Tensile properties of hot rolled Mg97Zn1Y2 alloy sheets at elevated temperatures

SU Zhen-guo(苏振国), NIU Xiao-dong(牛晓冬), AN Jian(安 健), LI Guang-yu(李光玉)

Key Laboratory of Automobile Materials, Ministry of Education,Department of Materials Science and Engineering, Jilin University, Changchun 130025, China

Received 26 November 2008; accepted 28 June 2009

Abstract: The elevated temperature tensile properties of Mg97Zn1Y2 magnesium alloy sheets, hot rolled at 390, 420 and 450 ℃ respectively, were tested in a temperature range from room temperature to 250 ℃ with a strain rate of 1.0×10-3 s-1. The results show that the variations in yield strength for Mg97Zn1Y2 magnesium alloy sheets hot rolled at 390 ℃ and 420 ℃ with temperature resemble each other due to their similar morphology of the chain-shaped strengthening phase. The yield strength maintains at a high level of 283 MPa before 200 ℃ and decreases significantly at 250 ℃. Despite of the fine lamellar structure of Mg97Zn1Y2 magnesium alloy sheet hot rolled at 450 ℃, its yield strength decreases linearly owing to occurrence of the coarse grain, and drops to 239 MPa at 250 ℃. The elongation for all hot rolled Mg97Zn1Y2 magnesium alloy sheets increases slightly with increasing testing temperature.

Key words: magnesium alloy; tensile properties; elevated temperature

1 Introduction

In recent years, the structural applications of magnesium alloys in aerospace and automobile industries are increasing progressively due to their low densities and excellent properties such as electro-magnetic shielding, damping and recycling[1-4]. At present, the commercial AZ and AM magnesium alloys are widely used because of their high strength at room temperature, excellent castability and low cost. However, due to the low strength at elevated temperature, they are mostly used below 120 ℃. The reason is that the Mg17Al12 eutectic with low melting point of 437 ℃ distributed at grain boundary has non-coherence relation to α-Mg matrix and easily grows coarse, exhibiting poor thermal stability[5-7]. Usually, the magnesium alloys with high content of Al element show poor properties at high temperature[8-10]. Rare elements (RE) can greatly improve properties of magnesium alloy at both room and elevated temperature since they have low diffusion rate in Mg matrix and help to form thermally stable compounds with high melting point, which have good coherence relation to the Mg matrix and hence effectively hinder movement of dislocation[11]. In particular, the element Y is one of the most effective RE elements used to improve high temperature properties of Mg alloys[12-13]. KAWAMURA et al[14] and NISHIDA et al[15] reported a superior performance of rapidly solidified (RS) powder metallurgy Mg97Zn1Y2 (molar fraction, %) alloy with an extremely high tensile yield strength of 610 MPa and an elongation of 5%, in which Z phase (Mg12ZnY) with the long-period stacking order structure of 18R of ABABABCACACABCBCBC was considered to be a dominant strengthening phase. The dissolution temperature of Mg12ZnY phase in Mg-Zn-Y alloy is higher than the melting point of Mg17Al12 phase. This suggests that the Mg-Zn-Y alloy should have good elevated temperature properties. In the present study, the Mg97Zn1Y2 alloy was firstly fabricated by conventional cast technique, then hot-rolled at different temperatures. The elevated temperature mechanical properties were investigated.

2 Experimental

The testing alloy for this study was Mg97Zn1Y2 (in molar fraction, %) alloy. The alloy was prepared by conventional casting method from high purity 99.9% Mg, 99.9% Zn, and Mg-21.5%Y (mass fraction) alloy under a shielding gas of CO2-0.05% SF6. Specimens to be hot rolled with dimensions of 90 mm×18 mm×6.5 mm were machined from the cast ingot and were heated at 390, 420, and 450 ℃ for 20 min prior to each pass rolling, respectively. The rolling was employed with a reduction of about 15% per pass. The final thickness of specimens was 1.3 mm (reduction of about 80%). Mechanical properties of the Mg97Zn1Y2 alloy after severe hot rolling were evaluated by tensile tests in a temperature range from room temperature to 250 ℃ at an initial strain rate of 1.0×10-3 s-1.

3 Results and discussion

3.1 Microstructures and mechanical properties at room temperature

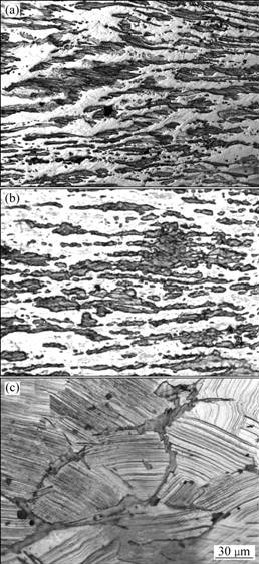

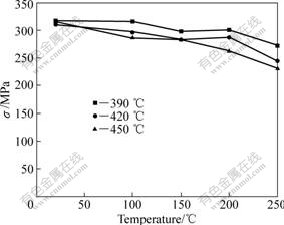

Fig.1 shows the microstructures of Mg97Zn1Y2 alloy hot-rolled at different temperatures, and Fig.2 shows the variation in yield strength with tensile test temperature. The yield strength curves for alloys hot-rolled at 390 ℃ and 420 ℃ resemble each other owing to their similar microstructure, in which the strengthening phase is the chain-shaped Mg12YZn. Careful observation can make some distinctions between Fig.1(a) and Fig.1(b) that the volume fraction of the chain-shaped Mg12YZn phase is different; and less is in the alloy hot-rolled at 390 ℃ and the morphology of Mg12YZn particles is rather round. It is because more Mg12YZn particles with fine size dissolve into Mg matrix as the hot rolling temperature is increased, leading to the slightly lower position of yield strength curve for the alloy hot rolled at 420 ℃ than the alloy hot rolled at 390 ℃. According to the alloy strengthening theory, the volume fraction, morphology and distribution exert directly influence on the strengthening effect. The morphology of Mg12YZn changes from the chain shape to the lamellar shape as the rolling temperature is increased to 450 ℃; correspondingly, the trend for the yield strength is different from the two curves mentioned above.

Fig.1 Microstructures of Mg97Zn1Y2 alloy hot-rolled at different temperatures: (a) 390 ℃; (b) 420 ℃; (c) 450 ℃

Fig.2 Variation in yield strength of hot-rolled alloys with tensile test temperature

3.2 Microstructures and mechanical properties at elevated temperature

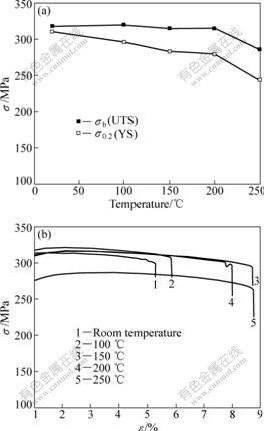

Stress—strain curves, yield strength (YS) and ultimate tensile strength (UTS) at different tensile test temperatures for alloy hot-rolled at 420 ℃ are illustrated in Fig.3. The yield strength and ultimate tensile strength maintain at high levels of 280 MPa and 310 MPa until 200 ℃, which is about 200 MPa higher than the hot-rolled AZ31 sheet[16]. The ultimate tensile strength does not change much before 250 ℃, whereas yield strength decreases a little. At 250 ℃ both UTS and YS decrease rapidly.

Fig.3 UTS, YS (a) and stress—strain curves (b) for 420℃ hot-rolled alloy at different tensile temperatures

The YS of 450 ℃ hot rolled alloy decreases from 100 ℃ to 250 ℃ whereas UTS does not descend remarkably until 200 ℃ (see Fig.4). The strain curves of the 420 ℃ and 450 ℃ hot rolled alloys resemble each other. To explain the rapid decrease in tensile strength at 250 ℃, microstructures of these two sheets after tensile test at 250 ℃ are shown in Fig.5. Compared with the microstructure shown in Fig.1, the difference before and after tensile test lies in two aspects: firstly, much more chain-shaped Mg12YZn particles at grain boundary dissolve into Mg matrix after tensile test for 420 ℃ and 450 ℃ hot rolled alloys; and secondly abnormal growth of Mg grain in the 450 ℃ hot rolled alloy can be found. These two factors may cause the rapid decrease in tensile strength at 250 ℃.

Fig.4 UTS, YS (a) and stress—strain curves (b) for 450℃ hot-rolled alloy at different tensile temperatures

Fig.5 Microstructures of 420 ℃ hot-rolled (a) and 450 ℃ hot-rolled (b) sheets after tensile test at 250 ℃

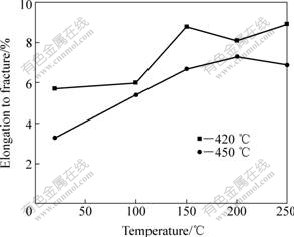

Fig.6 shows the elongation as a function of tensile temperature. The elongation for both alloys hot-rolled at 420 ℃ and 450 ℃ increases with increasing tensile temperature and the elongation of 420 ℃ hot rolled alloy is always higher than that of the 450 ℃ hot rolled alloy partly because the 450 ℃ hot rolled alloy has the coarse grain, and partly because it has the lamellar structure.

Fig.6 Variation in elongation with tensile temperature

4 Conclusions

1) The alloys hot-rolled at 390 ℃ and 420 ℃ demonstrate high elevated temperature mechanical properties. The yield strength and ultimate tensile strength maintain at high levels of 283 MPa and 310 MPa until 200 ℃.

2) The elongation of 420 ℃ hot-rolled alloy is always higher than that of the 450 ℃ hot-rolled alloy. And with increasing the tensile temperature, the elongations for both sheets increase.

References

[1] MOHRI T, MABUCHI M, NAKAMURA M, ASAHINA T, IWASAKI H, HIGASHI K. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn [J]. Materials Science and Engineering A, 2000, 290: 139-144.

[2] BAE D H, KIM S H, KIM W T, KIM D H. High strength Mg-Zn-Y alloy containing quasicrystalline particles [J]. Materials Transactions, 2001, 42(10): 2144-2147.

[3] SHI Fei, GUO Xue-feng, ZHANG Zhong-ming. Quasicrystal of as-cast Mg-Zn-Y alloy [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 113-116. (in Chinese)

[4] YANG Xu-yue, JI Ze-sheng, MIURA H, SAKAI T. Dynamic recrystallization and texture development during hot deformation of magnesium alloy AZ31 [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 55-60.

[5] LEE J Y, KIM D H, LIM H K, KIM D K. Effects of Zn/Y ratio on microstructure and mechanical properties of Mg-Zn-Y alloys [J]. Materials Letters, 2005, 59(29): 3801-3805.

[6] GARCES G, MAESO M, TODD I, PEREZ P, ADEVA P. Deformation behaviour in rapidly solidified Mg97Y2Zn (at.%) alloy [J]. Journal of Alloys and Compounds, 2007,432: L10-L14.

[7] YANG Q, GHOSH A K. Deformation behavior of ultrafine-grain (UFG) AZ31B Mg alloy at room temperature [J]. Acta Materialia, 2006, 549(19): 5159-5170.

[8] LU Chen, WEI Zhong-shan, HUANG Xiao-fong, LIU Man-ping, DING Wen-jiang. Research and development of heat resistant magnesium alloy [J]. Foundry, 2005, 54(2): 112-114. (in Chinese)

[9] WANG Jun, LIU Yong-bing, YANG Xiao-hong. Effect of cerium on microstructure and elevated temperature properties of die-cast AZ91 magnesium alloy [J]. Journal of the Chinese Rare Earth Society, 2005, 23(3): 378-381. (in Chinese)

[10] ZHANG Y L, LIU L F, WEI Z S, LU C. Effects of alloying elements on heat-resistant properties of magnesium alloys [J]. Foundry Technology, 2005, 26(8): 48-51.

[11] HUANG D M, LIU H M, CHEN Y G, TANG Y B, TU M J. Development of research and application of cast magnesium alloy at elevated temperature [J]. Light Metals, 2005, 8: 52-57.

[12] SUZUKI M, KIMURA T, KOIKE J, MARUYAMA K. Strengthening effect of Zn in heat resistant Mg-Y-Zn solid solution alloys [J]. Scripta Materialia, 2003, 48(8): 997-1002.

[13] MATSUDA M, LI S, KAWAMURA Y, IKUHARA Y, NISHIDA M. Variation of long-period stacking order structures in rapidly solidified Mg97Zn1Y2 alloy [J]. Materials Science and Engineering A, 2005, 393: 269-274.

[14] KAWAMURA Y, HAYASHI K, INOUE A, MASUMOTO T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa [J]. Materials Transactions, 2001, 42(7): 1172-1176.

[15] NISHIDA M, KAWAMURA Y, YAMAMURO T. Formation process of unique microstructure in rapidly solidified Mg97Zn1Y2 alloy [J]. Materials Science and Engineering A, 2004, 375/377: 1217-1223.

[16] JAGER A, LUKAC P, GARTNEROVA V, BOHLEN J, KAINER K U. Tensile properties of hot rolled AZ31 Mg alloy sheets at elevated temperatures [J]. Journal of Alloy and Compounds, 2004, 378: 184-187.

Foundation item: Project(2001BA311A07-3) supported by the National Science and Technology Support Program during the 10th Five-Year Plan of China

Corresponding author: LI Guang-yu; Tel: +86-431-85095474; Fax: +86-431-85095876; E-mail: anjian@jlu.edu.cn

DOI: 10.1016/S1003-6326(09)60094-7

(Edited by YANG Bing)