Effect of different incidence angles on bonding performance in cold spraying

LI Gang(李 刚)1, WANG Xiao-fang(王晓放)1, LI Wen-ya(李文亚)2

1. School of Energy and Power Engineering, Dalian University of Technology, Dalian 116024, China;

2. LERMPS, Université de Technologie de Belfort-Montbéliard, Site de Sévenans, 90010 Belfort Cedex, France

Received 25 April 2006; accepted 25 November 2006

Abstract: The deformation behaviour of spray particles impacting upon a substrate under the oblique impact condition in cold spraying was investigated using finite element analysis(FEA) method. The effect of incidence angle of particle on the deformation of particle and substrate was examined. It is found that the contact area between the deformed particle and substrate decreases and the crater depth in the substrate reduces with increasing the tilting angle at the same impact velocity. The normal component of impact velocity takes an important role in the impacting process and formation of bonding.

Key words: cold spraying; numerical simulation; oblique impact; deformation behaviour

1 Introduction

A wide variety of impact phenomena are observed in many cases both in micro- and macro-scales when an object impinges on another one, such as erosion of particles colliding with a solid surface at relatively low velocity, ballistic impact and penetration of a macro-body at a higher velocity causing a destruction of the impacted surface[1-3]. However, metallic particles of intermediate velocities, typically 300-1 200 m/s, can adhere to the impacted surface and form a coating. This phenomenon has been discovered during the test of supersonic wind tunnel in the middle of 1980s at the Institute for Theoretical and Applied Mechanics of the Siberian Division of the Russian Academy of Science in Novosibirsk and firstly reported by the Russian scientists[4-5]. It is now the so-called cold spray or kinetic spray. In this process, spray particles (typically <50 ?m) are accelerated to a high velocity by a supersonic gas flow that is generated through a converging-divergent de Laval nozzle. A coating is formed through the intensive plastic deformation of particles impacting on a substrate at a temperature well below the melting point of spray material. Cold spray has been widely investigated owing to its advantages over the conventional thermal spray to deposit most of the metals and alloys[3-21].

Many experimental results[4,7,10-11,13-21] indicated that besides the mechanical properties of both the particle and substrate, particle conditions prior to impact, such as velocity, temperature, and size will influence the deformation behavior of particles and thus the deposition efficiency. However, there are few reports focused on the influence of particle impacting angles except some results on effect of spray angle on deposition efficiency[13,18]. Moreover, owing to the instantaneous feature of particle impact, it is very difficult to observe the whole deformation process of particles. Only the deformed particles can be observed by a microscope. The numerical method has been employed by some investigators to study the particle deformation process[7-12]. Therefore, in this study, the effect of incidence angle of particle on the deformation behaviour of particle and substrate is numerically investigated with Cu material using an explicit finite element(FEA) program LS-DYNA.

2 Numerical modelling

2.1 Numerical method

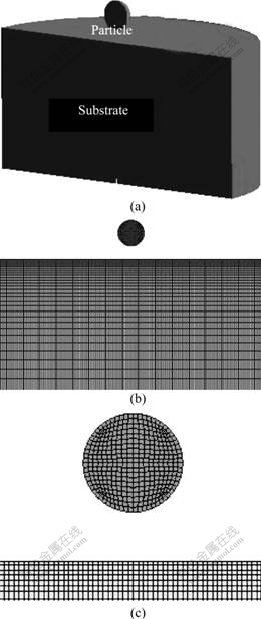

The impacting behaviour of particle on a substrate is modelled using an explicit FEA program LS-DYNA. The Lagrangian formulation is used in solution. Because the inertial force is the control one during high velocity impact process, other body forces, such as gravity, are neglected. For simplification, a 3D model shown in Fig.1(a) is substituted by a 2D model shown in Fig.1(b). The substrate is taken as a cylinder. The contact process is implemented by using an automatic 2D single surface penalty formulation available in LS-DYNA[22]. According to the primary study, the radius and height of the substrate are taken as 10 times of particle diameter (20 μm) to avoid the effect of the calculating dimensions on the simulation results near the deformed zone. The meshing is conducted by using the 4-node 2D quad element with one-point integration. The meshing size for particle is 1 μm. Moreover, the local contact zone in the substrate, which also experiences intensive deformation, is meshed with fine meshing to ensure the accuracy as shown in Fig.1(c). In the simulations, the bottom boundary of substrate is constrained for all DOF (degree of freedom). The other boundaries are set as free ones.

Fig.1 Schematic diagrams of geometric model of particle impact (a, b) and meshing of particle and substrate (c)

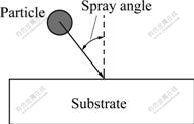

Note that the spray angle in this study is defined as the angle between the particle approaching direction and the normal direction to substrate surface as shown in Fig.2.

Fig.2 Schematic diagram of spray angle

2.2 Material model

As for material model, particle and substrate are taken as a Johnson and Cook plasticity model, which accounts for strain hardening, strain rate hardening and thermal softening. The Von Mises plasticity model is used. The yield stress (σy) of this material is expressed as follows[22-23]:

(1)

(1)

where A, B, N, C, M are user defined input constants.  is the effective plastic strain; ε* is the effective plastic strain rate normalized with respect to a reference strain rate; T* is a homologous temperature defined as the following[22-23]:

is the effective plastic strain; ε* is the effective plastic strain rate normalized with respect to a reference strain rate; T* is a homologous temperature defined as the following[22-23]:

(2)

(2)

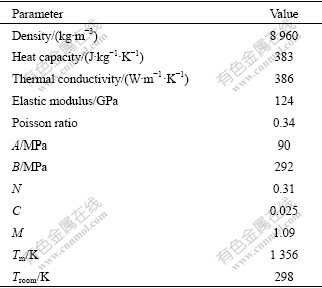

where Tm is the melting temperature and Troom is the reference temperature. A linear Mie-Gruneisen equation of state(EOS) is employed for Cu[22]. The properties used in simulation are listed in Table 1[23].

Table 1 Properties of Cu used in this study[23]

3 Results and discussion

3.1 Deformation behavior of spray particles under oblique impact condition

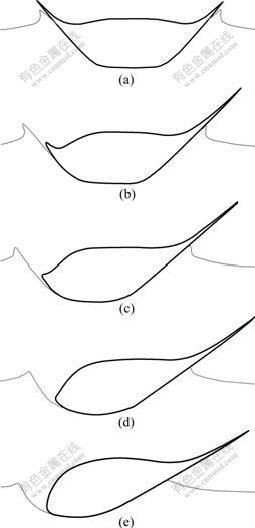

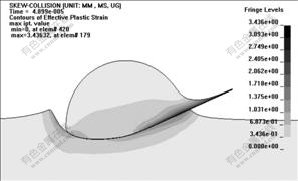

Fig.3 shows the effect of incidence angle on the deformed shapes of Cu particles impacting on Cu substrate with a velocity of 500 m/s at the tilting angles of 0?, 10?, 20?, 30? and 40?. It is obviously observed that the particles experience intensive deformation and flatten to present lens-like shapes. According to the distribution of effective plastic strain as shown in Fig.4, it is found that the narrow interfacial regions experience intensive deformation. A crater is clearly developed in the flat substrate, which will be discussed in the next section. Moreover, a metal jet of highly deformed material is formed at the surrounding of the contact zone because the plastic deformation is mainly concentrated at the interfaces. These results are consistent with the previous simulation results reported by different investigators[7-10]. However, compared with the shape at normal impact (spray angle 0?) as shown in Fig.3(a), the shapes at the tilting angles as shown in Figs.3(b) to (e) are much different, which present a non-symmetric deformation. The deformation is concentrated on one side of the particles. On the other hand, owing to the presence of tangential component of impact velocity, a transverse movement along substrate surface occurs for the particles. With increasing the tilting angle, the contact area between the particle and substrate is thus decreased. Therefore, the bonding between the particle and substrate may be degraded.

Fig.3 Deformed shapes of particles impacting at different tilting angles: (a) 0?; (b) 10?; (c) 20?; (d) 30?; (e) 40?

Fig.4 Contours of effective plastic strain at 50 ns of Cu particle impacting on Cu substrate at velocity of 500 m/s and spray angle of 40?

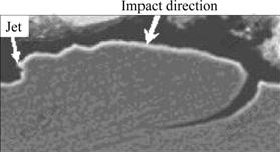

Fig.5 shows the typical experimental result of cross-section morphology of a deformed Cu particle on Cu substrate at a spray angle of 20? reported in Ref.[24]. It is clearly seen that the particles deform significantly and the jet can be found at one side of the deformed particle as marked by white arrow. A crater has also formed in the substrate after the impacting. This result is in good agreement with the simulated result in this study.

Fig.5 Deformed shape of Cu particle impacting on Cu substrate at spray angle of 20? by experiment [24]

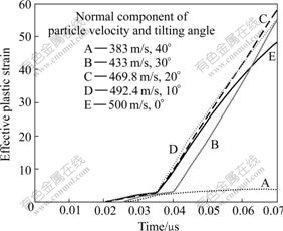

Fig.6 shows the simulated temporal development of maximum effective plastic strain in particle during impacting at a velocity of 500 m/s under different tilting angles. With the progressing of impact process, the effective plastic strain increases obviously. It is observed that as the spray angle is less than 40?, the effective plastic stain increases steeply at a certain impact time. This means that the adiabatic shear instability may occur at these tilting angles. As for normal impact, ASSADI et al[10] and LI et al[11,15] found through numerical simulation that the instability of adiabatic shear flow occurs as particle velocity becomes higher than a critical velocity. Adiabatic shear flow boosts bonding capacity since metallic plastic deformation upgrades. Under the simulation conditions of this study, this critical velocity corresponds to the normal component of velocity of about 383 m/s to 433 m/s as shown in Eqn.(3):

Fig.6 Simulated temporal development of maximum effective plastic strain in particle during impacting at velocity of 500 m/s under different tilting angles

(3)

(3)

where vn is the normal component of velocity; vcr is the critical velocity; v is the impacting velocity; α is the spray angle as shown in Fig.2.

However, owing to the severe deformation of meshing at the contact areas in simulation by a Lagrangian algorithm, this calculated critical velocity is much dependent on the meshing size[15]. Although ASSADI et al[10] reported a calculated critical velocity of 580 m/s for Cu under their simulation conditions and LI et al[15] reported a much lower calculated critical velocity of about 310 m/s, this issue is still open to be further clarified.

4 Crater depth in substrate

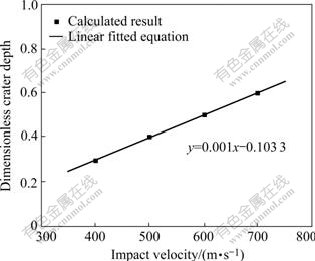

After impacting of a cold spray particle on a substrate, a crater is formed in the substrate. The formation of crater can also take an important role in the particle bonding process. In this study, for simplicity, the dimensionless crater depth is used to characterize the deformation extent of substrate, which is defined as the ratio of crater depth to the original particle diameter. Fig.7 shows the effect of particle impact velocity on the dimensionless crater depth under normal impact condition for Cu particle impacting on Cu substrate. It is clear that with the increase in particle impact velocity, the crater depth increases almost linearly. This means that the deformation of substrate becomes more intensive at higher particle impact velocities. DYKHUIZEN et al[7] also reported the similar results in their study of Cu particle impacting on stainless steel substrate by both the experiment and simulation methods. A linear fit of the calculated results in this study yields a correlating equation between the impact velocity and dimensionless crater depth, which is also given in Fig.7.

Fig.7 Effect of particle impact velocity on dimensionless crater depth under normal impact condition

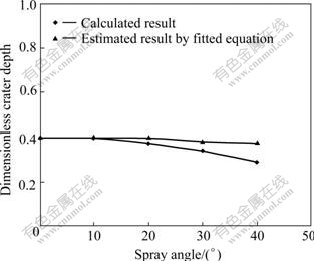

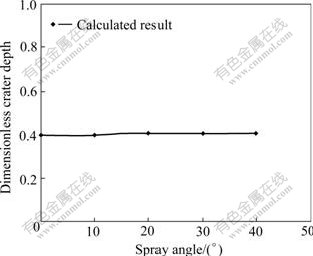

Fig.8 shows the effect of spray angle on the dimensionless crater depth under the impact velocity of 500 m/s. For comparison, the estimated results by the fitted equation given in Fig.7 with the normal component of particle velocity are also shown in Fig.8. It is seen from Fig.8 that the dimensionless crater depth decreases with increasing the tilting angle. It is because the increase of tilting angle results in the decrease of normal component of particle velocity, and thus the decrease of crater depth. Through the comparison of the directly calculated results with the estimated results by the fitted equation with the normal component of velocity under different tilting angles, it is found that the difference between these two results is small when the tilting angle is less than 20? and it is relatively big when the tilting angle is larger than 30?. This fact suggests that the normal component of velocity takes an important role in particle bonding process. The tangential component of velocity can be negligible when the tilting angle is less than 20?. However, when the tilting angle is larger than 30?, the effect of tangential component of velocity can not be omitted. On the other hand, when the normal component of particle velocity is constant, the dimensionless crater depth changes little with the increase of spray angle as shown in Fig.9. This result also indicates that the normal component of velocity takes an important role in the particle impacting process on substrate.

Fig.8 Effect of spray angle on dimensionless crater depth under impact velocity of 500 m/s

Fig.9 Effect of spray angle on dimensionless crater depth under same normal impact velocity of 500 m/s for different spray angles

5 Conclusions

1) The particle and substrate present a non- symmetric deformation under oblique impact condition compared with that in normal impact.

2) The normal component of particle impact velocity takes an important role in the impacting process and formation of bonding during deposition, while the tangential component of the velocity causes the particle to move along the substrate surface.

3) The impacting velocity and spray angle should be adjusted when the spray angle is less than 30? in order to obtain high deposition efficiency.

References

[1] ZUKAS J A. High Velocity Impact Dynamics [M]. New York: John Wiley & Sons, 1990: 1-235.

[2] WANG L L, YU T X, LI Y C. Development on Impact Dynamics [M]. Hefei: University of Science and Technology of China Press, 1992. (in Chinese)

[3] KLINKOV S V, KOSAREV V F, REIN M. Cold spray deposition: Significance of particle impact phenomena [J]. Aerosp Sci Technol, 2005, 9: 582-591.

[4] ALKIMOV A P, KOSAREV V F, PAPYRIN A N. A method of cold gas dynamic deposition [J]. Dokl Akad Nauk SSSR, 1990, 315(5): 1062-1065.

[5] PAPYRIN A. Cold spray technology [J]. Adv Mater Process, 2001, 159(9): 49-51.

[6] SCHMIDT T, G?RTNER F, KREYE H. High strain rate deformation phenomena in explosive powder compaction and cold gas spraying [A]. MOREAU C, MARPLE B. Thermal Spray 2003: Advancing the Science & Applying the Technology [C]. Ohio, USA: ASM International, Materials Park, 2003: 9-18.

[7] DYKHUIZEN R C, SMITH M F, GILMORE D L, NEISER R A, JIANG X, SAMPATH S. Impact of high velocity cold spray particles [J]. J Therm Spray Technol, 1999, 8(4): 559-564.

[8] GRUJICIC M, SAYLOR J R, BEASLEY D E, DEROSSET W S, HELFRITCH D. Computational analysis of the interfacial bonding between feed-powder particles and the substrate in the cold-gas dynamic spray process [J]. Appl Surf Sci, 2003, 219(3/4): 211-227.

[9] GRUJICIC M, ZHAO C L, DEROSSET W S, HELFRITCH D. Adiabatic shear instability based mechanism for particle/substrate bonding in the cold-gas dynamic-spray process [J]. Mater Des, 2004, 25: 681-688.

[10] ASSADI H, G?RTNER F, STOLTENHOFF T, KREYE H. Bonding mechanism in cold gas spraying [J]. Acta Mater, 2003, 51(15): 4379-4394.

[11] LI W Y, LI C J, WANG Y Y, YANG G J. Effect of Cu particle parameters on its impacting behavior in cold spraying [J]. Acta Metall Sin, 2005, 41(3): 282-286. (in Chinese)

[12] PAPYRIN A N, KOSAREV V F, KLINKOV S V, ALKHIMOV A P. On the interaction of high speed particles with a substrate under the cold spraying [A]. LUGSCHEIDER E, BERNDT C C. International Thermal Spray Conference [C]. Essen, Germany: DVS, 2002: 380-384.

[13] GILMORE D L, DYKHUIZEN R C, NEISER R A, ROEMER T J, SMITH M F. Particle velocity and deposition efficiency in the cold spray process [J]. J Therm Spray Technol, 1999, 8(4): 576-582.

[14] LI C J, LI W Y. Deposition characteristics of titanium coating in cold spraying [J]. Surf Coat Technol, 2003, 167(2/3): 278-283.

[15] LI C J, LI W Y. Examination of the critical velocity for deposition of particles in cold spraying [A]. LUGSCHEIDER E. Thermal Spray Connects: Explore Its Surface Potential [C]. Basel, Switzerland: DVS, 2005: 217-224.

[16] ZHANG D, SHIPWAY P H, MCCARTNEY D G. Particle-substrate interactions in cold gas dynamic spraying [A]. MOREAU C, MARPLE B. Thermal Spray 2003: Advancing the Science & Applying the Technology [C]. Ohio, USA: ASM International, Materials Park, 2003: 45-52.

[17] VAN STEENKISTE T H, SMITH J R, TEETS R E, MOLESKI J J, GORKIEWICZ D W, TISON R P, MARANTZ D R, KOWALSKY K A, RIGGS W L, ZAJCHOWSKI P H, PILSNER B, MCCUNE R C, BARNETT K J. Kinetic spray coatings [J]. Surf Coat Technol, 1999, 111(1): 62-71.

[18] LI C J, LI W Y, WANG Y Y, FUKANUMA H. Effect of spray angle on deposition characteristics in cold spraying [A]. MOREAU C, MARPLE B. Thermal Spray 2003: Advancing the Science & Applying the Technology [C]. Ohio, USA: ASM International, Materials Park, 2003: 91-96.

[19] DYKHUIZEN R C, NEISER R A. Optimizing the cold spray process [A]. MOREAU C, MARPLE B. Thermal Spray 2003: Advancing the Science & Applying the Technology [C]. Ohio, USA: ASM International, Materials Park, 2003: 19-26.

[20] SCHMIDT T, G?RTNER F, STOLTENHOFF T, KREYE H, ASSADI H. High velocity impact phenomena and coating quality in cold spraying [A]. LUGSCHEIDER E. Thermal Spray Connects: Explore Its Surface Potential [C]. Basel, Switzerland: DVS, 2005: 232-238.

[21] VAN STEENKISTE T H, SMITH J R, TEETS R E. Aluminum coatings via kinetic spray with relatively large powder particles [J]. Surf Coat Technol, 2002, 154(2/3): 237-252.

[22] HALLQUIST J Q. LS-DYNA Keyword User’s Manual [M]. Livermore, CA: Livermore Software Technology Corporation, 2003.

[23] JOHNSON C R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures [J]. Eng Fract Mech, 1985, 21(1): 31-48.

[24] LI W Y. Study on the Effect of Particle Parameters on Deposition Behavior, Microstructure Evolution and Properties in Cold Spraying [D]. Xi’an: Xi’an Jiaotong University, 2005. (in Chinese)

Foundation item: Project(50476075) supported by the National Natural Science Foundation of China

Corresponding author: WANG Xiao-fang; Tel: +86-411-84707905; E-mail: dlwxf@dlut.edu.cn

(Edited by YUAN Sai-qian)