycle assessment

1 Introduction

Since 1990s, primary magnesium has had a rapid increase in its production in China and become the fifth domestic major nonferrous metal after aluminum, copper, lead and zinc[1]. By 2005, the production ability of primary magnesium reached 816 000 t, and the produc- tion of primary magnesium reached 467 600 t; mean- while, its export volume stayed at 353 100 t, accounting for 70% of the global output[2]. China is the largest primary magnesium producer in the world, and the Pidgeon process invented in 1940s in Canada is an important technique to produce primary magnesium in China. China is among the global countries that are richest in magnesium, whose major raw materials of the magnesium industry come from the resources of magnesite, dolomite, lake brines and seawater[3]. Compared with other structural materials, magnesium and magnesium alloys boast a number of advantages [4-6], such as low density, high specific strength, good thermoformability, and high performance of electro- magnetic shielding, so these outstanding features would make them possess both significant application value and broad application prospects.

Magnesium production by the Pidgeon process has the advantages of short technical process, low investment input, quick completion of workshop and low production cost. But the process consumes large number of natural resources and leads to relatively severe environment pollution. The emission of air pollutants resulting from the fuel combustion process in particular has already attracted much attention from the local government and enterprises.

Evaluating sustainable development of magnesium production requires methods and tools to measure and compare the environmental impacts. Life cycle assessment(LCA) is a systematic methodology that can be used for such purpose to identify and quantify the potential environmental impacts associated with a material, process, application or disposal during its entire life span. At present, the international LCA research on both the production of primary magnesium and the magnesium products is still at its initial stage, and what environmental impacts caused by the extensive use of the magnesium products is not yet clear. A cradle-to-gate life cycle study was conducted using averaged data for magnesium production in China to calculate the global warming impact of Chinese magnesium ingots[7]. Followed the ISO14040 standard[8] (Environmental Management–Life Cycle Assessment–Principles and Framework), this work carries out environmental assessment based on the domestic practices of magnesium production, compares the characterization results and the accumulative environmental impacts of different energy use scenarios and discusses the adoption of “clean energy” and technological improvements that reduce these impacts.

2 Life cycle assessment

2.1 Goal and scope definition

A goal and scope definition, such as a stage generally associated with the main issues of goal, scope, functional unit, system boundaries, is the first phase of a life cycle assessment. In this section, the purpose of applying the LCA is to investigate the environmental impacts of magnesium production.

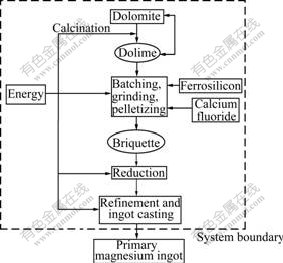

The Pidgeon process can be subdivided in four main subsystems: dolomite calcinations, briquette production, reduction of dolime, and refinement and ingot casting, as shown schematically in Fig.1. The system boundary (Fig.1) includes the Pidgeon process and the auxiliary subsystem (the thermal power plant supplies energy to the processes). Dolomite is the major raw material of magnesium production. The domestic dolomite reserves required by magnesium production are very rich, and mineral resources spread all over the country. The ensured reserves stayed at above 230×10-6 t by the end of 2 000[9]. The proportion of MgO in dolomite ore is usually at around 20%. Mining of dolomite ore is not included in this system. The environmental issue of ore from mining is considered in more detail later.

Fig.1 System boundary of magnesium production using Pidgeon process

The form of energy use included in LCA study is the gross energy consumption, which is the cumulative amount of primary energy consumed in all stages of magnesium production life cycle. The three representative practices of energy use in magnesium production process are selected, which are coal, producer gas and coke-oven gas(COG). China enjoys rich and widespread coal resources with relatively low price compared with petroleum and natural gas, so coal is the major fuel of magnesium production. The coal and gas co-firing and combustion is adopted in the process of magnesium production because the lower calorific value of producer gas and the limitations on the gas supply conditions for COG make them unable to totally replace coal powder at present.

A functional unit of 1 t magnesium ingot is set in this paper. The primary objectives of this study are: 1) Display quantitatively the environmental emissions directly (during combustion of the fossil fuels and processing) and indirectly (e.g. in the generation of electric power) and compare the environmental impacts of energy use in production practices; 2) Illustrate the accumulative environmental performances of magnesium production with the three scenarios and provide a suggestion about energy use strategy.

2.2 Inventory analysis

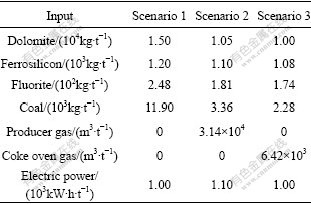

To assess the most accurate environmental impacts associated to China magnesium production, we mainly consider data from China Magnesium Association. The inventory of main resources and energy consumption of the three scenarios for the Pidgeon process are listed in Table 1. The gross energy consumption of the three practices calculated are 261, 247 and 171 GJ/t, respectively.

Table 1 Inventory of main resources and energy consumption for 1 t Mg of three scenarios

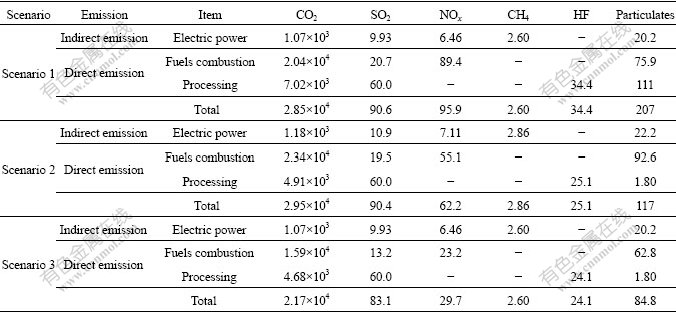

In order to present the results of the pollutants emission legibly, the indirect emission from the electricity generation and direct emission which includes the fuels combustion and processing are edited in the inventory. Life cycle emissions inventory of air pollutants of three scenarios for magnesium production is listed in Table 2. The major waste gases produced in the process include CO2, SO2, CH4, NOx, HF and particulates.

Table 2 Air pollutants inventory of three scenarios (kg/t )

The energy source used to generate the electricity consumed in magnesium production process also influences the environmental impact of that process. The emission factors of electric power plants in China are obtained from Ref.[10].

The estimation of CO2 emissions from fuel combustion in this study is based on energy consumption and emission factors by fuel type[11-12]. SO2 and NOx emission estimates depend on the energy consumption and emission factors from the corresponding references [13-14]. Particulates emission from the direct emission is mainly based on the operation conditions, combustion equipment and technology, dust catcher and fuels consumption[15]. HF emission estimate from the processing is based on the fluorite consumption, the content of CaF2 and emission factor[15].

The inventory results indicate that CO2 emission from Scenario 2 is increased by 14.7% compared with Scenario 1. The producer gas used as the main fuels of magnesium production will not reduce the CO2 emission. But the reduction purpose of SO2, NOx, and particulates emission is evident. The overall pollutants emission from Scenario 3 will be reduced clearly compared with Scenario 1 and Scenario 2. Especially, particulates from the direct emission of Scenario 1 will decrease by 49.5% and 65.4% compared with Scenario 2 and Scenario 3.

2.3 Life cycle impact assessment

According to the ISO 14044 standard[16], the impact assessment method consists of three steps: characterization, normalization and weighting. The problem-oriented approach, which was developed by the Institute of Environmental Sciences(CML) of Leiden University, is used to calculate the following environmental impact of the case study: abiotic depletion potential(ADP), global warming potential(GWP), acidification potential(AP) and human toxicity potential (HTP).

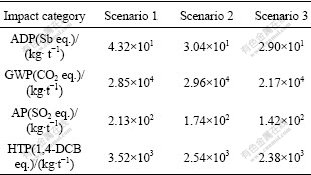

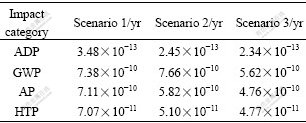

The characterization factors of GWP, AP and HTP for the emissions are chosen from Ref.[17]. For the characterization factors of ADP, the model recommended by Ref.[18] is used to calculate the depletion potential of minerals extraction. The “antimony” is chosen as a reference. Based on the ensured reserves and extraction rate of coal, dolomite, fluorite and antimony in China[9], the characterization factors (antimony eq.) of coal, dolomite, and fluorite are calculated to be 4.81×10-8, 2.64×10-3 and 1.35×10-2 kg/kg, respectively. According to Ref.[19], to produce 1 t ferrosilicon needs the materials of 1 820 kg silica and 220 kg scrap iron. Calculated by the same model, the characterization factors (antimony eq.) of silica and scrap iron are 1.18×10-4 and 5.20×10-6 kg/kg. The characterized results of ADP, GWP, AP and HTP for the three scenarios are listed in Table 3.

Table 3 Characterization results for Pidgeon process

The normalization factors (World, mid 1995) for GWP, AP and HTP are chosen from Ref.[17], while the normalized value for depletion of abiotic resources is based on China resources situation in 2002, which is 1.24×1014 kg antimony eq.[20]. The normalization results for three scenarios are listed in Table 4.

Table 4 Normalization results for three scenarios

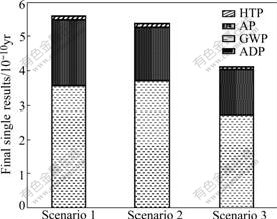

In the final stage, the normalized results multiplied by a weighting factor represent the relative importance of the total environmental impact. It enables an overall comparison of the three scenarios. The analytic hierarchy process(AHP), a matrix-based approach measuring impact priorities in a hierarchical structure[21-22], is used to determine the weight factors. The consistency testing shows that the results have a very high consistency. The calculated weights of ADP, GWP, AP and HTP are 0.088, 0.482, 0.272 and 0.158, respectively. The final single results of Scenario 1-3 were 5.60×10-10, 5.36×10-10 and 4.08×10-10 yr, respectively.

3 Interpretation

3.1 Global warming potential(GWP)

In this study, CO2 is the major gas to cause global warming impact. Global warming potential(GWP) of Scenario 2 is higher than that of Scenario 1. It is shown that adopting producer gas as major fuel for magnesium production cannot reduce the emission of greenhouse gases. While GWP of Scenario 3, which uses COG as major fuel for magnesium production, is decreased by 20% compared with that of Scenario 1. It can effectively reduce global warming potential, but magnesium plant needs to be constructed near the coke plant, and the choice of the location is restricted.

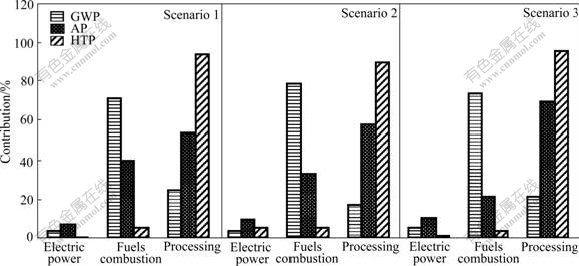

Fig.2 illustrates that from Scenario 1-3, GWP of fuel combustion respectively accounts for 72%, 79% and 73% in their accumulative global warming potential. Therefore, fuels reduction and efficiency improvement are the basic points of controlling greenhouse gas emission. The reduction of greenhouse gases in dolomite calcination is also significant, but this seems to be difficult for the primary magnesium producer to use the Pidgeon process because of the composition of dolomite.

Fig.2 Contribution of GWP, AP and HTP in different processes

3.2 Acidification potential(AP)

The gases that contribute to acidification are mainly SO2 and NOx. SO2 is mainly generated from the dispersed sulphur oxidized on molten magnesium surface at high temperature (about 700 ℃) in the process of refinement and ingot casting. HF from magnesium production by reduction is another type of gas contributed to acidification. The total accumulative reductions of 18% and 33% are obtained for Scenario 2 and 3, respectively.

The AP resulting from the SO2 and NOx emission is decreased with the reduction of direct consumption of coal (Fig.2). The processes of gasification and coking of coal would help to reduce SO2 and NOx emission[12,23]. So the contribution of AP in the process of fuels combustion is decreased. While the contribution in the processing is increased because the quantity of sulphur used changes a little.

3.3 Human toxicity potential(HTP)

The emissions contributing to this impact category are mainly SO2, NOx, HF, and particulates. For three scenarios, HF from reduction in the processing, taking an average 93% in the cumulative human toxicity potential (Fig.2), poses to a large environmental threat to human health. The total cumulative reductions of 28% and 33% are achieved for Scenario 2 and 3, respectively.

3.4 Abiotic depletion potential(ADP)

The depletion of abiotic resources includes the coal, dolomite and fluorite that are all directly used in the Pidgeon process. The characterization factor of coal is comparatively small because of the abundant reserves, so its impact on the cumulative consumption of resources can be neglected. ADP of Scenario 2 and 3 are dropped by 30% and 33% respectively compared with that of Scenario 1. This is mostly due to the reduction of dolomite of Scenario 2 and 3.

3.5 Final single results

The final single results indicate that the accumulative environmental performance of Scenario 3 to produce primary magnesium is the lowest, and that of Scenario 2 comes to the next, which is 31% higher than that of Scenario 3. Scenario 1 shows the highest accumulative environmental load which is 37% higher than that of Scenario 3. Fig.3 illustrates that the GWP and AP are the major impacts of the magnesium production. The different fuel use strategies in the practice of magnesium production by Pidgeon process causes much different results on the accumulative environmental performance. The environmental performance of Scenario 3, which adopts the combination mode of coke-ferrosilicon-magnesium and using COG as major fuel, is the best; but Scenario 1, which burns coal directly as total fuel, shows the poor environmental performance. By considering the limitation of the COG supply condition and the location of magnesium plants, producer gas, in areas where coke production is not concentrated, can be used as the major fuel for primary magnesium production.

Fig.3 Final single results of three scenarios

4 Conclusions

1) According to the LCA procedure, the environmental impact assessment was carried out on the practice of magnesium production with Pidgeon process in current China. The emissions inventory shows that the combustion of fuels is the main contributor to the pollutant emissions in the life cycle of magnesium production.

2) Adopting producer gas as major fuel for magnesium production cannot reduce the emission of greenhouse gases. The characterization results indicate that abiotic depletion potential(ADP), acidification potential (AP) and human-toxicity potential(HTP) are decreased cumulatively from Scenario 1 to 3, with the exception of global warming potential(GWP). The final single scores show that the accumulative environmental performance of Scenario 3 is the best compared with Scenario 1 and 2.

3) The producer gas (Scenario 2) is an alternative fuel for the magnesium production rather than the coal burned directly (Scenario 1) in the areas where high cost of coke oven gas is produced. The utilization of “clean” energy and reduction of greenhouse gases and acidic gases emission are the main goal of the technological improvements and cleaner production of the magnesium industry in China.

References

[1] Editorial Board of the Yearbook of Nonferrous Metals Industry of China. The yearbook of nonferrous metals industry of China 2005 [M]. Beijing: China Nonferrous Metals Industry Association, 2005: 503-504. (in Chinese)

[2] MENG Shu-kun. Report for the magnesium industry of China in 2005 [J]. China Metal Bulletin, 2006(21): 3-10. (in Chinese)

[3] CHEN Wan-kun, SHI Jun-wu. Development for nonferrous metals (light metals) [M]. Changsha: Central South University of Technology Press, 1995: 165-166. (in Chinese)

[4] MORDIKE B L, EBERT T. Magnesium properties- application-potential [J]. Mater Sci Eng A, 2001, 302: 37-45.

[5] LIU Zheng, WANG Zhong-guang, WANG Yue, LI Feng, HAN Xing-lin, KLEIN F. Application and developing tendency of magnesium die casting alloys in automobile industry [J]. Special Casting & Nonferrous Alloys, 1999, 19(5): 55-58. (in Chinese)

[6] LIU Bai-cheng. Material processing technology in the 21st century [J]. Aeronautical Manufacturing Technology, 2003(6): 17-21. (in Chinese)

[7] RAMAKRISHNAN S, KOLTUN P. Global warming impact of the magnesium produced in China using the Pidgeon process [J]. Resources Conservation & Recycling, 2004, 24: 49-64.

[8] ISO 14040. Environmental Management—Life Cycle Assessment— Principles and framework [S]. 2006.

[9] WANG Shi-yuan. China land and resources almanac 2002 [M]. Beijing: China Land & Resources Almanac Press, 2002. (in Chinese)

[10] DI Xiang-hua, NIE Zuo-ren, ZUO Tie-yong. Life cycle inventory for the emission of fuel consumption of in China [J]. China Environmental Science, 2005, 25(5): 631-634. (in Chinese)

[11] IPCC/OECD. Revised 1996 IPCC guidelines for national greenhouse gas inventories, reference manual [M]. Bracknell: UK Meteorological Office, 1999.

[12] WU Zong-xin, CHEN Wen-ying. The diversified clean energy resources strategies with coal as the backbone [M]. Beijing: Tsinghua University Press, 2001: 144-147. (in Chinese)

[13] WANG Wen-xing, WANG Wei, ZHANG Wan-hua, HONG Shao-xian. Geographical distribution of SO2 and NOx emission intensities and trends in China [J]. China Environmental Science, 1996, 16(3): 161-167. (in Chinese)

[14] TIAN He-zhong, HAO Ji-ming, LU Yong-qi, ZHU Tian-he. Inventories and distribution characteristics of NOx emissions in China [J]. China Environmental Science, 2001, 21(6): 493-497. (in Chinese)

[15] WANG Yu-bin. Practicality handbook of air environment engineer [M]. Beijing: China Environmental Science Press, 2003. (in Chinese)

[16] ISO 14044. Environmental management—Life cycle assessment— Requirements and guidelines [S]. 2006.

[17] GUIN?E J B, GORR?E M, HEIJUNGS R, HUPPES G, KLEIJN R. Life cycle assessment: An operational guide to the ISO standards [M]. Netherlands: Kluwer Academic Publishers, 2001.

[18] van OERS L, de KONING A, GUINEE J B, HUPPES G. Abiotic resource depletion in LCA [M]. Netherlands: Road and Hydraulic Engineering Institute, 2002.

[19] ZHOU He-min. Life cycle assessment on iron and steel processes [D]. Beijing: Beijing University of Technology, 2001: 139-140. (in Chinese)

[20] DI Xiang-hua. Several fundamental researches in the life cycle assessment for mineral resources and materials [D]. Beijing: Beijing University of Technology, 2005: 92. (in Chinese)

[21] ONG S K, KOH T H, NEE A Y C. Assessing the environmental impact of materials processing techniques using an analytical hierarchy process method [J]. Journal of Materials Processing Technology, 2001, 113: 424-431.

[22] SAATY T L. The analytic hierarchy process, planning, priority setting, resource allocation [M]. New York: McGraw-Hill Company, 1980.

[23] GUO Zhan-cheng, TANG Hui-qing, LIU Jun-li. Desulfurization of coke by recycling COG in coking process [J]. Fuel, 2005, 84: 893-901.

Foundation item: Project(50525413) supported by the National Natural Science Foundation of China; Project(2006BAE04B09-6) supported by National Key Technology R&D Program

Corresponding author: NIE Zuo-ren; Tel: +86-10-67391536; E-mail: zrnie@bjut.edu.cn

(Edited by YUAN Sai-qian)