文章编号: 1004-0609(2005)12-1896-07

冷轧工艺对1050H19空调箔微观结构及深冲性能的影响

吉泽升1, 3, 王 涛2, 胡茂良1, Yanagimoto Jun3, Sigiyama Sumio3

(1. 哈尔滨理工大学 材料科学与工程学院, 哈尔滨 150040;

2. 东北轻合金有限责任公司, 哈尔滨 150060;

3. 东京大学 生产技术研究所, 东京 153-8505)

摘 要: 考察了不同冷轧工艺生产的1050H19电站用空调箔的性能, 并结合X射线织构分析和透射电镜微观结构分析结果, 讨论了织构及微观结构对深冲性能的影响。 结果表明: 4种工艺中试样的变形织构均属于典型的Cu型织构, 不存在再结晶的R织构和立方织构组分, 主要织构组分仍为Cu织构, 但取向密度不同, 易开裂者Cu织构的取向密度值达160, 织构较强, 并含有较难变形的织构组分P织构和戈斯织构。 经分析可知, 由于减少道次压下率和实施中间停留, 使得铝箔消除了较难变形的织构组分, 减小了Cu取向织构的取向密度, 宏观上表现为深冲开裂倾向的减小, 从而改善了铝箔的深冲性能。

关键词: 1050H19铝箔; 微观结构; 织构; 冷轧工艺; 深冲性能 中图分类号: TG113.26

文献标识码: A

Effect of cold rolling-process on microstructure and deep-drawing

property of 1050H19 aluminum foils used in air-conditioner

JI Ze-sheng1, 3, WANG Tao2, HU Mao-liang1

Yanagimoto Jun3, Sigiyama Sumio3

(1. Department of Materials Science and Engineering,

Harbin University of Science and Technology, Harbin 150040, China;

2. North-east Light Alloy Co. Ltd., Harbin 150060, China;

3. Institute of Industry Science, The University of Tokyo, Tokyo 153-8505, Japan)

Abstract: The property of 1050H19 aluminum foils used in the air-conditioner of electric station by cold rolling-process was studied. Combining with X-ray goniometer and TEM microstructure analysis, the effects of textures and microstructures on deep-drawing properties were discussed. The results show that deforming textures in the specimens using four cold rolling-processes were all typical Cu components, and recrystallized R-texture and Cube-texture do not exist. Cu-texture is still the predominant component but has different orientation densities. The orientation densities of Cu-texture in the specimens being prone to crack can reach 160 and the textures are high, and the samples contain difficult deforming P-texture and Gross-texture. The analysis indicates that with decreasing rate of reduction/rolling-press and the execution of intermediate holding, difficult deforming textures are eliminated, and orientation density of Cu-texture is weakened. Thus, deep-drawing cracking tendency of aluminium foils decreases macroscopically and deep-drawing properties are improved.

Key words: 1050H19 aluminium foils; microstructure; texture; cold rolling-process; deep-drawing property

许多材料工作者从各方面对铝箔、 铝板的性能进行了研究[1-4], 在影响铝箔性能的诸多因素中, 除成分、 铁硅比、 晶粒度外, 轧制工艺和时效工艺也是影响铝箔深冲性能的主要因素[5-10]。 已有研究者开始采用极图、 取向分布函数(ODF)研究薄铝箔的深冲性能[11-16], 如电容器箔[17]、 室用空调箔等[18]都是厚度小于0.2mm的薄箔, 而讨论织构对1050H19厚箔深冲性能的影响未见报道, 本文作者通过对不同冷轧工艺生产的1050H19厚度为0.3mm电站用空调箔进行性能检测和织构测量, 并结合透射电镜分析结果, 讨论了生产工艺对织构及亚结构的影响规律以及最终改善深冲性能的机理, 并给出了最佳工艺参数。

1 实验

1050工业纯铝其化学成分列于表1。 铸锭先均匀化处理后, 在双膛链式加热炉加热12~14h, 使金属温度达到480~520℃, 经四重可逆式热轧机轧制到9.0mm厚的热轧卷, 然后在意大利MINO公司生产的四辊可逆式冷轧机上采用不同变形程度, 不同道次加工率及不同的冷轧制工艺, 分别冷轧至0.3mm, 然后进行深冲实验。 深冲性能考核结合生产完成, 冲成d18mm的通孔, 翻边高度1.9mm, 以其边缘不出现裂口为合格。

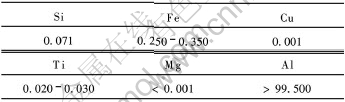

表1 1050纯铝的化学成分

Table 1 Composition of pure 1050 aluminium (mass fraction, %)

采用荷兰Philips公司制造的CM-12型透射电镜(TEM)观察位错及亚结构的形态和分布。 TEM分析薄膜样品的最终减薄方式为: 对于较厚的样品先用线切割方法割取0.5~0.8mm厚的薄片, 然后用500#~1000#砂纸磨至50~80μm厚, 薄膜试样采用双喷电解减薄, 电解液为30%HNO3+70%CH3OH(体积分数), 电压为10V, 电流为200mA。 织构的测定在Philips公司制造带织构附件的XpertMRD衍射仪上进行, Cu Kα辐射, 40kV, 40mA, 具有平行光束的Lens反射镜, 正比计数管测量。

2 结果与分析

2.1 力学性能

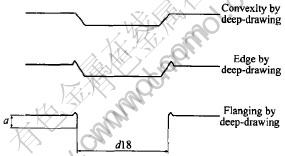

深冲过程为一连续过程, 如图1所示, 各工序所得实物照片如图2所示。

图1 深冲过程示意图

Fig.1 Schematic of deep-drawing process

图2 各工序所得实物照片

Fig.2 Practicality photo adopting different procedures

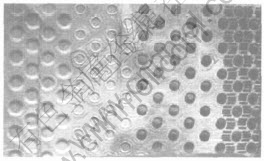

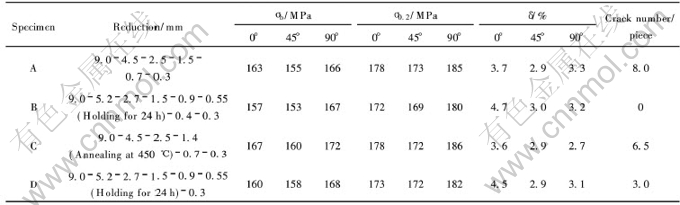

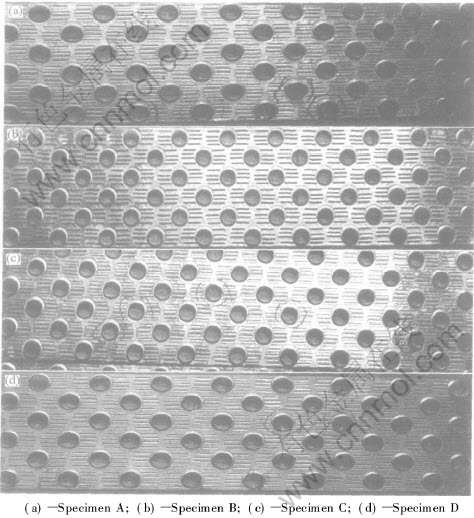

各试样的生产工艺及性能列于表2, 4种工艺所生产空调箔深冲实验的实物照片如图3所示。 从表2和图3中可看出, A工艺出现较多开裂, B工艺则没有开裂, C工艺仍然开裂较多, D工艺有所改善, 开裂倾向较小。 B和D两种试样的道次压下率较小, 且在轧至0.55mm厚时停留24h。 对于A和C试样, 道次压下量较大, 深冲性能差, 但C试样在轧制到1.4mm时, 经一次中间退火, 深冲性能仍然没有改善。 这是由于织构是在冷变形过程中形成的, 虽然经过一次中间退火, 但并不能消除织构和各向异性[19], 且因而后的道次压下率仍然较大, 使材料产生了新的较大变形。 由此可见, 道次压下量是一个关键控制因素, 其次是中间停留。 如表2所示, 不同工艺最终成品铝带沿与轧制方向成0°, 45°, 90°方向的力学性能指标不同, 比较各方向的力学性能值可见, 垂直于轧向的强度值大于其他方向的值; 延伸率则是平行于轧向的最大, 90°和45°方向上的值大体一样。 而4种试样其σb、 σ0.2及δ均无大的差异, 可是其深冲性能却有不同, 由此认为是亚结构和织构在起作用[11]。

表2 4种工艺生产的试样及其沿不同轧制方向的力学性能

Table 2 Four specimens by different technologies and

mechanical properties along different rolling directions

图3 4种工艺所生产空调箔深冲实验的实物照片

Fig.3 Practicality photos of four specimens by deep-drawing process

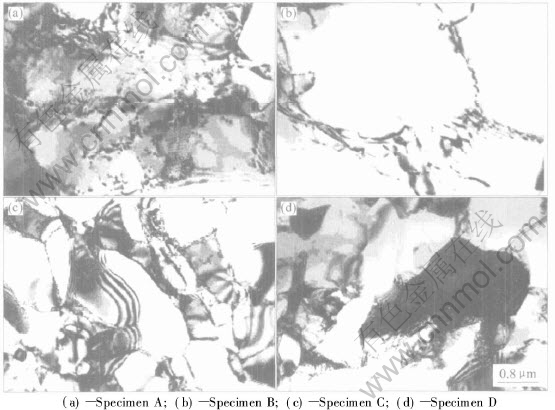

2.2 TEM亚结构实验

图4所示为4种试样亚结构电镜照片, 从图4(a)看出, 位错紊乱地分布在整个晶粒中, 且相互缠结在一起, 构成胞状亚结构, 图4(b)和图4(d)所示为轧制过程中放置24h后再接着塑性变形的亚结构电镜照片, 从图中可以看出, 位错不像图4(a)那样呈紊乱分布, 而是比较有规律地平行排列, 特别是图4(b)更加规则。 这是由于在放置过程中, 处在滑移面上的位错, 通过滑移、 攀移、 交滑移等多种运动形式, 从紊乱的塞积状态逐渐转变为平行排列, 形成位错壁。 于是晶体被位错壁隔成许多位向差小、 原子排列基本规则的小晶块。 这些小晶块, 趋于多边形化, 形成等轴亚晶。 位错规则排列后, 在上下两个正刃型位错的区域内, 上面一个位错所产生的拉应力场, 正好与下面一个位错所产生的压应力场相互叠加而部分抵消, 从而使这时铝箔的应变能降低, 处于较稳定状态。

塑性变形的过程即是位错运动的过程, 由于在位错密集缠结的胞壁区域中, 位错相互干扰, 使位错难以越过这些障碍, 运动产生困难, 内应力增加, 要使金属继续变形, 就需要不断增加外力, 去克服位错间强大的交互作用力, 宏观上表现出深冲的开裂。 位错规则排列后, 点缺陷减少, 位错密度有所下降, 位错分布形态经过重新调整和组合处于低能态, 位错发团变薄, 网络更清晰, 亚晶增大, 且晶格畸变程度减小, 释放了大量畸变能, 缓解了内应力, 使得位错运动变得容易, 变形阻力减小[6, 12]。 宏观上表现为深冲性能改善, 开裂倾向小。 B工艺经停留后, 冷轧时道次压下率比D工艺小, 因此变形程度相对较小, 位错密度低, 因此深冲性能比D工艺好。

图4(c)所示为中间退火组织, 按一般规律, 位错排列应该更加整齐, 但由于退火后, 冷轧的道次压下量仍然较大, 则又形成了新的位错塞积现象, 位错的分布仍然比较紊乱, 深冲性能没有得到改善。

2.3 织构实验

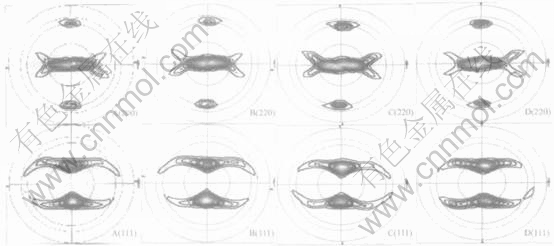

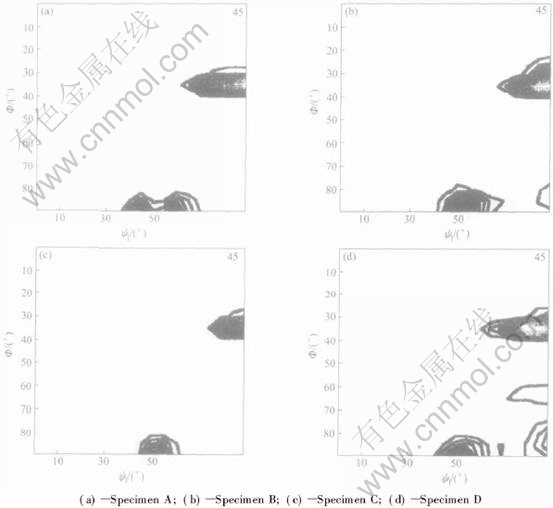

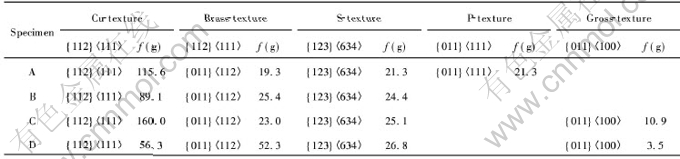

实验给出了(111)和(220)的校正极图(对本底校正)及φ2(45°)截面的ODF谱图, 分别如图5和6所示。 表3所列为4种典型试样的织构组分及其取向密度f(g)。

随着道次压下率的增加, 金属的性能将显示各向异性。 从4种试样的织构分析看, 均属轧制变形织构, 也即Cu型织构为主, 含Cu取向{112}〈111〉, 黄Cu取向{011}〈112〉, S取向{123}〈634〉, 但取向密度f(g)有差别, 如A试样和C试样, Cu取向织构的密度f(g)较大, 分别为115.6和160的强度, 且试样A含有P织构取向, f(g)为21.3, 而试样C还含有戈斯织构取向, f(g)为10.9。 对于B和D组试样, Cu取向织构强度相对较弱, B的f(g)为89.1, D的f(g)为56.3。 4种试样的S织构取向的f(g)基本上是一样的, 而黄Cu取向织构的密度f(g)变化不大。

图4 4种试样亚结构的透射电镜照片

Fig.4 TEM images of substructures of four typical specimens

图5 (220)和 (111)的校正极图

Fig.5 Revising pole figures of (220) and (111) plane

图6 φ2(45°)截面的ODF谱图

Fig.6 ODF patterns of φ2(45°) sections

表3 4种典型试样的织构组分及其取向密度f(g)

Table 3 Textures and orientation densities f(g) of four typical specimens

1050铝板材属于高层错能的材料, 层错宽度较小, 容易在轧制变形过程中形成Cu型织构, 其主要织构组分及制耳(杯凸)倾向为4次杯凸, 杯凸角度45°[10, 13]。 根据实验结果, 通过分析可知, 4种工艺中试样的变形织构仍属于典型的Cu型织构, 不存在制耳倾向大的再结晶的R织构和立方织构组分, 主要织构组分仍为Cu取向织构, 但取向密度不同, 易开裂者Cu取向织构的取向密度值大, 织构较强, 并含有较难变形的织构组分P织构和戈斯织构, 无开裂B试样Cu织构密度值很小, 并消除了制耳倾向大的P织构。 Hibino[11]在研究3004系合金时, 也证明在200℃、 300℃轧制与室温一样{111}〈110〉滑移系活动, 立方织构组分分解, 与本实验结果相一致。 这就合理地解释了为什么强度、 延伸率等力学性能相差不大, 而深冲性能不同的原因。

3 结论

1) 实施中间退火, 并不能改变变形织构的存在形式, 降低位错的缠结程度, 改善深冲性能。

2) 降低道次压下率和实施中间停留, 可以使亚结构中位错缠结程度降低, 排列规则, 释放大量畸变能, 缓解内应力, 使位错运动变得容易, 宏观上表现为深冲开裂倾向的减小, 从而改善深冲加工性能, 即本实验条件下最佳工艺为9.0-5.2-2.7-1.5-0.9-0.55(24h)-0.4-0.3。

3) 1050H19的最终轧制织构仍属于典型的Cu型织构, 工艺不同其密度不同, 道次压下率减小和中间停留使Cu取向织构的取向密度值减小, 并消除了较难变形的P织构和戈斯织构, 使深冲性能得到提高。

致谢

感谢北京有色金属研究总院王超群教授在织构分析实验过程中给予的大力帮助。

REFERENCES

[1]黄建芳, 李志宏, 王明海. 提高工业纯铝板带材机械性能的工艺措施[J]. 轻合金加工技术, 1999, 27(8): 25-27.

HUANG Jian-fang, LI Zhi-hong, WANG Ming-hai. Technological methods of improving mechanical property of aluminium strip[J]. Light Alloy Fabrication Technology, 1999, 27(8): 25-27.

[2]Endou S, Inagaki H. Microstructures and textures in hot-rolled sheets of high purity aluminum for electrolytic capacitor[J]. Journal Japan Institute of Light Metals, 2002, 52(11): 167-173.

[3]张新明, 孟亚, 周卓平. Fe杂质对高纯铝箔再结晶织构及比电容的影响[J]. 中国有色金属学报, 1999, 9(1): 19-24.

ZHANG Xing-ming, MENG Ya, ZHOU Zhuo-ping. Effects of Fe impurity on recrystallization textures and specific capacitances of high pure aluminium foils[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 19-24.

[4]Furui M, Kawakami T, Saji S. Stored energy and its release behavior during recovery and recrystallization processes for aluminum alloys rolled at cryogenic temperature[J]. Journal of Japan Institute of Light Metals, 2002, 50(8): 339-345.

[5]张克伟, 李晓玲, 姜远军. 冷轧工艺对铝箔坯料退火产生粗大晶粒的影响[J]. 轻合金加工技术, 2001, 29(7): 22-24.

ZHANG Ke-wei, LI Xiao-ling, JIANG Yuan-jun. Effects of cold rolling processes on coarse grains of aluminium foil blanks in annealing[J]. Light Alloy Fabrication Technology, 2001, 29(7): 22-24.

[6]聂祚仁, 张新明, 尹志民, 等. 深冲铝板坯冷轧显微组织、 结构与力学性能[J]. 中南工业大学学报, 1997, 28(3); 242-245.

NEI Zuo-ren, ZHANG Xin-min, YIN Zhi-min, et al. Cold-rolled microstructures, textures and mechanical properties in deep drawing Aluminium plate[J]. J Cent South Univ Technol, 1997, 28(3): 242-245.

[7]王超群, 林瑞冬, 丁海宁, 等. 金属板材深冲制耳的晶体学计算[J]. 中国有色金属学报, 1998, 8(1): 53-55.

WANG Chao-qun, LIN Rui-dong, DING Hai-ning, et al. Crystallographical calculation of earing in deep drawing metal sheet[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 53-55.

[8]Kajihara K, Tokuda K, Sugizaki Y, et al. The formation process of cube texture during the final annealing in high-purity aluminum foil[J]. Journal of Japan Institute of Light Metals, 2001, 51(3): 182-187.

[9]王显锋. 铸轧带坯内部质量对铝板深冲性能的影响[J]. 轻合金加工技术, 2000, 28(6): 9-10.

WANG Xian-feng. Effect of cast-rolling strip quality on deep-drawing property of aluminium sheet[J]. Light Alloy Fabrication Technology, 2000, 28(6): 9-10.

[10]刘楚明, 张新明, 陈志永. 高纯铝在轧制及退火过程中微观组织与织构的演变[J]. 轻合金加工技术, 2001, 29(1): 18-21.

LIU Chu-ming, ZHANG Xing-ming, CHEN Zhi-yong. Evolution of microstructures and textures of high purity aluminum during rolling and annealing[J]. Light Alloy Fabrication Technology, 2001, 29(1): 18-21.

[11]Hibino A. Earing and texture of aluminum can body sheet[J]. Journal of Japan Institute of Light Metals, 2002, 52(11): 530-535.

[12]刘楚明, 张新明, 陈志永. 中间退火对高纯铝箔立方织构的影响[J]. 金属热处理, 2001, 26(3): 28-29.

LIU Chu-ming, ZHANG Xin-ming, CHEN Zhi-yong, et al. Effect of intermediate annealing on cubic texture of high-purity aluminium foils[J]. Heat Treatment of Metals, 2001, 26(3): 28-29.

[13]聂祚仁, 张新明, 尹志民, 等. 深冲铝板中的再结晶织构与选择生长[J]. 金属学报, 1997, 33(9): 976-980.

NIE Zuo-ren, ZHANG Xin-ming, YIN Zhi-min, et al. Recrystallization texture and oriented growth in deep drawing aluminium sheet[J]. Acta Metallurgica, 1997, 33(9): 976-980.

[14]Bate P S. Texture inhomogeneity and limit strains in aluminum sheet [J]. Script Metallurgica Materially, 1992, 27(5): 515-52.

[15]Savoie J, Zhou Y, Jonas J J, et al. Textures induced by tension and deep drawing in aluminum sheets[J]. Acta Metallurgica Inc, 1996, 44(2): 587-605.

[16]SHEN Fu-fa, YUAN Wen-qing. Effect of texture on phase-transformation strain in CuZnAl shape memory sheets [J]. Tran Nonferrous Met Soc China, 2002, 12(1): 1-5.

[17]Takata N, Ikeda K I, Yoshida F. Influence of purity on the formation of cube texture in aluminum foils for electrolytic capacitors[J]. Materials Transactions, 2004, 45(5): 1687-1692.

[18]Kido T A, Sato Y, Takeshima Y. The effect of sheet characteristics on disarrangement of aluminum fins in the heat exchanger of room air conditioner[J]. Journal of Japan Institute of Light Metals, 2002, 50(2): 54-59.

[19]余汉卿, 陈金德. 金属塑性成形原理[M]. 北京: 机械工业出版社, 2001. 17-18.

YU Han-qing, CHEN Jin-de. The Metal Principle of Plastic Formation[M]. Beijing: China Machine Industry Press, 2001. 17-18.

基金项目: 黑龙江省留学回国人员基金资助项目(LC01C09); 哈尔滨市攻关资助项目(0111211108)

收稿日期: 2005-04-25; 修订日期: 2005-10-17

作者简介: 吉泽升(1962-), 男, 教授, 博士

通讯作者: 吉泽升, 教授; 电话: 0451-86392557; E-mail: jizesheng@yahoo.com.cn

(编辑陈爱华)